CIESC Journal ›› 2025, Vol. 76 ›› Issue (9): 4425-4439.DOI: 10.11949/0438-1157.20241439

• Special Column: Modeling and Simulation in Process Engineering • Previous Articles Next Articles

Zhengzong HUANG1( ), Kecheng LIU1, Zefang LI1, Pingsheng ZENG2, YongFu LIU2, Hongjie YAN1, Liu LIU1(

), Kecheng LIU1, Zefang LI1, Pingsheng ZENG2, YongFu LIU2, Hongjie YAN1, Liu LIU1( )

)

Received:2024-12-12

Revised:2025-01-09

Online:2025-10-23

Published:2025-09-25

Contact:

Liu LIU

黄正宗1( ), 刘科成1, 李泽方1, 曾平生2, 刘永富2, 闫红杰1, 刘柳1(

), 刘科成1, 李泽方1, 曾平生2, 刘永富2, 闫红杰1, 刘柳1( )

)

通讯作者:

刘柳

作者简介:黄正宗(1995—),男,博士研究生,z.z.huang@csu.edu.cn

基金资助:CLC Number:

Zhengzong HUANG, Kecheng LIU, Zefang LI, Pingsheng ZENG, YongFu LIU, Hongjie YAN, Liu LIU. Numerical simulation and field synergy optimization of brick-built heat exchange chamber in zinc refining furnace[J]. CIESC Journal, 2025, 76(9): 4425-4439.

黄正宗, 刘科成, 李泽方, 曾平生, 刘永富, 闫红杰, 刘柳. 锌精馏炉砖砌式换热室数值模拟与场协同优化[J]. 化工学报, 2025, 76(9): 4425-4439.

Add to citation manager EndNote|Ris|BibTeX

| 材料 | 密度/(kg/m3) | 比热容/(J/(kg∙K)) | 热导率/(W/(m∙K)) | 吸收系数/m-1 | 散射系数/m-1 |

|---|---|---|---|---|---|

| 墙体 | 2200 | 750 | 1.5 | 3.7 | 50.88 |

Table 1 Physical parameters of the wall of a zinc refining furnace

| 材料 | 密度/(kg/m3) | 比热容/(J/(kg∙K)) | 热导率/(W/(m∙K)) | 吸收系数/m-1 | 散射系数/m-1 |

|---|---|---|---|---|---|

| 墙体 | 2200 | 750 | 1.5 | 3.7 | 50.88 |

| 序号 | 测点位置 | 测试值/K | 计算值/K | 相对误差/% |

|---|---|---|---|---|

| 1 | 换热室烟气出口 | 825.13 | 882.46 | 6.9 |

| 2 | 换热室空气出口 | 1070.85 | 1001.23 | 6.5 |

Table 2 Comparison of calculated and measured flue gas and air temperatures in the heat exchange chamber

