CIESC Journal ›› 2024, Vol. 75 ›› Issue (3): 782-788.DOI: 10.11949/0438-1157.20231321

• Thermodynamics • Previous Articles Next Articles

Xinzi ZHOU( ), Zenghui LI, Xianyang MENG(

), Zenghui LI, Xianyang MENG( ), Jiangtao WU

), Jiangtao WU

Received:2023-12-11

Revised:2024-02-20

Online:2024-05-11

Published:2024-03-25

Contact:

Xianyang MENG

通讯作者:

孟现阳

作者简介:周辛梓(1996—),男,博士研究生,xinzizhou@stu.xjtu.edu.cn

基金资助:CLC Number:

Xinzi ZHOU, Zenghui LI, Xianyang MENG, Jiangtao WU. Experimental study on viscosity of high purity air at low temperatures[J]. CIESC Journal, 2024, 75(3): 782-788.

周辛梓, 李增辉, 孟现阳, 吴江涛. 低温下高纯空气黏度实验研究[J]. 化工学报, 2024, 75(3): 782-788.

Add to citation manager EndNote|Ris|BibTeX

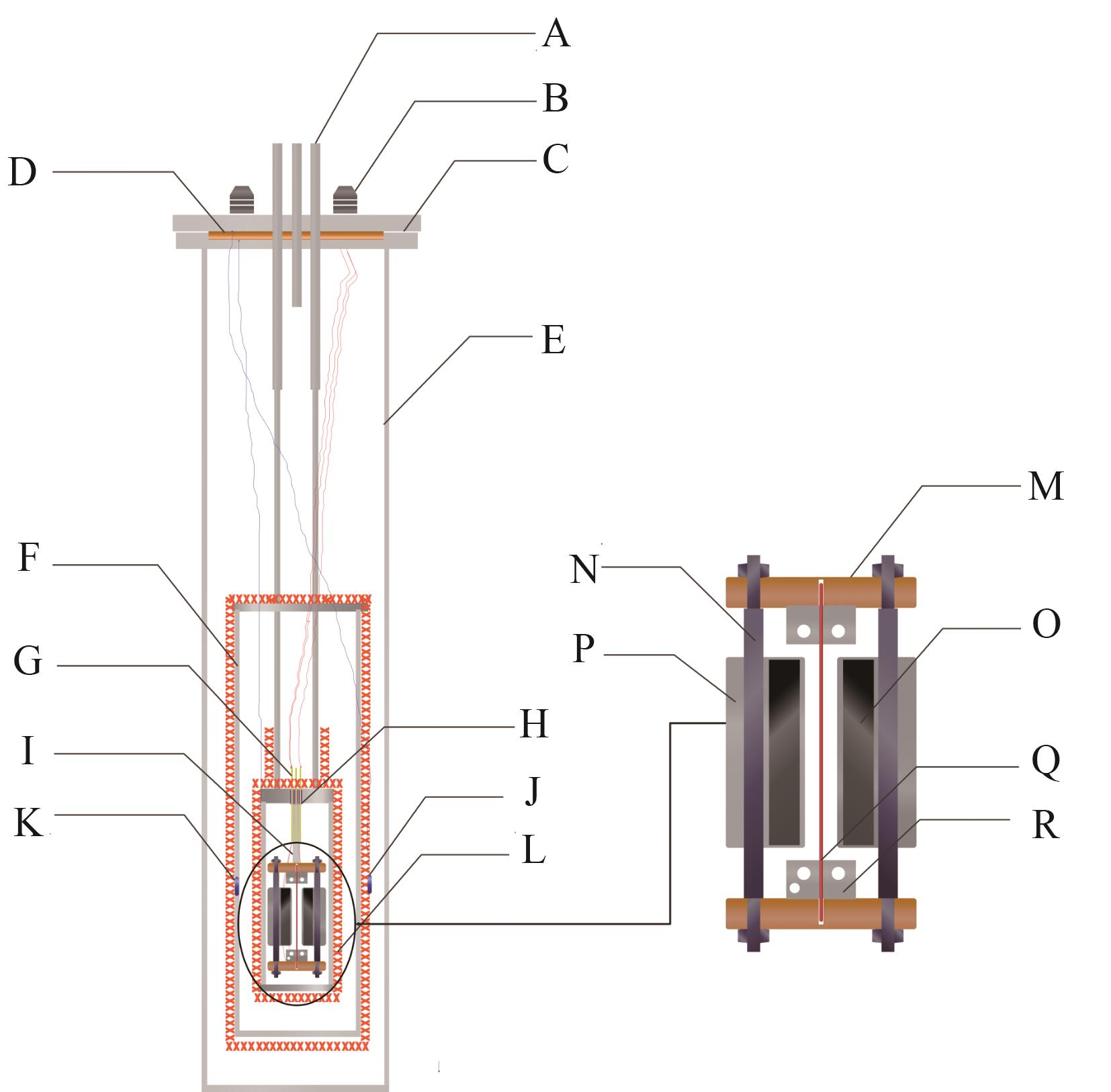

Fig.1 Schematic diagram of the vibrating-wire viscometer assemblyA—stainless-steel tube; B—aviation connector; C—ConFlat flange; D—gasket ring; E—external shield; F—heating wire; G—internal shield; H—Au-plated contact pin; I—suspension boom; J—platinum resistance thermometer 1; K—platinum resistance thermometer 2; L—measuring cell; M—alumina ceramics substrate; N—tungsten rod; O—magnet; P—stainless steel ring; Q—tungsten wire; R—clamp

