CIESC Journal ›› 2019, Vol. 70 ›› Issue (3): 1056-1064.DOI: 10.11949/j.issn.0438-1157.20181051

• Energy and environmental engineering • Previous Articles Next Articles

Chao WANG1( ),Changming LI2,Lin HUANGFU2,Ping LI1,Yunquan YANG1,Shiqiu GAO2,Jian YU2(

),Changming LI2,Lin HUANGFU2,Ping LI1,Yunquan YANG1,Shiqiu GAO2,Jian YU2( ),Guangwen XU3

),Guangwen XU3

Received:2018-09-19

Revised:2018-12-11

Online:2019-03-05

Published:2019-03-05

Contact:

Jian YU

王超1( ),李长明2,皇甫林2,李萍1,杨运泉1,高士秋2,余剑2(

),李长明2,皇甫林2,李萍1,杨运泉1,高士秋2,余剑2( ),许光文3

),许光文3

通讯作者:

余剑

作者简介:<named-content content-type="corresp-name">王超</named-content>(1993—),男,硕士研究生,<email>wang_chao999058@163.com</email>|余剑(1979—),男,博士,副研究员,<email>yujian@ipe.ac.cn</email>

基金资助:CLC Number:

Chao WANG, Changming LI, Lin HUANGFU, Ping LI, Yunquan YANG, Shiqiu GAO, Jian YU, Guangwen XU. Preparation of red mud-based catalyst and performance for trace ammonia in simulative tail gas[J]. CIESC Journal, 2019, 70(3): 1056-1064.

王超, 李长明, 皇甫林, 李萍, 杨运泉, 高士秋, 余剑, 许光文. 赤泥催化剂的制备及其对模拟烟气中微量氨的脱除性能[J]. 化工学报, 2019, 70(3): 1056-1064.

Add to citation manager EndNote|Ris|BibTeX

URL: https://hgxb.cip.com.cn/EN/10.11949/j.issn.0438-1157.20181051

| 样品 | 主要组成/%(mass) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Na2O | MgO | Al2O3 | CaO | SO3 | Fe2O3 | TiO2 | SiO2 | Others | |

| RM | 10.97 | 0.23 | 19.92 | 1.29 | 0.64 | 44.18 | 8.01 | 13.43 | 1.33 |

| MRM | 0.00 | 0.00 | 19.12 | 0.75 | 4.58 | 53.78 | 8.81 | 11.83 | 0.26 |

Table 1 Main chemical composition of RM and MRM

| 样品 | 主要组成/%(mass) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Na2O | MgO | Al2O3 | CaO | SO3 | Fe2O3 | TiO2 | SiO2 | Others | |

