CIESC Journal ›› 2019, Vol. 70 ›› Issue (7): 2411-2425.DOI: 10.11949/0438-1157.20190011

• Reviews and monographs • Previous Articles Next Articles

Zhengzhong MAO( ),Yi SUN,Zhipeng HUANG,Chaochao LI,Haobin HUANG,Shao an CHENG(

),Yi SUN,Zhipeng HUANG,Chaochao LI,Haobin HUANG,Shao an CHENG( )

)

Received:2019-01-04

Revised:2019-04-03

Online:2019-07-05

Published:2019-07-05

Contact:

Shao an CHENG

通讯作者:

成少安

作者简介:毛政中(1994—),男,博士研究生,<email>11627025@zju.edu.cn</email>

基金资助:CLC Number:

Zhengzhong MAO, Yi SUN, Zhipeng HUANG, Chaochao LI, Haobin HUANG, Shao an CHENG. Progress of research on methanogenic microbial electrolysis cell[J]. CIESC Journal, 2019, 70(7): 2411-2425.

毛政中, 孙怡, 黄志鹏, 李超超, 黄浩斌, 成少安. 微生物电解池产甲烷技术研究进展[J]. 化工学报, 2019, 70(7): 2411-2425.

Add to citation manager EndNote|Ris|BibTeX

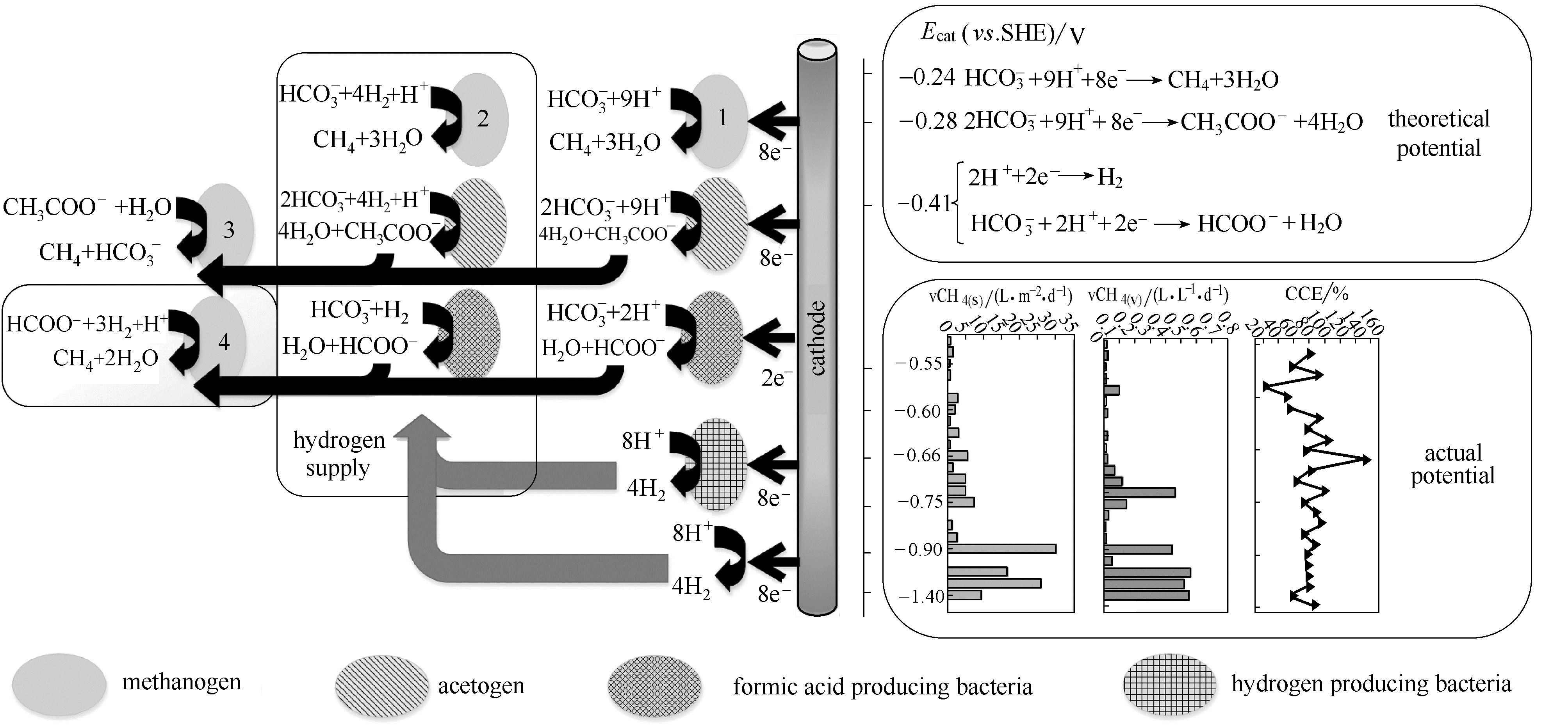

Fig.3 Summary of methanogenic biocathode electron transport pathways and properties(All chemical substances involved in the calculation of the theoretical electrode potential are 1 mol·L-1 or 0.1 MPa, pH 7 and temperature 298 K) [6,33]

