CIESC Journal ›› 2023, Vol. 74 ›› Issue (7): 2869-2879.DOI: 10.11949/0438-1157.20230419

• Fluid dynamics and transport phenomena • Previous Articles Next Articles

Hai WANG( ), Hong LIN, Chen WANG, Haojie XU, Lei ZUO, Junfeng WANG(

), Hong LIN, Chen WANG, Haojie XU, Lei ZUO, Junfeng WANG( )

)

Received:2023-04-26

Revised:2023-06-26

Online:2023-08-31

Published:2023-07-05

Contact:

Junfeng WANG

通讯作者:

王军锋

作者简介:王海(1988—),男,博士,副教授,wangh@ujs.edu.cn

基金资助:CLC Number:

Hai WANG, Hong LIN, Chen WANG, Haojie XU, Lei ZUO, Junfeng WANG. Investigation of enhanced boiling heat transfer on porous structural surfaces by high voltage electric field[J]. CIESC Journal, 2023, 74(7): 2869-2879.

王海, 林宏, 王晨, 许浩洁, 左磊, 王军锋. 高压静电场强化多孔介质表面沸腾传热特性研究[J]. 化工学报, 2023, 74(7): 2869-2879.

Add to citation manager EndNote|Ris|BibTeX

| 试样表面 | 步骤一 | 步骤二 | ||

|---|---|---|---|---|

| 电流密度/ (A/cm2) | 电镀时长/s | 电流密度/ (A/cm2) | 电镀时长/s | |

| ED-1.0-0.05 | 1.0 | 20 | 0.05 | 4500 |

| ED-1.8-0.05 | 1.8 | 20 | 0.05 | 4500 |

| ED-2.2-0.05 | 2.2 | 20 | 0.05 | 4500 |