| RM | 10.97 | 0.23 | 19.92 | 1.29 | 0.64 | 44.18 | 8.01 | 13.43 | 1.33 |

| MRM | 0.00 | 0.00 | 19.12 | 0.75 | 4.58 | 53.78 | 8.81 | 11.83 | 0.26 |

| 样品 | 比表面积/(m2/g) | 孔体积/ (cm3/g) | 孔径/nm | |

|---|---|---|---|---|

| Vtotal | Vmeso | |||

| RM | 83.32 | 0.210 | 0.202 | 9.78 |

| MRM | 335.14 | 0.525 | 0.525 | 5.44 |

Table 2 Specific surface area and pore volumes of RM and MRM

| 样品 | 比表面积/(m2/g) | 孔体积/ (cm3/g) | 孔径/nm | |

|---|---|---|---|---|

| Vtotal | Vmeso | |||

| RM | 83.32 | 0.210 | 0.202 | 9.78 |

| MRM | 335.14 | 0.525 | 0.525 | 5.44 |

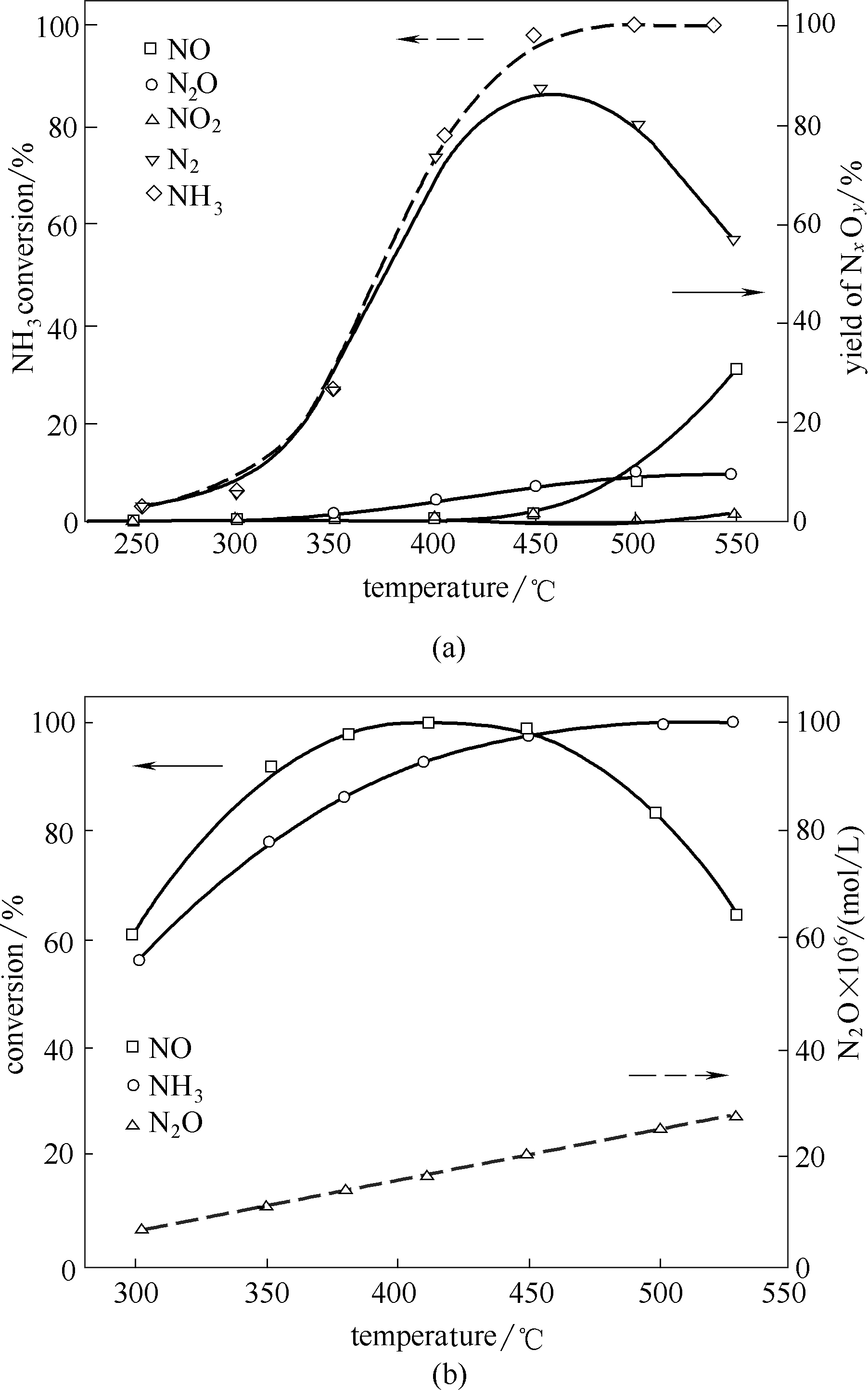

Fig.6 NH3-SCO (a) and NH3-SCR (b) performance and yield proportions of reaction products over MRM at different temperatures[reaction conditions: 1.5 g of catalyst, [NH3]=500×10-6 mol/L, [NO]=500×10-6 mol/L(only for SCR process), [O2]=5%(vol), balance gas: N2, total flow rate 1500 ml/min, GHSV=10000 h-1]