Exp. Num. | Type | Voltage①/V | Inoculum/substrate | vCH4(v)/(L·L-1·d-1) | Location | Dominant archaea genus | Ref. |

|---|---|---|---|---|---|---|---|

| (1) | DC②(20ml each) | 0.7 | ADS③/acetate | - | anode | Methanobacterium (65%) | [10] |

| (2) | DC(20ml each) | 0.7 | ADS/propionate | - | anode | Methanobacterium(57%) | [10] |

| (3) | SC④ | 0.6 | raw waste sludge | 0.083 | anode | Methanocorpusculum(93%) | [13] |

| (4) | SC | 0.6 | alkali pretreatment of the waste sludge | 0.1 | anode | Methanocorpusculum(85%) | [13] |

| (5) | SC(15 L) | 0.3 | food waste leachate | 0.34 L·g-1TCODremoved | bulk sludge | Methanosarcina(45%) | [53] |

| (6) | SC(20 L) | 0.3 | AD sludge FWTP | (0.34 ± 0.02) L·g-1TCODremoved | bulk sludge | Methanosarcina(24%), Methanobacterium(19%) | [54] |

| (7) | SC(0.8m3) | 4 | FTWW⑤/ADS from winery WWTP⑥ | 1.16 ± 0.06 | matured sludge | Methanomassillicoccus(22%), Methanosphaerula(14%) | [15] |

| (8) | SC(0.8m3)(anaerobic effluent recycling of 200%) | 4 | FTWW /ADS from winery WWTP | 2.01±0.13 | matured sludge | Methanothrix(37.33%), Methanosphaerula(11.17%) | [15] |

| (9) | SC (Φ80×120 mm) | 0.6 | waste activated sludge | 2.26±0.16 | suspended sludge | Methanosaeta(74%) | [55] |

| (10) | DC (300 ml each bottle) | -0.8 | CO2 | 5 L·m-2·d-1 | cathode | Methanobacterium(86.7%) | [1] |

| (11) | DC(800ml cathode working volume)continuous mode | -0.7 | AGS/ethanol and organic acids | — | cathode | Methanobacterium(77%) | [56] |

| (12) | DC(800ml cathode working volume)batch mode | -0.7 | AGS/ethanol and organic acids | — | cathode | Methanobacterium(84%) | [56] |

| (13) | SC | 0.6 | raw waste sludge | 0.083 | cathode | Methanocorpusculum(77%) | [13] |

| (14) | SC | 0.6 | alkali pretreatment of the waste sludge | 0.1 | cathode | Methanobacterium(98%) | [13] |

| (15) | SC(open circuit) | 0 | raw waste sludge | 0.064 | cathode | Methanosaeta(48.2%) | [13] |

Table 1 Main composition of archaea in methanogenic microbial electrolysis cell

Exp. Num. | Type | Voltage①/V | Inoculum/substrate | vCH4(v)/(L·L-1·d-1) | Location | Dominant archaea genus | Ref. |

|---|---|---|---|---|---|---|---|

| (1) | DC②(20ml each) | 0.7 | ADS③/acetate | - | anode | Methanobacterium (65%) | [10] |

| (2) | DC(20ml each) | 0.7 | ADS/propionate | - | anode | Methanobacterium(57%) | [10] |

| (3) | SC④ | 0.6 | raw waste sludge | 0.083 | anode | Methanocorpusculum(93%) | [13] |

| (4) | SC | 0.6 | alkali pretreatment of the waste sludge | 0.1 | anode | Methanocorpusculum(85%) | [13] |

| (5) | SC(15 L) | 0.3 | food waste leachate | 0.34 L·g-1TCODremoved | bulk sludge | Methanosarcina(45%) | [53] |

| (6) | SC(20 L) | 0.3 | AD sludge FWTP | (0.34 ± 0.02) L·g-1TCODremoved | bulk sludge | Methanosarcina(24%), Methanobacterium(19%) | [54] |

| (7) | SC(0.8m3) | 4 | FTWW⑤/ADS from winery WWTP⑥ | 1.16 ± 0.06 | matured sludge | Methanomassillicoccus(22%), Methanosphaerula(14%) | [15] |

| (8) | SC(0.8m3)(anaerobic effluent recycling of 200%) | 4 | FTWW /ADS from winery WWTP | 2.01±0.13 | matured sludge | Methanothrix(37.33%), Methanosphaerula(11.17%) | [15] |

| (9) | SC (Φ80×120 mm) | 0.6 | waste activated sludge | 2.26±0.16 | suspended sludge | Methanosaeta(74%) | [55] |

| (10) | DC (300 ml each bottle) | -0.8 | CO2 | 5 L·m-2·d-1 | cathode | Methanobacterium(86.7%) | [1] |

| (11) | DC(800ml cathode working volume)continuous mode | -0.7 | AGS/ethanol and organic acids | — | cathode | Methanobacterium(77%) | [56] |

| (12) | DC(800ml cathode working volume)batch mode | -0.7 | AGS/ethanol and organic acids | — | cathode | Methanobacterium(84%) | [56] |

| (13) | SC | 0.6 | raw waste sludge | 0.083 | cathode | Methanocorpusculum(77%) | [13] |

| (14) | SC | 0.6 | alkali pretreatment of the waste sludge | 0.1 | cathode | Methanobacterium(98%) | [13] |

| (15) | SC(open circuit) | 0 | raw waste sludge | 0.064 | cathode | Methanosaeta(48.2%) | [13] |

| Coupling system | Effective volume/L | OLR①/(g TCOD·L-1·d-1) | HRT/d | Applied voltage/V | Current density/ (A·m-2) | TCOD removal/% | Other contaminants removal indicators/% | Ce②/% | CCE③/% | vCH4(v)④/ (L·L-1·d-1) | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|

