CIESC Journal ›› 2024, Vol. 75 ›› Issue (1): 255-267.DOI: 10.11949/0438-1157.20231148

• Fluid dynamics and transport phenomena • Previous Articles Next Articles

Bidan ZHAO1,2( ), Yiyang DAI1,3, Junwu WANG1,2(

), Yiyang DAI1,3, Junwu WANG1,2( ), Yongmin ZHANG3(

), Yongmin ZHANG3( )

)

Received:2023-11-08

Revised:2023-12-19

Online:2024-03-11

Published:2024-01-25

Contact:

Junwu WANG, Yongmin ZHANG

赵碧丹1,2( ), 代伊杨1,3, 王军武1,2(

), 代伊杨1,3, 王军武1,2( ), 张永民3(

), 张永民3( )

)

通讯作者:

王军武,张永民

作者简介:赵碧丹(1990—),女,博士,副研究员,bdzhao@ipe.ac.cn

基金资助:CLC Number:

Bidan ZHAO, Yiyang DAI, Junwu WANG, Yongmin ZHANG. CFD-DEM-IBM simulation on force characteristic on inclined-surface baffles in fluidized beds[J]. CIESC Journal, 2024, 75(1): 255-267.

赵碧丹, 代伊杨, 王军武, 张永民. CFD-DEM-IBM方法探究流化床倾斜挡板内构件受力特性[J]. 化工学报, 2024, 75(1): 255-267.

