• •

兰蕊( ), 田宇, 刘荣正, 杨旭, 刘兵, 邵友林, 刘马林(

), 田宇, 刘荣正, 杨旭, 刘兵, 邵友林, 刘马林( )

)

收稿日期:2025-12-08

修回日期:2026-01-08

出版日期:2026-02-02

通讯作者:

刘马林

作者简介:兰蕊(2002-),女,硕士研究生,lanr24@mails.tsinghua.edu.cn

基金资助:

Rui LAN( ), Yu TIAN, Rongzheng LIU, Xu YANG, Bing LIU, Youlin SHAO, Malin LIU(

), Yu TIAN, Rongzheng LIU, Xu YANG, Bing LIU, Youlin SHAO, Malin LIU( )

)

Received:2025-12-08

Revised:2026-01-08

Online:2026-02-02

Contact:

Malin LIU

摘要:

颗粒包覆过程在药物制备、功能颗粒制备、核燃料颗粒制备等工业领域有着重要应用。颗粒包覆的均匀性是颗粒包覆过程优化控制的主要目的,是一种包覆工艺成熟的主要标志。其一般包括两个主要方面,即颗粒间包覆均匀性(inter-particle coating uniformity)和颗粒内包覆均匀性(intra-particle coating uniformity),文献中均有相关实验和模拟研究报道。本文详细综述颗粒包覆均匀性的数值模拟方法,对其发展历程和演化机理进行分析,并给出未来发展的启示。在颗粒间均匀性数值模拟方面,研究工作涵盖了四种主要方法:基于停留时间分布的统计模型、基于Monte Carlo方法描述的随机沉积模型、耦合流体力学与颗粒运动的CFD-DEM框架,以及多尺度耦合等高保真模型,这些方法旨在全面揭示包覆前驱物质分布、混合特性与颗粒动力学对包覆均匀性的影响;在颗粒内包覆均匀性数值模拟方面,主要包括表面离散化模型、连续场模型、球谐函数模型及颗粒绑定型非均相包覆模型四类,对比分析了其优缺点。颗粒内包覆均匀性是精细调节整体包覆质量的关键环节,目前多是实验规律研究,数学建模和机理研究还很不完善,亟待深入。未来颗粒包覆均匀性数学模拟需要在精确性和复杂性之间取得平衡,构建兼具可计算性与符合物理机制的多尺度耦合框架,以更高效地支撑包覆工艺优化与揭示包覆机理。

中图分类号:

兰蕊, 田宇, 刘荣正, 杨旭, 刘兵, 邵友林, 刘马林. 气固系统中颗粒包覆均匀性数值模拟研究进展[J]. 化工学报, DOI: 10.11949/0438-1157.20251378.

Rui LAN, Yu TIAN, Rongzheng LIU, Xu YANG, Bing LIU, Youlin SHAO, Malin LIU. Research progress in numerical simulation of particle coating uniformity in gas-solid systems[J]. CIESC Journal, DOI: 10.11949/0438-1157.20251378.

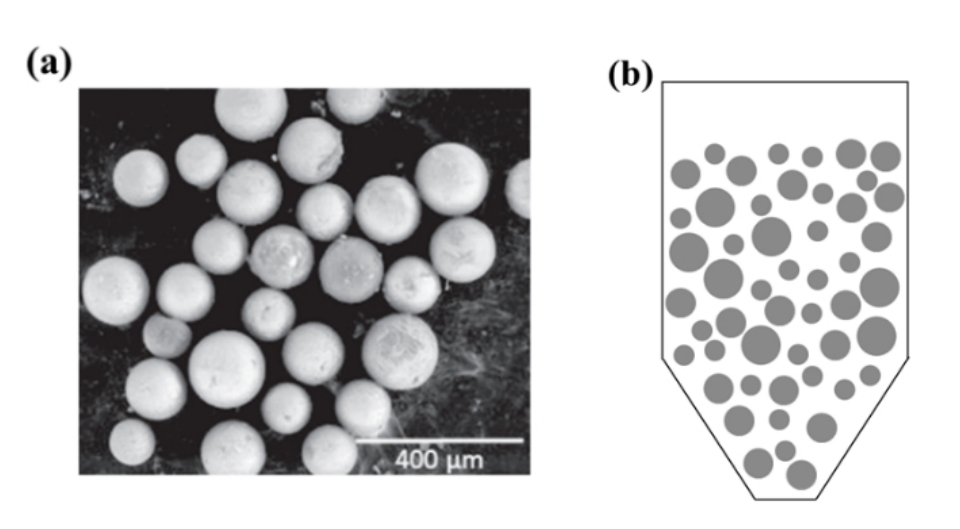

图 1 颗粒间包覆非均匀性:(a) 聚合物球形颗粒SEM图像[26]; (b) 通过颗粒尺寸分布描述非均匀性的示意图

Fig.1 Inter-particle coating non-uniformity: (a) SEM image of polymer spherical particles [26]; (b) Schematic diagram of non-uniformity characterized by particle size distribution