AD-MEC DW⑤ treatment | 3 | 0.08 | 1 | 1 | — | 50 | — | 95 | 80 | 0.012 | [58] |

| AD-MEC | 0.5 | 2.02 | 24 | 0.8 | 0.0501±0.0028 | 87.5±2.2 | 36.9±1.7(VSS) | 56.37±3.31 | >100 | 0.073±0.001 | [65] |

| AD-MEC FWTP⑥ wastewater treatment | 20 | 3.0 | 20 | 0.3 | — | 76.1±3.3 | 73.2±2.1%(TVS⑦) | — | — | (0.34±0.02) L·(g COD)-1 | [54] |

| AD-MEC SEOR⑧ wastewater treatment | 0.022 | 0.21 | 20 | 1.2 | 80 A·m-3 | 95.8 | — | — | — | 0.133±0.0045 | [61] |

| TP-AD-MEC(fermentate-digestate mixture, 55℃) | anode:0.86; cathode:0.86 | 1.5 | 20 | anode: +0.2 V vs SHE | 0.723±0.048 (830 cm2) | 28±3 | — | 119±28(particulate COD) | 51±1 | 0.111±0.010 | [12] |

| UAR⑨-MEC | 0.6 | 1.5—2 | 1 | 0.8±0.01 | 8.6 mA | 83 | 97%(carbohydrate) 62%(protein) 83%(TOC) | 15 | — | 142.8 ml·(g COD)-1 | [23] |

| MEC-AnMBR? | 12000 | 5.88—7.85 | 10 | 0.6 | — | 88.8 | 72.1%(TN⑩) 87.4%( 86.9%(BOD5) | — | — | 0.123 | [75] |

AD-MEC (PS?treatment) | anode:0.5; cathode:0.1 | 0.89 | 9 | anode:-0.03 V vs SHE | 2 | 70±4 | 61±9 (VSS) | 63 | — | — | [79] |

ABR?-MFC-MEC fecal wastewater treatment | ABR:28;MFC:9.6; MEC:9.6 | 0.75 | 48 | MFC output voltage:(452.5±10.5)mV | — | 95.9 | 95%( | — | — | biogas components: CH4:55%–65% | [77] |

| PEC?-MEC | anode:0.08; cathode:0.15 | — | 3 | galvanostatic electrolysis at 2.5 mA | 3.33(7.5 cm2) | — | — | — | 82±10 | 0.0391 | [80] |

| PEC-MEC | anode:0.45;cathode:0.45 | — | — | — | 0.275(40 cm2) | — | — | — | 96 | (192.0 ± 3.6) μl·d-1·cm-2 | [81] |

| MEC-UASB?(pilot scale F-T? wastewater treatment) | 800 | 30.23±1.07 | MEC:0.11 UASB:1.67 | 4.0 | — | 93.5±1.6 | — | — | — | 2.01±0.13 | [15] |

N-MEC? (3 groups: M/C/N) | 1 | M:1.6 C/N:0.9 | M:0.58 C/N:1 | M:1.3 C/N:1 | — | M:80.9±3 C/N:99 | C: 65%±2.4% N: 83%±3% ( | — | — | M: 0.451 | [74] |

| UT?-UASB-MEC | UASB-MEC:35; UT:10 | 0.92±0.02 | 7 | 0.5 | 45 mA | 71.4 | 37.86%(VSS/SS) | — | — | — | [82] |

Table 2 Summary of MEC coupled other systems for methane production

| Coupling system | Effective volume/L | OLR①/(g TCOD·L-1·d-1) | HRT/d | Applied voltage/V | Current density/ (A·m-2) | TCOD removal/% | Other contaminants removal indicators/% | Ce②/% | CCE③/% | vCH4(v)④/ (L·L-1·d-1) | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|

AD-MEC DW⑤ treatment | 3 | 0.08 | 1 | 1 | — | 50 | — | 95 | 80 | 0.012 | [58] |

| AD-MEC | 0.5 | 2.02 | 24 | 0.8 | 0.0501±0.0028 | 87.5±2.2 | 36.9±1.7(VSS) | 56.37±3.31 | >100 | 0.073±0.001 | [65] |

| AD-MEC FWTP⑥ wastewater treatment | 20 | 3.0 | 20 | 0.3 | — | 76.1±3.3 | 73.2±2.1%(TVS⑦) | — | — | (0.34±0.02) L·(g COD)-1 | [54] |

| AD-MEC SEOR⑧ wastewater treatment | 0.022 | 0.21 | 20 | 1.2 | 80 A·m-3 | 95.8 | — | — | — | 0.133±0.0045 | [61] |

| TP-AD-MEC(fermentate-digestate mixture, 55℃) | anode:0.86; cathode:0.86 | 1.5 | 20 | anode: +0.2 V vs SHE | 0.723±0.048 (830 cm2) | 28±3 | — | 119±28(particulate COD) | 51±1 | 0.111±0.010 | [12] |

| UAR⑨-MEC | 0.6 | 1.5—2 | 1 | 0.8±0.01 | 8.6 mA | 83 | 97%(carbohydrate) 62%(protein) 83%(TOC) | 15 | — | 142.8 ml·(g COD)-1 | [23] |

| MEC-AnMBR? | 12000 | 5.88—7.85 | 10 | 0.6 | — | 88.8 | 72.1%(TN⑩) 87.4%( 86.9%(BOD5) | — | — | 0.123 | [75] |

AD-MEC (PS?treatment) | anode:0.5; cathode:0.1 | 0.89 | 9 | anode:-0.03 V vs SHE | 2 | 70±4 | 61±9 (VSS) | 63 | — | — | [79] |

