CIESC Journal ›› 2021, Vol. 72 ›› Issue (S1): 482-493.DOI: 10.11949/0438-1157.20201771

• Energy and environmental engineering • Previous Articles Next Articles

CHEN Chen( ),WANG Mingming,WANG Zhigang(

),WANG Mingming,WANG Zhigang( ),TAN Xiaoyao(

),TAN Xiaoyao( )

)

Received:2020-12-09

Revised:2021-01-15

Online:2021-06-20

Published:2021-06-20

Contact:

WANG Zhigang,TAN Xiaoyao

通讯作者:

王志刚,谭小耀

作者简介:陈晨(1995—),女,硕士研究生,基金资助:CLC Number:

CHEN Chen, WANG Mingming, WANG Zhigang, TAN Xiaoyao. Hydrogen production by ethanol autothermal reforming using nickel-based asymmetric hollow fiber membranes[J]. CIESC Journal, 2021, 72(S1): 482-493.

陈晨, 王明明, 王志刚, 谭小耀. 镍基非对称中空纤维膜用于乙醇自热重整制氢[J]. 化工学报, 2021, 72(S1): 482-493.

Add to citation manager EndNote|Ris|BibTeX

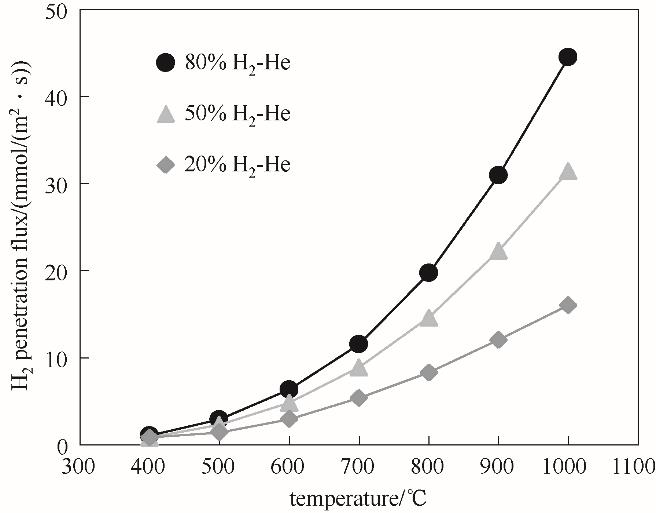

Fig.3 H2 permeation flux of Ni hollow fiber membrane as a function of temperature at different feed concentrations (H2-He feed rate=30 ml/min; N2 sweep rate=60 ml/min)

Fig.4 Ethanol autothermal reforming in Ni hollow fiber membrane reactor and blank reactor at different temperatures, ethanol conversion, hydrogen yield, product concentration of MR and Blank (Reaction conditions: S/C=4, O2/C=0.8, no sweep gas, feed flow rate=13 μl/min)

Fig.5 Effect of sweep gas flow rate on ethanol conversion, hydrogen yield, CO selectivity and hydrogen penetration flux at different temperatures (Reaction conditions: S/C=4, O2/C=0.8, sweep gas flow rate=0,30,50,70 ml/min, feed flow rate=13 μl/min)

Fig.6 Effect of S/C on ethanol conversion, hydrogen yield, CO selectivity and hydrogen penetration flux at different temperatures (Reaction conditions: S/C=3,4,5,6, O2/C=0.8, sweep gas flow rate=30 ml/min, feed flow rate=13 μl/min)

Fig.7 Effect of O2/C on ethanol conversion, hydrogen yield, CO selectivity and hydrogen penetration flux at different temperatures (Reaction conditions: S/C=4, O2/C=0,0.5,0.8,1, sweep gas flow rate=30 ml/min, feed flow rate=13 μl/min)