Add to citation manager EndNote|Ris|BibTeX

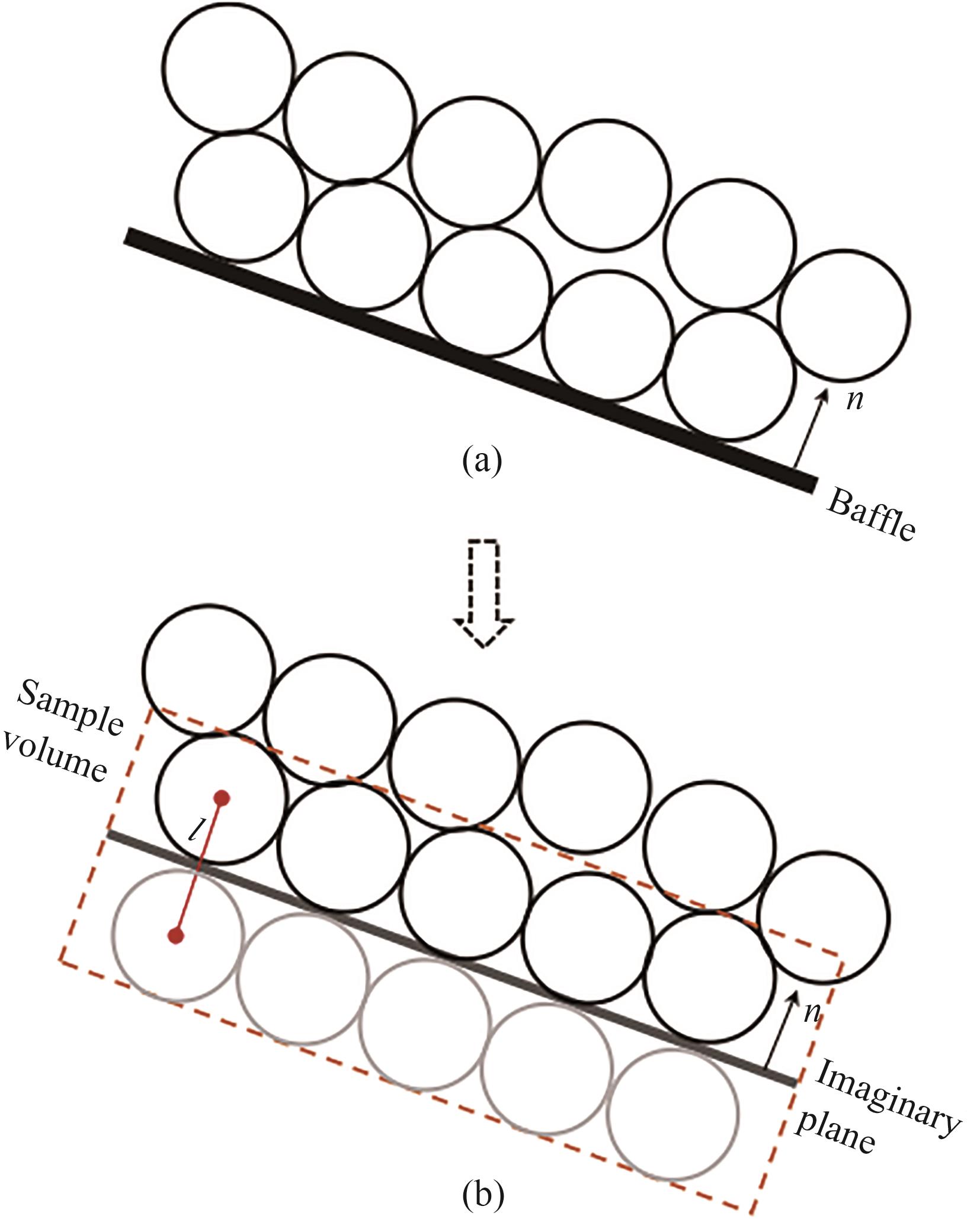

Fig.3 (a) Schematic diagram of contact between baffle and particles; (b) Schematic diagram of contact between an imaginary plane and particles in dense bed[36]