ABR?-MFC-MEC fecal wastewater treatment | ABR:28;MFC:9.6; MEC:9.6 | 0.75 | 48 | MFC output voltage:(452.5±10.5)mV | — | 95.9 | 95%( | — | — | biogas components: CH4:55%–65% | [77] |

| PEC?-MEC | anode:0.08; cathode:0.15 | — | 3 | galvanostatic electrolysis at 2.5 mA | 3.33(7.5 cm2) | — | — | — | 82±10 | 0.0391 | [80] |

| PEC-MEC | anode:0.45;cathode:0.45 | — | — | — | 0.275(40 cm2) | — | — | — | 96 | (192.0 ± 3.6) μl·d-1·cm-2 | [81] |

| MEC-UASB?(pilot scale F-T? wastewater treatment) | 800 | 30.23±1.07 | MEC:0.11 UASB:1.67 | 4.0 | — | 93.5±1.6 | — | — | — | 2.01±0.13 | [15] |

N-MEC? (3 groups: M/C/N) | 1 | M:1.6 C/N:0.9 | M:0.58 C/N:1 | M:1.3 C/N:1 | — | M:80.9±3 C/N:99 | C: 65%±2.4% N: 83%±3% ( | — | — | M: 0.451 | [74] |

| UT?-UASB-MEC | UASB-MEC:35; UT:10 | 0.92±0.02 | 7 | 0.5 | 45 mA | 71.4 | 37.86%(VSS/SS) | — | — | — | [82] |

| 1 | ChengS A, XingD F, CallD F, et al. Direct biological conversion of electrical current into methane by electromethanogenesis[J]. Environmental Science & Technology, 2009, 43(10): 3953-3958. |

| 2 | AryalN, TremblayP, LizakD M, et al. Performance of different Sporomusa species for the microbial electrosynthesis of acetate from carbon dioxide[J]. Bioresource Technology, 2017, 233: 184-190. |

| 3 | BajracharyaS, YuliasniR, VanbroekhovenK, et al. Long-term operation of microbial electrosynthesis cell reducing CO2 to multi-carbon chemicals with a mixed culture avoiding methanogenesis[J]. Bioelectrochemistry, 2017, 113: 26-34. |

| 4 | SchlagerS, HaberbauerM, FuchsbauerA, et al. Bio-electrocatalytic application of microorganisms for carbon dioxide reduction to methane[J]. Chemsuschem, 2017, 10(1SI): 226-233. |

| 5 | RabaeyK, RozendalR A. Microbial electrosynthesis - revisiting the electrical route for microbial production[J]. Nature Reviews Microbiology, 2010, 8(10): 706. |

| 6 | GeppertF, LiuD, van Eerten-JansenM, et al. Bioelectrochemical power-to-gas: state of the art and future perspectives[J]. Trends in Biotechnology, 2016, 34(11): 879-894. |

| 7 | VillanoM, ScardalaS, AulentaF, et al. Carbon and nitrogen removal and enhanced methane production in a microbial electrolysis cell[J]. Bioresource Technology, 2013, 130(1): 366. |

| 8 | LiF, LiY X, CaoY X, et al. Modular engineering to increase intracellular NAD(H/+) promotes rate of extracellular electron transfer of Shewanella oneidensis[J]. Nature Communications, 2018, 9(1): 3637. |

| 9 | ThauerR K, KasterA K, SeedorfH, et al. Methanogenic archaea: ecologically relevant differences in energy conservation[J]. Nature Reviews Microbiology, 2008, 6(8): 579-591. |

| 10 | HariA R, VenkidusamyK, KaturiK P, et al. Temporal microbial community dynamics in microbial electrolysis cells - influence of acetate and propionate concentration[J]. Frontiers in Microbiology, 2017, 8: 1371. |

| 11 | SteinbuschK J J, HamelersH V M, SchaapJ D, et al. Bioelectrochemical ethanol production through mediated acetate reduction by mixed cultures[J]. Environmental Science & Technology, 2010, 44(1): 513-517. |

| 12 | ZeppilliM, PavesiD, GottardoM, et al. Using effluents from two-phase anaerobic digestion to feed a methane-producing microbial electrolysis[J]. Chemical Engineering Journal, 2017, 328: 428-433. |

| 13 | LiuQ, RenZ J, HuangC, et al. Multiple syntrophic interactions drive biohythane production from waste sludge in microbial electrolysis cells[J]. Biotechnology for Biofuels, 2016, 9: 162. |

| 14 | CusickR D, KielyP D, LoganB E. A monetary comparison of energy recovered from microbial fuel cells and microbial electrolysis cells fed winery or domestic wastewaters[J]. International Journal of Hydrogen Energy, 2010, 35(17): 8855-8861. |