Table 1 Electroplating parameters of different sample surfaces

| 试样表面 | 步骤一 | 步骤二 | ||

|---|---|---|---|---|

| 电流密度/ (A/cm2) | 电镀时长/s | 电流密度/ (A/cm2) | 电镀时长/s | |

| ED-1.0-0.05 | 1.0 | 20 | 0.05 | 4500 |

| ED-1.8-0.05 | 1.8 | 20 | 0.05 | 4500 |

| ED-2.2-0.05 | 2.2 | 20 | 0.05 | 4500 |

| 参数 | 数值 |

|---|---|

| 化学式 | CF3CH2OCF2CHF2 |

| 沸点/℃ | 56 |

| 表面张力(25℃)/(mN/m) | 16.4 |

| 热导率(25℃)/(mW/(m·K)) | 89 |

| 汽化潜热(25℃)/(kJ/kg) | 163 |

| 液体介电常数(25℃) | 6.6 |

| 电阻率/(Ω·m) | 1.3×109 |

| 电导率(25℃)/(μS/m) | 7.7×10-4 |

| 介质击穿电压(25℃)/kV | 39.5 |

Table 2 Properties of the working liquid at standard atmosphere pressure

| 参数 | 数值 |

|---|---|

| 化学式 | CF3CH2OCF2CHF2 |

| 沸点/℃ | 56 |

| 表面张力(25℃)/(mN/m) | 16.4 |

| 热导率(25℃)/(mW/(m·K)) | 89 |

| 汽化潜热(25℃)/(kJ/kg) | 163 |

| 液体介电常数(25℃) | 6.6 |

| 电阻率/(Ω·m) | 1.3×109 |

| 电导率(25℃)/(μS/m) | 7.7×10-4 |

| 介质击穿电压(25℃)/kV | 39.5 |

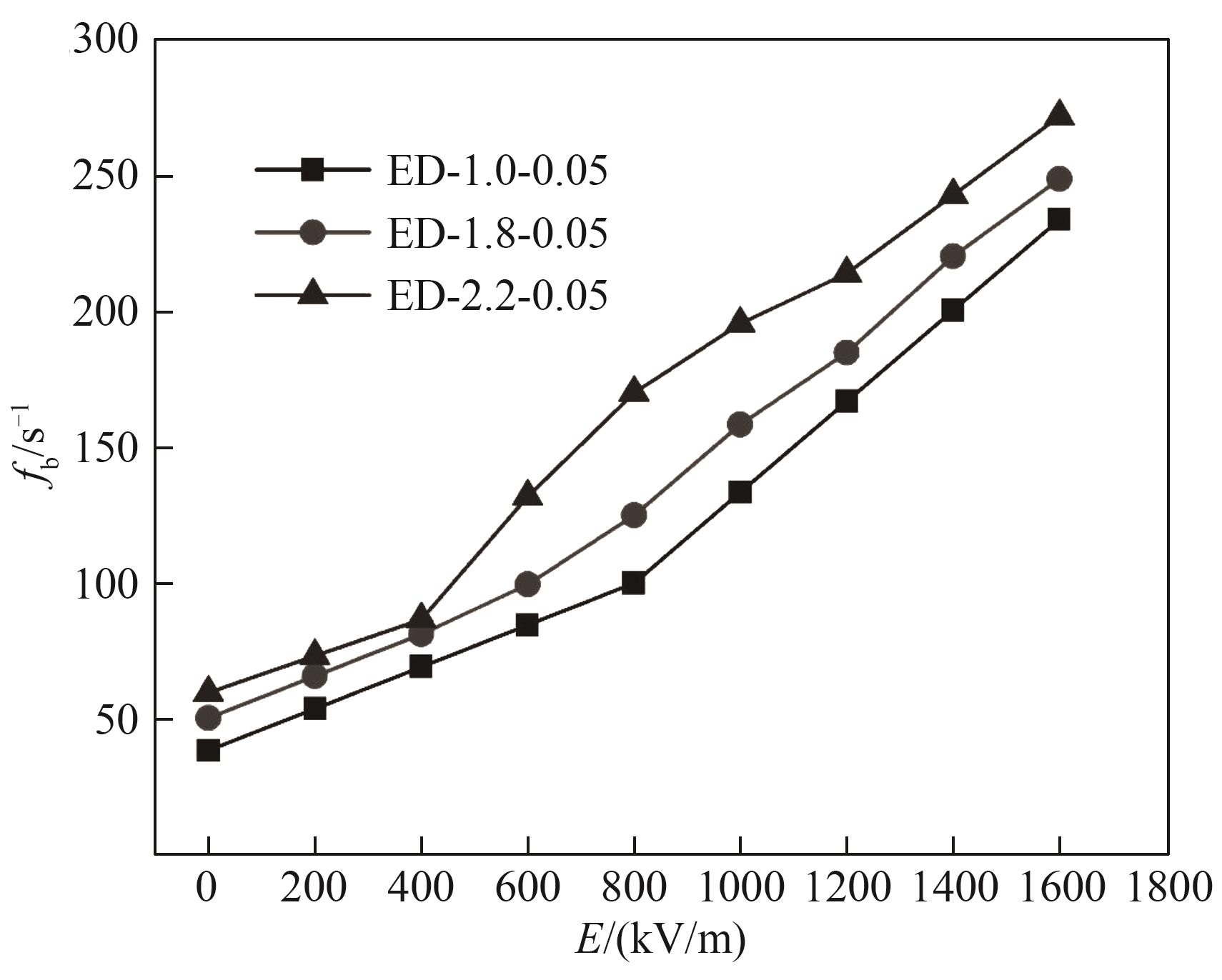

Fig.11 Relation between bubble departure frequency and electric field intensity on different porous micro-structured surfaces with the heat flux of 2.88W/cm2

