CIESC Journal ›› 2023, Vol. 74 ›› Issue (2): 953-967.DOI: 10.11949/0438-1157.20221046

• Process safety • Previous Articles Next Articles

Peixu ZHOU1( ), Yalun LI1, Gongran YE1, Yuan ZHUANG1, Xilei WU1, Zhikai GUO2, Xiaohong HAN1(

), Yalun LI1, Gongran YE1, Yuan ZHUANG1, Xilei WU1, Zhikai GUO2, Xiaohong HAN1( )

)

Received:2022-07-06

Revised:2023-01-26

Online:2023-03-21

Published:2023-02-05

Contact:

Xiaohong HAN

周培旭1( ), 李亚伦1, 叶恭然1, 庄园1, 吴曦蕾1, 郭智恺2, 韩晓红1(

), 李亚伦1, 叶恭然1, 庄园1, 吴曦蕾1, 郭智恺2, 韩晓红1( )

)

通讯作者:

韩晓红

作者简介:周培旭(1998—),男,硕士研究生,22027101@zju.edu.cn

基金资助:CLC Number:

Peixu ZHOU, Yalun LI, Gongran YE, Yuan ZHUANG, Xilei WU, Zhikai GUO, Xiaohong HAN. Influence of physical properties of working fluids on leakage and diffusion characteristics of refrigerant in limited space[J]. CIESC Journal, 2023, 74(2): 953-967.

周培旭, 李亚伦, 叶恭然, 庄园, 吴曦蕾, 郭智恺, 韩晓红. 有限空间内工质物性对制冷剂泄漏扩散特性的影响[J]. 化工学报, 2023, 74(2): 953-967.

Add to citation manager EndNote|Ris|BibTeX

| 工质 | 泄漏压力/MPa | 泄漏速率/(g/s) |

|---|---|---|

| R717 | 0.998 | 1.308 |

| R290 | 0.948 | 2.018 |

| R1234yf | 0.68 | 3.191 |

| R22 | 1.04 | 2.902 |

| R32 | 1.68 | 2.394 |

| R744 | 6.41 | 2.001 |

Table 1 Critical flow mass flow rates of common working fluids at room temperature(25℃) with leakage aperture of 3 mm

| 工质 | 泄漏压力/MPa | 泄漏速率/(g/s) |

|---|---|---|

| R717 | 0.998 | 1.308 |

| R290 | 0.948 | 2.018 |

| R1234yf | 0.68 | 3.191 |

| R22 | 1.04 | 2.902 |

| R32 | 1.68 | 2.394 |

| R744 | 6.41 | 2.001 |

| 泄漏孔尺寸/m | 空间尺寸/m | 网格质量 | 网格数/个 |

|---|---|---|---|

| 0.0005 | 0.2 | 0.835 | 66469 |

| 0.0005 | 0.1 | 0.845 | 301558 |

| 0.0001 | 0.08 | 0.847 | 600119 |

| 0.0001 | 0.06 | 0.849 | 1324453 |

| 0.0001 | 0.05 | 0.850 | 2232378 |

Table 2 Grid size settings

| 泄漏孔尺寸/m | 空间尺寸/m | 网格质量 | 网格数/个 |

|---|---|---|---|

| 0.0005 | 0.2 | 0.835 | 66469 |

| 0.0005 | 0.1 | 0.845 | 301558 |

| 0.0001 | 0.08 | 0.847 | 600119 |

| 0.0001 | 0.06 | 0.849 | 1324453 |

| 0.0001 | 0.05 | 0.850 | 2232378 |

| 工质 | T/K | p/MPa | 密度/ (kg/m³) | 比定压热容/ (kJ/(kg·K)) | 热导率/ (mW/(m·K)) | 黏度/ (μPa·s) | 动量扩散 系数μ/ρ | 热扩散系数λ/(ρcp ) |