| 15 | WangD X, HanY X, HanH J, et al. Enhanced treatment of Fischer-Tropsch wastewater using up-flow anaerobic sludge blanket system coupled with micro-electrolysis cell: a pilot scale study[J]. Bioresource Technology, 2017, 238: 333-342. |

| 16 | YuZ S, LengX Y, ZhaoS, et al. A review on the applications of microbial electrolysis cells in anaerobic digestion[J]. Bioresource Technology, 2018, 255: 340-348. |

| 17 | ZhenG Y, LuX Q, KumarG, et al. Microbial electrolysis cell platform for simultaneous waste biorefinery and clean electrofuels generation: current, situation, challenges and future perspectives[J]. Progress in Energy and Combustion Science, 2017, 63: 119-145. |

| 18 | ZhenG Y, ZhengS J, LuX Q, et al. A comprehensive comparison of five different carbon-based cathode materials in CO2 electromethanogenesis: long-term performance, cell-electrode contact behaviors and extracellular electron transfer pathways[J]. Bioresource Technology, 2018, 266: 382-388. |

| 19 | FuQ, KuramochiY, FukushimaN, et al. Bioelectrochemical analyses of the development of a thermophilic biocathode catalyzing electromethanogenesis[J]. Environmental Science & Technology, 2015, 49(2): 1225-1232. |

| 20 | VillanoM, AulentaF, CiucciC, et al. Bioelectrochemical reduction of CO2 to CH4via direct and indirect extracellular electron transfer by a hydrogenophilic methanogenic culture[J]. Bioresource Technology, 2010, 101(9): 3085-3090. |

| 21 | van Eerten-JansenM, Ter HeijneA, BuismanC, et al. Microbial electrolysis cells for production of methane from CO2: long-term performance and perspectives[J]. International Journal of Energy Research, 2012, 36(6): 809-819. |

| 22 | van Eerten-JansenM, VeldhoenA B, PluggeC M, et al. Microbial community analysis of a methane-producing biocathode in a bioelectrochemical system[J]. Archaea-An International Microbiological Journal, 2013, 2013: 481784. |

| 23 | SangeethaT, GuoZ, LiuW, et al. Cathode material as an influencing factor on beer wastewater treatment and methane production in a novel integrated upflow microbial electrolysis cell (Upflow-MEC)[J]. International Journal of Hydrogen Energy, 2016, 41(4): 2189-2196. |

| 24 | LoganB, ChengS, WatsonV, et al. Graphite fiber brush anodes for increased power production in air-cathode microbial fuel cells[J]. Environmental Science & Technology, 2007, 41(9): 3341-3346. |

| 25 | ClauwaertP, VerstraeteW. Methanogenesis in membraneless microbial electrolysis cells[J]. Applied Microbiology and Biotechnology, 2009, 82(5): 829-836. |

| 26 | ZhenG Y, LuX Q, KobayashiT, et al. Promoted electromethanosynthesis in a two-chamber microbial electrolysis cells (MECs) containing a hybrid biocathode covered with graphite felt (GF)[J]. Chemical Engineering Journal, 2016, 284: 1146-1155. |

| 27 | JiaY, FengH, ShenD, et al. Enhanced production of methane from waste activated sludge by pretreatment using a gas-diffusion cathode[J]. Energy & Fuels, 2016, 30(12): 10511–10515. |

| 28 | ChengS A, YeY L, DingW J, et al. Enhancing power generation of scale-up microbial fuel cells by optimizing the leading-out terminal of anode[J]. Journal of Power Sources, 2014, 248: 931-938. |

| 29 | BajracharyaS, VanbroekhovenK, BuismanC J N, et al. Application of gas diffusion biocathode in microbial electrosynthesis from carbon dioxide[J]. Environmental Science and Pollution Research, 2016, 23(22): 22292-22308. |

| 30 | WangQ N, DongH, YuH B, et al. Enhanced electrochemical reduction of carbon dioxide to formic acid using a two-layer gas diffusion electrode in a microbial electrolysis cell[J]. RSC Advances, 2015, 5(14): 10346-10351. |

| 31 | AlqahtaniM F, KaturiK P, BajracharyaS, et al. Porous hollow fiber nickel electrodes for effective supply and reduction of carbon dioxide to methane through microbial electrosynthesis[J]. Advanced Functional Materials, 2018, 28(43): 1804860. |

| 32 | JourdinL, FreguiaS, DonoseB C, et al. Autotrophic hydrogen-producing biofilm growth sustained by a cathode as the sole electron and energy source[J]. Bioelectrochemistry, 2015, 102: 56-63. |

| 33 | van Eerten-JansenM, JansenN C, PluggeC M, et al. Analysis of the mechanisms of bioelectrochemical methane production by mixed cultures[J]. Journal of Chemical Technology and Biotechnology, 2015, 90(5): 963-970. |

| 34 | LienemannM, DeutzmannJ S, MiltonR D, et al. Mediator-free enzymatic electrosynthesis of formate by the Methanococcus maripaludis heterodisulfide reductase supercomplex[J]. Bioresource Technology, 2018, 254: 278-283. |

