CIESC Journal ›› 2024, Vol. 75 ›› Issue (3): 727-742.DOI: 10.11949/0438-1157.20240025

• Reviews and monographs • Next Articles

Shaoyang MA( ), Hanzhuo XU, Liangliang ZHANG, Baochang SUN, Haikui ZOU, Yong LUO, Guangwen CHU(

), Hanzhuo XU, Liangliang ZHANG, Baochang SUN, Haikui ZOU, Yong LUO, Guangwen CHU( )

)

Received:2024-01-05

Revised:2024-03-01

Online:2024-05-11

Published:2024-03-25

Contact:

Guangwen CHU

马韶阳( ), 徐涵卓, 张亮亮, 孙宝昌, 邹海魁, 罗勇, 初广文(

), 徐涵卓, 张亮亮, 孙宝昌, 邹海魁, 罗勇, 初广文( )

)

通讯作者:

初广文

作者简介:马韶阳(2001—),男,博士研究生,buct_yangyang@163.com

基金资助:CLC Number:

Shaoyang MA, Hanzhuo XU, Liangliang ZHANG, Baochang SUN, Haikui ZOU, Yong LUO, Guangwen CHU. Research progress of reactors for liquid-liquid heterogeneous system[J]. CIESC Journal, 2024, 75(3): 727-742.

马韶阳, 徐涵卓, 张亮亮, 孙宝昌, 邹海魁, 罗勇, 初广文. 液-液非均相反应器研究进展[J]. 化工学报, 2024, 75(3): 727-742.

Add to citation manager EndNote|Ris|BibTeX

Fig.2 Impellers of different structures (a); influence of the impeller type on the steady state drop size d32 in correlation with the mean energy dissipation rate ε¯ (b)[44]