| 1 | 程刚, 段俊, 李金香, 等. 北京市交通环境大气氨污染水平分析[J]. 大气与环境光学学报, 2018, 13(3): 193-207. |

| ChengG, DuanJ, LiJ X, et al. Analysis of atmospheric ammonia pollution level in Beijing traffic environment[J]. Journal of Atmospheric and Environmental Optics, 2018, 13(3): 193-207. | |

| 2 | 李穹, 吴玉新, 杨海瑞, 等. SNCR脱硝特性的模拟及优化[J]. 化工学报, 2013, 64(5): 1789-1796. |

| LiQ, WuY X, YangH R, et al. Simulation and optimization of SNCR process[J]. CIESC Journal, 2013, 64(5): 1789-1796. | |

| 3 | LaiJ K, WachsI E. A perspective on the selective catalytic reduction (SCR) of NO with NH3 by supported V2O5-WO3/TiO2 catalysts[J]. ACS Catalysis, 2018, 8(3): 6537-6551. |

| 4 | 顾卫荣, 周明吉, 马薇. 燃煤烟气脱硝技术的研究进展[J]. 化工进展, 2012, 31(9): 2084-2092. |

| GuW R, ZhouM J, MaW. Technology statue and analysis on coal-fired flue gas denitrification[J]. Chemical Industry and Engineering Progress, 2012, 31(9): 2084-2092. | |

| 5 | ChungY, HuangC, LiuC H, et al. Biotreatment of hydrogen sulfide-and ammonia-containing waste gases by fluidized bed bioreactor[J]. Journal of the Air & Waste Management Association, 2001, 51(2): 163-172. |

| 6 | BurchR, SouthwardB, W L. The nature of the active metal surface of catalysts for the clean combustion of biogas containing ammonia[J]. Journal of Catalysis, 2001, 98(2): 286-295. |

| 7 | HuangT L, CliffeK R, MacinnesJ M. The removal of ammonia from water by a hydrophobic catalyst[J]. Environmental Science & Technology, 2000, 34(22): 4804-4809. |

| 8 | ChmielarzL, KustrowskiP, RafalskaL A, et al. Selective oxidation of ammonia to nitrogen on transition metal containing mixed metal oxides[J]. Applied Catalysis B-Environmental, 2005, 48(3/4): 235-244. |

| 9 | RamisG, YiL, BuscaG. Ammonia activation over catalysts for the selective catalytic reduction of NOx and the selective catalytic oxidation of NH3: an FT-IR study[J]. Catalysis Today, 1996, 28(4): 373-380. |

| 10 | WangZ, QuZ, QuanX, et al. Selective catalytic oxidation of ammonia to nitrogen over ceria–zirconia mixed oxides[J]. Applied Catalysis A: General, 2012, 411/412(16): 131-138. |

| 11 | HongS, KarimA, RahmanT S, et al. Selective oxidation of ammonia on RuO2(110): a combined DFT and KMC study[J]. Journal of Catalysis, 2010, 276(2): 371-381. |

| 12 | WangF, MaJ, HeG, et al. Nanosize effect of Al2O3 in Ag/Al2O3 catalyst for the selective catalytic oxidation of ammonia[J]. ACS Catalysis, 2018, 8(4): 2670-2682. |

| 13 | OlofssonG, HinzA, AnderssonA. A transient response study of the selective catalytic oxidation of ammonia to nitrogen on Pt/CuO/Al2O3[J]. Chemical Engineering Science, 2004, 59(16): 4113-4123. |

| 14 | YuanR M, FuG, XuX, et al. Mechanisms for selective catalytic oxidation of ammonia over vanadium oxides[J]. The Journal of Physical Chemistry C, 2011, 115(43): 21218-21229. |

| 15 | LeeJ Y, KimS B, HongS C. Characterization and reactivity of natural manganese ore catalysts in the selective catalytic oxidation of ammonia to nitrogen[J]. Chemosphere, 2003, 50(8): 1115-1122. |

| 16 | WangH, NingP, ZhangQ, et al. Promotional mechanism of WO3 over RuO2-Fe2O3 catalyst for NH3-SCO reaction[J]. Applied Catalysis A: General, 2018, 561(5): 158-167. |