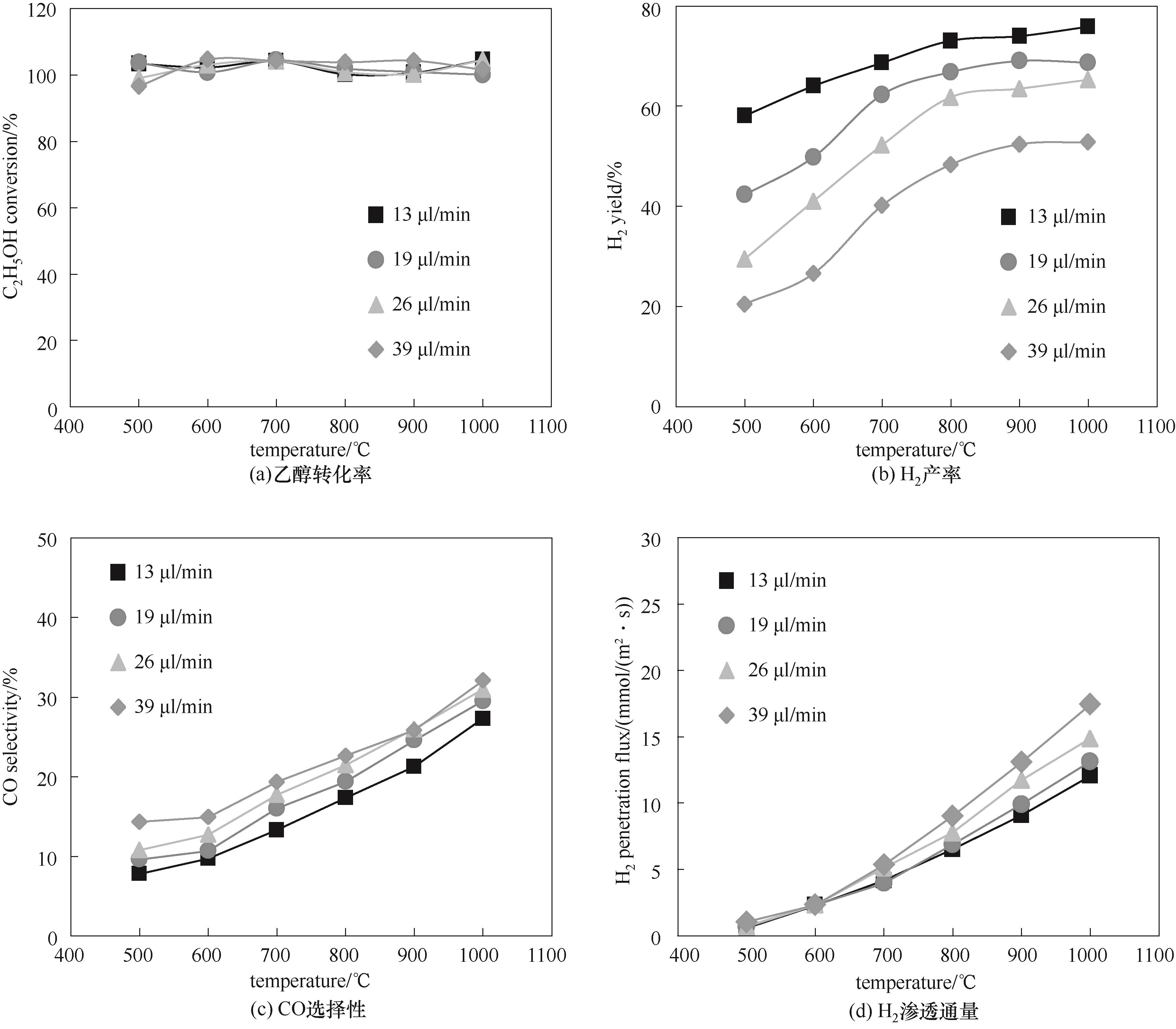

Fig.8 Effect of feed flow rate on ethanol conversion, hydrogen yield, CO selectivity and hydrogen permeation flux at different temperatures (Reaction conditions: S/C=4, O/C=0.8, sweep gas flow rate=30 ml/min, feed flow rate=13,19,26,39 μl/min)