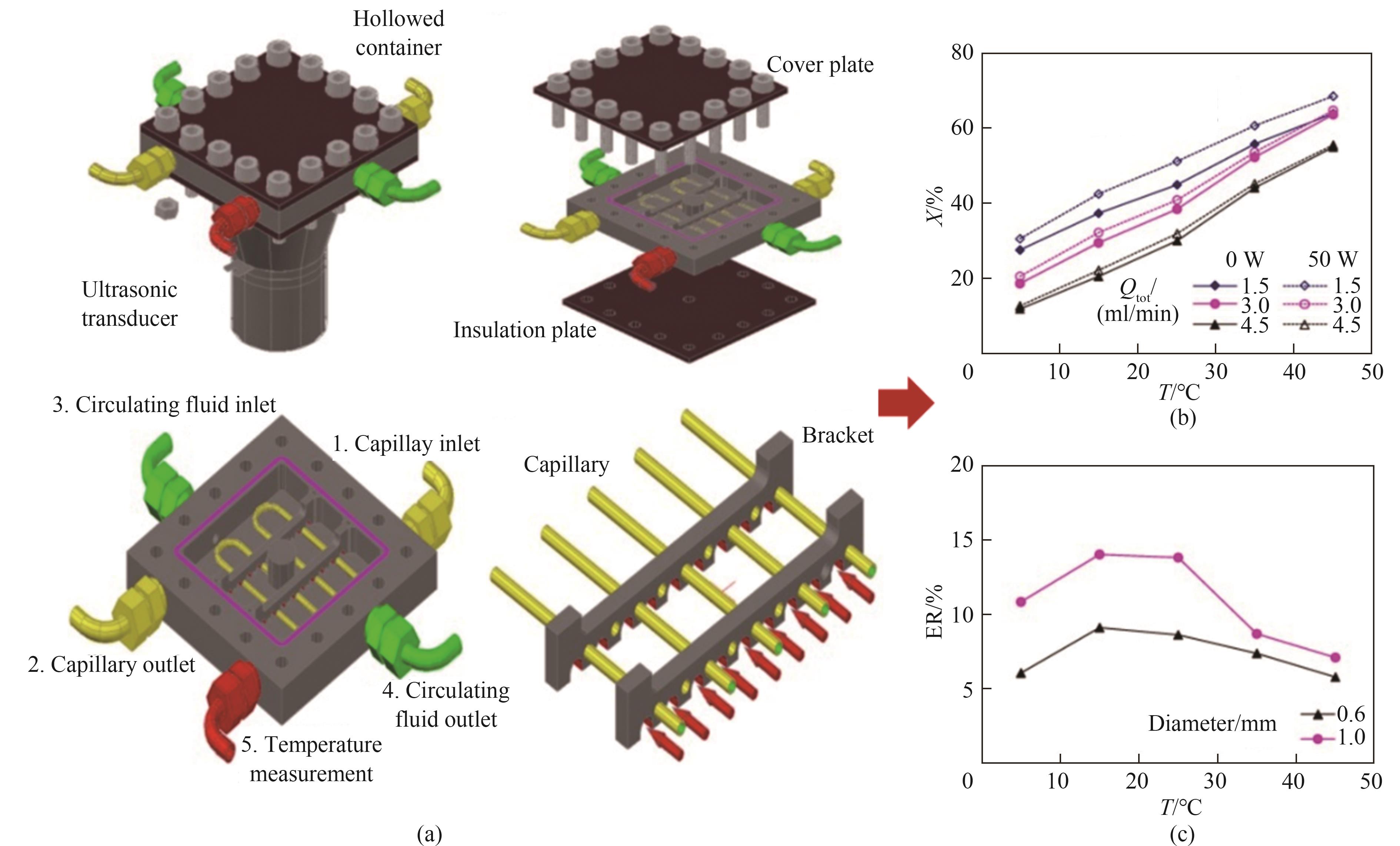

Fig. 6 Configuration of the temperature-controlled ultrasonic microreactor (a); effects of reaction temperatures, reactant flow rates and ultrasound on conversion of toluene (b); comparison of ultrasound enhancement ratio with varying dimension of microchannel (c)[70]