| 35 | RotaruA E, ShresthaP M, LiuF, et al. A new model for electron flow during anaerobic digestion: direct interspecies electron transfer to Methanosaeta for the reduction of carbon dioxide to methane[J]. Energy & Environmental Science, 2013, 7(1): 408-415. |

| 36 | AulentaF, CatapanoL, SnipL, et al. Linking bacterial metabolism to graphite cathodes: electrochemical insights into the H2-producing capability of Desulfovibrio sp.[J]. Chemsuschem, 2012, 5(6SI): 1080-1085. |

| 37 | FischerF, LieskeR, WinzerK. Biological gas reactions Ⅱ concerning the formation of acetic acid in the biological conversion of carbon oxide and carbonic acid with hydrogen to methane[J]. Biochemische Zeitschrift, 1932, 245: 2-12. |

| 38 | DanielsL, SparlingR, SprottG D. The bioenergetics of methanogenesis[J]. Biochimica et Biophysica Acta, 1984, 768(2): 113-163. |

| 39 | FerryJ G. Fundamentals of methanogenic pathways that are key to the biomethanation of complex biomass[J]. Current Opinion in Biotechnology, 2011, 22(3): 351-357. |

| 40 | WelteC, DeppenmeierU. Bioenergetics and anaerobic respiratory chains of aceticlastic methanogens[J]. Biochimica et Biophysica Acta-Bioenergetics, 2014, 1837(7SI): 1130-1147. |

| 41 | NevinK P, WoodardT L, FranksA E, et al. Microbial electrosynthesis: feeding microbes electricity to convert carbon dioxide and water to multicarbon extracellular organic compounds[J]. MBIO, 2010, 1:e00103-102. |

| 42 | FaraghiparapariN, ZenglerK. Production of organics from CO2 by microbial electrosynthesis (MES) at high temperature[J]. Journal of Chemical Technology and Biotechnology, 2017, 92(2): 375-381. |

| 43 | JourdinL, FreguiaS, DonoseB C, et al. A novel carbon nanotube modified scaffold as an efficient biocathode material for improved microbial electrosynthesis[J]. Journal of Materials Chemistry A, 2014, 2(32): 13093-13102. |

| 44 | JourdinL, GriegerT, MonettiJ, et al. High acetic acid production rate obtained by microbial electrosynthesis from carbon dioxide[J]. Environmental Science & Technology, 2015, 49(22): 13566-13574. |

| 45 | ShenL, ZhaoQ C, WuX E, et al. Interspecies electron transfer in syntrophic methanogenic consortia: from cultures to bioreactors[J]. Renewable & Sustainable Energy Reviews, 2016, 54: 1358-1367. |

| 46 | RotaruA, ShresthaP M, LiuF, et al. Direct interspecies electron transfer between Geobacter metallireducens and Methanosarcina barkeri[J]. Applied and Environmental Microbiology, 2014, 80(15): 4599-4605. |

| 47 | LiuF, RotaruA, ShresthaP M, et al. Promoting direct interspecies electron transfer with activated carbon[J]. Energy & Environmental Science, 2012, 5(10): 8982-8989. |

| 48 | ChenS, RotaruA, LiuF, et al. Carbon cloth stimulates direct interspecies electron transfer in syntrophic co-cultures[J]. Bioresource Technology, 2014, 173: 82-86. |

| 49 | ChenS, RotaruA, ShresthaP M, et al. Promoting interspecies electron transfer with biochar[J]. Scientific Reports, 2014, 4(1): 5019. |

| 50 | LovleyD R. Syntrophy goes electric: direct interspecies electron transfer[J]. Annual Review of Microbiology, 2017, 71: 643-664. |

| 51 | ParkJ H, KangH J, ParkK H, et al. Direct interspecies electron transfer via conductive materials: a perspective for anaerobic digestion applications[J]. Bioresource Technology, 2018, 254: 300-311. |

| 52 | FengQ, SongY C, AhnY. Electroactive microorganisms in bulk solution contribute significantly to methane production in bioelectrochemical anaerobic reactor[J]. Bioresource Technology, 2018, 259: 119-127. |

| 53 | LeeB, ParkJ G, ShinW B, et al. Microbial communities change in an anaerobic digestion after application of microbial electrolysis cells[J]. Bioresource Technology, 2017, 234: 273-280. |

| 54 | ParkJ, LeeB, TianD, et al. Bioelectrochemical enhancement of methane production from highly concentrated food waste in a combined anaerobic digester and microbial electrolysis cell[J]. Bioresource Technology, 2018, 247: 226-233. |

| 55 | ZhaoZ S, ZhangY B, QuanX, et al. Evaluation on direct interspecies electron transfer in anaerobic sludge digestion of microbial electrolysis cell[J]. Bioresource Technology, 2016, 200: 235-244. |

| 56 | XuH, WangK, HolmesD E. Bioelectrochemical removal of carbon dioxide (CO2): an innovative method for biogas upgrading[J]. Bioresource Technology, 2014, 173: 392-398. |

| 57 | ZhaoZ, ZhangY, QuanX, et al. Evaluation on direct interspecies electron transfer in anaerobic sludge digestion of microbial electrolysis cell[J]. Bioresource Technology, 2016, 200: 235-244. |

| 58 | MorenoR, San-MartinM I, EscapaA, et al. Domestic wastewater treatment in parallel with methane production in a microbial electrolysis cell[J]. Renewable Energy, 2016, 93: 442-448. |

