CIESC Journal ›› 2021, Vol. 72 ›› Issue (1): 619-627.DOI: 10.11949/0438-1157.20201000

• Material science and engineering, nanotechnology • Previous Articles

SHI Pan1( ),YAN Xiaoxiao1,WANG Xingzheng1,FENG Leyun1,CHEN Dong1,2(

),YAN Xiaoxiao1,WANG Xingzheng1,FENG Leyun1,CHEN Dong1,2( )

)

Received:2020-07-23

Revised:2020-10-26

Online:2021-01-05

Published:2021-01-05

Contact:

CHEN Dong

通讯作者:

陈东

作者简介:石盼(1997—),男,硕士研究生,基金资助:CLC Number:

SHI Pan, YAN Xiaoxiao, WANG Xingzheng, FENG Leyun, CHEN Dong. One-step fabrication of biocompatible oil-core microcapsules with controlled release[J]. CIESC Journal, 2021, 72(1): 619-627.

石盼, 颜肖潇, 王行政, 冯乐耘, 陈东. 一步法制备生物相容油核微胶囊及其可控释放[J]. 化工学报, 2021, 72(1): 619-627.

Add to citation manager EndNote|Ris|BibTeX

| 密度/(g/ml) | 黏度/(mPa?s) | 表面张力/(mN/m) | |

|---|---|---|---|

| 内相 | 0.88 | 6 | 35.3 |

| 外相 | 1.00 | 300 | 70.2 |

Table 1 Physical properties of inner or outer fluids

| 密度/(g/ml) | 黏度/(mPa?s) | 表面张力/(mN/m) | |

|---|---|---|---|

| 内相 | 0.88 | 6 | 35.3 |

| 外相 | 1.00 | 300 | 70.2 |

Fig.1 Preparation of oil-core microcapsules by glass-capillary microfluidic device. Glass capillary microfluidic device with inner nozzle extending from outer nozzle(a). Microcapsule formation process (b). Oil core microcapsules(c). Phase diagram of the prepared microcapsules, the red circle indicates that mononuclear microcapsules can be formed, and the black cross indicates that microcapsules cannot be formed (d)

Fig.2 Effect of inter phase flow rate and outer phase flow rate on the diameter and wall thickness of the oil-core microcapsules. Effect of inter phase flow rate on the diameter and wall thickness of the microcapsules, external phase flow rate remains constant at 10 ml/h (a). The physical map of the microcapsules generated at different inter phase flow rates, external phase flow rate remains constant at 10 ml/h (b). Effect of external phase flow rate on the diameter and wall thickness of the microcapsules, inter phase flow rate remains constant at 0.5 ml/h (c). The physical map of the microcapsules generated at different external phase flow rates, inter phase flow rate remains constant at 0.5 ml/h (d). The formation process of microcapsules captured by a high-speed camera (e)