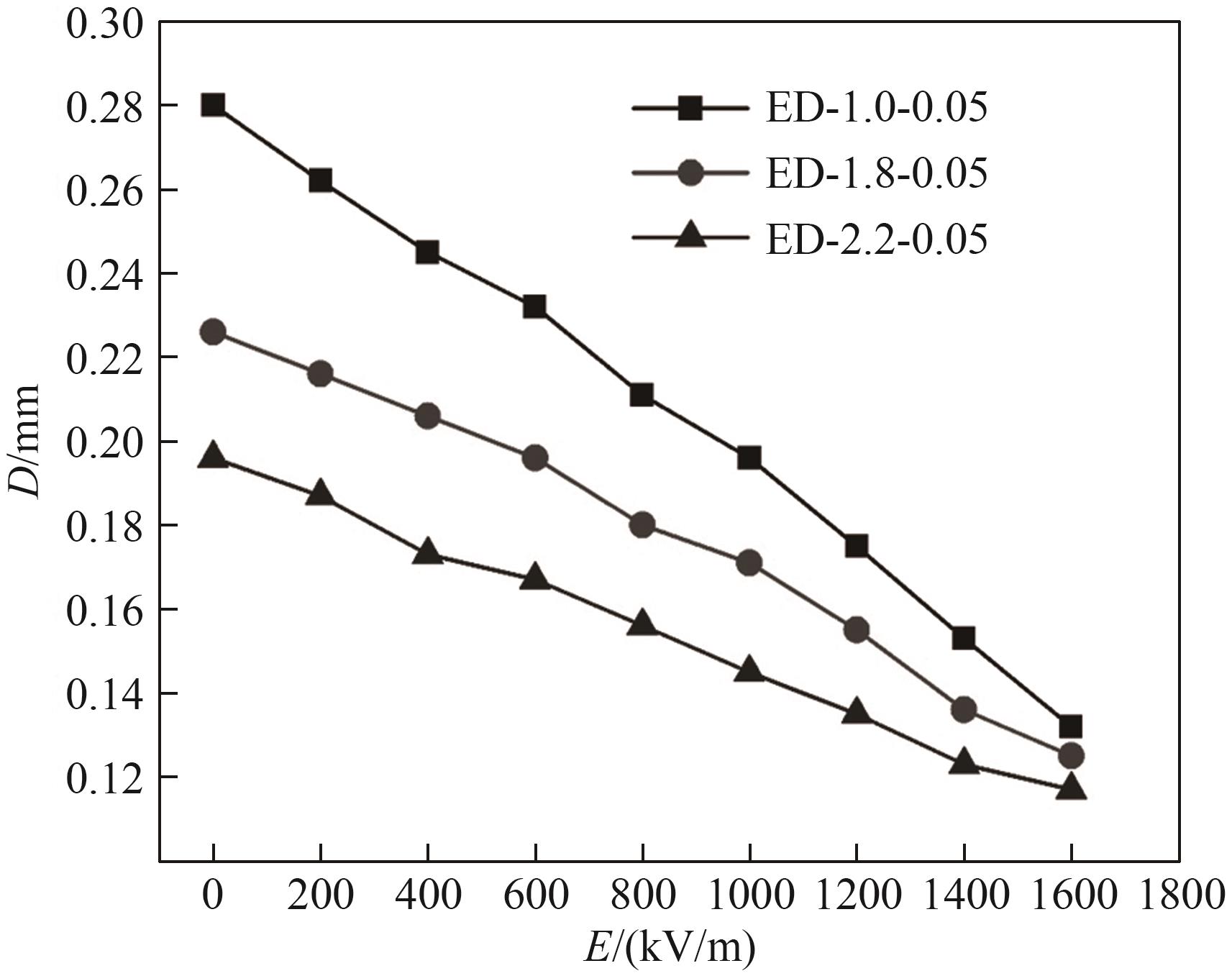

Fig.12 Relation between average bubble departure diameter and electric field intensity on different porous micro-structured surfaces with the heat flux of 2.88 W/cm2