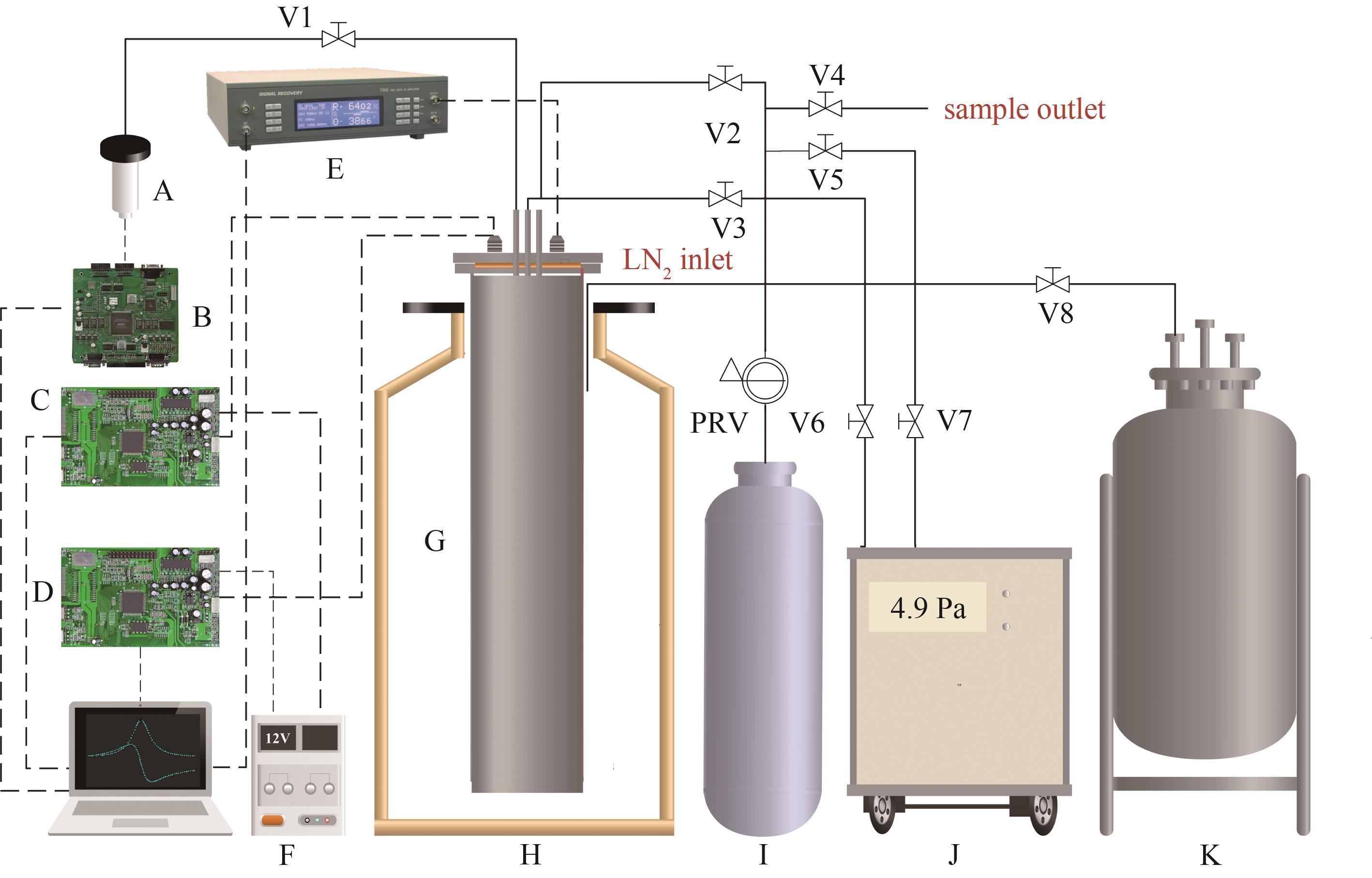

Fig. 2 Schematic diagram of the experimental setupA—pressure transducer; B—data-collecting measurement unit; C—temperature control and measurement unit 1; D—temperature control and measurement unit 2; E—lock-in amplifier; F—AC power supply; G—vibrating-wire viscometer; H—cryogenic Dewar bottle; I—sample container; J—vacuum pump; K—liquid nitrogen tank; PRV—relief valve; V1~V8—valves

| 参数 | 数值 | 来源 |

|---|---|---|

| 丝半径/μm | 24.34 | 液氮标定 |

| 丝长/mm | 50 | 测量 |

| 丝密度/(kg·m-3) | 19251.3 | 文献[ |

| 内部阻尼系数 | 2.77×10-5 | 真空测量 |

Table 1 Parameters of vibrating-wire viscometer

| 参数 | 数值 | 来源 |

|---|---|---|

| 丝半径/μm | 24.34 | 液氮标定 |

| 丝长/mm | 50 | 测量 |

| 丝密度/(kg·m-3) | 19251.3 | 文献[ |

| 内部阻尼系数 | 2.77×10-5 | 真空测量 |

| 来源 | 因素自身的 不确定度 | 黏度测量的不确定度 |

|---|---|---|

| 合计 | 2.64% | |

| 温度 | 18 mK | 0.1% |

| 压力 | 6 kPa | 0.1% |

| 丝半径 | 1% | 2% |

| 流体的密度计算及混合物的组分 | 0.8% | 0.8% |

| 金属丝的内部阻尼系数 | 30% | 1.4% |

| 钨丝的密度 | 30 kg·m-3 | 0.3% |

| 测量的重复性 | — | 0.5% |

Table 2 Contributions to uncertainty for the viscosity measurements.