|---|---|---|---|---|---|---|---|---|

| R717 (7664-41-7) | 298 | 0.1 | 0.69 | 2.16 | 25.16 | 10.08 | 14.52 | 16.75 |

| R290 (74-98-6) | 298 | 0.1 | 1.81 | 1.68 | 18.29 | 8.12 | 4.49 | 6.01 |

| R1234yf (754-12-1) | 298 | 0.1 | 4.71 | 0.90 | 13.83 | 11.46 | 2.44 | 3.25 |

| R22 (75-45-6) | 298 | 0.1 | 3.54 | 0.66 | 10.57 | 12.62 | 3.56 | 2.13 |

| R32 (75-10-5) | 298 | 0.1 | 2.13 | 0.85 | 12.51 | 12.61 | 5.93 | 6.95 |

| R744 (14485-07-5) | 298 | 0.1 | 1.79 | 0.85 | 16.62 | 14.91 | 8.35 | 10.95 |

Table 3 Physical properties of common working fluids at room temperature and pressure (25℃,0.1 MPa)

| 工质 | T/K | p/MPa | 密度/ (kg/m³) | 比定压热容/ (kJ/(kg·K)) | 热导率/ (mW/(m·K)) | 黏度/ (μPa·s) | 动量扩散 系数μ/ρ | 热扩散系数λ/(ρcp ) |