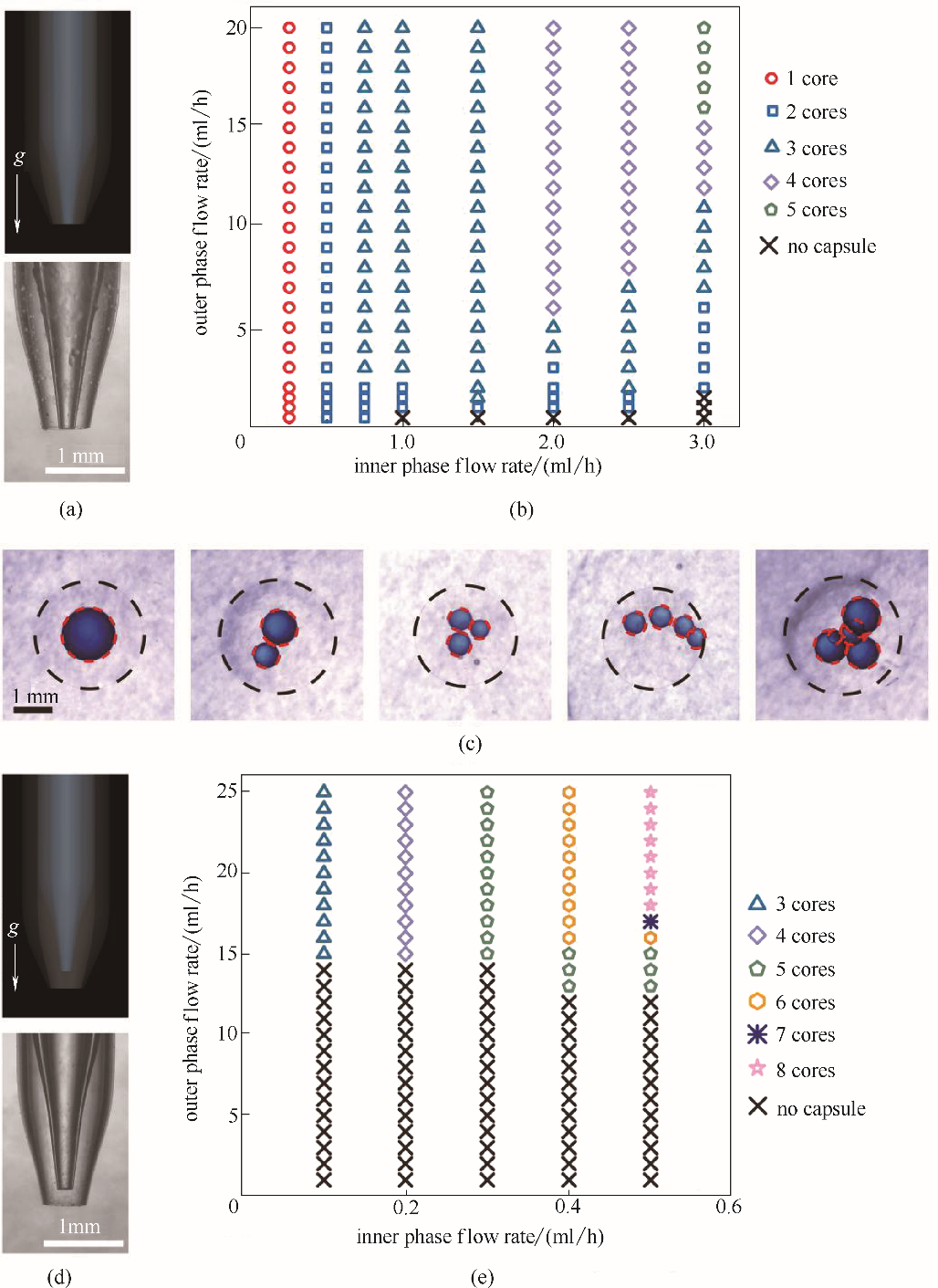

Fig.3 Effect of glass capillary microfluidic devices on the oil-core microcapsules. Glass capillary microfluidic device with inner tube orifice flush with outer tube orifice (a). Phase diagram of microcapsules prepared by microfluidic devices with flush nozzles (b). Physical image of multi-core microcapsules prepared by a flush nozzle microfluidic device (c). Glass capillary microfluidic device with inner tube orifice retracted into outer tube orifice (d). Phase diagram of microcapsules prepared by microfluidic device with inner tube retracted into outer tube (e)