| 来源 | 因素自身的 不确定度 | 黏度测量的不确定度 |

|---|---|---|

| 合计 | 2.64% | |

| 温度 | 18 mK | 0.1% |

| 压力 | 6 kPa | 0.1% |

| 丝半径 | 1% | 2% |

| 流体的密度计算及混合物的组分 | 0.8% | 0.8% |

| 金属丝的内部阻尼系数 | 30% | 1.4% |

| 钨丝的密度 | 30 kg·m-3 | 0.3% |

| 测量的重复性 | — | 0.5% |

| 状态 | 温度/K | 压力/MPa | 密度/(kg·m-3) | 黏度/(μPa·s) |

|---|---|---|---|---|

| 气态 | 100.00 | 0.45 | 17.27 | 6.46 |

| 110.00 | 0.50 | 17.03 | 7.22 | |

| 119.99 | 0.55 | 16.72 | 8.01 | |

| 119.99 | 1.14 | 39.02 | 8.47 | |

| 129.99 | 0.58 | 16.49 | 8.76 | |

| 129.99 | 1.25 | 38.30 | 9.25 | |

| 129.99 | 3.24 | 164.53 | 12.32 | |

| 139.99 | 0.62 | 16.27 | 9.45 | |

| 139.99 | 1.36 | 37.78 | 9.95 | |

| 139.99 | 2.81 | 93.19 | 10.93 | |

| 150.00 | 0.54 | 12.83 | 10.00 | |

| 150.00 | 1.03 | 25.49 | 10.39 | |

| 150.00 | 3.10 | 91.10 | 11.60 | |

| 160.00 | 0.57 | 12.66 | 10.70 | |

| 160.00 | 1.09 | 25.03 | 11.11 | |

| 160.00 | 3.36 | 89.06 | 12.35 | |

| 170.01 | 0.60 | 12.48 | 11.35 | |

| 170.01 | 1.15 | 24.60 | 11.42 | |

| 170.01 | 2.91 | 67.70 | 12.75 | |

| 180.00 | 1.20 | 24.18 | 12.41 | |

| 180.00 | 3.07 | 66.17 | 13.35 | |

| 180.01 | 0.54 | 10.51 | 11.85 | |

| 189.99 | 0.56 | 10.41 | 12.43 | |

| 190.00 | 0.81 | 15.14 | 12.71 | |

| 190.00 | 3.26 | 65.41 | 14.02 | |

| 液态 | 84.97 | 0.20 | 843.86 | 138.55 |

| 84.97 | 0.53 | 844.81 | 138.31 | |

| 84.97 | 0.87 | 845.78 | 140.88 | |

| 84.97 | 2.72 | 850.99 | 149.96 | |

| 89.99 | 0.31 | 819.06 | 118.54 | |

| 89.99 | 0.62 | 820.12 | 118.30 | |

| 89.99 | 1.29 | 822.40 | 120.74 | |

| 89.99 | 3.02 | 828.02 | 125.01 | |

| 89.99 | 4.73 | 833.29 | 129.19 | |

| 100.00 | 0.68 | 765.31 | 89.01 | |

| 100.00 | 0.98 | 766.85 | 88.75 | |

| 100.00 | 2.94 | 776.26 | 92.94 | |

| 100.01 | 4.92 | 784.76 | 98.13 | |

| 110.00 | 1.27 | 702.73 | 67.53 | |

| 110.00 | 2.91 | 715.74 | 70.50 | |

| 110.00 | 4.81 | 728.50 | 74.28 | |

| 119.99 | 2.16 | 576.18 | 49.90 | |

| 119.99 | 2.79 | 633.59 | 51.01 | |

| 119.99 | 4.85 | 660.56 | 56.57 | |

| 129.99 | 4.03 | 530.53 | 36.50 | |

| 129.99 | 4.81 | 560.47 | 40.62 | |

| 超临界态 | 139.99 | 4.85 | 282.17 | 17.78 |