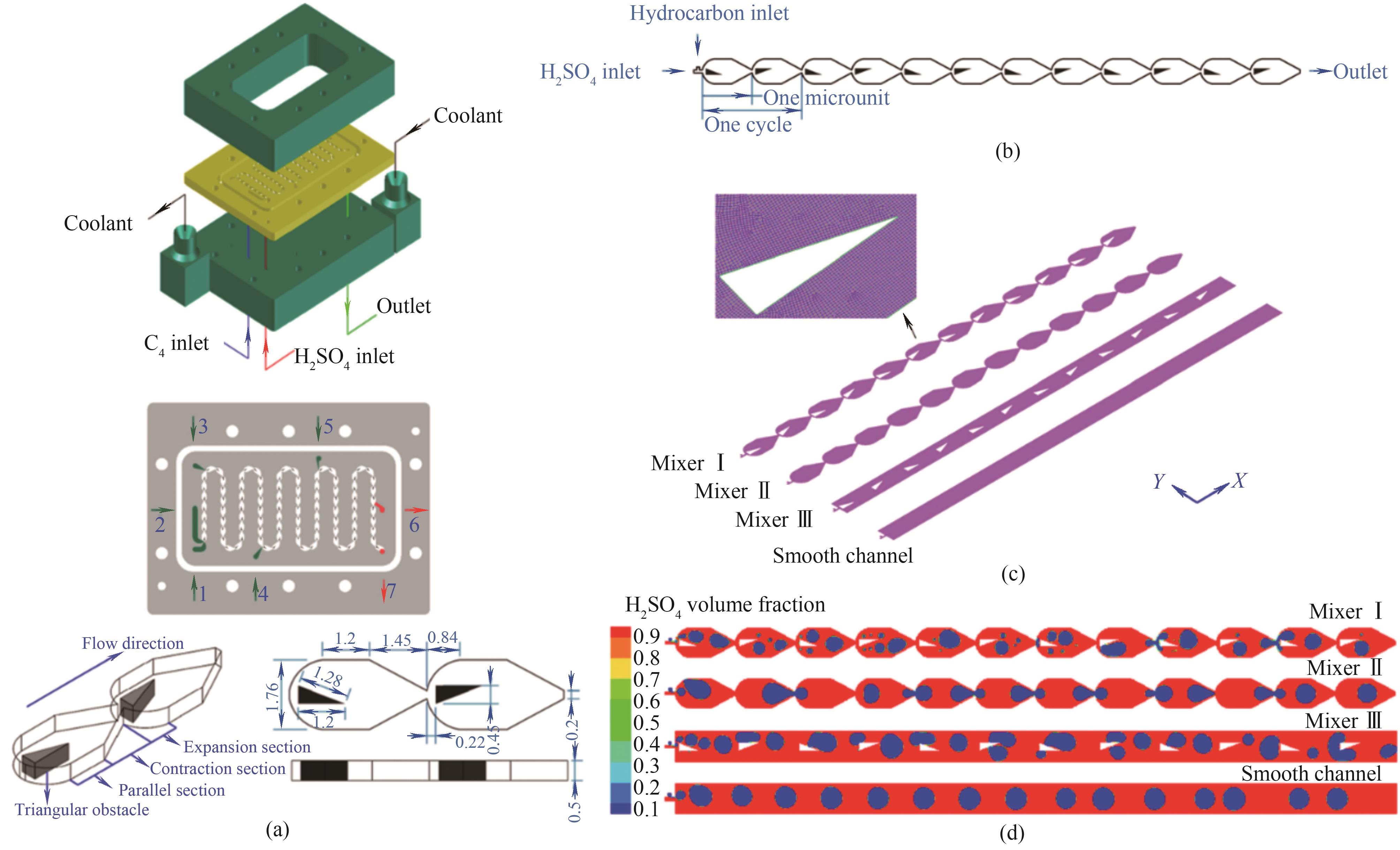

Fig. 8 Schematic diagram of the microreactor configured with a micro-mixer, process plate details and geometric constructure and dimensions of the micro-mixing cell (a); geometric model of the microchannel with contraction-expansion structures and triangular obstacles (b); physical models of four different microchannels (Mixer Ⅰ─microchannel with contraction-expansion structures and triangular obstacles; Mixer Ⅱ─microchannel with contraction-expansion structures; Mixer Ⅲ─straight-tube microchannel with triangular obstacles; smooth channel─straight-tube microchannel without any mixing structure) (c); effects of different micro-mixing structures on the dispersion performance of the isobutane/1-butene mixture in the H2SO4 phase (d)[95]