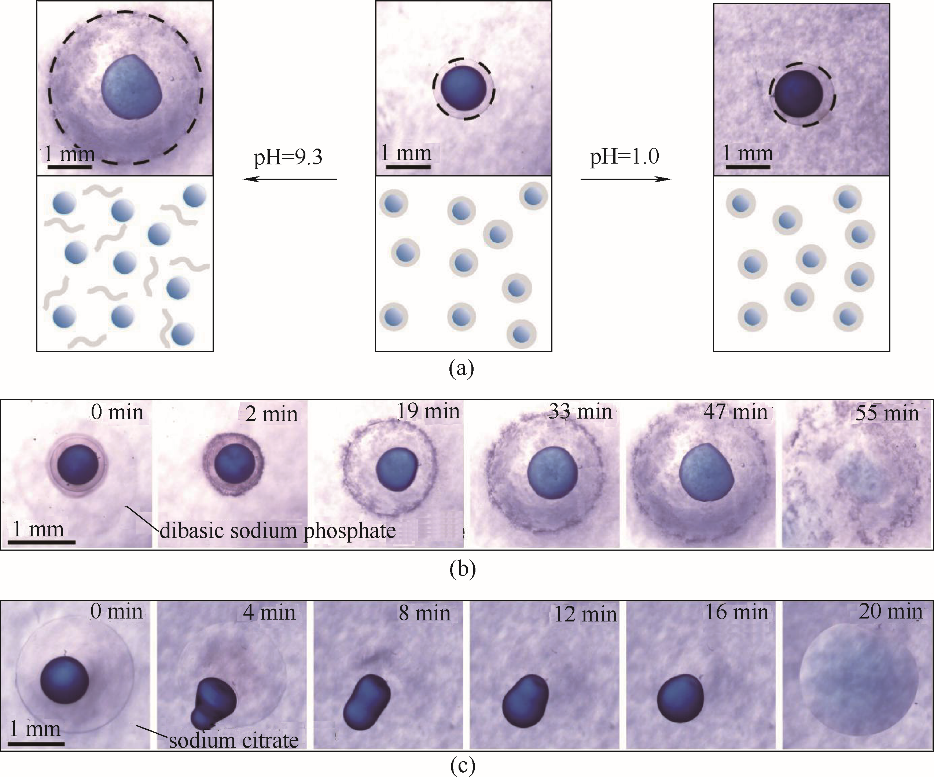

Fig.4 pH-triggered fast release of oil cores from biocompatible microcapsules. pH response of oil core microcapsules (a). Dibasic sodium phosphate stimulates rapid release of oil core microcapsules (b). Sodium citrate stimulates rapid release of oil core microcapsules (c)

Fig.5 Sustained release of oil-core microcapsules. Sustained release curves of active substances in oil-core microcapsules with different wall thicknesses (a). Physical image of oil core microcapsules with different wall thicknesses (b)

| 1 | Amstad E. Capsules: their past and opportunities for their future[J]. ACS Macro Letters, 2017, 6(8): 841-847. |

| 2 | Zhang X P, Luo J, Zhang D X, et al. Porous microcapsules with tunable pore sizes provide easily controllable release and bioactivity[J]. Journal of Colloid and Interface Science, 2018, 517: 86-92. |

| 3 | Szczepanowicz K, Bazylińska U, Pietkiewicz J, et al. Biocompatible long-sustained release oil-core polyelectrolyte nanocarriers: from controlling physical state and stability to biological impact[J]. Advances in Colloid and Interface Science, 2015, 222: 678-691. |

| 4 | Dowding P J, Atkin R, Vincent B, et al. Oil core/polymer shell microcapsules by internal phase separation from emulsion droplets(Ⅱ): Controlling the release profile of active molecules[J]. Langmuir, 2005, 21(12): 5278-5284. |

| 5 | Kong L, Amstad E, Hai M, et al. Biocompatible microcapsules with a water core templated from single emulsions[J]. Chinese Chemical Letters, 2017, 28(9): 1897-1900. |

| 6 | Sun Z, Yang C J, Wang F, et al. Biocompatible and pH‐responsive colloidal surfactants with tunable shape for controlled interfacial curvature[J]. Angewandte Chemie International Edition, 2020, 59(24): 9365-9369. |

| 7 | Wagdare N A, Marcelis A T, Boom R M, et al. Microcapsules with a pH responsive polymer: influence of the encapsulated oil on the capsule morphology[J]. Colloids and Surfaces B: Biointerfaces, 2011, 88(1): 175-180. |

| 8 | Kong L L, Chen R, Wang X Z, et al. Controlled co-precipitation of biocompatible colorant-loaded nanoparticles by microfluidics for natural color drinks[J]. Lab on a Chip, 2019, 19(12): 2089-2095. |

| 9 | Ding T, Wang L, Zhang J, et al. Interfacially active polydopamine for nanoparticle stabilized nanocapsules in a one-pot assembly strategy toward efficient drug delivery [J]. Journal of Materials Chemistry B, 2018, 6(12): 1754-1763. |

| 10 | Song W, Das M, Xu Y, et al. Leveraging biomaterials for cancer immunotherapy: targeting pattern recognition receptors[J]. Materials Today Nano, 2019, 5: 100029. |

| 11 | Williams D F. Biocompatibility pathways in tissue-engineering templates[J]. Engineering, 2018, 4(2): 286-290. |

| 12 | Sun Z, Yang C, Eggersdorfer M, et al. A general strategy for one-step fabrication of biocompatible microcapsules with controlled active release[J]. Chinese Chemical Letters, 2020, 31(1): 249-252. |

| 13 | Lavanya M, Kathiravan T, Moses J, et al. Influence of spray-drying conditions on microencapsulation of fish oil and chia oil[J]. Drying Technology, 2020, 38(3): 279-292. |

| 14 | Wu B H, Yang C J, Li B, et al. Active encapsulation in biocompatible nanocapsules[J]. Small, 2020, 16(30): 2002716. |

| 15 | Mahdavi S A, Jafari S M, Ghorbani M, et al. Spray-drying microencapsulation of anthocyanins by natural biopolymers: a review[J]. Drying Technology, 2014, 32(5): 509-518. |

| 16 | Başyiğit B, Sağlam H, Ş Kandemir, et al. Microencapsulation of sour cherry oil by spray drying: evaluation of physical morphology, thermal properties, storage stability, and antimicrobial activity[J]. Powder Technology, 2020, 364: 654-663. |