|---|---|---|---|---|---|---|---|---|

| R717 (7664-41-7) | 298 | 0.1 | 0.69 | 2.16 | 25.16 | 10.08 | 14.52 | 16.75 |

| R290 (74-98-6) | 298 | 0.1 | 1.81 | 1.68 | 18.29 | 8.12 | 4.49 | 6.01 |

| R1234yf (754-12-1) | 298 | 0.1 | 4.71 | 0.90 | 13.83 | 11.46 | 2.44 | 3.25 |

| R22 (75-45-6) | 298 | 0.1 | 3.54 | 0.66 | 10.57 | 12.62 | 3.56 | 2.13 |

| R32 (75-10-5) | 298 | 0.1 | 2.13 | 0.85 | 12.51 | 12.61 | 5.93 | 6.95 |

| R744 (14485-07-5) | 298 | 0.1 | 1.79 | 0.85 | 16.62 | 14.91 | 8.35 | 10.95 |

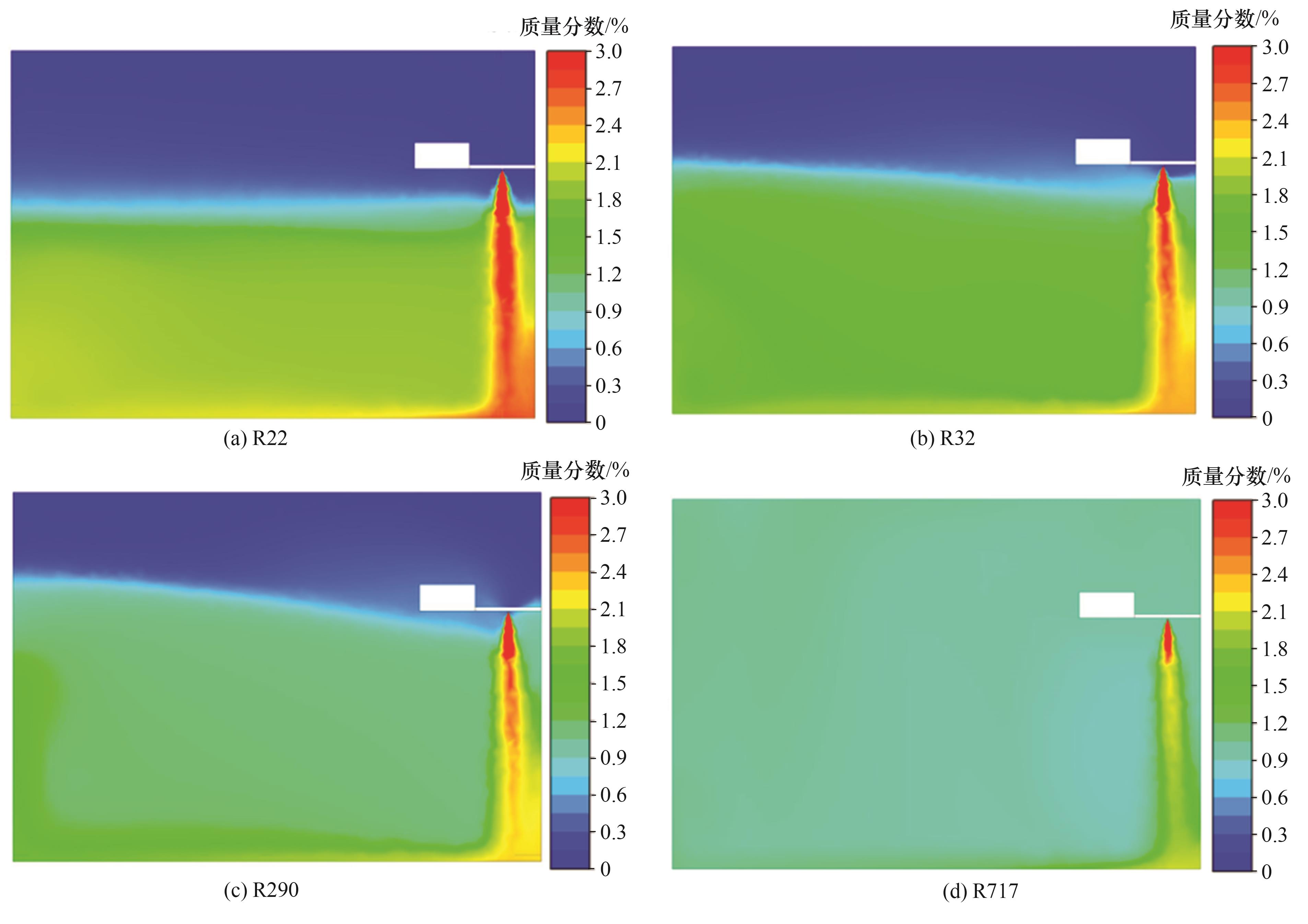

Fig.12 Contours of concentration distribution of different working fluids at the intersecting surface of the center of the leakage hole (Z=0.115 m) during diffusion process

| 序号 | X/m | Y/m | Z/m | 序号 | X/m | Y/m | Z/m | 序号 | X/m | Y/m | Z/m |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 点1 | 1.0 | 0.7 | 0.7 | 点10 | 2.0 | 0.7 | 0.7 | 点19 | 3.0 | 0.7 | 0.7 |

| 点2 | 1.0 | 0.7 | 1.4 | 点11 | 2.0 | 0.7 | 1.4 | 点20 | 3.0 | 0.7 | 1.4 |

| 点3 | 1.0 | 0.7 | 2.1 | 点12 | 2.0 | 0.7 | 2.1 | 点21 | 3.0 | 0.7 | 2.1 |

| 点4 | 1.0 | 1.4 | 0.7 | 点13 | 2.0 | 1.4 | 0.7 | 点22 | 3.0 | 1.4 | 0.7 |

| 点5 | 1.0 | 1.4 | 1.4 | 点14 | 2.0 | 1.4 | 1.4 | 点23 | 3.0 | 1.4 | 1.4 |

| 点6 | 1.0 | 1.4 | 2.1 | 点15 | 2.0 | 1.4 | 2.1 | 点24 | 3.0 | 1.4 | 2.1 |

| 点7 | 1.0 | 2.1 | 0.7 | 点16 | 2.0 | 2.1 | 0.7 | 点25 | 3.0 | 2.1 | 0.7 |

| 点8 | 1.0 | 2.1 | 1.4 | 点17 | 2.0 | 2.1 | 1.4 | 点26 | 3.0 | 2.1 | 1.4 |

| 点9 | 1.0 | 2.1 | 2.1 | 点18 | 2.0 | 2.1 | 2.1 | 点27 | 3.0 | 2.1 | 2.1 |

Table 4 Layouts of monitoring points

| 序号 | X/m | Y/m | Z/m | 序号 | X/m | Y/m | Z/m | 序号 | X/m | Y/m | Z/m |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 点1 | 1.0 | 0.7 | 0.7 | 点10 | 2.0 | 0.7 | 0.7 | 点19 | 3.0 | 0.7 | 0.7 |