| 序号 | 测点位置 | 测试值/K | 计算值/K | 相对误差/% |

|---|---|---|---|---|

| 1 | 换热室烟气出口 | 825.13 | 882.46 | 6.9 |

| 2 | 换热室空气出口 | 1070.85 | 1001.23 | 6.5 |

| 工况 | Case-1 | Case-2 | Case-3 | Case-4 |

|---|---|---|---|---|

| 数值/mm | 240 | 305 | 370 | 435 |

Table 3 Horizontal width of air duct inlet on east side at bottom layer

| 工况 | Case-1 | Case-2 | Case-3 | Case-4 |

|---|---|---|---|---|

| 数值/mm | 240 | 305 | 370 | 435 |

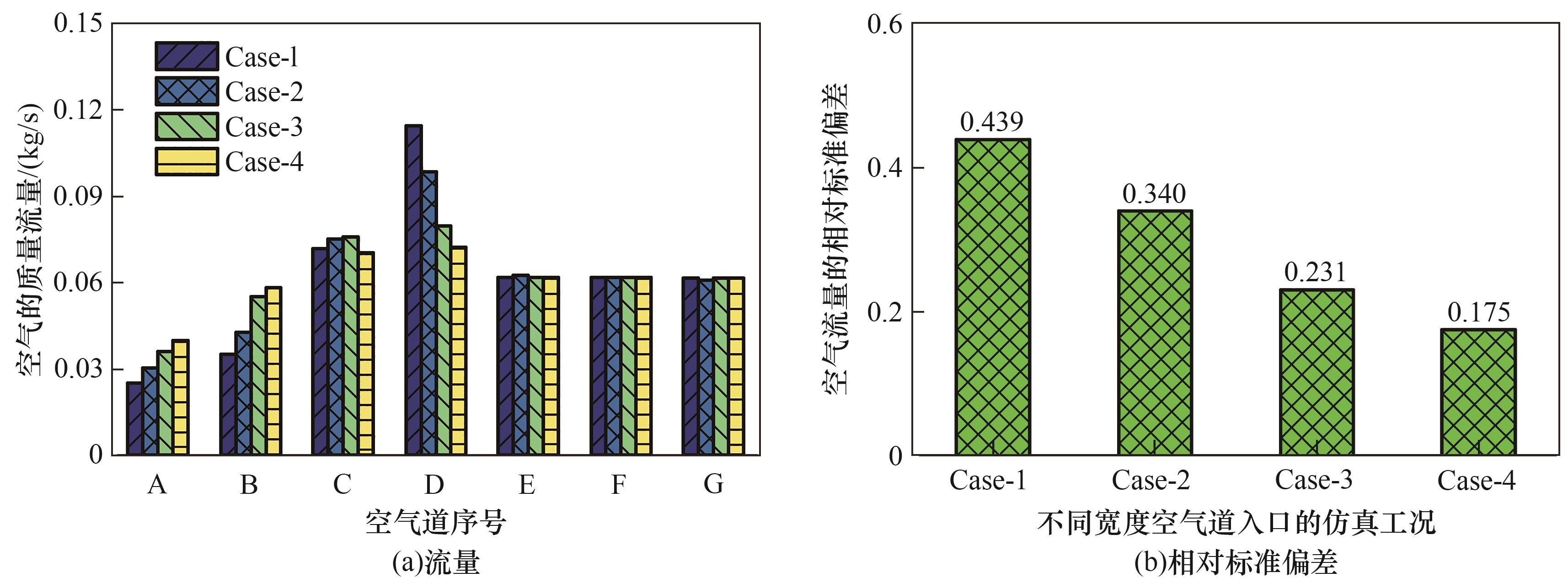

Fig.13 Histograms of air mass flows and their relative standard deviations for different rows of chimney checkers at different inlet widths of air duct

| [1] | 赵浩然, 黄嗣罗, 林梅. 余热锅炉入口管箱底面沉积特性[J]. 化工学报, 2024, 75(10): 3464-3476. |

| Zhao H R, Huang S L, Lin M. Sedimentation characteristics of the bottom surface of the inlet pipe box of a waste heat boiler[J]. CIESC Journal, 2024, 75(10): 3464-3476. | |

| [2] | Guo X Y, Jiang B C, Chen J H, et al. Effect of oxygen lance seat arrangement on flow characteristics of large-scale copper smelting bottom-blown furnace[J]. Journal of Central South University, 2023, 30(8): 2542-2555. |

| [3] | 曹健, 钱红亮, 冯新, 等. 热力学视角下的碳中和三问[J]. 化工学报, 2024, 75(11): 4378-4384. |

| Cao J, Qian H L, Feng X, et al. Three questions on carbon neutrality from the perspective of thermodynamics[J]. CIESC Journal, 2024, 75(11): 4378-4384. | |

| [4] | 张岭, 蔡晖, 张乐如. ISP技术能耗分析[J]. 世界有色金属, 2021(12): 148-150. |

| Zhang L, Cai H, Zhang L R. Energy consumption of ISP technology[J]. World Nonferrous Metals, 2021(12): 148-150. | |