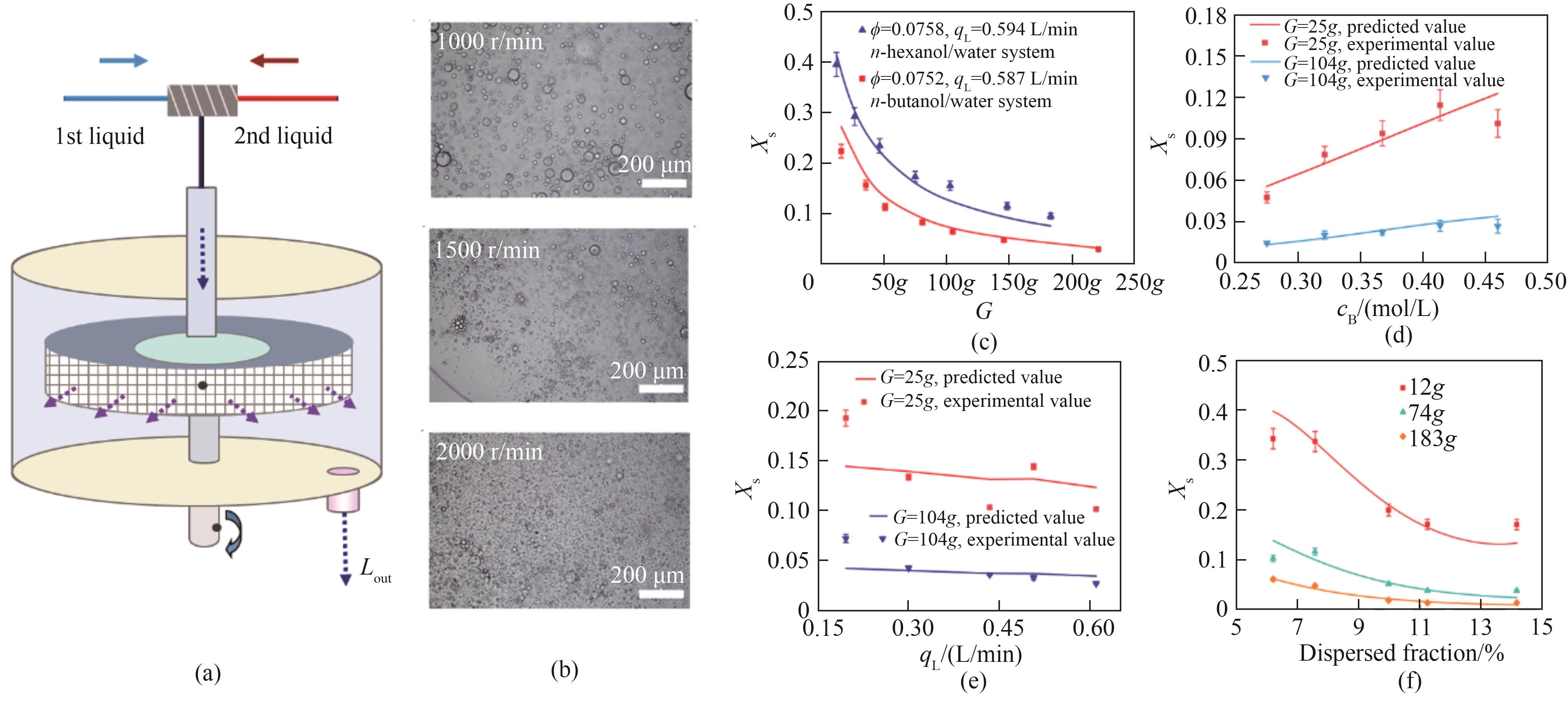

Fig. 9 Schematic diagram of the rotating packed bed reactor for liquid-liquid heterogeneous reactions (a); micrograph of samples from dispersed experiments in rotating packed bed (water dispersed in butanal) (b); effects of the high‐gravity level on mixing efficiencies of different systems (c); effects of the reactant concentration on mixing efficiencies (d); effects of the liquid flow rate on mixing efficiencies (e); effects of the dispersed phase fraction on mixing efficiencies (f) [114]

| 反应器类型 | d32/μm | kLa/s-1 | kL/(m/s) | 文献 |

|---|---|---|---|---|

| 釜式反应器 | 100~2000 | 10-3~10-1 | 10-7~10-6 | [ |

| 超声强化釜式反应器 | — | 10-2~1 | — | [ |

| 定-转子旋转圆盘反应器 | 5~130 | 10-4~10 | 10-9~10-5 | [ |

| 气体搅拌微通道反应器 | 10~20 | 1~10 | 10-6~10-5 | [ |

| 方形微通道反应器 | 200~600 | 10-2~10-1 | 10-6~10-5 | [ |

| 旋转填充床 | 10~150 | 1~102 | 10-5~10-4 | [ |

Table 1 Some reported d32 and kLa values of different reactors in liquid-liquid heterogeneous reaction process