| 59 | EscapaA, GilcarreraL, GarcíaV, et al. Performance of a continuous flow microbial electrolysis cell (MEC) fed with domestic wastewater[J]. Bioresource Technology, 2012, 117(10): 55-62. |

| 60 | TencaA, CusickR D, SchievanoA, et al. Evaluation of low cost cathode materials for treatment of industrial and food processing wastewater using microbial electrolysis cells[J]. International Journal of Hydrogen Energy, 2013, 38(4): 1859-1865. |

| 61 | YuN, XingD, LiW, et al. Electricity and methane production from soybean edible oil refinery wastewater using microbial electrochemical systems[J]. International Journal of Hydrogen Energy, 2017, 42(1): 96-102. |

| 62 | KielyP D, CusickR, CallD F, et al. Anode microbial communities produced by changing from microbial fuel cell to microbial electrolysis cell operation using two different wastewaters[J]. Bioresource Technology, 2011, 102(1): 388-394. |

| 63 | WagnerR C, ReganJ M, OhS E, et al. Hydrogen and methane production from swine wastewater using microbial electrolysis cells[J]. Water Research, 2009, 43(5): 1480-1488. |

| 64 | CerrilloM, VinasM, BonmatiA. Anaerobic digestion and electromethanogenic microbial electrolysis cell integrated system: Increased stability and recovery of ammonia and methane[J]. Renewable Energy, 2018, 120: 178-189. |

| 65 | ZhaoZ, ZhangY, YuQ, et al. Enhanced decomposition of waste activated sludge via anodic oxidation for methane production and bioenergy recovery[J]. International Biodeterioration & Biodegradation, 2016, 106: 161-169. |

| 66 | ZhenG Y, LuX Q, KobayashiT, et al. Continuous micro-current stimulation to upgrade methanolic wastewater biodegradation and biomethane recovery in an upflow anaerobic sludge blanket (UASB) reactor[J]. Chemosphere, 2017, 180: 229-238. |

| 67 | DouZ, DykstraC M, PavlostathisS G. Bioelectrochemically assisted anaerobic digestion system for biogas upgrading and enhanced methane production[J]. Science of the Total Environment, 2018, 633: 1012-1021. |

| 68 | BeegleJ R, BoroleA P. Energy production from waste: evaluation of anaerobic digestion and bioelectrochemical systems based on energy efficiency and economic factors[J]. Renewable & Sustainable Energy Reviews, 2018, 96: 343-351. |

| 69 | FengQ, SongY C, BaeB U. Influence of applied voltage on the performance of bioelectrochemical anaerobic digestion of sewage sludge and planktonic microbial communities at ambient temperature[J]. Bioresource Technology, 2016, 220: 500-508. |

| 70 | PantD, SinghA, BogaertG V, et al. An introduction to the life cycle assessment (LCA) of bioelectrochemical systems (BES) for sustainable energy and product generation: relevance and key aspects[J]. Renewable & Sustainable Energy Reviews, 2011, 15(2): 1305-1313. |

| 71 | EscapaA, SanmartínM I, MoránA. Potential use of microbial electrolysis cells in domestic wastewater treatment plants for energy recovery[J]. Frontiers in Energy Research, 2014, 2(51): 17519-17527. |

| 72 | ZhenG Y, LuX Q, KatoH, et al. Overview of pretreatment strategies for enhancing sewage sludge disintegration and subsequent anaerobic digestion: current advances, full-scale application and future perspectives[J]. Renewable & Sustainable Energy Reviews, 2017, 69: 559-577. |

| 73 | WangL, AzizT N, RdD L R F. Determining the limits of anaerobic co-digestion of thickened waste activated sludge with grease interceptor waste[J]. Water Research, 2013, 47(11): 3835. |

| 74 | HussainA, LebrunF M, TartakovskyB. Removal of organic carbon and nitrogen in a membraneless flow-through microbial electrolysis cell[J]. Enzyme and Microbial Technology, 2017, 102: 41-48. |

| 75 | 蔡文忠,张希晨,周耀辉. MEC/AnMBR反应器组合处理生活污水[J]. 南华大学学报(自然科学版), 2017, (2): 107-112. |

| CaiW Z, ZhangX C, ZhouY H. MEC/AnMBR reactor combined treatment of domestic sewage[J]. Journal of Nanhua University(Natural Science), 2017, (2): 107-112. | |

| 76 | JiangY, SuM, LiD. Removal of sulfide and production of methane from carbon dioxide in microbial fuel cells-microbial electrolysis cell (MFCs-MEC) coupled system[J]. Applied Biochemistry and Biotechnology, 2014, 172(5): 2720-2731. |

| 77 | LiuH B, LengF, GuanY L, et al. Simultaneous pollutant removal and electricity generation in a combined ABR-MFC-MEC system treating fecal wastewater[J]. Water Air and Soil Pollution, 2017,228: 179. |

| 78 | HuangL, JiangL, WangQ, et al. Cobalt recovery with simultaneous methane and acetate production in biocathode microbial electrolysis cells[J]. Chemical Engineering Journal, 2014, 253: 281-290. |

| 79 | KiD, ParameswaranP, PopatS C, et al. Maximizing Coulombic recovery and solids reduction from primary sludge by controlling retention time and pH in a flat-plate microbial electrolysis cell[J]. Environmental Science-Water Research & Technology, 2017, 3(2): 333-339. |