| 17 | LeeS M, HongS C. Promotional effect of vanadium on the selective catalytic oxidation of NH3 to N2 over Ce/V/TiO2 catalyst[J]. Applied Catalysis B: Environmental, 2015, 163: 30-39. |

| 18 | 张以河, 王新珂, 吕凤柱, 等. 赤泥脱碱及功能新材料研究进展[J]. 环境工程学报, 2016, 10(7): 3383-3390. |

| ZhangY H, WangX K, LyuF Z, et al. Study process of alkali removal from red mud and novel functional materials[J]. Chinese Journal of Environmental Engineering, 2016, 10(7): 3383-3390. | |

| 19 | 南相莉, 张廷安, 刘燕, 等. 我国赤泥综合利用分析[J]. 过程工程学报, 2010, 10(S1): 264-270. |

| NanX L, ZhangT A, LiuY, et al. Analysis of comprehensive utilization of red mud in China[J]. The Chinese Journal of Process Engineering, 2010, 10(S1): 264-270. | |

| 20 | 杜军, 王怀彬, 金霄. 国内外垃圾焚烧炉技术概述[J]. 工业锅炉, 2003, 5: 15-19. |

| DuJ, WangH B, JinX. An analysis summary of urban waste incineration technology in our and foreign countries[J]. Industrial Boiler, 2003, 5: 15-19. | |

| 21 | XiongS, WengJ, LiaoY, et al. Alkali metal deactivation on the low temperature selective catalytic reduction of NOx with NH3 over MnOx-CeO2: a mechanism study[J]. The Journal of Physical Chemistry C, 2016, 120(28): 15299-15309. |

| 22 | PengY, LiJ, ChenL, et al. Alkali metal poisoning of a CeO2-WO3 catalyst used in the selective catalytic reduction of NOx with NH3: an experimental and theoretical study[J]. Environmental Science & Technology, 2012, 46(5): 2864-2869. |

| 23 | SunJ, LuY, ZhangL, et al. Comparative study of different doped metal cations on the reduction, acidity, and activity of Fe9M1Ox (M=Ti4+, Ce4+/3+, Al3+) catalysts for NH3-SCR reaction[J]. Industrial & Engineering Chemistry Research, 2017, 56(42): 12101-12110. |

| 24 | KimT H, GongG T, LeeB G, et al. Catalytic decomposition of sulfur trioxide on the binary metal oxide catalysts of Fe/Al and Fe/Ti[J]. Applied Catalysis A: General, 2006, 305(1): 39-45. |

| 25 | YangS, WangC, MaL, et al. Substitution of WO3 in V2O5/WO3-TiO2 by Fe2O3 for selective catalytic reduction of NO with NH3[J]. Catalysis Science & Technology 2013, 3: 161-168. |

| 26 | MaL, LiJ, KeR, et al. Catalytic performance, characterization, and mechanism study of Fe2(SO4)3/TiO2 catalyst for selective catalytic reduction of NOx by ammonia[J]. The Journal of Physical Chemistry C, 2011, 115(15): 7603-7612. |

| 27 | AkahA, CundyC, GarforthA. The selective catalytic oxidation of NH3 over Fe-ZSM-5[J]. Applied Catalysis B: Environmental, 2005, 59(3/4): 221-226. |

| 28 | SjövallH, BlintR J, OlssonL. Detailed kinetic modeling of NH3 and H2O adsorption, and NH3 oxidation over Cu-ZSM-5[J]. The Journal of Physical Chemistry C, 2009, 113(4): 1393-1405. |

| 29 | WangC, YangS, ChangH, et al. Structural effects of iron spinel oxides doped with Mn, Co, Ni and Zn on selective catalytic reduction of NO with NH3[J]. Journal of Molecular Catalysis A: Chemical, 2013, 376: 13-21. |

| 30 | YangS, LiuC, ChangH, et al. Improvement of the activity of γ-Fe2O3 for the selective catalytic reduction of NO with NH3 at high temperatures: NO reduction versus NH3 oxidization[J]. Industrial & Engineering Chemistry Research, 2013, 52(6): 5601-5610. |