| 点2 | 1.0 | 0.7 | 1.4 | 点11 | 2.0 | 0.7 | 1.4 | 点20 | 3.0 | 0.7 | 1.4 |

| 点3 | 1.0 | 0.7 | 2.1 | 点12 | 2.0 | 0.7 | 2.1 | 点21 | 3.0 | 0.7 | 2.1 |

| 点4 | 1.0 | 1.4 | 0.7 | 点13 | 2.0 | 1.4 | 0.7 | 点22 | 3.0 | 1.4 | 0.7 |

| 点5 | 1.0 | 1.4 | 1.4 | 点14 | 2.0 | 1.4 | 1.4 | 点23 | 3.0 | 1.4 | 1.4 |

| 点6 | 1.0 | 1.4 | 2.1 | 点15 | 2.0 | 1.4 | 2.1 | 点24 | 3.0 | 1.4 | 2.1 |

| 点7 | 1.0 | 2.1 | 0.7 | 点16 | 2.0 | 2.1 | 0.7 | 点25 | 3.0 | 2.1 | 0.7 |

| 点8 | 1.0 | 2.1 | 1.4 | 点17 | 2.0 | 2.1 | 1.4 | 点26 | 3.0 | 2.1 | 1.4 |

| 点9 | 1.0 | 2.1 | 2.1 | 点18 | 2.0 | 2.1 | 2.1 | 点27 | 3.0 | 2.1 | 2.1 |

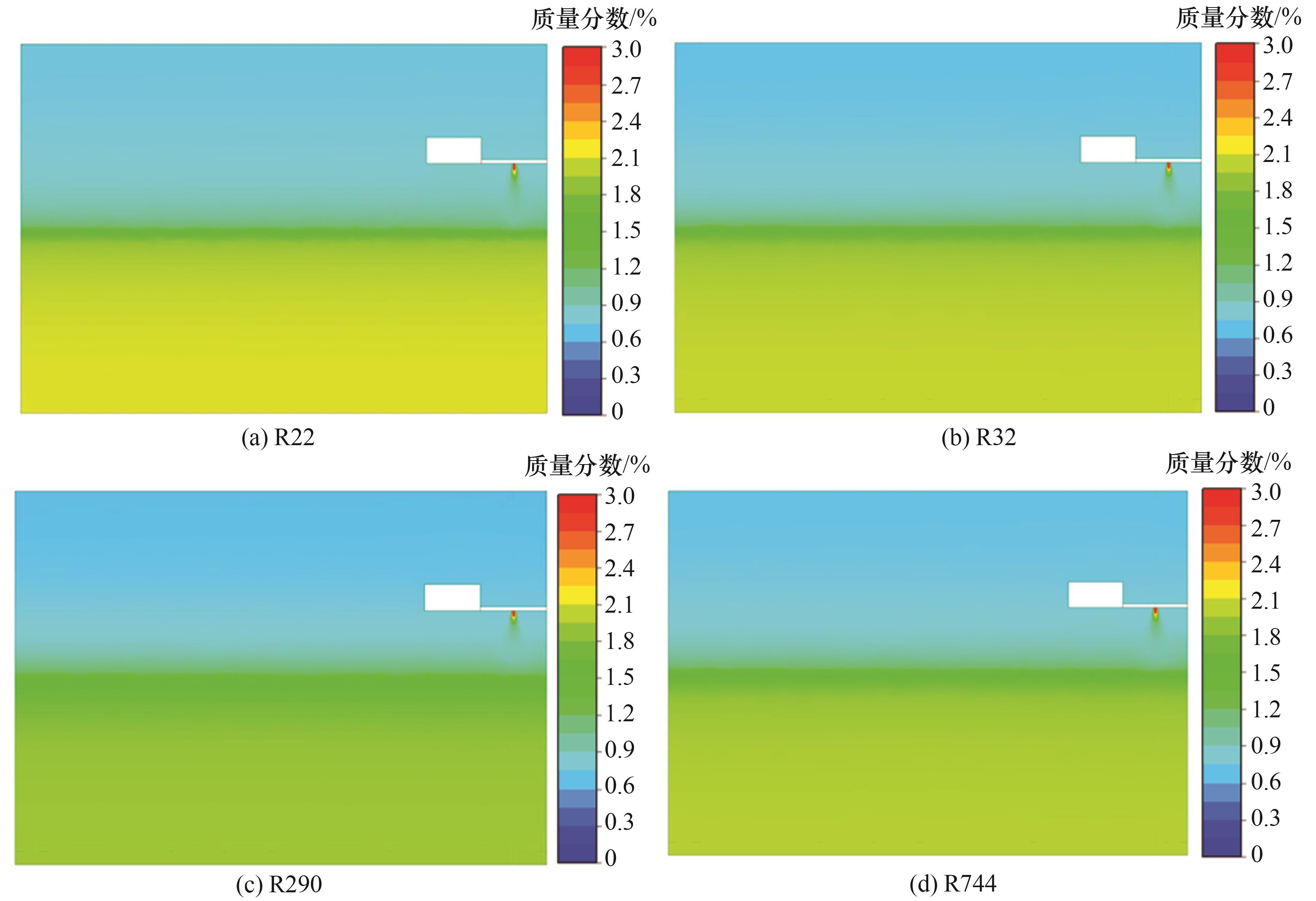

Fig.19 Contours of concentration distribution of different working fluids at the intersecting surface of the center of the leakage hole (Z=0.115 m) during deposition process

| 1 | National Oceanic and Atmospheric Administration. Climate Change: global temperature[EB/OL]. . |

| 2 | United States Environmental Protection Agency. Greenhouse gas emissions and sinks: 1990-2019 [EB/OL]. . |

| 3 | Levenspiel O. Engineering Flow and Heat Exchange[M]. Boston, MA: Springer, 1984. |

| 4 | Li Y L, Zhou P X, Zhuang Y, et al. An improved gas leakage model and research on the leakage field strength characteristics of R290 in limited space[J]. Applied Sciences, 2022, 12(11): 5657. |

| 5 | Hu M J, Li J B, Liu Z, et al. Experimental and numerical simulation analysis of R-290 air conditioner leak[J]. International Journal of Refrigeration, 2018, 90: 163-173. |

| 6 | Muliawan R, Pasek A D, Lukitobudi A R, et al. Effect of leakage on refrigerant distribution in an air conditioned room using propane as working fluid[J]. IOP Conference Series: Materials Science and Engineering, 2020, 830(4): 042023. |

| 7 | 陆毅. 制冷系统R290泄漏扩散机理及安全评估[D]. 南京: 南京理工大学, 2018. |

| Lu Y. Leakage and diffusion mechanism of R290 in refrigeration system and safety assessment[D]. Nanjing: Nanjing University of Science and Technology, 2018. | |