| 17 | Wu L, Zhang M, Liu Y, et al. Characteristics and release of monosodium glutamate microcapsules obtained by spray drying[J]. Drying Technology, 2019, 37(11): 1340-1351. |

| 18 | 倪卓, 林煜豪, 黄苇颖, 等. 环氧树脂微胶囊合成及其反应动力学[J]. 化工学报, 2018, 69(4): 1790-1798. |

| Ni Z, Lin Y H, Huang W Y, et al, Preparation and reaction kinetics of epoxy resin microcapsules[J]. CIESC Journal, 2018, 69(4): 1790-1798. | |

| 19 | Sun Z, Wu B H, Ren Y X, et al. Diverse particle carriers prepared by co-precipitation and phase separation: formation and applications[J]. ChemPlusChem, 2020, 85: 1-11. |

| 20 | Abang S, Chan E S, Poncelet D. Effects of process variables on the encapsulation of oil in Ca-alginate capsules using an inverse gelation technique[J]. Journal of Microencapsulation, 2012, 29(5): 417-428. |

| 21 | Bremond N, Santanach-Carreras E, Chu L Y, et al. Formation of liquid-core capsules having a thin hydrogel membrane: liquid pearls[J]. Soft Matter, 2010, 6(11): 2484-2488. |

| 22 | Tsaur L S, Shen S, Aronson M P, et al. Compositions comprising capsule comprising oil surrounding hydrophobic or hydrophilic active and polymeric shell surrounding oil: US5441660[P]. 1995-08-15. |

| 23 | Samakradhamrongthai R S, Angeli P T, Kopermsub P, et al. Optimization of gelatin and gum arabic capsule infused with pandan flavor for multi-core flavor powder encapsulation[J]. Carbohydrate Polymers, 2019, 226: 115262. |

| 24 | Seiffert S. Microgel capsules tailored by droplet-based microfluidics[J]. ChemPhysChem, 2013, 14(2): 295-304. |

| 25 | Lensen D, Van Breukelen K, Vriezema D M, et al. Preparation of biodegradable liquid core PLLA microcapsules and hollow PLLA microcapsules using microfluidics[J]. Macromolecular Bioscience, 2010, 10(5): 475-480. |

| 26 | Liu C, Zheng W, Xie R, et al. Microfluidic fabrication of water-in-water droplets encapsulated in hydrogel microfibers[J]. Chinese Chemical Letters, 2019, 30(2): 457-460. |

| 27 | 蔡泉威, 巨晓洁, 谢锐, 等. 微流控技术可控制备异形微颗粒功能材料的研究进展[J]. 化工学报, 2019, 70(10): 3738-3747. |

| Cai Q W, Ju X J, Xie R, et al. Recent progress in controllable preparation of anisotropic microparticle functional materials based on microfluidics[J]. CIESC Journal, 2019, 70(10): 3738-3747. | |

| 28 | Zhao Y C, Chen G W, Yuan Q. Liquid-liquid two-phase flow patterns in a rectangular microchannel[J]. AIChE Journal, 2006, 52(12): 4052-4060. |

| 29 | Arriaga L, Amstad E, Weitz D. Scalable single-step microfluidic production of single-core double emulsions with ultra-thin shells[J]. Lab on a Chip, 2015, 15(16): 3335-3340. |

| 30 | Kong L L, Jin X Y, Hu D P, et al. Functional delivery vehicle of organic nanoparticles in inorganic crystals[J]. Chinese Chemical Letters, 2019, 30(12): 2351-2354. |

| 31 | Fang Z, Cao X R, Yu Y L, et al. Fabrication and characterization of microcapsule encapsulating EOR surfactants by microfluidic technique[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2019, 570: 282-292. |

| 32 | Deng W, Guo H C, Li G A, et al. Fabrication of polymeric-laponite composite hollow microspheres via LBL assembly [J]. Chinese Chemical Letters, 2017, 28(2): 367-371. |

| 33 | Calvo P, Castaño Á L, Lozano M, et al. Influence of the microencapsulation on the quality parameters and shelf-life of extra-virgin olive oil encapsulated in the presence of BHT and different capsule wall components[J]. Food Research International, 2012, 45(1): 256-261. |

| 34 | Suryanarayana C, Rao K C, Kumar D. Preparation and characterization of microcapsules containing linseed oil and its use in self-healing coatings[J]. Progress in Organic Coatings, 2008, 63(1): 72-78. |

| 35 | Zhou T, Song Z, Sundmacher K. Big data creates new opportunities for materials research: a review on methods and applications of machine learning for materials design[J]. Engineering, 2019, 5(6): 1017-1026. |