| 1 | Li J Q, Mou L W, Zhang J Y, et al. Enhanced pool boiling heat transfer during quenching of water on superhydrophilic porous surfaces: effects of the surface wettability[J]. International Journal of Heat and Mass Transfer, 2018, 125: 494-505. |

| 2 | 纪献兵, 徐进良. 流体在超轻多孔金属泡沫中的流动和换热特性[J]. 化工学报, 2009, 60(1): 21-27. |

| Ji X B, Xu J L. Fluid flow and heat transfer characteristics in ultra-light porous metal foam[J]. CIESC Journal, 2009, 60(1): 21-27. | |

| 3 | 陈宏霞, 黄林滨, 宫逸飞. 多孔结构及表面润湿性对池沸腾传热影响的研究进展[J]. 化工进展, 2017, 36(8): 2798-2808. |

| Chen H X, Huang L B, Gong Y F. Progress on boiling heat transfer from porous structure and surface wettability[J]. Chemical Industry and Engineering Progress, 2017, 36(8): 2798-2808. | |

| 4 | Chu K H, Enright R, Wang E N. Structured surfaces for enhanced pool boiling heat transfer[J]. Applied Physics Letters, 2012, 100(24): 241603. |

| 5 | Dong L N, Quan X J, Cheng P. An experimental investigation of enhanced pool boiling heat transfer from surfaces with micro/nano structures[J]. International Journal of Heat and Mass Transfer, 2014, 71: 189-196. |

| 6 | Wang K K, Leong K C. Saturated pool boiling enhancement using porous lattice structures produced by selective laser melting[J]. International Journal of Heat and Mass Transfer, 2018, 121: 46-63. |

| 7 | Hwang G S, Kaviany M. Critical heat flux in thin, uniform particle coatings[J]. International Journal of Heat and Mass Transfer, 2006, 49: 844-849. |

| 8 | Weibel J A, Garimella S V, North M T. Characterization of evaporation and boiling from sintered powder wick fed by capillary action[J]. International Journal of Heat and Mass Transfer, 2010, 53: 4204-4215. |

| 9 | Jiang Y W, Zhou G H, Zhou J Z, et al. Saturated pool boiling heat transfer of HFE-7100 on sintered copper powder and wire mesh microporous surfaces: a comparison study[J]. Applied Thermal Engineering, 2022, 216: 119067. |

| 10 | Dang C, Min R Q, Pan L Y, et al. Saturated pool boiling heat transfer enhancement of R245fa based on the surface covered by sintered copper powder with and without nanostructure[J]. International Journal of Thermal Sciences, 2023, 187: 108183. |

| 11 | Gouda R K, Pathak M, Khan M K. Pool boiling heat transfer characteristics of a biosurfactant particle deposited heating surface[J]. International Journal of Heat and Mass Transfer, 2020, 163: 120455. |

| 12 | Filho E S, Kiyomura I S, Andrade B A, et al. Pool boiling performance of HFE-7100 on hierarchically structured surfaces[J]. Case Studies in Thermal Engineering, 2021, 28: 101536 |

| 13 | Doran B, Zhang B, Walker A, et al. Experimental determination of the role of increased surface area in pool boiling form nanostructured surfaces[J]. Experimental Thermal and Fluid Science, 2020, 111: 109956. |

| 14 | Joseph A, Mohan S, Kumar C S S, et al. An experimental investigation on pool boiling heat transfer enhancement using sol-gel derived nano CuO porous coating[J]. Experimental Thermal and Fluid Science, 2019, 103: 37-50. |

| 15 | Li C, Peterson G P. Parametric study of pool boiling on horizontal highly conductive microporous coated surfaces[J]. Journal of Heat Transfer, 2007, 129: 1465-1475. |

| 16 | EI-Genk M S, Ali A F. Enhanced nucleate boiling on copper micro-porous surfaces[J]. International Journal of Multiphase Flow, 2010, 36: 780-792. |