| 8 | Tang W E, He G G, Sun W, et al. Assessment of leakage and risk reduction of R290 in a split type household air conditioner[J]. International Journal of Refrigeration, 2018, 89: 70-82. |

| 9 | Tang W E, He G G, Cai D H, et al. The experimental investigation of refrigerant distribution and leaking characteristics of R290 in split type household air conditioner[J]. Applied Thermal Engineering, 2017, 115: 72-80. |

| 10 | Tang W E, He G G, Zhou S, et al. The experimental study of R290 mass distribution and indoor leakage of 2 HP and 3 HP split type household air conditioner[J]. International Journal of Refrigeration, 2019, 100: 246-254. |

| 11 | Zhang Y, Liu C C, Wang T Y, et al. Leakage analysis and concentration distribution of flammable refrigerant R290 in the automobile air conditioner system[J]. International Journal of Refrigeration, 2020, 110: 286-294. |

| 12 | 郭春辉, 刘知新, 徐永恩. 泄漏管直径对R290空调器使用安全性的影响[J]. 制冷与空调, 2014, 14(12): 66-68, 137. |

| Guo C H, Liu Z X, Xu Y E. Impacts of leakage pipe's diameter on safety application of R290 air-conditioner[J]. Refrigeration and Air-Conditioning, 2014, 14(12): 66-68, 137. | |

| 13 | Liang J R, Li T X. Detailed dynamic refrigerant migration characteristics in room air-conditioner with R290[J]. International Journal of Refrigeration, 2018, 88: 108-116. |

| 14 | 张网, 张欣, 慕洋洋. R717和R290爆炸参数实验研究[J]. 消防科学与技术, 2016, 35(6): 737-740. |

| Zhang W, Zhang X, Mu Y Y. Experimental study on the explosion characteristics of R717 and R290[J]. Fire Science and Technology, 2016, 35(6): 737-740. | |

| 15 | Li K, Wang J W, Luo S X, et al. Experimental investigation on combustion characteristics of flammable refrigerant R290/R1234yf leakage from heat pump system for electric vehicles[J]. Royal Society Open Science, 2020, 7(4): 191478. |