| 150.00 | 4.72 | 168.43 | 13.75 | |

| 170.01 | 4.74 | 121.49 | 13.84 | |

| 180.00 | 4.83 | 111.42 | 14.20 | |

| 190.00 | 4.60 | 96.08 | 14.42 |

Table 3 Experimental data on viscosity of high-purity air

| 状态 | 温度/K | 压力/MPa | 密度/(kg·m-3) | 黏度/(μPa·s) |

|---|---|---|---|---|

| 气态 | 100.00 | 0.45 | 17.27 | 6.46 |

| 110.00 | 0.50 | 17.03 | 7.22 | |

| 119.99 | 0.55 | 16.72 | 8.01 | |

| 119.99 | 1.14 | 39.02 | 8.47 | |

| 129.99 | 0.58 | 16.49 | 8.76 | |

| 129.99 | 1.25 | 38.30 | 9.25 | |

| 129.99 | 3.24 | 164.53 | 12.32 | |

| 139.99 | 0.62 | 16.27 | 9.45 | |

| 139.99 | 1.36 | 37.78 | 9.95 | |

| 139.99 | 2.81 | 93.19 | 10.93 | |

| 150.00 | 0.54 | 12.83 | 10.00 | |

| 150.00 | 1.03 | 25.49 | 10.39 | |

| 150.00 | 3.10 | 91.10 | 11.60 | |

| 160.00 | 0.57 | 12.66 | 10.70 | |

| 160.00 | 1.09 | 25.03 | 11.11 | |

| 160.00 | 3.36 | 89.06 | 12.35 | |

| 170.01 | 0.60 | 12.48 | 11.35 | |

| 170.01 | 1.15 | 24.60 | 11.42 | |

| 170.01 | 2.91 | 67.70 | 12.75 | |

| 180.00 | 1.20 | 24.18 | 12.41 | |

| 180.00 | 3.07 | 66.17 | 13.35 | |

| 180.01 | 0.54 | 10.51 | 11.85 | |

| 189.99 | 0.56 | 10.41 | 12.43 | |

| 190.00 | 0.81 | 15.14 | 12.71 | |

| 190.00 | 3.26 | 65.41 | 14.02 | |

| 液态 | 84.97 | 0.20 | 843.86 | 138.55 |

| 84.97 | 0.53 | 844.81 | 138.31 | |

| 84.97 | 0.87 | 845.78 | 140.88 | |

| 84.97 | 2.72 | 850.99 | 149.96 | |

| 89.99 | 0.31 | 819.06 | 118.54 | |

| 89.99 | 0.62 | 820.12 | 118.30 | |

| 89.99 | 1.29 | 822.40 | 120.74 | |

| 89.99 | 3.02 | 828.02 | 125.01 | |

| 89.99 | 4.73 | 833.29 | 129.19 | |

| 100.00 | 0.68 | 765.31 | 89.01 | |

| 100.00 | 0.98 | 766.85 | 88.75 | |

| 100.00 | 2.94 | 776.26 | 92.94 | |

| 100.01 | 4.92 | 784.76 | 98.13 | |

| 110.00 | 1.27 | 702.73 | 67.53 | |

| 110.00 | 2.91 | 715.74 | 70.50 | |

| 110.00 | 4.81 | 728.50 | 74.28 | |

| 119.99 | 2.16 | 576.18 | 49.90 | |

| 119.99 | 2.79 | 633.59 | 51.01 | |

| 119.99 | 4.85 | 660.56 | 56.57 | |

| 129.99 | 4.03 | 530.53 | 36.50 | |

| 129.99 | 4.81 | 560.47 | 40.62 | |

| 超临界态 | 139.99 | 4.85 | 282.17 | 17.78 |

| 150.00 | 4.72 | 168.43 | 13.75 | |