Fig.10 Morphology of Ni hollow fiber membranes after ESR (a) and EATR (b) hydrogen permeation tests; EDS mappings (c) and EDS patterns (d) of nickel hollow fiber membranes before and after ESR and EATR hydrogen permeation tests

| 1 | Ni M, Leung D Y C, Leung M K H. A review on reforming bio-ethanol for hydrogen production [J]. International Journal of Hydrogen Energy, 2007, 32(15): 3238-3247. |

| 2 | Lin H Q, He Z J, Sun Z, et al. CO2-selective membranes for hydrogen production and CO2 capture (I): Membrane development [J]. Journal of Membrane Science, 2014, 457: 149-161. |

| 3 | Mazloomi K, Gomes C. Hydrogen as an energy carrier: prospects and challenges [J]. Renewable and Sustainable Energy Reviews, 2012, 16(5): 3024-3033. |

| 4 | Spallina V, Matturro G, Ruocco C, et al. Direct route from ethanol to pure hydrogen through autothermal reforming in a membrane reactor: experimental demonstration, reactor modelling and design [J]. Energy, 2018, 143: 666-681. |

| 5 | Conte M, Iacobazzi A, Ronchetti M, et al. Hydrogen economy for a sustainable development: state-of-the-art and technological perspectives [J]. Journal of Power Sources, 2001, 100(1/2): 171-187. |

| 6 | Lin W H, Liu Y C, Chang H F. Hydrogen production from oxidative steam reforming of ethanol in a palladium-silver alloy composite membrane reactor [J]. Journal of the Chinese Institute of Chemical Engineers, 2008, 39(5): 435-440. |

| 7 | Lin W H, Liu Y C, Chang H F. Autothermal reforming of ethanol in a Pd-Ag/Ni composite membrane reactor [J]. International Journal of Hydrogen Energy, 2010, 35(23): 12961-12969. |

| 8 | Weng S F, Wang Y H, Lee C S. Autothermal steam reforming of ethanol over La2Ce2-xRuxO7 (x = 0~0.35) catalyst for hydrogen production [J]. Applied Catalysis B: Environmental, 2013, 134/135: 359-366. |

| 9 | Iulianelli A, Palma V, Bagnato G, et al. From bioethanol exploitation to high grade hydrogen generation: steam reforming promoted by a Co-Pt catalyst in a Pd-based membrane reactor [J]. Renewable Energy, 2018, 119: 834-843. |

| 10 | Graschinsky C, Giunta P, Amadeo N, et al. Thermodynamic analysis of hydrogen production by autothermal reforming of ethanol [J]. International Journal of Hydrogen Energy, 2012, 37(13): 10118-10124. |

| 11 | Guil-López R, Navarro R M, Peña M A, et al. Hydrogen production by oxidative ethanol reforming on Co, Ni and Cu ex-hydrotalcite catalysts [J]. International Journal of Hydrogen Energy, 2011, 36(2): 1512-1523. |

| 12 | Espinal R, Anzola A, Adrover E, et al. Durable ethanol steam reforming in a catalytic membrane reactor at moderate temperature over cobalt hydrotalcite [J]. International Journal of Hydrogen Energy, 2014, 39(21): 10902-10910. |

| 13 | Cheng Y S, Peña M A, Fierro J L, et al. Performance of alumina, zeolite, palladium, Pd-Ag alloy membranes for hydrogen separation from Towngas mixture [J]. Journal of Membrane Science, 2002, 204(1/2): 329-340. |

| 14 | Paiman S H, Rahman M A, Othman M H D, et al. Morphological study of yttria-stabilized zirconia hollow fibre membrane prepared using phase inversion/sintering technique [J]. Ceramics International, 2015, 41(10): 12543-12553. |

| 15 | Tan X Y, Liu Y T, Li K. Preparation of LSCF ceramic hollow-fiber membranes for oxygen production by a phase-inversion/sintering technique [J]. Industrial & Engineering Chemistry Research, 2005, 44(1): 61-66. |

| 16 | Lytkina A A, Orekhova N V, Ermilova M M, et al. Ru Rh based catalysts for hydrogen production via methanol steam reforming in conventional and membrane reactors [J]. International Journal of Hydrogen Energy, 2019, 44(26): 13310-13322. |