| 17 | Tang Y, Tang B, Li Q, et al. Pool boiling enhancement by novel metallic nanoporous surface[J]. Experimental Thermal and Fluid Science, 2013, 44: 194-198. |

| 18 | Deng D X, Feng J Y, Huang Q S, et al. Pool boiling heat transfer of porous structures with reentrant cavities[J]. International Journal of Heat and Mass Transfer, 2016, 99: 556-568. |

| 19 | Hong M, Lu H R, Luo J, et al. Model based experimental analysis of enhanced boiling heat transfer by micro-nano porous surfaces[J]. Applied Thermal Engineering, 2021, 192: 116809. |

| 20 | Sajjad U, Kumar A, Wang C C. Nucleate pool boiling of sintered coated porous surfaces with dielectric liquid, HFE-7200[J]. Journal of Enhanced Heat Transfer, 2020, 27(8): 767-784. |

| 21 | Kweon Y C, Kim M H. Experimental study on nucleate boiling enhancement and bubble dynamic behavior in saturated pool boiling using a nonuniform DC electric field[J]. International Journal of Multiphase Flow, 2000, 26: 1351-1368. |

| 22 | Gao M, Cheng P, Quan X J. An experimental investigation on effects of an electric filed on bubble growth on a smaller heater in pool boiling[J]. International Journal of Heat and Mass Transfer, 2013, 67: 984-991. |

| 23 | Kano I. Effect of electric field distribution generated in a microspace on pool boiling heat transfer[J]. Journal of Heat Transfer, 2014, 136: 101501. |

| 24 | Di Marco P, Grassi W. A review on saturated pool boiling enhancement by means of an electric field[J]. Journal of Enhanced Heat Transfer, 2017, 24: 383-398. |

| 25 | Liu B, Garivalis A L, Cao Z Z, et al. Effects of electric filed on pool boiling heat transfer over microstructured surfaces under different liquid subcoolings[J]. International Journal of Heat and Mass Transfer, 2022, 183: 122154. |

| 26 | Chang H Z, Liu B, Li Q, et al. Effects of electric field on pool boiling heat transfer over composite microstructured surfaces with microcavities on micro-pin fins[J]. International Journal of Heat and Mass Transfer, 2023, 205: 123893. |

| 27 | Chen Y J, Guo J, Liu X L, et al. Experiment and prediction model study on pool boiling heat transfer of water in the electric field with periodically changing direction[J]. International Journal of Multiphase Flow, 2022, 150: 104027. |

| 28 | 郭俊, 李双菲, 陈彦君, 等. 非匀强电场强化水的池沸腾传热特性实验研究与分析[J]. 工程热物理学报, 2022, 43(3): 788-796. |

| Guo J, Li S F, Chen Y J, et al. Experimental study and analysis of water pool boiling heat transfer enhanced by non-uniform electric field[J]. Journal of Engineering Thermophysics, 2022, 43(3): 788-796. | |

| 29 | Quan X J, Gao M, Cheng P, et al. An experimental investigation of pool boiling heat transfer on smooth/rib surfaces under an electric field[J]. International Journal of Heat and Mass Transfer, 2015, 85: 595-608. |

| 30 | Kline S J, McClintock F A. Describing uncertainties in single sample experiments[J]. Mechanical Engineering, 1953, 75: 3-8. |

| 31 | Moze M, Zupancic M, Golobic I. Investigation of the scatter in reported pool boiling CHF measurements including analysis of heat flux and measurement uncertainty evaluation methodology[J]. Applied Thermal Engineering, 2020, 169: 114938. |

| 32 | Rohsenow W M. A method of correlating heat transfer data for surface boiling of liquids[J]. Journal of Heat and Mass Transfer, 1952, 74: 969-976. |

| [1] | Ben ZHANG, Songbai WANG, Ziya WEI, Tingting HAO, Xuehu MA, Rongfu WEN. Capillary liquid film condensation and heat transfer enhancement driven by superhydrophilic porous metal structure [J]. CIESC Journal, 2023, 74(7): 2824-2835. |