| 反应器类型 | d32/μm | kLa/s-1 | kL/(m/s) | 文献 |

|---|---|---|---|---|

| 釜式反应器 | 100~2000 | 10-3~10-1 | 10-7~10-6 | [ |

| 超声强化釜式反应器 | — | 10-2~1 | — | [ |

| 定-转子旋转圆盘反应器 | 5~130 | 10-4~10 | 10-9~10-5 | [ |

| 气体搅拌微通道反应器 | 10~20 | 1~10 | 10-6~10-5 | [ |

| 方形微通道反应器 | 200~600 | 10-2~10-1 | 10-6~10-5 | [ |

| 旋转填充床 | 10~150 | 1~102 | 10-5~10-4 | [ |

| 反应器类型 | 结构特征 | 应用于液-液非均相反应体系 待优化方向 | 适用范围 | 优化策略 | |

|---|---|---|---|---|---|

| 反应类型 | 体系物性 | ||||

| 釜式反应器 | 通常为在中心轴安装有一个或多个搅拌叶轮的釜式结构 | 1.液体在叶轮附近受到剪切作用最为强烈,但在挡板附近却会存在死区,因此叶轮常受到侵蚀损伤,挡板附近需定期清除沉积物 2.常存在传质速率无法与快速/瞬时液-液非均相反应的反应速率相匹配的问题,很难快速实现分子级别的均匀混合 | 热效应较小的中、慢速液-液非均相体系 | 适用于高密度差,高黏度体系和反应结晶体系 | 新型叶轮结构,新型挡板结构及安装位置,增加叶轮级数,改变叶片位置及材质 |

管式反应器 (不含静态混合内构件) | 具有较大长径比的管状结构连续操作反应器 | 1.液体主要依靠自身经泵送所获得能量经过管路折流、收缩扩张、扰动等作用实现液-液非均相的混合,对于慢速反应需要较长的反应管道 2.缺少主动混合方式,传质与混合效果受限,在长停留时间下,易发生分层 | 热效应大的慢速反应 | 适用于低密度差、低黏度体系和固体生成反应体系 | 增加螺纹或收缩扩张等结构,改变管形与排布方式 |

| 静态混合器 | 在管路内部添加混合单元或管壁安装不同结构的叶片 | 1.复杂结构混合单元虽能提供较好的混合程度,但增大流体阻力与静态混合器的生产成本 2.径向混合较多,轴向混合较少 3.连接结构较多,对于一些强放热或危险化学反应需要考虑及时撤热、防泄漏,防腐蚀等问题 | 处理量较大的吸放热反应 | 适用于低密度差,中高黏度体系,对于高密度差体系容易分层,不易实现均匀混合 | 设计新型混合器件结构或者管壁安装不同形状叶片结构 |

| 微反应器 | 利用不同方式的预混形式和不同几何结构的微通道实现混合 | 1.工业放大只能通过“数量放大”,不适用于较高产量需求的化学品工业生产 2.微通道尺寸狭小,目前增强微通道内部液体混合只能通过改变入口直径和方式、挡板数量和挡板之间的间隔距离等,这会导致微通道结构过于复杂,难以批量生产,实用性下降 3.微反应器内流体流动具有Reynolds数低和高表面张力的特点,对流扩散通常较弱,存在堵塞敏感性高的问题,特别是对于生产工艺中有固体反应物以及反应结晶体系[ | 强吸放热快速反应 | 适用于低密度差,低黏度体系,对于有固体生成或高黏度体系易出现堵塞问题 | 优化微通道几何结构构型,优化两相流体接触方式 |

| 旋转填充床 | 利用高速旋转的填料将经过液体分布器的液体进行破碎分散 | 1.相对于径向运动,液体在填料中的横向漂移能力有限,导致液体在填料中的分布不均匀 2.旋转部件包括转子、轴承等需要保证密封,尤其是对于一些腐蚀性或危险化学反应,需要保证长期的可靠性[ | 快速复杂反应 | 适用于高密度差体系和高黏度体系,对于有固体生成体系易出现堵塞问题 | 优化转子结构,优化预混合及液体分布器结构 |

Table 2 The performances of typical reactors applied to liquid-liquid heterogeneous reaction systems

| 反应器类型 | 结构特征 | 应用于液-液非均相反应体系 待优化方向 | 适用范围 | 优化策略 | |

|---|---|---|---|---|---|

| 反应类型 | 体系物性 | ||||

| 釜式反应器 | 通常为在中心轴安装有一个或多个搅拌叶轮的釜式结构 | 1.液体在叶轮附近受到剪切作用最为强烈,但在挡板附近却会存在死区,因此叶轮常受到侵蚀损伤,挡板附近需定期清除沉积物 2.常存在传质速率无法与快速/瞬时液-液非均相反应的反应速率相匹配的问题,很难快速实现分子级别的均匀混合 | 热效应较小的中、慢速液-液非均相体系 | 适用于高密度差,高黏度体系和反应结晶体系 | 新型叶轮结构,新型挡板结构及安装位置,增加叶轮级数,改变叶片位置及材质 |