| 170.01 | 4.74 | 121.49 | 13.84 | |

| 180.00 | 4.83 | 111.42 | 14.20 | |

| 190.00 | 4.60 | 96.08 | 14.42 |

| 1 | 李式模. 低温工程技术综述[J]. 低温工程, 1999(3): 1-5, 26. |

| Li S M. The summary for cryogenic engineering technology[J]. Cryogenics, 1999(3): 1-5, 26. | |

| 2 | Smith A R, Klosek J. A review of air separation technologies and their integration with energy conversion processes[J]. Fuel Processing Technology, 2001, 70(2): 115-134. |

| 3 | Vecchi A, Li Y L, Ding Y L, et al. Liquid air energy storage (LAES): a review on technology state-of-the-art, integration pathways and future perspectives[J]. Advances in Applied Energy, 2021, 3: 100047. |

| 4 | Qi M, Park J, Lee I, et al. Liquid air as an emerging energy vector towards carbon neutrality: a multi-scale systems perspective[J]. Renewable and Sustainable Energy Reviews, 2022, 159: 112201. |

| 5 | Babikova D, Petrov A. Study of cavitation characteristics of a cryogenic pump by computational fluid dynamic methods[J]. IOP Conference Series: Materials Science and Engineering, 2020, 779(1): 012010. |

| 6 | Bhutta M U, Khan Z A, Garland N, et al. A historical review on the tribological performance of refrigerants used in compressors[J]. Tribology in Industry, 2018, 40(1): 19-51. |

| 7 | 孙琳, 付必伟, 魏梦辉, 等. 新型同轴套管式换热器强化传热研究[J]. 液压与气动, 2023, 47(2): 164-173. |

| Sun L, Fu B W, Wei M H, et al. New coaxial borehole heat exchanger strengthens heat transfer research[J]. Chinese Hydraulics & Pneumatics, 2023, 47(2): 164-173. | |

| 8 | Wu W, Wei C H, Zhou J J, et al. Numerical and experimental nonlinear dynamics of a proportional pressure-regulating valve[J]. Nonlinear Dynamics, 2021, 103(2): 1415-1425. |

| 9 | Huber M L, Lemmon E W, Bell I H, et al. The NIST REFPROP database for highly accurate properties of industrially important fluids[J]. Industrial & Engineering Chemistry Research, 2022, 61(42): 15449-15472. |

| 10 | Kadoya K, Matsunaga N, Nagashima A. Viscosity and thermal conductivity of dry air in the gaseous phase[J]. Journal of Physical and Chemical Reference Data, 1985, 14(4): 947-970. |