| [5] | 曾平生, 黄正宗, 郑关平, 等. 塔式锌精馏炉热工诊断与节能分析[J]. 中国有色冶金, 2022, 51(6): 45-53. |

| Zeng P S, Huang Z Z, Zheng G P, et al. Thermal diagnosis and energy saving analysis of a tower-type zinc refining furnace[J]. China Nonferrous Metallurgy, 2022, 51(6): 45-53. | |

| [6] | 陈杰. 锌精馏工艺中铅塔燃烧室内温度场研究[D]. 沈阳: 东北大学, 2011. |

| Chen J. Temperature field study of zinc refining process in plumbean tower burner[D]. Shenyang: Northeastern University, 2011. | |

| [7] | 李泽方. 基于场协同的锌精馏过程余热高效利用技术研究[D]. 长沙: 中南大学, 2023. |

| Li Z F. Research on the waste heat recovery technology of zinc refining process based on field synergy principle[D]. Changsha: Central South University, 2023. | |

| [8] | Khaled M, Mortada M, Faraj J, et al. Effect of airflow non-uniformities on the thermal performance of water-air heat exchangers: experimental study and analysis[J]. Energies, 2022, 15(21): 8120. |

| [9] | Yan H J, Xie H Y, Zheng W Y, et al. Numerical simulation of combustion and melting process in an aluminum melting furnace: a study on optimizing stacking mode[J]. Applied Thermal Engineering, 2024, 245: 122840. |

| [10] | Yan H J, Huang Z Z, Hu M, et al. Numerical modeling of gas-solid two-phase flow in a plasma melting furnace[J]. Powder Technology, 2022, 412: 117967. |

| [11] | 李杰, 胡国林, 朱永红, 等. 隧道窑烟气换热器肋板强化传热的数值研究[J]. 陶瓷学报, 2014, 35(3): 318-321. |

| Li J, Hu G L, Zhu Y H, et al. Numerical study on finned enhanced heat transfer used in a tunnel kiln's flue gas heat exchanger[J]. Journal of Ceramics, 2014, 35(3): 318-321. | |

| [12] | 何金桥, 赵华庚, 曾丹, 等. 基于多孔介质模型的低质燃气燃烧排放特性数值模拟[J]. 长沙理工大学学报(自然科学版), 2017, 14(2): 80-84. |

| He J Q, Zhao H G, Zeng D, et al. Numerical simulation of low-quality gas emission characteristics based on porous medium model[J]. Journal of Changsha University of Science & Technology (Natural Science), 2017, 14(2): 80-84. | |

| [13] | Xiong Q G, Izadi M, Shokri rad M, et al. 3D numerical study of conical and fusiform turbulators for heat transfer improvement in a double-pipe heat exchanger[J]. International Journal of Heat and Mass Transfer, 2021, 170: 120995. |

| [14] | 鄂加强, 邢德跃, 王曙辉, 等. 柴油机高压喷油嘴喷射过程空化效应数值模拟[J]. 湖南大学学报(自然科学版), 2013, 40(2): 45-51. |

| E J Q, Xing D Y, Wang S H, et al. Numerical simulation of cavitation effect in the injection process of high pressure injector nozzle in diesel[J]. Journal of Hunan University (Natural Sciences), 2013, 40(2): 45-51. | |

| [15] | Huang Z Z, Liu L, Chen L, et al. Numerical modeling and parameter optimization of the combustion chamber in a tower-type zinc refining furnace[J]. Case Studies in Thermal Engineering, 2024, 64: 105450. |

| [16] | Yan H J, Huang Z Z, Zeng P S, et al. CFD-based burner parameter optimization of a sintering ignition furnace[J]. Applied Thermal Engineering, 2024, 241: 122430. |

| [17] | 曾平生, 黄正宗, 江新辉, 等. 铅锌冶炼烧结点火炉点火过程数值模拟[J]. 中国有色金属学报, 2024, 34(1): 254-267. |