| 80 | NicholsE M, GallagherJ J, LiuC, et al. Hybrid bioinorganic approach to solar-to-chemical conversion[J]. Proceedings of the National Academy of Sciences of the United States of America, 2015, 112(37): 11461-11466. |

| 81 | FuQ, XiaoS, LiZ, et al. Hybrid solar-to-methane conversion system with a Faradaic efficiency of up to 96%[J]. Nano Energy, 2018, 53: 232-239. |

| 82 | LiX J, ZhuT, ZhangK, et al. Enhanced sludge degradation process using a microbial electrolysis cell in an up-flow anaerobic sludge blanket reactor with ultrasound treatment[J]. Chemical Engineering Journal, 2016, 306: 17-21. |

| 83 | BarberJ, TranP D. From natural to artificial photosynthesis[J]. Journal of the Royal Society Interface, 2013, 10(81): 20120984. |

| [1] | Yifei ZHANG, Fangchen LIU, Shuangxing ZHANG, Wenjing DU. Performance analysis of printed circuit heat exchanger for supercritical carbon dioxide [J]. CIESC Journal, 2023, 74(S1): 183-190. |

| [2] | Ruitao SONG, Pai WANG, Yunpeng WANG, Minxia LI, Chaobin DANG, Zhenguo CHEN, Huan TONG, Jiaqi ZHOU. Numerical simulation of flow boiling heat transfer in pipe arrays of carbon dioxide direct evaporation ice field [J]. CIESC Journal, 2023, 74(S1): 96-103. |

| [3] | Baiyu YANG, Yue KOU, Juntao JIANG, Yali ZHAN, Qinghong WANG, Chunmao CHEN. Chemical conversion of dissolved organic matter in petrochemical spent caustic along a wet air oxidation pretreatment process [J]. CIESC Journal, 2023, 74(9): 3912-3920. |

| [4] | Yepin CHENG, Daqing HU, Yisha XU, Huayan LIU, Hanfeng LU, Guokai CUI. Application of ionic liquid-based deep eutectic solvents for CO2 conversion [J]. CIESC Journal, 2023, 74(9): 3640-3653. |

| [5] | Rui HONG, Baoqiang YUAN, Wenjing DU. Analysis on mechanism of heat transfer deterioration of supercritical carbon dioxide in vertical upward tube [J]. CIESC Journal, 2023, 74(8): 3309-3319. |

| [6] | Xin YANG, Xiao PENG, Kairu XUE, Mengwei SU, Yan WU. Preparation of molecularly imprinted-TiO2 and its properties of photoelectrocatalytic degradation of solubilized PHE [J]. CIESC Journal, 2023, 74(8): 3564-3571. |

| [7] | Qiyu ZHANG, Lijun GAO, Yuhang SU, Xiaobo MA, Yicheng WANG, Yating ZHANG, Chao HU. Recent advances in carbon-based catalysts for electrochemical reduction of carbon dioxide [J]. CIESC Journal, 2023, 74(7): 2753-2772. |

| [8] | Chao NIU, Shengqiang SHEN, Yan YANG, Bonian PAN, Yiqiao LI. Flow process calculation and performance analysis of methane BOG ejector [J]. CIESC Journal, 2023, 74(7): 2858-2868. |

| [9] | Xiaoyang LIU, Jianliang YU, Yujie HOU, Xingqing YAN, Zhenhua ZHANG, Xianshu LYU. Effect of spiral microchannel on detonation propagation of hydrogen-doped methane [J]. CIESC Journal, 2023, 74(7): 3139-3148. |

| [10] | Xiaowen ZHOU, Jie DU, Zhanguo ZHANG, Guangwen XU. Study on the methane-pulsing reduction characteristics of Fe2O3-Al2O3 oxygen carrier [J]. CIESC Journal, 2023, 74(6): 2611-2623. |

| [11] | Yanmei ZHANG, Tao YUAN, Jiang LI, Yajie LIU, Zhanxue SUN. Study on the construction of high-efficient SRB mixed microflora and its performance under acid stress [J]. CIESC Journal, 2023, 74(6): 2599-2610. |

| [12] | Chenxi LI, Yongfeng LIU, Lu ZHANG, Haifeng LIU, Jin’ou SONG, Xu HE. Quantum chemical analysis of n-heptane combustion mechanism under O2/CO2 atmosphere [J]. CIESC Journal, 2023, 74(5): 2157-2169. |

| [13] | Caihong LIN, Li WANG, Yu WU, Peng LIU, Jiangfeng YANG, Jinping LI. Effect of alkali cations in zeolites on adsorption and separation of CO2/N2O [J]. CIESC Journal, 2023, 74(5): 2013-2021. |

| [14] | Bingguo ZHU, Jixiang HE, Jinliang XU, Bin PENG. Heat transfer characteristics of supercritical pressure CO2 in diverging/converging tube under cooling conditions [J]. CIESC Journal, 2023, 74(3): 1062-1072. |

| [15] | Xinlong YAN, Zhigang HUANG, Qingxun HU, Xin ZHANG, Xiaoyan HU. Catalytic nitrophenol degradation via peroxymonosulfate activation over Cu/Co doped porous carbon [J]. CIESC Journal, 2023, 74(3): 1102-1112. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||