| 11 | Lemmon E W, Jacobsen R T. Viscosity and thermal conductivity equations for nitrogen, oxygen, argon, and air[J]. International Journal of Thermophysics, 2004, 25(1): 21-69. |

| 12 | Johnston H L, McCloskey K E. Viscosities of several common gases between 90°K. and room temperature[J]. The Journal of Physical Chemistry, 1940, 44(9): 1038-1058. |

| 13 | Matthews G P, Thomas C M S R, Dufty A N, et al. Viscosities of oxygen and air over a wide range of temperatures[J]. Journal of the Chemical Society, Faraday Transactions 1: Physical Chemistry in Condensed Phases, 1976, 72: 238-244. |

| 14 | Sutherland B P, Maass O. Measurement of the viscosity of gases over a large temperature range[J]. Canadian Journal of Research, 1932, 6(4): 428-443. |

| 15 | Diller D E, Aragon A S, Laesecke A. Measurements of the viscosity of compressed liquid air at temperatures between 70 and 130 K[J]. Cryogenics, 1991, 31(12): 1070-1072. |

| 16 | Latto B, Saunders M W. Absolute viscosity of air down to cryogenic temperatures and up to high pressures[J]. Journal of Mechanical Engineering Science, 1973, 15(4): 266-270. |

| 17 | Haynes W M, Diller D E, Roder H M. Transport properties of fluids of cryogenic interest[J]. Cryogenics, 1987, 27(7): 348-360. |

| 18 | Kestin J, Sokolov M, Wakeham W. Theory of capillary viscometers[J]. Applied Scientific Research, 1973, 27(1): 241-264. |

| 19 | Nieuwoudt J C, Sengers J V, Kestin J. On the theory of oscillating-cup viscometers[J]. Physica A: Statistical Mechanics and Its Applications, 1988, 149(1/2): 107-122. |

| 20 | Diller D E, Frederick N V. Torsional piezoelectric crystal viscometer for compressed gases and liquids[J]. International Journal of Thermophysics, 1989, 10(1): 145-157. |

| 21 | Tough J T, McCormick W D, Dash J G. Viscosity of liquid He Ⅱ[J]. Physical Review, 1963, 132(6): 2373-2378. |

| 22 | Retsina T, Richardson S M, Wakeham W A. The theory of a vibrating-rod densimeter[J]. Applied Scientific Research, 1986, 43(2): 127-158. |

| 23 | Retsina T, Richardson S M, Wakeham W A. The theory of a vibrating-rod viscometer[J]. Applied Scientific Research, 1987, 43(4): 325-346. |

| 24 | Pádua A A H, Fareleira J M N A, Calado J C G, et al. Electromechanical model for vibrating-wire instruments[J]. Review of Scientific Instruments, 1998, 69(6): 2392-2399. |

| 25 | Kandil M E, Marsh K N, Goodwin A R H. Vibrating wire viscometer with wire diameters of (0.05 and 0.15) mm: results for methylbenzene and two fluids with nominal viscosities at T = 298 K and p=0.01 MPa of (14 and 232) mPa·s at temperatures between (298 and 373) K and pressures below 40 MPa[J]. Journal of Chemical & Engineering Data, 2005, 50(2): 647-655. |

| 26 | Caetano F J P, Fareleira J M N A, Oliveira C M B P, et al. Validation of a vibrating-wire viscometer: measurements in the range of 0.5 to 135 mPa·s[J]. Journal of Chemical & Engineering Data, 2005, 50(1): 201-205. |

| 27 | Span R, Lemmon E W, Jacobsen R T, et al. A reference equation of state for the thermodynamic properties of nitrogen for temperatures from 63.151 to 1000 K and pressures to 2200 MPa[J]. Journal of Physical and Chemical Reference Data, 2000, 29(6): 1361-1433. |

| 28 | Lassner E, Schubert W D. Tungsten: Properties, Chemistry, Technology of the Element, Alloys, and Chemical Compounds[M]. New York: Kluwer Academic/Plenum Publishers, 1999. |

| 29 | Kunz O, Wagner W. The GERG-2008 wide-range equation of state for natural gases and other mixtures: an expansion of GERG-2004[J]. Journal of Chemical & Engineering Data, 2012, 57(11): 3032-3091. |