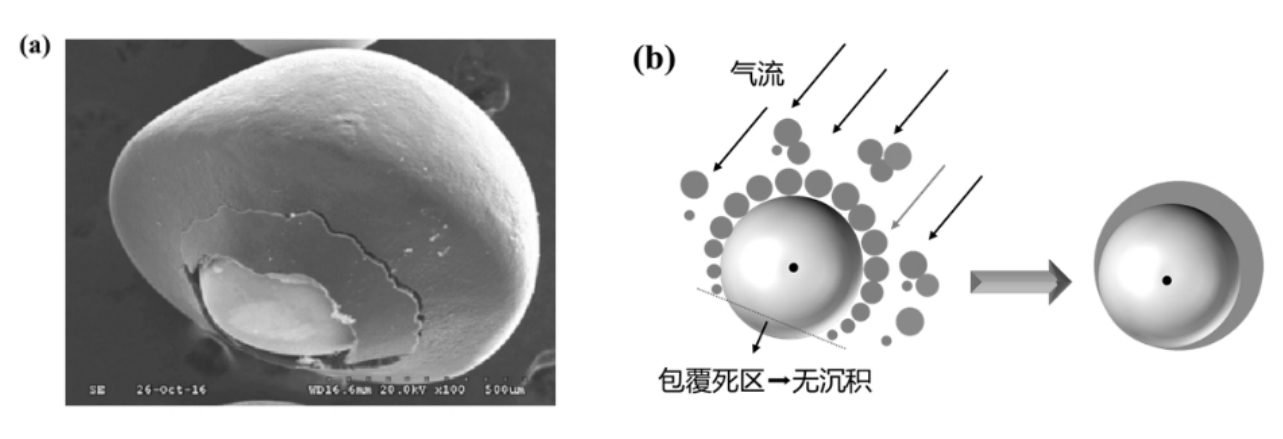

图 2 颗粒内包覆非均匀性:(a) TRISO燃料颗粒SiC层缺陷的SEM图像; (b) 通过颗粒表面局部包覆描述非均匀性的示意图

Fig.2 Intra-particle coating non-uniformity: (a) SEM image of defects in the SiC layer of a TRISO fuel particle; (b) Schematic diagram of non-uniformity characterized by local coating features on the particle surface

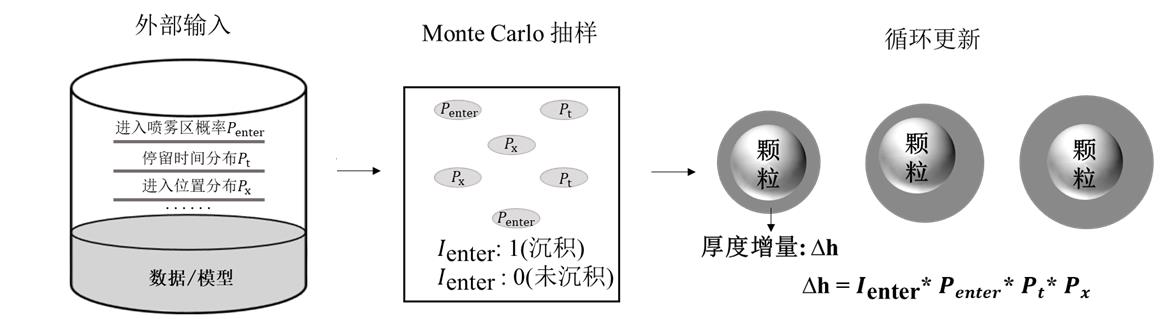

图 5 包覆过程Monte Carlo模型中的“外部输入-抽样-循环更新”框架示意图

Fig.5 Schematic diagram of the “external input–sampling–iterative update” framework of the Monte Carlo model for the coating process

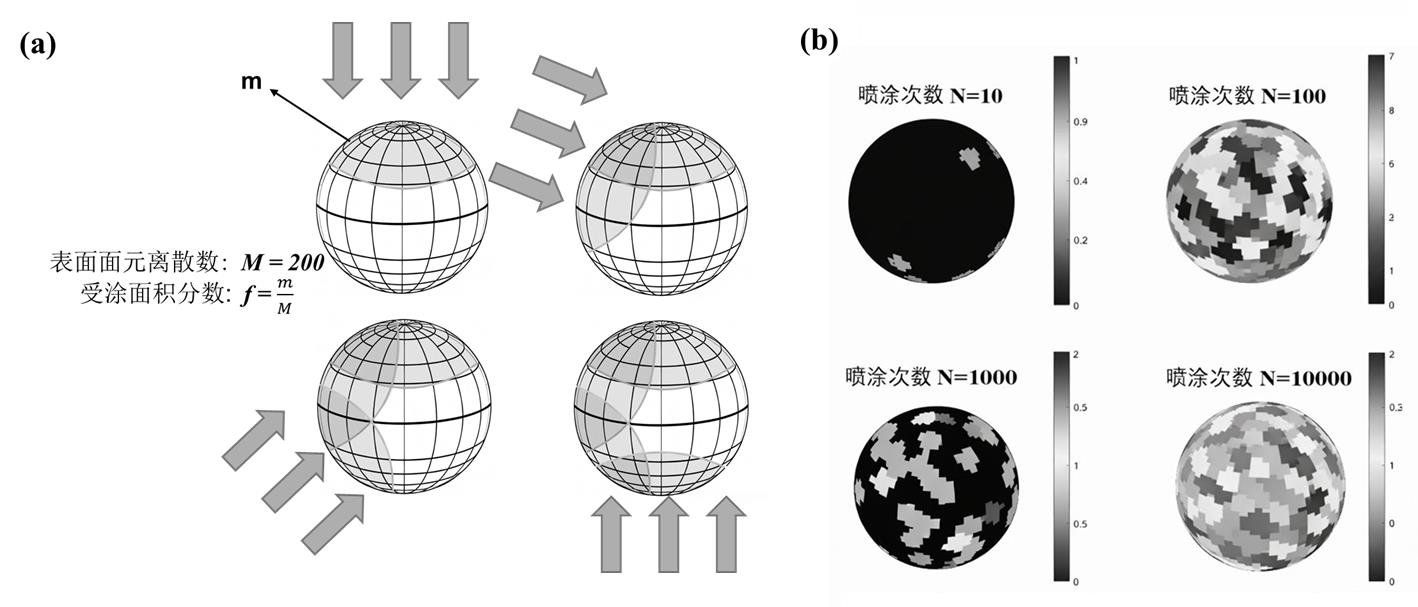

图 6 (a) 单次随机喷涂下的表面沉积分布[57];(b) 喷涂次数N=10、100、1000、10000 时包覆均匀性的演化

Fig.6 (a) Surface deposition distribution under a single random spraying event[57]; (b) Evolution of coating uniformity at spraying numbers of N = 10, 100, 1000, and 10000