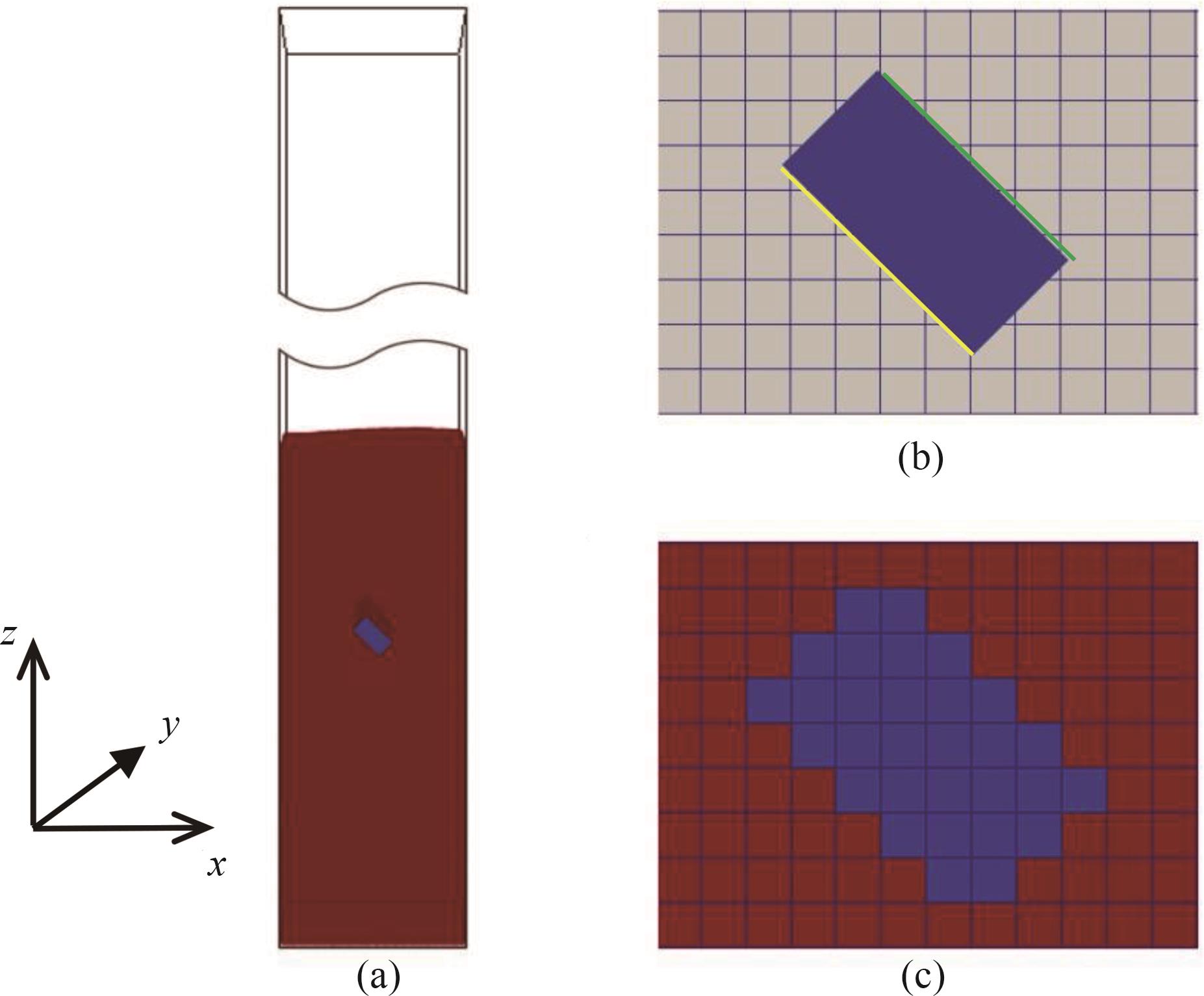

Fig.4 (a) The simplified geometric structure of the fluidized bed in the simulation with red indicating the particle phase; (b) The relationship between inclined baffles and fluid grids (The upper surface of the baffle is colored by green, and the lower surface is colored by yellow); (c) Fluid grid (red) and solid+IBM grid (blue) identified by IBM method

| 项目 | 参数 | 数值 |

|---|---|---|

| 床内网格数 | Lx ×Ly ×Lz | 300×300×2200 |

| 挡板网格数 | lx ×ly ×lz | 60×300×30 |

| 颗粒 | Sauter平均颗粒直径/μm | 595 |

| 密度/(kg/m3) | 2906 | |

| 最小流态化时空隙率 | 0.47 | |

| 最小流化速度/(m/s) | 0.33 | |

| 球形度 | 0.86 | |

| 颗粒粗粒化率 | 5 | |

| 粗粒化后床内颗粒总数 | 3439103 | |

| 非弹性碰撞恢复系数 | 0.9 | |

| 滑动摩擦系数 | 0.3 | |

| 滚动摩擦系数 | 0.01 | |

| 特征速度/(m/s) | 0.5 | |

| 杨氏模量/Pa | 1×108 | |

| 泊松比 | 0.3 | |

| 时间步长/s | 1×10-5 | |

| 静止堆积床高/m | 1 | |

| 气体 | 密度/(kg/m3) | 1.2 |

| 黏度/(Pa·s) | 1.8×10-5 | |

| 表观气速/(m/s) | 0.6 | |

| 出口压力/Pa | 101325 | |

| CFD网格大小/mm | 10×10×10 | |

| 时间步长/s | 1×10-4 |

Table 1 Parameter settings in fluidized beds

| 项目 | 参数 | 数值 |

|---|---|---|

| 床内网格数 | Lx ×Ly ×Lz | 300×300×2200 |

| 挡板网格数 | lx ×ly ×lz | 60×300×30 |

| 颗粒 | Sauter平均颗粒直径/μm | 595 |

| 密度/(kg/m3) | 2906 | |

| 最小流态化时空隙率 | 0.47 | |

| 最小流化速度/(m/s) | 0.33 | |

| 球形度 | 0.86 | |

| 颗粒粗粒化率 | 5 | |

| 粗粒化后床内颗粒总数 | 3439103 | |

| 非弹性碰撞恢复系数 | 0.9 | |

| 滑动摩擦系数 | 0.3 | |

| 滚动摩擦系数 | 0.01 | |

| 特征速度/(m/s) | 0.5 | |

| 杨氏模量/Pa | 1×108 | |

| 泊松比 | 0.3 | |

| 时间步长/s | 1×10-5 | |

| 静止堆积床高/m | 1 | |

| 气体 | 密度/(kg/m3) | 1.2 |

| 黏度/(Pa·s) | 1.8×10-5 | |

| 表观气速/(m/s) | 0.6 | |

| 出口压力/Pa | 101325 | |

| CFD网格大小/mm | 10×10×10 | |

| 时间步长/s | 1×10-4 |

| 1 | 郭慕孙,李洪钟.流态化手册[M].北京:化学工业出版社,2008: 150. |

| Kwauk M, Li H Z. Fluidization Manual [M]. Beijing:Chemical Industry Press, 2008: 150. | |

