CIESC Journal ›› 2020, Vol. 71 ›› Issue (5): 2202-2214.DOI: 10.11949/0438-1157.20191586

• Surface and interface engineering • Previous Articles Next Articles

Cheng GE( ),Jianjun SUN(

),Jianjun SUN( ),Xuchen SU,Chenbo MA,Qiuping YU

),Xuchen SU,Chenbo MA,Qiuping YU

Received:2019-12-26

Revised:2020-03-03

Online:2020-05-05

Published:2020-05-05

Contact:

Jianjun SUN

通讯作者:

孙见君

作者简介:葛诚(1994—),男,硕士研究生,基金资助:CLC Number:

Cheng GE, Jianjun SUN, Xuchen SU, Chenbo MA, Qiuping YU. Performance analysis on diffuser self-pumping hydrodynamic and hydrostatic mechanical seal[J]. CIESC Journal, 2020, 71(5): 2202-2214.

葛诚, 孙见君, 苏徐辰, 马晨波, 於秋萍. 扩压式自泵送流体动静压型机械密封性能分析[J]. 化工学报, 2020, 71(5): 2202-2214.

Add to citation manager EndNote|Ris|BibTeX

| 边界 | 边界类型 |

|---|---|

| 引流孔道E | pressure-inlet(P|E=p o) |

| 内径AB | pressure-outlet (P|AB=p i) |

| 外径CD | pressure-outlet (P|CD=p o) |

| 环槽FG、HI | periodic boundary(P|FG=P|HI) |

| 液膜AD、BC | periodic boundary(P|AD=P|BC) |

| 引流孔低面与环槽上表面 | interface |

| 环槽下表明与液膜上表面 | interface |

| 液膜下表面与螺旋槽上表面 | interface |

| 螺旋槽出口JK与扩压环内径侧面LM | interface |

| 螺旋槽底面 | moving wall |

| 螺旋槽两侧面和内径侧面 | moving wall |

| 其余壁面 | stationary wall |

Table 1 Boundary condition setting

| 边界 | 边界类型 |

|---|---|

| 引流孔道E | pressure-inlet(P|E=p o) |

| 内径AB | pressure-outlet (P|AB=p i) |

| 外径CD | pressure-outlet (P|CD=p o) |

| 环槽FG、HI | periodic boundary(P|FG=P|HI) |

| 液膜AD、BC | periodic boundary(P|AD=P|BC) |

| 引流孔低面与环槽上表面 | interface |

| 环槽下表明与液膜上表面 | interface |

| 液膜下表面与螺旋槽上表面 | interface |

| 螺旋槽出口JK与扩压环内径侧面LM | interface |

| 螺旋槽底面 | moving wall |

| 螺旋槽两侧面和内径侧面 | moving wall |

| 其余壁面 | stationary wall |

| 参数 | 数值 |

|---|---|

| 密封环外径,r k/mm | 46.5~50 |

| 螺旋槽外径,r o/mm | 44.5 |

| 螺旋槽根径,r g/mm | 35.5 |

| 密封环内径,r i/mm | 26.5 |

| 扩压环深,h k/μm | 40~60 |

| 螺旋槽深,h g/μm | 50 |

| 膜厚,h c/μm | 1.2 |

| 槽台宽比,γ | 0.5~0.9 |

| 槽数,N g | 16~30 |

| 螺旋角,α/(°) | 22~50 |

| 引流环槽宽,L/mm | 2 |

| 引流环槽深,H/mm | 0.5 |

| 引流孔径,D/mm | 2 |

| 密封介质压差,Δp/MPa | 0.1~0.9 |

| 转速,n/(r?min-1) | 600~6000 |

Table 2 Numerical simulation parameters

| 参数 | 数值 |

|---|---|

| 密封环外径,r k/mm | 46.5~50 |

| 螺旋槽外径,r o/mm | 44.5 |

| 螺旋槽根径,r g/mm | 35.5 |

| 密封环内径,r i/mm | 26.5 |

| 扩压环深,h k/μm | 40~60 |

| 螺旋槽深,h g/μm | 50 |

| 膜厚,h c/μm | 1.2 |

| 槽台宽比,γ | 0.5~0.9 |

| 槽数,N g | 16~30 |

| 螺旋角,α/(°) | 22~50 |

| 引流环槽宽,L/mm | 2 |

| 引流环槽深,H/mm | 0.5 |

| 引流孔径,D/mm | 2 |

| 密封介质压差,Δp/MPa | 0.1~0.9 |

| 转速,n/(r?min-1) | 600~6000 |

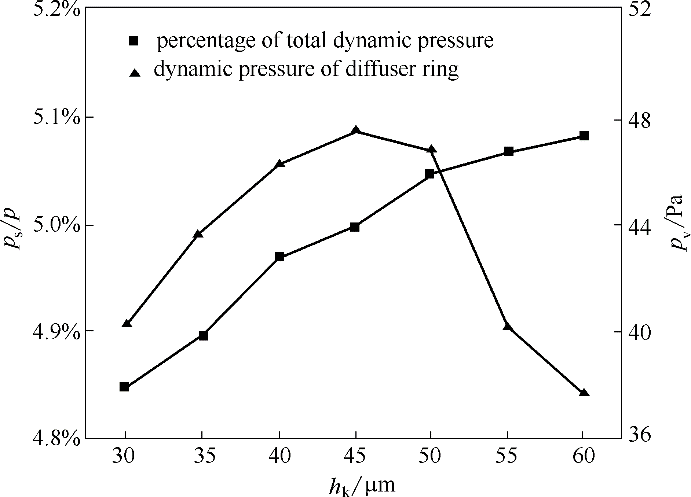