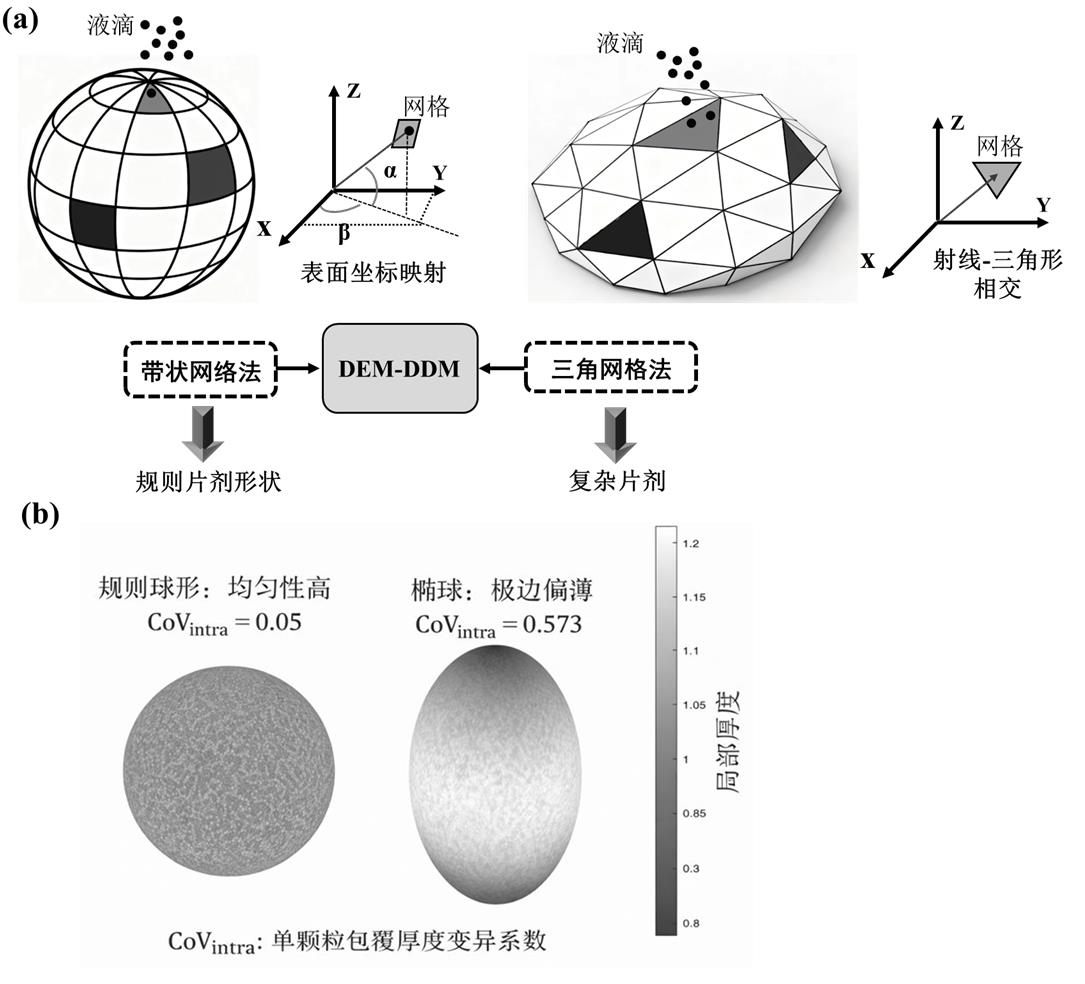

图 8 DEM-DDM耦合框架示意图[58]:(a) 颗粒表面离散化方式;(b) 不同颗粒形状下局部包覆厚度分布差异

Fig.8 Schematic diagram of the DEM-DDM coupled framework[58]: (a) Discretization scheme of the particle surface; (b) Differences in local coating thickness distributions for particles with different shapes