| 2 | John R G, Knowlton T M, Avidan A A. Circulating Fluidized Beds[M]. Springer Science & Business Media, 2012: 5. |

| 3 | Nelson M J, Nakhla G, Zhu J. Fluidized-bed bioreactor applications for biological wastewater treatment: a review of research and developments[J]. Engineering, 2017, 3(3): 330-342. |

| 4 | Li J, Kwauk M. Particle-Fluid Two-Phase Flow: The Energy-Minimization Multi-Scale Method[M]. Beijing:Metallurgical Industry Press, 1994: 122-125. |

| 5 | Li J, Ge W, Wang W, et al. Focusing on mesoscales: from the energy-minimization multiscale model to mesoscience[J]. Current Opinion in Chemical Engineering, 2016, 13: 10-23. |

| 6 | 卢天雄. 流化床反应器[M]. 北京:化学工业出版社, 1986: 74-82. |

| Lu T X. Fluidized Bed Reactor [M]. Beijing:Chemical Industry Press, 1986: 74-82. | |

| 7 | 周遊, 鲁维民, 郑冲,等. 多孔挡板导流筒型流化床内构件研究[J]. 过程工程学报, 1995(2): 143-150. |

| Zhou Y, Lu W M, Zheng C, et al. Investigations on the draft tube internal in gas-solid fluidized beds[J]. The Chinese Journal of Process Engineering, 1995(2): 143-150. | |

| 8 | 黄学静, 徐文青, 魏耀东, 等. 半干法循环流化床脱硫反应器内构件研究进展[J]. 化工进展, 2014, 33(10): 2540-2545. |

| Huang X J, Xu W Q, Wei Y D, et al. Studies on internal components in semi-dry circulating fluidized bed desulfurization reactor[J]. Chemical Industry and Engineering Progress, 2014, 33(10): 2540-2545. | |

| 9 | 杨帅. 内构件鼓泡流化床中流动结构及其计算机模拟研究[D]. 北京: 中国科学院大学, 2016. |

| Yang S. Study on flow structure and computer simulation in a bubbling fluidized bed with internal components[D]. Beijing: University of Chinese Academy of Sciences, 2016. | |

| 10 | 董群, 贾昭, 王丽, 等. 催化裂化流化床内构件的研究进展[J]. 化工进展, 2010, 29(9): 1609-1614. |

| Dong Q, Jia Z, Wang L, et al. An outline for inner-loop studies in FCC fluidized bed[J]. Chemical Industry and Engineering Progress, 2010, 29(9): 1609-1614. | |

| 11 | Rall R R. Apparatus for contacting of gases and solids in fluidized beds: US6224833[P]. 2001-05-01. |

| 12 | 金涌, 俞芷青, 张礼, 等. 流化床反应器塔形内构件的研究[J]. 化工学报, 1980, 31(2): 117-128. |

| Jin Y, Yu Z Q, Zhang L, et al. Study on tower internals of fluidized bed reactor[J]. Journal of Chemical Industry and Engineering(China), 1980, 31(2): 117-128. | |

| 13 | 金涌, 俞芷青, 张礼, 等. 流化床脊形内构件[J]. 石油化工, 1986, 15(5): 269-277. |

| Jin Y, Yu Z Q, Zhang L, et al. Fluidized bed ridge internals[J]. Petrochemical Technology, 1986, 15(5): 269-277. | |

| 14 | 张永民, 王红梅, 卢春喜, 等. 导向挡板对催化裂化颗粒湍动流化床流动特性的影响[J]. 中国石油大学学报(自然科学版), 2008(4): 118-122. |

| Zhang Y M, Wang H M, Lu C X, et al. Effects of louvre baffles on hydrodynamic properties of turbulent fluidized beds of FCC particles[J]. Journal of China University of Petroleum (Edition of National Science),2008(4): 118-122. | |

| 15 | Yang Z, Zhang Y, Zhang H. CPFD simulation on effects of louver baffles in a two-dimensional fluidized bed of Geldart A particles[J]. Advanced Powder Technology, 2019, 30(11): 2712-2725. |