| [1] | Xin YANG, Wen WANG, Kai XU, Fanhua MA. Simulation analysis of temperature characteristics of the high-pressure hydrogen refueling process [J]. CIESC Journal, 2023, 74(S1): 280-286. |

| [2] | Jiahao SONG, Wen WANG. Study on coupling operation characteristics of Stirling engine and high temperature heat pipe [J]. CIESC Journal, 2023, 74(S1): 287-294. |

| [3] | Siyu ZHANG, Yonggao YIN, Pengqi JIA, Wei YE. Study on seasonal thermal energy storage characteristics of double U-shaped buried pipe group [J]. CIESC Journal, 2023, 74(S1): 295-301. |

| [4] | Congqi HUANG, Yimei WU, Jianye CHEN, Shuangquan SHAO. Simulation study of thermal management system of alkaline water electrolysis device for hydrogen production [J]. CIESC Journal, 2023, 74(S1): 320-328. |

| [5] | Zhanyu YE, He SHAN, Zhenyuan XU. Performance simulation of paper folding-like evaporator for solar evaporation systems [J]. CIESC Journal, 2023, 74(S1): 132-140. |

| [6] | Long ZHANG, Mengjie SONG, Keke SHAO, Xuan ZHANG, Jun SHEN, Runmiao GAO, Zekang ZHEN, Zhengyong JIANG. Simulation study on frosting at windward fin end of heat exchanger [J]. CIESC Journal, 2023, 74(S1): 179-182. |

| [7] | Yifei ZHANG, Fangchen LIU, Shuangxing ZHANG, Wenjing DU. Performance analysis of printed circuit heat exchanger for supercritical carbon dioxide [J]. CIESC Journal, 2023, 74(S1): 183-190. |

| [8] | Zhiguo WANG, Meng XUE, Yushuang DONG, Tianzhen ZHANG, Xiaokai QIN, Qiang HAN. Numerical simulation and analysis of geothermal rock mass heat flow coupling based on fracture roughness characterization method [J]. CIESC Journal, 2023, 74(S1): 223-234. |

| [9] | Song HE, Qiaomai LIU, Guangshuo XIE, Simin WANG, Juan XIAO. Two-phase flow simulation and surrogate-assisted optimization of gas film drag reduction in high-concentration coal-water slurry pipeline [J]. CIESC Journal, 2023, 74(9): 3766-3774. |

| [10] | Jie CHEN, Yongsheng LIN, Kai XIAO, Chen YANG, Ting QIU. Study on catalytic synthesis of sec-butanol by tunable choline-based basic ionic liquids [J]. CIESC Journal, 2023, 74(9): 3716-3730. |

| [11] | Yuanchao LIU, Bin GUAN, Jianbin ZHONG, Yifan XU, Xuhao JIANG, Duan LI. Investigation of thermoelectric transport properties of single-layer XSe2 (X=Zr/Hf) [J]. CIESC Journal, 2023, 74(9): 3968-3978. |

| [12] | Yitong LI, Hang GUO, Hao CHEN, Fang YE. Study on operating conditions of proton exchange membrane fuel cells with non-uniform catalyst distributions [J]. CIESC Journal, 2023, 74(9): 3831-3840. |

| [13] | Zhewen CHEN, Junjie WEI, Yuming ZHANG. System integration and energy conversion mechanism of the power technology with integrated supercritical water gasification of coal and SOFC [J]. CIESC Journal, 2023, 74(9): 3888-3902. |

| [14] | Minghao SONG, Fei ZHAO, Shuqing LIU, Guoxuan LI, Sheng YANG, Zhigang LEI. Multi-scale simulation and study of volatile phenols removal from simulated oil by ionic liquids [J]. CIESC Journal, 2023, 74(9): 3654-3664. |

| [15] | Xuejin YANG, Jintao YANG, Ping NING, Fang WANG, Xiaoshuang SONG, Lijuan JIA, Jiayu FENG. Research progress in dry purification technology of highly toxic gas PH3 [J]. CIESC Journal, 2023, 74(9): 3742-3755. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||