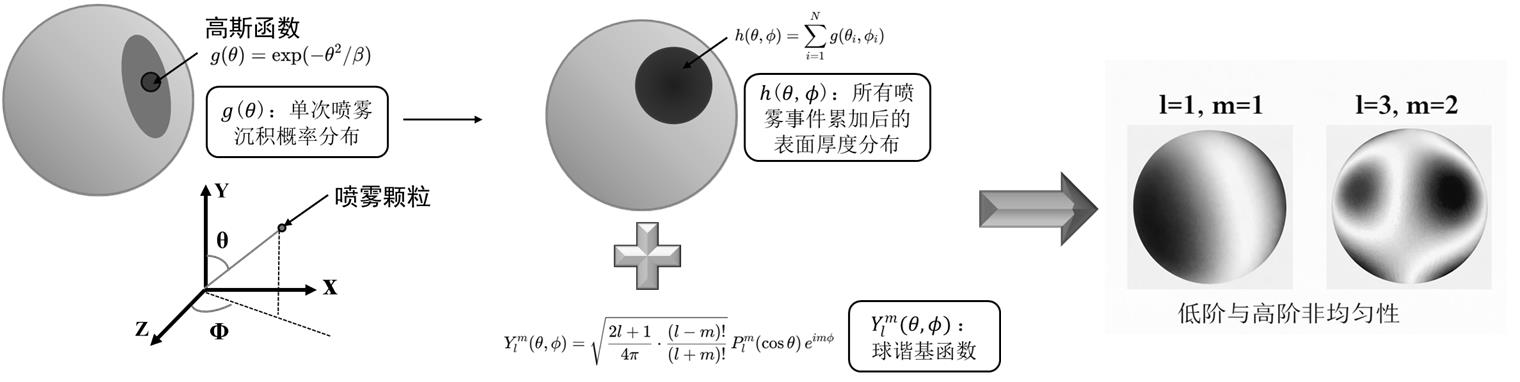

图 10 基于球谐展开的单颗粒包覆厚度分布定量分析示意图[60]

Fig.10 Schematic diagram of the quantitative analysis of single-particle coating thickness distribution using spherical harmonic expansion[60]

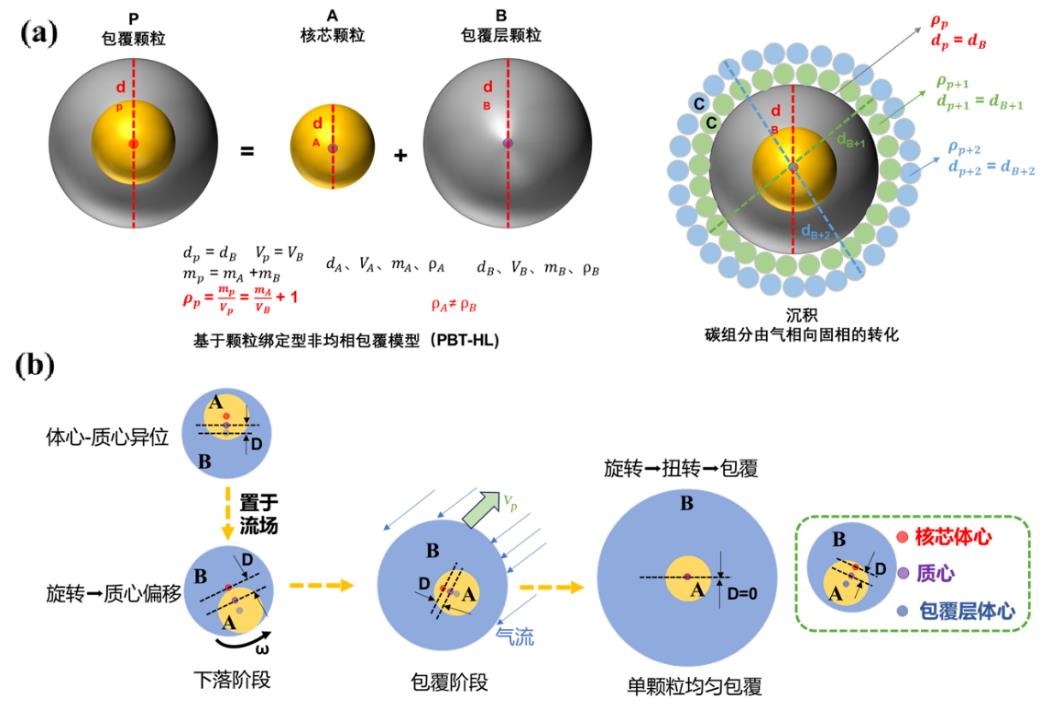

图 11 PBT-HL模型及复合颗粒“自均匀化”[61]:(a) PBT-HL模型;(b) 单颗粒包覆均匀性演变

Fig.11 PBT-HL model and “self-uniformization” behavior of composite particles [61]: (a) PBT-HL model; (b) Evolution of single-particle coating uniformity

| 模型类型 | 主要思路 | 主要优势 | 主要局限 |

|---|---|---|---|

| 时间分布模型 | 基于颗粒群体的停留时间分布或循环频率等宏观统计量预测包覆颗粒均匀性 | 模型简洁,计算高效;宏观均匀性趋势预测 | 无法直接量化涂层增量、忽略局部沉积 |

| 蒙特卡洛模拟 | 以概率方式模拟液滴沉积与膜厚随机增长过程 | 高效预测群体涂层分布,可捕捉不确定性对包覆均匀性差异的影响 | 依赖实验或物理模型概率分布 |

| 离散元模型 | 追踪单颗粒运动状态,描述群体尺度包覆均匀性 | 物理真实性、良好可扩展性 | 计算量大,仅刻画颗粒动力学 |

| 多尺度耦合模型 | 从机理层面解析颗粒包覆演化的动态行为与均匀性调控机制。 | 能够完整捕捉“气流—液滴—颗粒—沉积-均匀性”全过程 | 建模复杂、参数多;大规模应用受限 |