| 36 | Chandran R, Chevva H, Zeng Z, et al. Solid-state synthesis of silver nanowires using biopolymer thin films[J]. Materials Today Nano, 2018, 1: 22-28. |

| 37 | Utada A S, Fernandez-Nieves A, Stone H A, et al. Dripping to jetting transitions in coflowing liquid streams[J]. Phys.Rev.Lett., 2007, 90(9):094502. |

| 38 | Geng Y, Ling S D, Huang J, et al. Multiphase microfluidics: fundamentals, fabrication, and functions[J]. Small, 2020, 16(6): 1906357. |

| [1] | He JIANG, Junfei YUAN, Lin WANG, Guyu XING. Experimental study on the effect of flow sharing cavity structure on phase change flow characteristics in microchannels [J]. CIESC Journal, 2023, 74(S1): 235-244. |

| [2] | Wenzhu LIU, Heming YUN, Baoxue WANG, Mingzhe HU, Chonglong ZHONG. Research on topology optimization of microchannel based on field synergy and entransy dissipation [J]. CIESC Journal, 2023, 74(8): 3329-3341. |

| [3] | Xuanzhi HE, Yongqing HE, Guiye WEN, Feng JIAO. Ferrofluid droplet neck self-similar breakup behavior [J]. CIESC Journal, 2023, 74(7): 2889-2897. |

| [4] | Shiting XIE, Zhuang LIU, Rui XIE, Xiaojie JU, Wei WANG, Dawei PAN, Liangyin CHU. Study on preparation of poly(N-isopropylacrylamide-co-allylthiourea) smart microgels and responsive performance of Hg2+ [J]. CIESC Journal, 2023, 74(6): 2689-2698. |

| [5] | Qin YANG, Chuanjian QIN, Mingzi LI, Wenjing YANG, Weijie ZHAO, Hu LIU. Fabrication and properties of dual shape memory MXene based hydrogels for flexible sensor [J]. CIESC Journal, 2023, 74(6): 2699-2707. |

| [6] | Lu DENG, Xiaojie JU, Wenjie ZHANG, Rui XIE, Wei WANG, Zhuang LIU, Dawei PAN, Liangyin CHU. Controllable preparation of radioactive chitosan embolic microspheres by microfluidic method [J]. CIESC Journal, 2023, 74(4): 1781-1794. |

| [7] | Lufan JIA, Yiying WANG, Yuman DONG, Qinyuan LI, Xin XIE, Hao YUAN, Tao MENG. Aqueous two-phase system based adherent droplet microfluidics for enhanced enzymatic reaction [J]. CIESC Journal, 2023, 74(3): 1239-1246. |

| [8] | Xueting ZHANG, Jijiang HU, Jing ZHAO, Bogeng LI. Preparation of high molecular weight polypropylene glycol in microchannel reactor [J]. CIESC Journal, 2023, 74(3): 1343-1351. |

| [9] | Xingyu YANG, You MA, Chunying ZHU, Taotao FU, Youguang MA. Study on liquid-liquid distribution in comb parallel microchannels [J]. CIESC Journal, 2023, 74(2): 698-706. |

| [10] | Xintong HUANG, Yuhao GENG, Hengyuan LIU, Zhuo CHEN, Jianhong XU. Research progress on new functional nanoparticles prepared by microfluidic technology [J]. CIESC Journal, 2023, 74(1): 355-364. |

| [11] | Lin SHENG, Yu CHANG, Jian DENG, Guangsheng LUO. Formation and flow characteristics of ordered bubble swarm in a step T-junction microchannel [J]. CIESC Journal, 2023, 74(1): 416-427. |

| [12] | Yifang DONG, Yingying YU, Xuegong HU, Gang PEI. Electric field effect on wetting and capillary flow characteristics in vertical microgrooves [J]. CIESC Journal, 2022, 73(7): 2952-2961. |

| [13] | Duanhui GAO, Weiqiang XIAO, Feng GAO, Qian XIA, Manqiu WANG, Xinbo LU, Xiaoli ZHAN, Qinghua ZHANG. Preparation and application of polyimide-based aerogels [J]. CIESC Journal, 2022, 73(7): 2757-2773. |

| [14] | Zhongdong WANG, Chunying ZHU, Youguang MA, Taotao FU. Liquid-liquid two-phase flow and mesoscale effect in parallel microchannels [J]. CIESC Journal, 2022, 73(6): 2563-2572. |

| [15] | Dawei PAN, Wei WANG, Rui XIE, Xiaojie JU, Zhuang LIU, Liangyin CHU. Progress on regulation of meso-scale structures for microfluidic emulsion-template synthesis of functional microparticles [J]. CIESC Journal, 2022, 73(6): 2306-2317. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||