Fig.12 Effect of diffuser ring depth on dynamic and static pressure change of liquid membrane (r k=49.5 mm,r o=44.5 mm,N g=18,γ=0.5,α=22°,Δp=0.5 MPa,n=4000 r·min-1)

| 1 | 阿兰·O勒贝克 . 机械密封原理与设计[M]. 北京: 机械工业出版社, 2016. |

| Alan O L . Principles and Design of Mechanical Face Seals[M]. Beijing: China Machine Press, 2016. | |

| 2 | Lai T . Development of non-contacting, non-leaking spiral groove liquid face seals[J]. Lubrication Engineering, 1994, 50(8): 625-631. |

| 3 | Wang B , Zhang H , Cao H . Flow dynamics of a spiral-groove dry-gas seal[J]. Chinese Journal of Mechanical Engineering, 2013, 26(1): 78-84. |

| 4 | Buck G S , Volden D . Upstream pumping: a new concept in mechanical sealing technology[J]. Lubrication Engineering, 1990, 46(4): 213-217. |

| 5 | 潘向东, 郭巍, 崔均, 等 . 机械密封辅助冲洗系统探讨与优化应用探索[J]. 石油和化工设备, 2019, 22(10): 106-108. |

| Pan X D , Guo W , Cui J , et al . Exploration and optimized application of mechanical seal aided flushing system[J]. Petro & Chemical Equipment, 2019, 22(10): 106-108. | |

| 6 | Qiu Y , Khonsari M M . Thermo hydrodynamic analysis of spiral groove mechanical face seal for liquid applications[J]. Journal of Tribology, 2012, 134(2): 021703-021713. |

| 7 | 陈汇龙, 左木子, 吴强波, 等 . 上游泵送机械密封润滑膜固液两相流动特性[J]. 排灌机械工程学报, 2015, 33(8): 685-690. |

| Chen H L , Zuo M Z , Wu Q B , et al . Study on solid-liquid two-phase flow characteristics of lubricating film in upstream pumping mechanical seal[J]. Journal of Drainage and Irrigation Machinery Engineering, 2015, 33(8): 685-690. | |

| 8 | 孙见君, 王敏, 周敏, 等 . 自泵送流体动压型机械密封: 103267132A[P]. 2013-05-28. |

| Sun J J , Wang M , Zhou M , et al . Self-pumping mechanical seal based on fluid dynamic pressure principle: 103267132A[P]. 2013-05-28. | |

| 9 | 陆建花, 孙见君, 陈卫, 等 . 自泵送机械密封与螺旋槽机械密封的性能比较[J]. 化工学报, 2016, 67(10): 4370-4377. |

| Lu J H , Sun J J , Chen W , et al . Performance comparison of self-pumping and spiral groove mechanical seals[J]. CIESC Journal, 2016, 67(10): 4370-4377. | |

| 10 | 顾东升, 孙见君, 马晨波, 等 . 基于数值模拟的自泵送机械密封正交试验[J]. 化工学报, 2015, 66(7): 2464-2473. |

| Gu D S , Sun J J , Ma C B , et al . Orthogonal test of self-pumping mechanical seal based on numerical simulation[J]. CIESC Journal, 2015, 66(7): 2464-2473. | |

| 11 | 陈群, 孙见君 . 自泵送流体动静压型机械密封自清洁性分析[J]. 摩擦学学报, 2019, 39(3): 259-268. |

| Chen Q , Sun J J . Analysis of self-cleaning for self-pumping hydrodynamic and hydrostatic mechanical seal[J]. Tribology, 2019, 39(3): 259-268. | |

| 12 | Sun J J , Ma C B , Yu Q P , et al . Numerical analysis on a new pump-out hydrodynamic mechanical seal[J]. Tribology International, 2017, 106: 62-70. |