表 1 颗粒间包覆均匀性数值模拟方法对比

Table 1 Comparative study of numerical methods for inter-particle coating uniformity

| 模型类型 | 主要思路 | 主要优势 | 主要局限 |

|---|---|---|---|

| 时间分布模型 | 基于颗粒群体的停留时间分布或循环频率等宏观统计量预测包覆颗粒均匀性 | 模型简洁,计算高效;宏观均匀性趋势预测 | 无法直接量化涂层增量、忽略局部沉积 |

| 蒙特卡洛模拟 | 以概率方式模拟液滴沉积与膜厚随机增长过程 | 高效预测群体涂层分布,可捕捉不确定性对包覆均匀性差异的影响 | 依赖实验或物理模型概率分布 |

| 离散元模型 | 追踪单颗粒运动状态,描述群体尺度包覆均匀性 | 物理真实性、良好可扩展性 | 计算量大,仅刻画颗粒动力学 |

| 多尺度耦合模型 | 从机理层面解析颗粒包覆演化的动态行为与均匀性调控机制。 | 能够完整捕捉“气流—液滴—颗粒—沉积-均匀性”全过程 | 建模复杂、参数多;大规模应用受限 |

| 模型类别 | 主要思路 | 主要优势 | 主要局限 |

|---|---|---|---|

| 表面离散化模型 | 颗粒表面划分面元,模拟局部沉积 | 易量化局部厚度,反映随机性 | 面元多计算量大,存在高效性与可控性之间的矛盾 |

| 连续场模型 | 包覆视为连续介质,偏微分方程描述沉积演化 | 捕捉连续物理过程,高保真 | 难处理复杂几何,沉积机理简化 |

| 球谐函数模型 | 颗粒表面厚度分布投影到球谐函数基上,角功率谱表征多尺度空间不均匀性 | 离散表面数据的连续谱域解析 | 计算代价高昂,仅适用于球形或近球形 |

| 颗粒绑定非均相包覆模型 | 包覆颗粒密度动态变化 | 定量化描述单颗粒包覆层厚度的各向异性 | 结构简化假设、动力学耦合不足 |

表 2 颗粒内包覆均匀性数值模拟方法对比

Table 2 Comparative study of numerical methods for intra-particle coating uniformity

| 模型类别 | 主要思路 | 主要优势 | 主要局限 |

|---|---|---|---|

| 表面离散化模型 | 颗粒表面划分面元,模拟局部沉积 | 易量化局部厚度,反映随机性 | 面元多计算量大,存在高效性与可控性之间的矛盾 |

| 连续场模型 | 包覆视为连续介质,偏微分方程描述沉积演化 | 捕捉连续物理过程,高保真 | 难处理复杂几何,沉积机理简化 |

| 球谐函数模型 | 颗粒表面厚度分布投影到球谐函数基上,角功率谱表征多尺度空间不均匀性 | 离散表面数据的连续谱域解析 | 计算代价高昂,仅适用于球形或近球形 |

| 颗粒绑定非均相包覆模型 | 包覆颗粒密度动态变化 | 定量化描述单颗粒包覆层厚度的各向异性 | 结构简化假设、动力学耦合不足 |

| [1] | Zhu Q, Chua M H, Ong P J, et al. Recent advances in nanotechnology-based functional coatings for the built environment[J]. Materials Today Advances, 2022, 15: 100270. |

| [2] | Pourhashem S, Saba F, Duan J Z, et al. Polymer/Inorganic nanocomposite coatings with superior corrosion protection performance: a review[J]. Journal of Industrial and Engineering Chemistry, 2020, 88: 29-57. |

| [3] | Zhang W, Wang H M, You C F. Numerical simulation of fluidized bed coating process considering particle abrasion[J]. Chemical Engineering Journal, 2022, 445: 136632. |

| [4] | Sharma R, Setia G. Mechanical dry particle coating on cohesive pharmaceutical powders for improving flowability - A review[J]. Powder Technology, 2019, 356: 458-479. |

| [5] | Vehring R. Pharmaceutical particle engineering via spray drying[J]. Pharmaceutical Research, 2008, 25(5): 999-1022. |

| [6] | Van Duong T, Nguyen H T, Wang F, et al. Surface nanocoating of high drug-loading spray-dried amorphous solid dispersions by atomic layer coating: Excellent physical stability under accelerated storage conditions for two years[J]. International Journal of Pharmaceutics, 2022, 620: 121747. |

| [7] | Zaid A N. A comprehensive review on pharmaceutical film coating: past, present, and future[J]. Drug Design, Development and Therapy, 2020, 14: 4613-4623. |

| [8] | Salawi A. Pharmaceutical coating and its different approaches, a review[J]. Polymers, 2022, 14(16): 3318. |

| [9] | Mansouri H, Ait Said H, Noukrati H, et al. Advances in controlled release fertilizers: cost-effective coating techniques and smart stimuli-responsive hydrogels[J]. Advanced Sustainable Systems, 2023, 7(9): 2300149. |

| [10] | Meher S, van Rooyen I J, Jiang C. Understanding of fission products transport in SiC layer of TRISO fuels by nanoscale characterization and modeling[J]. Journal of Nuclear Materials, 2019, 527: 151793. |

| [11] | Teunou E, Poncelet D. Batch and continuous fluid bed coating - review and state of the art[J]. Journal of Food Engineering, 2002, 53(4): 325-340. |

| [12] | Choy K L. Chemical vapour deposition of coatings[J]. Progress in Materials Science, 2003, 48(2): 57-170. |

| [13] | Bungert N, Kobler M, Scherließ R. In-depth comparison of dry particle coating processes used in DPI particle engineering[J]. Pharmaceutics, 2021, 13(4): 580. |

| [14] | Christensen F N, Bertelsen P. Qualitative description of the wurster-based fluid-bed coating process[J]. Drug Development and Industrial Pharmacy, 1997, 23(5): 451-463. |

| [15] | Arrieta M Y, Keiser D D, Perez-Nunez D, et al. Fluidized bed chemical vapor deposition of zirconium nitride films[J]. Nuclear Technology, 2017, 199(2): 219-226. |

| [16] | 邓爱明, 何玉荣, 唐天琪, 等. 导流板对喷雾流化床内颗粒生长过程影响的模拟[J]. 化工学报, 2024, 75(8): 2787-2799. |