| 30 | Ely J F, Hanley H J M. Prediction of transport properties (1): Viscosity of fluids and mixtures[J]. Industrial & Engineering Chemistry Fundamentals, 1981, 20(4): 323-332. |

| [1] | Haoqi CHEN, Bohui SHI, Qi PENG, Qi KANG, Shangfei SONG, Haiyuan YAO, Haihong CHEN, Haihao WU, Jing GONG. Phase equilibrium calculation of acid/alcohol hydrocarbon and water system based on stability analysis [J]. CIESC Journal, 2024, 75(3): 789-800. |

| [2] | Xiaobin ZHAN, Huibin WANG, Yalong JIANG, Tielin SHI. Research on power consumption characteristics of high viscosity fluid mixing in acoustic resonance mixer [J]. CIESC Journal, 2024, 75(2): 531-542. |

| [3] | Fan WU, Xudong PENG, Jinbo JIANG, Xiangkai MENG, Yangyang LIANG. Study on adaptability of molecular dynamics in predicting density and viscosity of natural gas [J]. CIESC Journal, 2024, 75(2): 450-462. |

| [4] | Xin YANG, Wen WANG, Kai XU, Fanhua MA. Simulation analysis of temperature characteristics of the high-pressure hydrogen refueling process [J]. CIESC Journal, 2023, 74(S1): 280-286. |

| [5] | Minghui CHANG, Lin WANG, Jiajia YUAN, Yifei CAO. Study on the cycle performance of salt solution-storage-based heat pump [J]. CIESC Journal, 2023, 74(S1): 329-337. |

| [6] | Jianbo HU, Hongchao LIU, Qi HU, Meiying HUANG, Xianyu SONG, Shuangliang ZHAO. Molecular dynamics simulation insight into translocation behavior of organic cage across the cellular membrane [J]. CIESC Journal, 2023, 74(9): 3756-3765. |

| [7] | Xianheng YI, Wu ZHOU, Xiaoshu CAI, Tianyi CAI. Measurable range of nanoparticle concentration using optical fiber backward dynamic light scattering [J]. CIESC Journal, 2023, 74(8): 3320-3328. |

| [8] | Shuang LIU, Linzhou ZHANG, Zhiming XU, Suoqi ZHAO. Study on molecular level composition correlation of viscosity of residual oil and its components [J]. CIESC Journal, 2023, 74(8): 3226-3241. |

| [9] | Manzheng ZHANG, Meng XIAO, Peiwei YAN, Zheng MIAO, Jinliang XU, Xianbing JI. Working fluid screening and thermodynamic optimization of hazardous waste incineration coupled organic Rankine cycle system [J]. CIESC Journal, 2023, 74(8): 3502-3512. |

| [10] | Xueyan WEI, Yong QIAN. Experimental study on the low to medium temperature oxidation characteristics and kinetics of micro-size iron powder [J]. CIESC Journal, 2023, 74(6): 2624-2638. |

| [11] | Bowen LEI, Jianhua WU, Qihang WU. Research on high injection superheat cycle for R290 low pressure ratio heat pump [J]. CIESC Journal, 2023, 74(5): 1875-1883. |

| [12] | Bimao ZHOU, Shisen XU, Xiaoxiao WANG, Gang LIU, Xiaoyu LI, Yongqiang REN, Houzhang TAN. Effect of burner bias angle on distribution characteristics of gasifier slag layer [J]. CIESC Journal, 2023, 74(5): 1939-1949. |

| [13] | Yongquan ZHANG, Weiwei XUAN. Mechanism of alkali metal/(FeO+CaO+MgO) influence on the structure and viscosity of silicate ash slag [J]. CIESC Journal, 2023, 74(4): 1764-1771. |

| [14] | Yuanjing MAO, Zhi YANG, Songping MO, Hao GUO, Ying CHEN, Xianglong LUO, Jianyong CHEN, Yingzong LIANG. Estimation of SAFT-VR Mie equation of state parameters and thermodynamic properties of C6—C10 alcohols [J]. CIESC Journal, 2023, 74(3): 1033-1041. |

| [15] | Junxian CHEN, Zhongli JI, Yu ZHAO, Qian ZHANG, Yan ZHOU, Meng LIU, Zhen LIU. Study on online detection method of particulate matter in natural gas pipeline based on microwave technology [J]. CIESC Journal, 2023, 74(3): 1042-1053. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||