| Zeng P S, Huang Z Z, Jiang X H, et al. Numerical simulation on the ignition process of sintering ignition furnace in lead-zinc smelting[J]. The Chinese Journal of Nonferrous Metals, 2024, 34(1): 254-267. | |

| [18] | 曹天明, 李保运. 马钢特钢电炉余热回收系统改造实践[J]. 冶金动力, 2022, 41(4): 119-123. |

| Cao T M, Li B Y. Practice of electric furnace waste heat recovery system renovation of masteel[J]. Metallurgical Power, 2022, 41(4): 119-123. | |

| [19] | Szwaja S, Zajemska M, Szwaja M, et al. Integration of waste biomass thermal processing technology with a metallurgical furnace to improve its efficiency and economic benefit[J]. Clean Technologies and Environmental Policy, 2023, 25(2): 577-587. |

| [20] | Delpech B, Axcell B, Jouhara H. Experimental investigation of a radiative heat pipe for waste heat recovery in a ceramics kiln[J]. Energy, 2019, 170: 636-651. |

| [21] | Hatami M, Jafaryar M, Ganji D D, et al. Optimization of finned-tube heat exchangers for diesel exhaust waste heat recovery using CFD and CCD techniques[J]. International Communications in Heat and Mass Transfer, 2014, 57: 254-263. |

| [22] | Soundararajan S, Selvaraj M. Investigations of protracted finned double pipe heat exchanger system for waste heat recovery from diesel engine exhaust[J]. Thermal Science, 2023, 27(5 Part A): 3783-3793. |

| [23] | Siva T, Chaitanya P S. Optimization of shell and tube heat exchanger used in a rankine cycle of exhaust gas waste heat recovery system using CFD[J]. International Journal of Chemical Sciences, 2016, 14(4): 2247-2258. |

| [24] | 李逸飞. 基于烟气余热回收的蒸发冷凝型换热器性能研究及优化[D]. 太原: 太原理工大学, 2023. |

| Li Y F. Research and optimization of evaporative condensing heat exchanger based on flue gas waste heat recovery[D]. Taiyuan: Taiyuan University of Technology, 2023. | |

| [25] | Duan Y R, Zhang X Y, Han Z Y, et al. Numerical investigation of coupled heat transfer and flow characteristics in helical coil heat exchanger for mine water waste heat recovery[J]. International Journal of Thermal Sciences, 2024, 202: 109089. |

| [26] | Wang L M, Lei Y G, Jing S L. Performance of a double-tube heat exchanger with staggered helical fins[J]. Chemical Engineering & Technology, 2022, 45(5): 953-961. |

| [27] | Yu C, Shao M Z, Zhang W B, et al. Enhancing heat transfer efficiency in corrugated tube heat exchangers: a comprehensive approach through structural optimization and field synergy analysis[J]. Heliyon, 2024, 10(9): e30113. |

| [28] | 李雪雪. 柱翼型散热器传热过程数值模拟与场协同优化研究[D]. 太原: 太原理工大学, 2023. |

| Li X X. Numerical simulation of heat transfer process and field collaborative optimization of cylindrical airfoil radiators[D]. Taiyuan: Taiyuan University of Technology, 2023. | |

| [29] | 李德涛, 安亚中, 张灵东, 等. 管壳式换热器折流板开孔流场特征及场协同分析[J]. 江西化工, 2024, 40(3): 105-109. |

| Li D T, An Y Z, Zhang L D, et al. Flow field characteristics and field synergy analysis of the orifices in the baffles of shell and tube heat exchangers[J]. Jiangxi Chemical Industry, 2024, 40(3): 105-109. | |

| [30] | 王福军. 计算流体力学分析—CFD软件原理与应用[M]. 北京: 清华大学出版社, 2004. |

| Wang F J. Computational Fluid Dynamics Analysis—CFD Software Principles and Applications[M]. Beijing: Tsinghua University Press, 2004. | |

| [31] | Launder B E, Spalding D B. Lectures in mathematical model of turbulence[D]. New York: Academic Press, 1972. |