| 17 | Haag S, Burgard M, Ernst B. Pure nickel coating on a mesoporous alumina membrane: preparation by electroless plating and characterization [J]. Surface and Coatings Technology, 2006, 201(6): 2166-2173. |

| 18 | Zhang K, Gade S K, Way J D. Effects of heat treatment in air on hydrogen sorption over Pd-Ag and Pd-Au membrane surfaces [J]. Journal of Membrane Science, 2012, 403/404: 78-83. |

| 19 | Maneerung T, Hidajat K, Kawi S. Ultra-thin (<1 μm) internally-coated Pd-Ag alloy hollow fiber membrane with superior thermal stability and durability for high temperature H2 separation [J]. Journal of Membrane Science, 2014, 452: 127-142. |

| 20 | Wang M M, Zhou Y L, Tan X Y, et al. Nickel hollow fiber membranes for hydrogen separation from reformate gases and water gas shift reactions operated at high temperatures [J]. Journal of Membrane Science, 2019, 575: 89-97. |

| 21 | Ryi S K, Park J S, Choi S H, et al. Fabrication and characterization of metal porous membrane made of Ni powder for hydrogen separation [J]. Separation and Purification Technology, 2006, 47(3): 148-155. |

| 22 | Ernst B, Haag S, Burgard M. Permselectivity of a nickel/ceramic composite membrane at elevated temperatures: a new prospect in hydrogen separation? [J]. Journal of Membrane Science, 2007, 288(1/2): 208-217. |

| 23 | Lee S K, Ohn Y G, Noh S J. Measurement of hydrogen permeation through nickel in the elevated temperature range of 450 — 850℃ [J]. Journal of the Korean Physical Society, 2013, 63(10): 1955-1961. |

| 24 | Wang Z G, Kathiraser Y, Kawi S. High performance oxygen permeable membranes with Nb-doped BaBi0.05Co0.95O3-δ perovskite oxides [J]. Journal of Membrane Science, 2013, 431: 180-186. |

| 25 | Tan X Y, Liu Y T, Li K. Mixed conducting ceramic hollow-fiber membranes for air separation [J]. AIChE Journal, 2005, 51(7): 1991-2000. |

| 26 | Wang Z G, Kathiraser Y, Soh T, et al. Ultra-high oxygen permeable BaBiCoNb hollow fiber membranes and their stability under pure CH4 atmosphere [J]. Journal of Membrane Science, 2014, 465: 151-158. |

| 27 | Liu Y T, Li K. Preparation of SrCe0.95Yb0.05O3-α hollow fibre membranes: study on sintering processes [J]. Journal of Membrane Science, 2005, 259(1/2): 47-54. |

| 28 | Wang M M, Tan X Y, Wang X B, et al. Asymmetric nickel hollow fibres as the catalytic membrane reactor for CO2 hydrogenation into syngas [J]. Chemical Communications, 2019, 55(29): 4226-4229. |

| 29 | Cross A, Miller J T, Danghyan V, et al. Highly active and stable Ni-Cu supported catalysts prepared by combustion synthesis for hydrogen production from ethanol [J]. Applied Catalysis A: General, 2019, 572: 124-133. |

| 30 | Ogo S, Sekine Y. Recent progress in ethanol steam reforming using non-noble transition metal catalysts: a review [J]. Fuel Processing Technology, 2020, 199: 106238. |

| 31 | Jia H Y, Zhang J X, Yu J F, et al. Efficient H2 production via membrane-assisted ethanol steam reforming over Ir/CeO2 catalyst [J]. International Journal of Hydrogen Energy, 2019, 44(45): 24733-24745. |

| 32 | Jin Y, Rui Z B, Tian Y, et al. Autothermal reforming of ethanol in dense oxygen permeation membrane reactor [J]. Catalysis Today, 2016, 264: 214-220. |

| [1] | Congqi HUANG, Yimei WU, Jianye CHEN, Shuangquan SHAO. Simulation study of thermal management system of alkaline water electrolysis device for hydrogen production [J]. CIESC Journal, 2023, 74(S1): 320-328. |