| Deng A M, He Y R, Tang T Q, et al. Simulation of effect of draft plate on particle growth process in spray fluidized beds[J]. CIESC Journal, 2024, 75(8): 2787-2799. | |

| [17] | Okokpujie I P, Tartibu L K, Musa-Basheer H O, et al. Effect of coatings on mechanical, corrosion and tribological properties of industrial materials: a comprehensive review[J]. Journal of Bio- and Tribo-Corrosion, 2023, 10(1): 2. |

| [18] | Narita T. Diffusion barrier coating system concept for high temperature applications[J]. Canadian Metallurgical Quarterly, 2011, 50(3): 278-290. |

| [19] | Ohno T, Kumar Padarti J, Hirai S, et al. Effects of coating layer homogeneity of cathode particles on lithium-ion battery performance[J]. Advanced Powder Technology, 2024, 35(9): 104608. |

| [20] | Jiang Z C, Rieck C, Bück A, et al. Modeling of inter- and intra-particle coating uniformity in a Wurster fluidized bed by a coupled CFD-DEM-Monte Carlo approach[J]. Chemical Engineering Science, 2020, 211: 115289. |

| [21] | Gerczak T J, Hunn J D, Lowden R A, et al. SiC layer microstructure in AGR-1 and AGR-2 TRISO fuel particles and the influence of its variation on the effective diffusion of key fission products[J]. Journal of Nuclear Materials, 2016, 480: 257-270. |

| [22] | Verfondern K, Nabielek H, Kendall J M. Coated particle fuel for high temperature gas cooled reactors[J]. Nuclear Engineering and Technology, 2007, 39(5): 603-616. |

| [23] | Černe B, Petkovšek M. High-speed camera-based optical measurement methods for in-mesh tooth deflection analysis of thermoplastic spur gears[J]. Materials & Design, 2022, 223: 111184. |

| [24] | Roncallo S, Painter J D, Cousins M A, et al. A method to quantify the degree of uniformity of thickness of thin films[J]. Thin Solid Films, 2008, 516(23): 8493-8497. |

| [25] | Taylor M, Simoes F, Smith J, et al. Quantifiable correlation of ToF-SIMS and XPS data from polymer surfaces with controlled amino acid and peptide content[J]. Surface and Interface Analysis, 2022, 54(4): 417-432. |

| [26] | Hejmady P, van Breemen L C A, Anderson P D, et al. A processing route to spherical polymer particles via controlled droplet retraction[J]. Powder Technology, 2021, 388: 401-411. |

| [27] | 陈猛, 刘马林, 唐亚平, 等. 颗粒包覆过程的数值模拟方法比较研究[J]. 中国粉体技术, 2018, 24(1): 7-15. |

| Chen M, Liu M L, Tang Y P, et al. Comparative study of numerical simulation method for particle coating process[J]. China Powder Science and Technology, 2018, 24(1): 7-15. | |

| [28] | Guo J N, Liu D Y, Ma J L, et al. Particle circulation and coating in a Wurster fluidized bed under different geometries[J]. Powder Technology, 2024, 433: 119223. |

| [29] | Cheng X X, Turton R. The prediction of variability occurring in fluidized bed coating equipment. II. the role of nonuniform particle coverage as particles pass through the spray zonemr[J]. Pharmaceutical Development and Technology, 2000, 5(3): 323-332. |

| [30] | Narita T, Hébraud P, Lequeux F. Effects of the rate of evaporation and film thickness on nonuniform drying of film-forming concentrated colloidal suspensions[J]. The European Physical Journal E, 2005, 17(1): 69-76. |

| [31] | Grohn P, Heinrich S, Antonyuk S. Numerical investigation of the particle dynamics in a rotorgranulator depending on the properties of the coating liquid[J]. Pharmaceutics, 2023, 15(2): 469. |

| [32] | Choi M M S, Meisen A. Sulfur coating of urea in shallow spouted beds[J]. Chemical Engineering Science, 1997, 52(7): 1073-1086. |

| [33] | Tian Y, Yan Z, Jiang L, et al. Multiscale Models of CVD Process: Review and Prospective[J]. Materials, 2024, 17(20): 5131. |

| [34] | Li L, Remmelgas J, van Wachem B G M, et al. Effect of drag models on residence time distributions of particles in a wurster fluidized bed: a DEM-CFD study[J]. KONA Powder and Particle Journal, 2016, 33: 264-277. |

| [35] | Li L, Rasmuson A, Ingram A, et al. PEPT study of particle cycle and residence time distributions in a Wurster fluid bed[J]. AIChE Journal, 2015, 61(3): 756-768. |

| [36] | Kariuki W I J, Freireich B, Smith R M, et al. Distribution nucleation: Quantifying liquid distribution on the particle surface using the dimensionless particle coating number[J]. Chemical Engineering Science, 2013, 92: 134-145. |

| [37] | Böhling P, Khinast J G, Jajcevic D, et al. Computational fluid dynamics-discrete element method modeling of an industrial-scale wurster coater[J]. Journal of Pharmaceutical Sciences, 2019, 108(1): 538-550. |

| [38] | Rieck C, Bück A, Tsotsas E. Monte Carlo modeling of fluidized bed coating and layering processes[J]. AIChE Journal, 2016, 62(8): 2670-2680. |

| [39] | Pandey P, Katakdaunde M, Turton R. Modeling weight variability in a pan coating process using Monte Carlo simulations[J]. AAPS PharmSciTech, 2014, 7(4): 83. |

| [40] | KuShaari K, Pandey P, Song Y X, et al. Monte Carlo simulations to determine coating uniformity in a Wurster fluidized bed coating process[J]. Powder Technology, 2006, 166(2): 81-90. |