| [32] | 刘伟, 刘志春, 马雷. 多场协同原理在管内对流强化传热性能评价中的应用[J]. 科学通报, 2012, 57(10): 867-874. |

| Liu W, Liu Z C, Ma L. Physical quantity application of a multi-field synergy principle in the performance evaluation of convective heat transfer enhancement in a tube[J]. Chinese Science Bulletin, 2012, 57(10): 867-874. | |

| [33] | 费凤繁, 陈亚平, 吴嘉峰, 等. 半圆柱空间异形孔板换热器热工水力性能的数值模拟[J]. 热能动力工程, 2023, 38(3): 126-132. |

| Fei F F, Chen Y P, Wu J F, et al. Numerical simulation of thermal and hydraulic performance of heat exchanger with orifice baffles in half cylindrical space[J]. Journal of Engineering for Thermal Energy and Power, 2023, 38(3): 126-132. | |

| [34] | 曹穆霁. 新型折流板管壳式换热器的传热研究[D]. 杭州: 浙江科技学院, 2022. |

| Cao M J. Study on heat transfer of a new baffled shell and tube heat exchanger[D]. Hangzhou: Zhejiang University of Science and Technology, 2022. | |

| [35] | 蒋屹. 铅铋合金-超临界二氧化碳换热器流动换热特性研究[D]. 北京: 华北电力大学(北京), 2022. |

| Jiang Y. Study on the heat transfer characteristics of lead bismuth eutectic and supercritical carbon dioxide in heat exchanger[D]. Beijing: North China Electric Power University (Beijing), 2022. | |

| [36] | Goyal M, Chakravarty A, Atrey M D. Experimental investigations and validation of two dimensional model for multistream plate fin heat exchangers[J]. Cryogenics, 2017, 82: 83-91. |

| [37] | Grzywacz R, Teper M. Experimental validation of a CFD model of a ground heat exchanger with slinky coils[J]. Polish Journal of Chemical Technology, 2024, 26(2): 86-91. |

| [38] | 田元. 大型循环流化床锅炉风室与布风板联合布风均匀性数值模拟与试验研究[D]. 重庆: 重庆大学, 2018. |

| Tian Y. Numerical simulation and experimental investigation of air flow uniformity in the windbox of large-scale CFB boiler[D]. Chongqing: Chongqing University, 2018. | |

| [39] | 王华东, 姚来军, 王金辉, 等. 等压送风在小吨位锅炉设计上的应用[J]. 电器工业, 2004(7): 38-39. |

| Wang H D, Yao L J, Wang J H, et al. Application of isobaric air supply in the design of small tonnage boilers[J]. China Electrical Equipment Industry, 2004(7): 38-39. | |

| [40] | 孟继安. 基于场协同理论的纵向涡强化换热技术及其应用[D]. 北京: 清华大学, 2003. |

| Meng J A. Enhanced heat transfer technology of longitudinal vortices based on field-coordination principle and its application[D]. Beijing: Tsinghua University, 2003. | |

| [41] | 包晓琳. 幂律流体螺旋管内流场与温度场协同优化研究[D]. 济南: 山东建筑大学, 2020. |

| Bao X L. Study on collaborative optimization of flow field and temperature field of power-law fluid in spiral tube[D]. Jinan: Shandong Jianzhu University, 2020. | |

| [42] | 周俊杰, 陶文铨, 王定标. 场协同原理评价指标的定性分析和定量探讨[J]. 郑州大学学报(工学版), 2006, 27(2): 45-47. |

| Zhou J J, Tao W Q, Wang D B. Qualitative analysis and quantitative discussion of index for field synergy principle[J]. Journal of Zhengzhou University (Engineering Science), 2006, 27(2): 45-47. |