| [2] | Bingguo ZHU, Jixiang HE, Jinliang XU, Bin PENG. Heat transfer characteristics of supercritical pressure CO2 in diverging/converging tube under cooling conditions [J]. CIESC Journal, 2023, 74(3): 1062-1072. |

| [3] | Jianxun CHEN, Jinping LIU, Xiongwen XU, Yinhao YU. Numerical simulation and performance optimization of a new loop gravity heat pipe [J]. CIESC Journal, 2023, 74(2): 721-734. |

| [4] | Qiaoling SU, Junfeng WANG, Wei ZHANG, Shuiqing ZHAN, Tianyi WU. Experimental study on polarization motion characteristics of bubbles in a low conductivity working medium [J]. CIESC Journal, 2022, 73(9): 3861-3869. |

| [5] | Yifang DONG, Yingying YU, Xuegong HU, Gang PEI. Electric field effect on wetting and capillary flow characteristics in vertical microgrooves [J]. CIESC Journal, 2022, 73(7): 2952-2961. |

| [6] | Zhimin LIN, Chongzhao WANG, Guozhi QIANG, Shushan LIU, Liangbi WANG. Analysis of flow and heat transfer characteristics of lubricating oil in circular tube with coaxial crossed vortex generators [J]. CIESC Journal, 2022, 73(11): 4957-4973. |

| [7] | LIN Shiquan, ZHAO Yaxin, LYU Zhongyuan, LAI Zhancheng, HU Haitao. Effect of hydrophilicity and hydrophobicity on pool boiling heat transfer characteristics on metal foam [J]. CIESC Journal, 2021, 72(S1): 295-301. |

| [8] | Zhengliang HUANG, Peng ZHANG, Yao YANG, Congjing REN, Jingdai WANG, Yongrong YANG. Effects of external DC/AC electric fields on particle motions and wall sticking in fluidized bed with electrostatics [J]. CIESC Journal, 2021, 72(9): 4544-4552. |

| [9] | Hai ZHANG, Ying XU, Tao ZHANG, Cenwei SUN, Chuanshun WEI, Zhixiang DAI. Investigation of visualized-measurement merits of wire mesh sensor for gas-liquid flow [J]. CIESC Journal, 2021, 72(9): 4573-4583. |

| [10] | Hailiang CAO, Hongfei ZHANG, Qianlong ZUO, Qi AN, Ziyang ZHANG, Hongbei LIU. Study on pool boiling heat transfer performance of trapezoidal microchannel surface [J]. CIESC Journal, 2021, 72(8): 4111-4120. |

| [11] | Weixiang LIN, Gangchuan SU, Qiang CHEN, Jian WEN, Simin WANG. Research on heat transfer enhancement of immersed coil heat exchanger by ultrasonic technology [J]. CIESC Journal, 2021, 72(8): 4055-4063. |

| [12] | Feng GAO, Yongchang CHEN, Jinlong ZHAO, Chongfang MA. Influence of magnetic field on jet impingement heat transfer with molten salt [J]. CIESC Journal, 2020, 71(S2): 92-97. |

| [13] | Xinghui GAO, Guoyan ZHOU, Shandong TU. Study on effects of structural parameters on shell-side heat transfer enhancement in spiral wound heat exchangers [J]. CIESC Journal, 2019, 70(7): 2456-2471. |

| [14] | Shuai MOU, Changying ZHAO, Zhiguo XU. Pool boiling heat transfer performance and mechanism of square copper pillar arrays with partially-modified surface [J]. CIESC Journal, 2019, 70(4): 1291-1301. |

| [15] | Hongxia CHEN, Yuan SUN, Yifei GONG, Linbin HUANG. Visual measurement and data analysis of pool boiling on silicon surfaces [J]. CIESC Journal, 2019, 70(4): 1309-1317. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||