| [41] | Yang Q L, Chen J L, Zhou X H, et al. Modeling of inter-tablet coating uniformity of electrostatic dry powder coating by discrete element method[J]. Powder Technology, 2022, 411: 117929. |

| [42] | Ketterhagen W R. Modeling the motion and orientation of various pharmaceutical tablet shapes in a film coating pan using DEM[J]. International Journal of Pharmaceutics, 2011, 409(1/2): 137-149. |

| [43] | Pasha M, Ghadiri M, Gunadi A, et al. Distinct element analysis of inter-particle coating variability in a batch seed coater[J]. EPJ Web of Conferences, 2017, 140: 15035. |

| [44] | Madlmeir S, Forgber T, Trogrlic M, et al. Modeling the coating layer thickness in a pharmaceutical coating process[J]. European Journal of Pharmaceutical Sciences, 2021, 161: 105770. |

| [45] | Norouzi H R. Simulation of pellet coating in Wurster coaters[J]. International Journal of Pharmaceutics, 2020, 590: 119931. |

| [46] | Farivar F, Zhang H, Tian Z F, et al. CFD-DEM-DDM model for spray coating process in a wurster coater[J]. Journal of Pharmaceutical Sciences, 2020, 109(12): 3678-3689. |

| [47] | Fries L, Antonyuk S, Heinrich S, et al. DEM–CFD modeling of a fluidized bed spray granulator[J]. Chemical Engineering Science, 2011, 66(11): 2340-2355. |

| [48] | Song Y Q, Liu N N, Fang R, et al. CFD-DEM simulation of the Wurster coating process with particle cohesion and heat and mass transfer[J]. Applied Thermal Engineering, 2025, 279: 127542. |

| [49] | Deng A M, Tang T Q, Sun S S, et al. Particle coating growth behaviors in a spray fluidized bed based on Gas-Liquid-Solid Quasi-Three-phase DEM numerical simulation[J]. Chemical Engineering Journal, 2023, 476: 146480. |

| [50] | Chen Z, Jiang L, Qiu M F, et al. CFD-DEM simulation of spouted bed dynamics under high temperature with an adhesive model[J]. Energies, 2021, 14(8): 2276. |

| [51] | Liu M L, Chen M, Li T J, et al. CFD–DEM–CVD multi-physical field coupling model for simulating particle coating process in spout bed[J]. Particuology, 2019, 42: 67-78. |

| [52] | Liu M L, Liu R Z, Chen M, et al. Preliminary simulation study of particle coating process by FB-CVD method using a CFD-DEM-PBM model[J]. Nuclear Engineering and Design, 2018, 329: 53-59. |

| [53] | Li J F, Freireich B, Wassgren C, et al. A general compartment-based population balance model for particle coating and layered granulation[J]. AIChE Journal, 2012, 58(5): 1397-1408. |

| [54] | Kumar R, Freireich B, Wassgren C. DEM–compartment–population balance model for particle coating in a horizontal rotating drum[J]. Chemical Engineering Science, 2015, 125: 144-157. |

| [55] | Chen M, Chen Z, Tang Y P, et al. CFD-DEM simulation of particle coating process coupled with chemical reaction flow model[J]. International Journal of Chemical Reactor Engineering, 2021, 19(4): 393-413. |

| [56] | Griesbach C, Gerczak T, Zhang Y F, et al. Microstructural heterogeneity of the buffer layer of TRISO nuclear fuel particles[J]. Journal of Nuclear Materials, 2023, 574: 154219. |

| [57] | Freireich B, Wassgren C. Intra-particle coating variability: Analysis and Monte-Carlo simulations[J]. Chemical Engineering Science, 2010, 65(3): 1117-1124. |

| [58] | Liu Z H, Ma H Q, Zhou L Y, et al. DEM-DDM investigation of the intra-tablet coating uniformity for tablets with different shapes[J]. Powder Technology, 2024, 438: 119666. |

| [59] | Suzzi D, Radl S, Khinast J G. Local analysis of the tablet coating process: Impact of operation conditions on film quality[J]. Chemical Engineering Science, 2010, 65(21): 5699-5715. |

| [60] | Hilton J E, Ying D Y, Cleary P W. Modelling spray coating using a combined CFD–DEM and spherical harmonic formulation[J]. Chemical Engineering Science, 2013, 99: 141-160. |

| [61] | Jiang L, Gong M, Lan R, et al. A novel heterogeneous binding model for simulating nuclear fuel particle FB-CVD coating process based on CFD-DEM concept[J]. Particuology, 2025, 103: 1-17. |

| [62] | 韩方伟, 彭莹莹, 张金宜, 等. 抑尘液滴对煤表面动态润湿特征模拟评估方法[J]. 煤炭学报, 2024, 49(4): 1931-1940. |

| Han F W, Peng Y Y, Zhang J Y, et al. Simulation and evaluation method of dynamic wetting characteristics of dust suppression droplets on coal surface[J]. Journal of China Coal Society, 2024, 49(4): 1931-1940. | |

| [63] | 张玉春, 王振波, 金有海, 等. 超短接触旋流反应器混合腔内气固混合特性的数值模拟[J]. 化工学报, 2012, 63(2): 424-432. |

| Zhang Y C, Wang Z B, Jin Y H, et al. Numerical simulation on gas-solid mixing characteristics in mixing cavity of quick-contact cyclone reactor[J]. CIESC Journal, 2012, 63(2): 424-432. | |