| [1] | Haolei DUAN, Haoyuan CHEN, Kunfeng LIANG, Lin WANG, Bin CHEN, Yong CAO, Chenguang ZHANG, Shuopeng LI, Dengyu ZHU, Yaru HE, Dapeng YANG. Performance analysis and comprehensive evaluation of thermal management system schemes with low GWP refrigerants [J]. CIESC Journal, 2025, 76(S1): 54-61. |

| [2] | Junpeng WANG, Jiaqi FENG, Enbo ZHANG, Bofeng BAI. Study on flow and cavitation characteristic in zigzag and array labyrinth valve core structures [J]. CIESC Journal, 2025, 76(S1): 93-105. |

| [3] | Zixiang ZHAO, Zhongdi DUAN, Haoran SUN, Hongxiang XUE. Numerical modelling of water hammer induced by two phase flow with large temperature difference [J]. CIESC Journal, 2025, 76(S1): 170-180. |

| [4] | Hao HUANG, Wen WANG, Longkun HE. Simulation and analysis on precooling process of membrane LNG carriers [J]. CIESC Journal, 2025, 76(S1): 187-194. |

| [5] | Bo HUANG, Hao HUANG, Wen WANG, Longkun HE. Analysis of temperature field of membrane liquid cargo in a LNG carrier [J]. CIESC Journal, 2025, 76(S1): 195-204. |

| [6] | Siyuan WANG, Guoqiang LIU, Tong XIONG, Gang YAN. Characteristics of non-uniform wind velocity distribution in window air conditioner axial fans and their impact on optimizing condenser circuit optimization [J]. CIESC Journal, 2025, 76(S1): 205-216. |

| [7] | Qingtai CAO, Songyuan GUO, Jianqiang LI, Zan JIANG, Bin WANG, Rui ZHUAN, Jingyi WU, Guang YANG. Numerical study on influence of perforated plate on retention performance of liquid oxygen tank under negative gravity [J]. CIESC Journal, 2025, 76(S1): 217-229. |

| [8] | Jiuchun SUN, Yunlong SANG, Haitao WANG, Hao JIA, Yan ZHU. Study on influence of jet flow on slurry transport characteristics in slurry chamber of shield tunneling machines [J]. CIESC Journal, 2025, 76(S1): 246-257. |

| [9] | Yifan SHI, Gang KE, Hao CHEN, Xiaosheng HUANG, Fang YE, Chengjiao LI, Hang GUO. Simulation of temperature control in large-scale high and low temperature environmental laboratory [J]. CIESC Journal, 2025, 76(S1): 268-280. |

| [10] | Ting HE, Shuyang HUANG, Kun HUANG, Liqiong CHEN. Research on the coupled process of natural gas chemical absorption decarbonization and high temperature heat pump based on waste heat utilization [J]. CIESC Journal, 2025, 76(S1): 297-308. |

| [11] | Ting HE, Kai ZHANG, Wensheng LIN, Liqiong CHEN, Jiafu CHEN. Research on integrated process of cryogenic CO2 removal under supercritical pressure and liquefaction for biogas [J]. CIESC Journal, 2025, 76(S1): 418-425. |

| [12] | Xinquan SHA, Ran HU, Lei DING, Zhenhua JIANG, Yinong WU. Development and testing of an independent two-stage valved linear compressor for space applications [J]. CIESC Journal, 2025, 76(S1): 114-122. |

| [13] | Haoran SUN, Chengyun WU, Yanmeng WANG, Jingnan SUN, Renyu HU, Zhongdi DUAN. Modeling and experimental study on the evaporation characteristics of liquid droplets subject to thermal convection [J]. CIESC Journal, 2025, 76(S1): 123-132. |

| [14] | Zhihong JIANG, Qian LEI, Yinjun ZHU, Zhigang LEI, Honglin CHEN. Study on physical property model and enrichment process of trioxane system [J]. CIESC Journal, 2025, 76(9): 4872-4881. |

| [15] | Kaiyuan YANG, Xizhong CHEN. Comparison of discrete element method and finite-discrete element method for simulation of agglomerate breakage [J]. CIESC Journal, 2025, 76(9): 4398-4411. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||