| 13 | 周敏, 孙见君, 马晨波, 等 . 自泵送流体动压型机械密封性能分析[J]. 化工学报, 2015, 66(2): 687-694. |

| Zhou M , Sun J J , Ma C B , et al . Analysis of self-pumped hydrodynamic mechanical seal performance[J]. CIESC Journal, 2015, 66(2): 687-694. | |

| 14 | Zhang G , Chen G , Zhao W , et al . An experimental test on a cryogenic high-speed hydrodynamic non-contact mechanical seal[J]. Tribology Letters, 2017, 65(3): 80-91. |

| 15 | 刘瑞韬, 徐忠 . 离心叶轮机械内部流动的研究进展[J]. 力学进展, 2003, 33(4): 518-532. |

| Liu R T , Xu Z . The research development of internal flow in centrifugal turbomachinery[J]. Advances in Mechanics, 2003, 33(4): 518-532. | |

| 16 | 韩戈, 阳诚武, 李紫良, 等 . 离心压气机管式扩压器研究进展及评述[J]. 航空学报, 2017, 38(9): 51-62. |

| Han G , Yang C W , Li Z L , et al . A review of studies on pipe diffuser of centrifugal compressor[J]. Acta Aeronautica et Astronautica Sinica, 2017, 38(9): 51-62. | |

| 17 | 程超, 秦国良, 张家忠, 等 . 扩压器对基本级性能的影响[J]. 航空动力学报, 2017, 32(1): 248-256. |

| Cheng C , Qin G L , Zhang J Z , et al . Influence of diffuser on basic stage performance[J]. Journal of Aerospace Power, 2017, 32(1): 248-256. | |

| 18 | Hu J B , Tao W J , Zhao Y M , et al . Numerical analysis of general groove geometry for dry gas seals[J]. Applied Mechanics and Materials, 2014, 457: 544-551. |

| 19 | 西安交通大学透平压缩机教研室 . 离心式压缩机原理[M]. 北京: 机械工业出版社, 1980. |

| Turbine and Compressor Lab on Xi an Jiaotong University . Fundamentals of Centrifugal Compressor[M]. Beijing: Machinery Industry Press, 1980. | |

| 20 | 黄苗苗, 李国君, 匡晓峰 . 水环真空泵内部气液两相流动的数值分析[J]. 船舶力学, 2011, 15(7): 722-729. |

| Huang M M , Li G J , Kuang X F . Numerical simulation of the gas-liquid two-phase flow in water-ring vacuum pump[J]. Journal of Ship Mechanics, 2011, 15(7): 722-729. | |

| 21 | Li Y , Song P Y , Xu H J . Performance analyses of the spiral groove dry gas seal with inner annular groove[J]. Applied Mechanics & Materials, 2013, 420: 51-55. |

| 22 | Wang Q , Chen H L . Research on performance of upstream pumping mechanical seal with different deep spiral groove[C]//IOP Conference Series: Earth and Environmental Science. IOP Publishing, 2012, 15(7): 072019-072027. |

| 23 | Basu P . Analysis of a radial groove gas face seal[J]. ASLE Transactions, 1992, 35(1): 11-20. |

| 24 | Nicolescu B N , Petrescu T C . Homogenization of the Reynolds equation in the radial face seals case[J]. Asymptotic Analysis, 2013, 81(1): 35-52. |

| 25 | 胡坤, 李振北 . ANSYS ICEM CFD工程实例详解[M]. 北京: 人民邮电出版社, 2014. |

| Hu K , Li Z B . Detailed Explanation of ANSYS ICEM CFD Engineering Example[M]. Beijing: Posts & Telecom Press, 2014. | |

| 26 | Ruan B . Finite element analysis of the spiral groove gas face seal at the slow speed and the low pressure conditions-slip flow consideration[J]. Tribology Transactions, 2000, 43(3): 411-418. |

| 27 | Hu X P , Song P Y . Theoretic analysis of the effect of real gas on the performance of the T-groove and radial groove dry gas seal[J]. Applied Mechanics and Materials, 2013, 271: 1218–1223. |

| 28 | 王福军 . 计算流体动力学分析: CFD软件原理与应用[M]. 北京: 清华大学出版社, 2004. |

| Wang F J . Computational Fluid Dynamics Analysis: Theory and Application of CFD Software[M]. Beijing: Tsinghua University Press, 2004. | |

| 29 | 宋鹏云, 陈匡民, 董宗玉, 等 . 端面内侧开螺旋槽机械密封性能的实验研究[J]. 润滑与密封, 2000, (4): 34-35. |

| Song P Y , Chen K M , Dong Z Y , et al . An experimental investigation of the seal characteristics of an internal spiral grove mechanical seal[J]. Lubrication Engineering, 2000, (4): 34-35. | |

| 30 | 宋鹏云 . 螺旋槽上游泵送机械密封性能影响因素分析[J]. 润滑与密封, 2000, (3): 50-53. |

| Song P Y . An analysis of factors affecting the characteristics of an upstream pumping mechanical seal[J]. Lubrication Engineering, 2000, (3): 50-53. | |