| [64] | Schönig N, Briesen H. Intra- and interparticle coating homogeneity and minimum coating amount of hot melt coating products identified by Monte Carlo-Model[J]. Powder Technology, 2026, 467: 121506. |

| [65] | 赵永志, 程易, 金涌. 颗粒移动床内不稳定运动的计算颗粒动力学模拟[J]. 化工学报, 2007, 58(9): 2216-2224. |

| Zhao Y Z, Cheng Y, Jin Y. Computational granular dynamics simulation of unsteady movement in particle moving bed[J]. CIESC Journal, 2007, 58(9): 2216-2224. | |

| [66] | Grohn P, Lawall M, Oesau T, et al. CFD-DEM simulation of a coating process in a fluidized bed rotor granulator[J]. Processes, 2020, 8(9): 1090. |

| [67] | Li L, Remmelgas J, van Wachem B G M, et al. Residence time distributions of different size particles in the spray zone of a Wurster fluid bed studied using DEM-CFD[J]. Powder Technology, 2015, 280: 124-134. |

| [68] | Song Y Q, Zhou T, Bai R Q, et al. Review of CFD-DEM modeling of wet fluidized bed granulation and coating processes[J]. Processes, 2023, 11(2): 382. |

| [69] | Jiang Z C, Bück A, Tsotsas E. CFD–DEM study of residence time, droplet deposition, and collision velocity for a binary particle mixture in a Wurster fluidized bed coater[J]. Drying Technology, 2018, 36(6): 638-650. |

| [70] | Ai J, Chen J F, Rotter J M, et al. Assessment of rolling resistance models in discrete element simulations[J]. Powder Technology, 2011, 206(3): 269-282. |

| [71] | Oesterle B, Petitjean A. Simulation of particle-to-particle interactions in gas solid flows[J]. International Journal of Multiphase Flow, 1993, 19(1): 199-211. |

| [72] | Jajcevic D, Siegmann E, Radeke C, et al. Large-scale CFD–DEM simulations of fluidized granular systems[J]. Chemical Engineering Science, 2013, 98: 298-310. |

| [73] | Wang S, Shen Y S. CFD-DEM modelling of dense gas-solid reacting flow: Recent advances and challenges[J]. Progress in Energy and Combustion Science, 2025, 109: 101221. |

| [1] | 密晓光, 孙国刚, 程昊, 张晓慧. 印刷电路板式天然气冷却器性能仿真模型和验证[J]. 化工学报, 2025, 76(S1): 426-434. |

| [2] | 黄灏, 王文, 李沛昀. 三角转子膨胀机串联运行特性研究[J]. 化工学报, 2025, 76(S1): 435-443. |

| [3] | 段浩磊, 陈浩远, 梁坤峰, 王林, 陈彬, 曹勇, 张晨光, 李硕鹏, 朱登宇, 何亚茹, 杨大鹏. 纯电动车热管理系统低GWP工质替代方案性能分析与综合评价[J]. 化工学报, 2025, 76(S1): 54-61. |

| [4] | 郭松源, 周晓庆, 缪五兵, 汪彬, 耑锐, 曹庆泰, 陈成成, 杨光, 吴静怡. 火箭上升段含多孔板液氧贮箱增压输运数值研究[J]. 化工学报, 2025, 76(S1): 62-74. |

| [5] | 张文锋, 郭玮, 张新玉, 曹昊敏, 丁国良. 铝管铝翅片换热器模型开发及软件实现[J]. 化工学报, 2025, 76(S1): 84-92. |

| [6] | 王俊鹏, 冯佳琪, 张恩搏, 白博峰. 曲折式与阵列式迷宫阀芯结构内流动与空化特性研究[J]. 化工学报, 2025, 76(S1): 93-105. |

| [7] | 刘豪, 王林, 丁昊, 耿嘉怡. R1150+R1234ze(E)二元体系223.15~253.15 K汽液相平衡研究[J]. 化工学报, 2025, 76(S1): 1-8. |

| [8] | 赵子祥, 段钟弟, 孙浩然, 薛鸿祥. 大温差两相流动诱导水锤冲击的数值模型[J]. 化工学报, 2025, 76(S1): 170-180. |

| [9] | 黄灏, 王文, 贺隆坤. LNG船薄膜型液货舱预冷过程模拟与分析[J]. 化工学报, 2025, 76(S1): 187-194. |

| [10] | 汪思远, 刘国强, 熊通, 晏刚. 窗式空调器轴流风机的风速非均匀分布特性及其对冷凝器流路优化设计的影响规律[J]. 化工学报, 2025, 76(S1): 205-216. |

| [11] | 曹庆泰, 郭松源, 李建强, 蒋赞, 汪彬, 耑锐, 吴静怡, 杨光. 负过载下多孔隔板对液氧贮箱蓄液性能的影响研究[J]. 化工学报, 2025, 76(S1): 217-229. |

| [12] | 郭纪超, 徐肖肖, 孙云龙. 基于植物工厂中的CO2浓度气流模拟及优化研究[J]. 化工学报, 2025, 76(S1): 237-245. |

| [13] | 孙九春, 桑运龙, 王海涛, 贾浩, 朱艳. 泥水盾构仓体内射流对泥浆输送特性影响研究[J]. 化工学报, 2025, 76(S1): 246-257. |

| [14] | 何婷, 黄舒阳, 黄坤, 陈利琼. 基于余热利用的天然气化学吸收脱碳-高温热泵耦合流程研究[J]. 化工学报, 2025, 76(S1): 297-308. |

| [15] | 马爱华, 赵帅, 王林, 常明慧. 太阳能吸收制冷循环动态特性仿真方法研究[J]. 化工学报, 2025, 76(S1): 318-325. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号