| 16 | 曲悦, 潘腾, 杨越林, 等. 三维单旋导向挡板鼓泡流化床内气固流动的CPFD模拟[J]. 高校化学工程学报, 2021, 35(4): 657-664. |

| Qu Y, Pan T, Yang Y L, et al. CPFD simulation of gas-solid flow in a three-dimensional bubbling fluidized bed with louver baffles[J]. Journal of Chemical Engineering of Chinese Universities, 2021, 35(4): 657-664. | |

| 17 | 时瑶, 王德武, 赵斌, 等. 旋流筛板式气固挡板流化床内压力脉动特性[J]. 过程工程学报, 2019, 19(1): 91-101. |

| Shi Y, Wang D W, Zhao B, et al. Pressure fluctuations in a gas-solid fluidized bed with rotating sieve tray type baffles[J]. The Chinese Journal of Process Engineering, 2019, 19(1): 91-101. | |

| 18 | 张英, 王强. CROSSER格栅在催化裂化装置中的应用[J]. 中外能源, 2010, 15(4): 69-71. |

| Zhang Y, Wang Q. The application of CROSSER grid in fluid catalytic cracking unit[J]. Sino-Global Energy, 2010, 15(4): 69-71. | |

| 19 | 魏飞, 杨艳辉, 金涌. 内构件对高密度提升管内气体混合行为的影响[J]. 化工学报, 2001, 52(9): 766-770. |

| Wei F, Yang Y H, Jin Y. Effect of internals on gas dispersion in high density riser[J]. Journal of Chemical Industry and Engineering(China), 2001, 52(9): 766-770. | |

| 20 | 刘会娥, 杨艳辉, 魏飞, 等. 内构件对于提升管中颗粒混合行为的影响[J]. 化学反应工程与工艺, 2002, 18(2): 109-114. |

| Liu H E, Yang Y H, Wei F, et al. Solids mixing behavior in riser with internals[J]. Chemical Reaction Engineering and Technology, 2002, 18(2): 109-114. | |

| 21 | Zhao G, Shi X, Wu Y, et al. 3D CFD simulation of gas-solids hydrodynamics and bubbles behaviors in empty and packed bubbling fluidized beds[J]. Powder Technology, 2019, 351: 1-15. |

| 22 | 王丽军, 王丽雅, 张煜, 等. 带阻尼内构件鼓泡塔的研究(Ⅱ):内构件对气液传质速率的影响[J]. 化学反应工程与工艺, 2007(2): 109-113. |

| Wang L J, Wang L Y, Zhang Y, et al. Study on the bubble column equipped with resistance internals(Ⅱ):Effects of the internals on gas-liquid mass transfer[J]. Chemical Reaction Engineering and Technology, 2007(2): 109-113. | |

| 23 | Youssef A A, Hamed M E, Grimes J T, et al. Hydrodynamics of pilot-scale bubble columns: effect of internals[J]. Industrial & Engineering Chemistry Research, 2013, 52(1): 43-55. |

| 24 | Baskakov A P, Michkovskii B A. Vertical forces acting on horizontal disks in a fluidized bed[J]. Journal of Engineering Physics, 1974, 27(6): 1464-1466. |

| 25 | Nguyen T H, Grace J R. Forces on objects immersed in fluidized beds[J]. Powder Technology, 1978, 19(2): 255-264. |

| 26 | Donovan J E. A study of forces on simulated heat exchange tubes immersed in a cold fluidized bed[D]. America: Oergon State University,1979. |

| 27 | Kennedy T C, Donovan J E, Trigas A. Forces on immersed tubes in fluidized beds[J]. AIChE Journal, 1981, 27(3): 351-357. |

| 28 | Nagahashi Y, Yamamoto D, Asako Y. Forces on horizontal tubes of non-circular cross-section in fluidized beds[C]//The 14th International Engineering Conference on Fluidization: From Fundamentals to Products. Netherlands, 2013: 1-8. |

| 29 | 王若艺, 刘对平, 李智, 等. 细颗粒气固流化床内斜片挡板受力特性的实验研究[J]. 过程工程学报, 2015, 15(3): 375-380. |