| 16 | Elatar A, Abu-Heiba A, Patel V, et al. Evaluation of flammable volume in the case of a catastrophic leak of R-32 from a rooftop unit[J]. International Journal of Refrigeration, 2018, 91: 39-45. |

| 17 | Li Y N, Tao J J, Han Y C, et al. Numerical and experimental study on the diffusion property of difluoromethane (HFC-32) in leakage[J]. Procedia Engineering, 2014, 71: 34-43. |

| 18 | Jia L Z, Jin W F, Zhang Y. Analysis of indoor environment safety with R32 leaking from a running air conditioner[J]. Procedia Engineering, 2015, 121: 1605-1612. |

| 19 | Jia L Z, Jin W F, Zhang Y. Experimental study on R32 leakage and diffusion characteristic of wall-mounted air conditioners under different operating conditions[J]. Applied Energy, 2017, 185: 2127-2133. |

| 20 | 金梧凤, 薛探栋, 袁小勇, 等. R32制冷剂泄漏位置对浓度分布与室内安全性的实验研究[J]. 制冷学报, 2022, 43(5): 114-121. |

| Jin W F, Xue T D, Yuan X Y, et al. Experimental study on concentration distribution and indoor safety of R32 refrigerant leakage location[J]. Journal of Re Frige Ration, 2022, 43(5): 114-121. | |

| 21 | Tan W, Du H, Liu L Y, et al. Experimental and numerical study of ammonia leakage and dispersion in a food factory[J]. Journal of Loss Prevention in the Process Industries, 2017, 47: 129-139. |

| 22 | Ji J, Chen X X, Han X F. Rapid simulation and visualization analysis of liquid ammonia tank leakage risk[J]. Procedia Engineering, 2014, 84: 682-688. |

| 23 | 田华, 马一太, 刘圣春, 等. CO2双级滚动转子压缩机泄漏分析[J]. 工程热物理学报, 2009, 30(6): 905-910. |

| Tian H, Ma Y T, Liu S C, et al. Leakage analysis of CO2 two stage rolling piston compressor[J]. Journal of Engineering Thermophysics, 2009, 30(6): 905-910. | |

| 24 | Tong X, Wang Z R, Cheng Z, et al. A modeling method for predicting the concentration of indoor carbon dioxide leakage and dispersion based on similarity theory[J]. Energy and Buildings, 2017, 151: 585-591. |

| 25 | 李康. 小尺度超临界二氧化碳泄漏过程物理机理研究[D]. 合肥: 中国科学技术大学, 2016. |

| Li K. The physical mechanism of the supercritical CO2 leakage process in small scale laboratory conditions[D]. Hefei: University of Science and Technology of China, 2016. | |

| 26 | Oreilly H, Crombie D, Monaghan R, et al. An experimental and numerical study of refrigerant leaks in refrigerated transport containers[C]// 1st IIR International Conference on the Application of HFO Refrigerants. Birmingham, UK: Proceedings of IIR Conferences, 2018. |

| 27 | Oreilly H, Crombie D, Monaghan R. Towards a comprehensive modelling framework for flammable refrigerant leaks in transport containers[C]// 25th IIR International Congress of Refrigeration. Montreal, Canada: Proceedings of IIR Conferences, 2019. |

| 28 | Papas P, Zhang S L, Jiang H, et al. Computational fluid dynamics modeling of flammable refrigerant leaks inside machine rooms: evaluation of ventilation mitigation requirements[J]. Science and Technology for the Built Environment, 2016, 22(4): 463-471. |

| 29 | Li Y L, Yang J L, Wu X L, et al. Explosion risk analysis of R290 leakage into a limited external space[J]. Applied Thermal Engineering, 2023, 225: 120122. |

| 30 | Lemmon E W, Bell I H, Huber M L, et al. NIST standard reference database 23: reference fluid thermodynamic and transport properties-REFPROP, version 10.0[DS]. National Institute of Standards and Technology, 2018. |

| 31 | 张网, 杨昭, 王婕, 等. 分体式空调器使用R290作为制冷剂的泄漏研究[J]. 制冷学报, 2013, 34(6): 42-47. |

| Zhang W, Yang Z, Wang J, et al. Leakage research of split-type air-conditioner using R290 as refrigerant[J]. Journal of Refrigeration, 2013, 34(6): 42-47. |