| [2] | Yanpeng WU, Xiaoyu LI, Qiaoyang ZHONG. Experimental analysis on filtration performance of electrospun nanofibers with amphiphobic membrane of oily fine particles [J]. CIESC Journal, 2023, 74(S1): 259-264. |

| [3] | Yitong LI, Hang GUO, Hao CHEN, Fang YE. Study on operating conditions of proton exchange membrane fuel cells with non-uniform catalyst distributions [J]. CIESC Journal, 2023, 74(9): 3831-3840. |

| [4] | Yepin CHENG, Daqing HU, Yisha XU, Huayan LIU, Hanfeng LU, Guokai CUI. Application of ionic liquid-based deep eutectic solvents for CO2 conversion [J]. CIESC Journal, 2023, 74(9): 3640-3653. |

| [5] | Jiayi ZHANG, Jiali HE, Jiangpeng XIE, Jian WANG, Yu ZHAO, Dongqiang ZHANG. Research progress of pervaporation technology for N-methylpyrrolidone recovery in lithium battery production [J]. CIESC Journal, 2023, 74(8): 3203-3215. |

| [6] | Yali HU, Junyong HU, Suxia MA, Yukun SUN, Xueyi TAN, Jiaxin HUANG, Fengyuan YANG. Development of novel working fluid and study on electrochemical characteristics of reverse electrodialysis heat engine [J]. CIESC Journal, 2023, 74(8): 3513-3521. |

| [7] | Yaxin CHEN, Hang YUAN, Guanzhang LIU, Lei MAO, Chun YANG, Ruifang ZHANG, Guangya ZHANG. Advances in enzyme self-immobilization mediated by protein nanocages [J]. CIESC Journal, 2023, 74(7): 2773-2782. |

| [8] | Xiaoling TANG, Jiarui WANG, Xuanye ZHU, Renchao ZHENG. Biosynthesis of chiral epichlorohydrin by halohydrin dehalogenase based on Pickering emulsion system [J]. CIESC Journal, 2023, 74(7): 2926-2934. |

| [9] | Zhaoguang CHEN, Yuxiang JIA, Meng WANG. Modeling neutralization dialysis desalination driven by low concentration waste acid and its validation [J]. CIESC Journal, 2023, 74(6): 2486-2494. |

| [10] | Lei MAO, Guanzhang LIU, Hang YUAN, Guangya ZHANG. Efficient preparation of carbon anhydrase nanoparticles capable of capturing CO2 and their characteristics [J]. CIESC Journal, 2023, 74(6): 2589-2598. |

| [11] | Tan ZHANG, Guang LIU, Jinping LI, Yuhan SUN. Performance regulation strategies of Ru-based nitrogen reduction electrocatalysts [J]. CIESC Journal, 2023, 74(6): 2264-2280. |

| [12] | Xiaowen ZHOU, Jie DU, Zhanguo ZHANG, Guangwen XU. Study on the methane-pulsing reduction characteristics of Fe2O3-Al2O3 oxygen carrier [J]. CIESC Journal, 2023, 74(6): 2611-2623. |

| [13] | Kuikui HAN, Xianglong TAN, Jinzhi LI, Ting YANG, Chun ZHANG, Yongfen ZHANG, Hongquan LIU, Zhongwei YU, Xuehong GU. Four-channel hollow fiber MFI zeolite membrane for the separation of xylene isomers [J]. CIESC Journal, 2023, 74(6): 2468-2476. |

| [14] | Yong LI, Jiaqi GAO, Chao DU, Yali ZHAO, Boqiong LI, Qianqian SHEN, Husheng JIA, Jinbo XUE. Construction of Ni@C@TiO2 core-shell dual-heterojunctions for advanced photo-thermal catalytic hydrogen generation [J]. CIESC Journal, 2023, 74(6): 2458-2467. |

| [15] | Lei WANG, Lei WANG, Yunlong BAI, Liuliu HE. Preparation of SA lithium ion sieve membrane and its adsorptive properties [J]. CIESC Journal, 2023, 74(5): 2046-2056. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||