管式反应器 (不含静态混合内构件) | 具有较大长径比的管状结构连续操作反应器 | 1.液体主要依靠自身经泵送所获得能量经过管路折流、收缩扩张、扰动等作用实现液-液非均相的混合,对于慢速反应需要较长的反应管道 2.缺少主动混合方式,传质与混合效果受限,在长停留时间下,易发生分层 | 热效应大的慢速反应 | 适用于低密度差、低黏度体系和固体生成反应体系 | 增加螺纹或收缩扩张等结构,改变管形与排布方式 |

| 静态混合器 | 在管路内部添加混合单元或管壁安装不同结构的叶片 | 1.复杂结构混合单元虽能提供较好的混合程度,但增大流体阻力与静态混合器的生产成本 2.径向混合较多,轴向混合较少 3.连接结构较多,对于一些强放热或危险化学反应需要考虑及时撤热、防泄漏,防腐蚀等问题 | 处理量较大的吸放热反应 | 适用于低密度差,中高黏度体系,对于高密度差体系容易分层,不易实现均匀混合 | 设计新型混合器件结构或者管壁安装不同形状叶片结构 |

| 微反应器 | 利用不同方式的预混形式和不同几何结构的微通道实现混合 | 1.工业放大只能通过“数量放大”,不适用于较高产量需求的化学品工业生产 2.微通道尺寸狭小,目前增强微通道内部液体混合只能通过改变入口直径和方式、挡板数量和挡板之间的间隔距离等,这会导致微通道结构过于复杂,难以批量生产,实用性下降 3.微反应器内流体流动具有Reynolds数低和高表面张力的特点,对流扩散通常较弱,存在堵塞敏感性高的问题,特别是对于生产工艺中有固体反应物以及反应结晶体系[ | 强吸放热快速反应 | 适用于低密度差,低黏度体系,对于有固体生成或高黏度体系易出现堵塞问题 | 优化微通道几何结构构型,优化两相流体接触方式 |

| 旋转填充床 | 利用高速旋转的填料将经过液体分布器的液体进行破碎分散 | 1.相对于径向运动,液体在填料中的横向漂移能力有限,导致液体在填料中的分布不均匀 2.旋转部件包括转子、轴承等需要保证密封,尤其是对于一些腐蚀性或危险化学反应,需要保证长期的可靠性[ | 快速复杂反应 | 适用于高密度差体系和高黏度体系,对于有固体生成体系易出现堵塞问题 | 优化转子结构,优化预混合及液体分布器结构 |

| 72 | Usefian A, Bayareh M. Numerical and experimental study on mixing performance of a novel electro-osmotic micro-mixer[J]. Meccanica, 2019, 54(8): 1149-1162. |

| 73 | Su Y H, Chen G W, Zhao Y C, et al. Intensification of liquid-liquid two-phase mass transfer by gas agitation in a microchannel[J]. AIChE Journal, 2009, 55(8): 1948-1958. |

| 74 | Lee C Y, Chang C L, Wang Y N, et al. Microfluidic mixing: a review[J]. International Journal of Molecular Sciences, 2011, 12(5): 3263-3287. |

| 75 | Li G X, Pu X, Shang M J, et al. Intensification of liquid-liquid two-phase mass transfer in a capillary microreactor system[J]. AIChE Journal, 2019, 65(1): 334-346. |

| 76 | Wang D, Zhang T, Yang Y C, et al. Simulation and design microreactor configured with micromixers to intensify the isobutane/1-butene alkylation process[J]. Journal of the Taiwan Institute of Chemical Engineers, 2019, 98: 53-62. |

| 77 | Fu L M, Fang W C, Hou H H, et al. Rapid vortex microfluidic mixer utilizing double-heart chamber[J]. Chemical Engineering Journal, 2014, 249: 246-251. |

| 78 | Lobasov A, Minakov A, Kuznetsov V, et al. Investigation of mixing efficiency and pressure drop in T-shaped micromixers[J]. Chemical Engineering and Processing: Process Intensification, 2018, 134: 105-114. |