| 31 | 宋鹏云, 陈匡民, 董宗玉, 等 . 螺旋槽上游泵送机械密封性能的解析计算[J]. 润滑与密封, 1999, (4): 5-7. |

| Song P Y , Chen K M , Dong Z Y , et al . A theoretical analysis of spiral groove upstream pumping mechanical seal[J]. Lubrication Engineering, 1999, (4): 5-7. | |

| 32 | 姜培正 . 过程流体机械[M]. 北京: 化学工业出版社, 2001. |

| Jiang P Z . Process Fluid Machinery[M]. Beijing: Chemical Industry Press, 2001. |

| [1] | Zhanyu YE, He SHAN, Zhenyuan XU. Performance simulation of paper folding-like evaporator for solar evaporation systems [J]. CIESC Journal, 2023, 74(S1): 132-140. |

| [2] | Xiaoqing ZHOU, Chunyu LI, Guang YANG, Aifeng CAI, Jingyi WU. Icing kinetics and mechanism of droplet impinging on supercooled corrugated plates with different curvature [J]. CIESC Journal, 2023, 74(S1): 141-153. |

| [3] | Lisen BI, Bin LIU, Hengxiang HU, Tao ZENG, Zhuorui LI, Jianfei SONG, Hanming WU. Molecular dynamics study on evaporation modes of nanodroplets at rough interfaces [J]. CIESC Journal, 2023, 74(S1): 172-178. |

| [4] | Yifei ZHANG, Fangchen LIU, Shuangxing ZHANG, Wenjing DU. Performance analysis of printed circuit heat exchanger for supercritical carbon dioxide [J]. CIESC Journal, 2023, 74(S1): 183-190. |

| [5] | Zhiguo WANG, Meng XUE, Yushuang DONG, Tianzhen ZHANG, Xiaokai QIN, Qiang HAN. Numerical simulation and analysis of geothermal rock mass heat flow coupling based on fracture roughness characterization method [J]. CIESC Journal, 2023, 74(S1): 223-234. |

| [6] | Jiahao SONG, Wen WANG. Study on coupling operation characteristics of Stirling engine and high temperature heat pipe [J]. CIESC Journal, 2023, 74(S1): 287-294. |

| [7] | Siyu ZHANG, Yonggao YIN, Pengqi JIA, Wei YE. Study on seasonal thermal energy storage characteristics of double U-shaped buried pipe group [J]. CIESC Journal, 2023, 74(S1): 295-301. |

| [8] | Junfeng LU, Huaiyu SUN, Yanlei WANG, Hongyan HE. Molecular understanding of interfacial polarization and its effect on ionic liquid hydrogen bonds [J]. CIESC Journal, 2023, 74(9): 3665-3680. |

| [9] | Kaijie WEN, Li GUO, Zhaojie XIA, Jianhua CHEN. A rapid simulation method of gas-solid flow by coupling CFD and deep learning [J]. CIESC Journal, 2023, 74(9): 3775-3785. |

| [10] | Song HE, Qiaomai LIU, Guangshuo XIE, Simin WANG, Juan XIAO. Two-phase flow simulation and surrogate-assisted optimization of gas film drag reduction in high-concentration coal-water slurry pipeline [J]. CIESC Journal, 2023, 74(9): 3766-3774. |

| [11] | Lei XING, Chunyu MIAO, Minghu JIANG, Lixin ZHAO, Xinya LI. Optimal design and performance analysis of downhole micro gas-liquid hydrocyclone [J]. CIESC Journal, 2023, 74(8): 3394-3406. |

| [12] | Dian LIN, Guomei JIANG, Xiubin XU, Bo ZHAO, Dongmei LIU, Xu WU. Preparation and drag reduction effect of silicon-based liquid-like anti-crude-oil-adhesion coatings [J]. CIESC Journal, 2023, 74(8): 3438-3445. |

| [13] | Chen HAN, Youmin SITU, Bin ZHU, Jianliang XU, Xiaolei GUO, Haifeng LIU. Study of reaction and flow characteristics in multi-nozzle pulverized coal gasifier with co-processing of wastewater [J]. CIESC Journal, 2023, 74(8): 3266-3278. |

| [14] | Yu FU, Xingchong LIU, Hanyu WANG, Haimin LI, Yafei NI, Wenjing ZOU, Yue LEI, Yongshan PENG. Research on F3EACl modification layer for improving performance of perovskite solar cells [J]. CIESC Journal, 2023, 74(8): 3554-3563. |

| [15] | Xiaosong CHENG, Yonggao YIN, Chunwen CHE. Performance comparison of different working pairs on a liquid desiccant dehumidification system with vacuum regeneration [J]. CIESC Journal, 2023, 74(8): 3494-3501. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||