| [1] | Weiqi JIN, Yuerong WU, Xia WANG, Li LI, Su QIU, Pan YUAN, Minghe WANG. Progress in infrared imaging detection technology and domestic equipment for industrial gas leakage in chemical industry parks [J]. CIESC Journal, 2023, 74(S1): 32-44. |

| [2] | Xi WU, Zudi OU, Xinjie ZHANG, Shiming XU, Xiaojing ZHU. Experimental study on the flammability of HFO-1243zf [J]. CIESC Journal, 2023, 74(S1): 346-352. |

| [3] | Baomin DAI, Qilong WANG, Shengchun LIU, Jianing ZHANG, Xinhai LI, Fandi ZONG. Thermodynamic performance analysis of combined cooling and heating system based on combination of CO2 with the zeotropic refrigerant assisted subcooled [J]. CIESC Journal, 2023, 74(S1): 64-73. |

| [4] | Runmiao GAO, Mengjie SONG, Enyuan GAO, Long ZHANG, Xuan ZHANG, Keke SHAO, Zekang ZHEN, Zhengyong JIANG. Review on greenhouse gas reduction related to refrigerants in cold chain [J]. CIESC Journal, 2023, 74(S1): 1-7. |

| [5] | Yingying TAN, Xiaoqing LIU, Lin WANG, Lisheng HUANG, Xiuzhen LI, Zhanwei WANG. Experimental study on startup dynamic characteristics of R1150/R600a auto-cascade refrigeration cycle [J]. CIESC Journal, 2023, 74(S1): 213-222. |

| [6] | Gang YIN, Yihui LI, Fei HE, Wenqi CAO, Min WANG, Feiya YAN, Yu XIANG, Jian LU, Bin LUO, Runting LU. Early warning method of aluminum reduction cell leakage accident based on KPCA and SVM [J]. CIESC Journal, 2023, 74(8): 3419-3428. |

| [7] | Chenxin LI, Yanqiu PAN, Liu HE, Yabin NIU, Lu YU. Carbon membrane model based on carbon microcrystal structure and its gas separation simulation [J]. CIESC Journal, 2023, 74(5): 2057-2066. |

| [8] | Xiangning HU, Yuanbo YIN, Chen YUAN, Yun SHI, Cuiwei LIU, Qihui HU, Wen YANG, Yuxing LI. Experimental study on visualization of refined oil migration in soil [J]. CIESC Journal, 2023, 74(4): 1827-1835. |

| [9] | Qian MING, Yi GAO, Jian HU, Shengjie LI, Jinjiang WANG. Virtual sensing method for leakage fault of heat exchanger [J]. CIESC Journal, 2023, 74(4): 1836-1846. |

| [10] | Xuanjun WU, Chao WANG, Zijian CAO, Weiquan CAI. Deep learning model of fixed bed adsorption breakthrough curve hybrid-driven by data and physical information [J]. CIESC Journal, 2023, 74(3): 1145-1160. |

| [11] | Zichao WU, Zhilei WANG, Rongye LI, Kexin LI, Min HUA, Xuhai PAN, Sanming WANG, Juncheng JIANG. Study on the effect of ignition mode on overpressure of underexpanded hydrogen jet explosion [J]. CIESC Journal, 2023, 74(3): 1409-1418. |

| [12] | Chen CHEN, Qian YANG, Yun CHEN, Rui ZHANG, Dong LIU. Chemical kinetic study on coal volatiles combustion for various oxygen concentrations [J]. CIESC Journal, 2022, 73(9): 4133-4146. |

| [13] | Jian CAO, Nannan YE, Guancong JIANG, Yao QIN, Shibo WANG, Jiahua ZHU, Xiaohua LU. Mass transfer resistance analysis of the interaction between porous carbon and hydrogen peroxide based on microcalorimetry [J]. CIESC Journal, 2022, 73(6): 2543-2551. |

| [14] | Wenhuai LI, Wei ZHOU. Analysis of influencing factors and design strategies of high oxygen ion conductivity perovskite [J]. CIESC Journal, 2022, 73(4): 1455-1471. |

| [15] | Yukun SUN, Tao YANG, Jiangtao WU. Measurement of vapor-liquid equilibrium for R32+R1234yf+R1234ze(E) [J]. CIESC Journal, 2022, 73(3): 1063-1071. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||