| Wang R Y, Liu D P, Li Z, et al. Experimental study on the acting forces on a single slant slat immersed in a gas and fine particles fluidized bed[J]. The Chinese Journal of Process Engineering, 2015, 15(3): 375-380. | |

| 30 | Liu D, Zhang S, Zhang Y, et al. Forces on an immersed horizontal slat during starting up a fluidized bed[J]. Chemical Engineering Science, 2017, 173: 402-410. |

| 31 | Liu D, Zhang S, Wang R, et al. Dynamic forces on a horizontal slat immersed in a fluidized bed of fine particles[J]. Chemical Engineering Research and Design, 2017, 117: 604-613. |

| 32 | 刘对平. 气固流化床挡板内构件受力特性的实验研究[D]. 北京:中国石油大学(北京), 2019. |

| Liu D P. Experimental study on stress characteristics of baffle inner members of gas-solid fluidized bed[D]. Beijing:China University of Petroleum, 2019. | |

| 33 | 李铁男, 赵碧丹, 赵鹏, 等. 气固流化床启动阶段挡板内构件受力特性的CFD-DEM模拟[J]. 化工学报, 2022, 73(6): 2649-2661. |

| Li T N, Zhao B D, Zhao P, et al. CFD-DEM simulation of the force acting on immersed baffles during the start-up stage of a gas-solid fluidized bed[J]. CIESC Journal, 2022, 73(6): 2649-2661. | |

| 34 | Tamarin A I, Livshits Y E, Galershtein D M, et al. Forces acting on a body in a nonuniform fluidized bed[J]. Journal of Engineering Physics, 1977, 32: 165-168. |

| 35 | Nagahashi Y, Asako Y, Lim K S, et al. Dynamic forces on a horizontal tube due to passing bubbles in fluidized beds[J]. Powder Technology, 1998, 98(2): 177-182. |

| 36 | Rong D, Mikami T, Horio M. Particle and bubble movements around tubes immersed in fluidized beds—a numerical study[J]. Chemical Engineering Science, 1999, 54(23): 5737-5754. |

| 37 | Nagahashi Y, Takeuchi H, Grace J R, et al. Dynamic forces on an immersed cylindrical tube and analysis of particle interaction in 2D-gas fluidized beds[J]. Advanced Powder Technology, 2018, 29(12): 3552-3560. |

| 38 | Ge W, Guo L, Liu X, et al. Mesoscience-based virtual process engineering[J]. Computers & Chemical Engineering, 2019, 126: 68-82. |

| 39 | Bian W, Chen X, Wang J. A critical comparison of two-fluid model, discrete particle method and direct numerical simulation for modeling dense gas-solid flow of rough spheres[J]. Chemical Engineering Science, 2019, 210: 115233. |

| 40 | Hua L, Zhao H, Li J, et al. Eulerian-Eulerian simulation of irregular particles in dense gas-solid fluidized beds[J]. Powder Technology, 2015, 284: 299-311. |

| 41 | Lan B, Xu J, Zhao P, et al. Scale-up effect of residence time distribution of polydisperse particles in continuously operated multiple-chamber fluidized beds[J]. Chemical Engineering Science, 2021, 244: 116809. |

| 42 | Tsuji Y, Kawaguchi T, Tanaka T. Discrete particle simulation of two-dimensional fluidized bed[J]. Powder Technology, 1993, 77(1): 79-87. |

| 43 | Peng Z, Doroodchi E, Luo C, et al. Influence of void fraction calculation on fidelity of CFD-DEM simulation of gas-solid bubbling fluidized beds[J]. AIChE Journal, 2014, 60(6): 2000-2018. |

| 44 | Zhao P, Xu J, Ge W, et al. A CFD-DEM-IBM method for Cartesian grid simulation of gas-solid flow in complex geometries[J]. Chemical Engineering Journal, 2020, 389: 124343. |

| 45 | Zhao P, Xu J, Liu X, et al. A computational fluid dynamics-discrete element-immersed boundary method for Cartesian grid simulation of heat transfer in compressible gas-solid flow with complex geometries[J]. Physics of Fluids, 2020, 32(10): 103306. |

| 46 | He M, Zhao B, Wang J. Particle pressures in gas-fluidized beds: a computational fluid dynamics-discrete element method study[J]. Industrial & Engineering Chemistry Research, 2022, 61(26): 9489-9497. |

| [1] | Yizhou CUI, Chengxiang LI, Linxiao ZHAI, Shuyu LIU, Xiaogang SHI, Jinsen GAO, Xingying LAN. Comparative study on the flow and mass transfer characteristics of sub-millimeter bubbles and conventional bubbles in gas-liquid two-phase flow [J]. CIESC Journal, 2024, 75(1): 197-210. |

| [2] | Junnan WANG, Chengxiang HE, Zhongdong WANG, Chunying ZHU, Youguang MA, Taotao FU. Numerical simulation of homogeneous mixing in T-junction micromixers [J]. CIESC Journal, 2024, 75(1): 242-254. |

| [3] | Yao ZHOU, Xiaoping YANG, Yicheng NI, Jiping LIU, Jinjia WEI, Junjie YAN. Numerical simulation of two-phase steam ejector applied in novel loop heat pipe [J]. CIESC Journal, 2024, 75(1): 268-278. |

| [4] | Yijiang WANG, Li SUN, Menghan LIU, Jinhong YANG, Guoyuan WANG. Optimization on parameter of plate-fin-and-tube air cooler in mines based on response surface method [J]. CIESC Journal, 2024, 75(1): 279-291. |

| [5] | Zhanyu YE, He SHAN, Zhenyuan XU. Performance simulation of paper folding-like evaporator for solar evaporation systems [J]. CIESC Journal, 2023, 74(S1): 132-140. |

| [6] | Keke SHAO, Mengjie SONG, Zhengyong JIANG, Xuan ZHANG, Long ZHANG, Runmiao GAO, Zekang ZHEN. Experimental study on the formation and distribution of trapped air bubbles in horizontal ice slice [J]. CIESC Journal, 2023, 74(S1): 161-164. |

| [7] | Yifei ZHANG, Fangchen LIU, Shuangxing ZHANG, Wenjing DU. Performance analysis of printed circuit heat exchanger for supercritical carbon dioxide [J]. CIESC Journal, 2023, 74(S1): 183-190. |

| [8] | Zhiguo WANG, Meng XUE, Yushuang DONG, Tianzhen ZHANG, Xiaokai QIN, Qiang HAN. Numerical simulation and analysis of geothermal rock mass heat flow coupling based on fracture roughness characterization method [J]. CIESC Journal, 2023, 74(S1): 223-234. |

| [9] | Jiahao SONG, Wen WANG. Study on coupling operation characteristics of Stirling engine and high temperature heat pipe [J]. CIESC Journal, 2023, 74(S1): 287-294. |

| [10] | Siyu ZHANG, Yonggao YIN, Pengqi JIA, Wei YE. Study on seasonal thermal energy storage characteristics of double U-shaped buried pipe group [J]. CIESC Journal, 2023, 74(S1): 295-301. |

| [11] | Mingkun XIAO, Guang YANG, Yonghua HUANG, Jingyi WU. Numerical study on bubble dynamics of liquid oxygen at a submerged orifice [J]. CIESC Journal, 2023, 74(S1): 87-95. |

| [12] | Jiaqi YUAN, Zheng LIU, Rui HUANG, Lefu ZHANG, Denghui HE. Investigation on energy conversion characteristics of vortex pump under bubble inflow [J]. CIESC Journal, 2023, 74(9): 3807-3820. |

| [13] | Song HE, Qiaomai LIU, Guangshuo XIE, Simin WANG, Juan XIAO. Two-phase flow simulation and surrogate-assisted optimization of gas film drag reduction in high-concentration coal-water slurry pipeline [J]. CIESC Journal, 2023, 74(9): 3766-3774. |

| [14] | Lei XING, Chunyu MIAO, Minghu JIANG, Lixin ZHAO, Xinya LI. Optimal design and performance analysis of downhole micro gas-liquid hydrocyclone [J]. CIESC Journal, 2023, 74(8): 3394-3406. |

| [15] | Xiaosong CHENG, Yonggao YIN, Chunwen CHE. Performance comparison of different working pairs on a liquid desiccant dehumidification system with vacuum regeneration [J]. CIESC Journal, 2023, 74(8): 3494-3501. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||