| 79 | Tomasi Masoni S, Antognoli M, Mariotti A, et al. Flow regimes, mixing and reaction yield of a mixture in an X-microreactor[J]. Chemical Engineering Journal, 2022, 437(P1): 135113. |

| 80 | Chen S L, Hao M, Shang J Y, et al. Numerical analysis of modified micromixers with staggered E-shape mixing units[J]. Chemical Engineering and Processing-Process Intensification, 2022, 179: 109087. |

| 81 | Alam A, Kim K Y. Analysis of mixing in a curved microchannel with rectangular grooves[J]. Chemical Engineering Journal, 2012, 181/182: 708-716. |

| 82 | Ahmad Ansari M, Kim K Y. Parametric study on mixing of two fluids in a three-dimensional serpentine microchannel[J]. Chemical Engineering Journal, 2009, 146(3): 439-448. |

| 83 | Hossain S, Kim K Y. Mixing analysis in a three-dimensional serpentine split-and-recombine micromixer[J]. Chemical Engineering Research and Design, 2015, 100: 95-103. |

| 84 | Hong H, Yeom E. Numerical and experimental analysis of effective passive mixing via a 3D serpentine channel[J]. Chemical Engineering Science, 2022, 261: 117972. |

| 85 | Hossain S, Ansari M A, Kim K Y. Evaluation of the mixing performance of three passive micromixers[J]. Chemical Engineering Journal, 2009, 150(2/3): 492-501. |

| 86 | Buglie William L N, Fikri T K, Ahmed S N, et al. Enhanced fluid mixing using a reversed multistage tesla micromixer[J]. Chemical Engineering & Technology, 2022, 45(7): 1255-1263. |

| 87 | Hossain S, Fuwad A, Kim K Y, et al. Investigation of mixing performance of two-dimensional micromixer using tesla structures with different shapes of obstacles[J]. Industrial & Engineering Chemistry Research, 2020, 59(9): 3636-3643. |

| 88 | Viktorov V, Mahmud M R, Visconte C. Numerical study of fluid mixing at different inlet flow-rate ratios in tear-drop and chain micromixers compared to a new H-C passive micromixer[J]. Engineering Applications of Computational Fluid Mechanics, 2016, 10(1): 182-192. |

| 89 | Mahmud M R, Hossain S, Kim J H. A SAR micromixer for water-water mixing: design, optimization, and analysis[J]. Processes, 2021, 9(11): 1926. |

| 90 | Jiang Y, Zhang B, Tian Y, et al. Analysis of different shapes of cross-sections and obstacles in variable-radius spiral micromixers on mixing efficiency[J]. Chemical Engineering and Processing: Process Intensification, 2022, 171: 108756. |

| 91 | Bahrami D, Bayareh M. Experimental and numerical investigation of a novel spiral micromixer with sinusoidal channel walls[J]. Chemical Engineering & Technology, 2022, 45(1): 100-109. |

| 92 | Su Y H, Zhao Y C, Jiao F J, et al. The intensification of rapid reactions for multiphase systems in a microchannel reactor by packing microparticles[J]. AIChE Journal, 2011, 57(6): 1409-1418. |

| 93 | Su Y H, Chen G W, Yuan Q. Ideal micromixing performance in packed microchannels[J]. Chemical Engineering Science, 2011, 66(13): 2912-2919. |

| 94 | Ebrahimpour A V, Ismail B, Rana A, et al. The effects of baffle configuration and number on inertial mixing in a curved serpentine micromixer: experimental and numerical study[J]. Chemical Engineering Research and Design, 2021, 168: 490-498. |

| 95 | Wang X, Zhang T, Lv L, et al. Reaction performance and flow behavior of isobutane/1-butene and H2SO4 in the microreactor configured with the micro-mixer[J]. Industrial & Engineering Chemistry Research, 2022, 61(25): 9122-9135. |

| 96 | Kelleher T, Fair J R. Distillation studies in a high-gravity contactor[J]. Industrial & Engineering Chemistry Research, 1996, 35(12): 4646-4655. |

| 1 | Pei D Y, Su M J, Wang Y Y, et al. Process intensification of 2,3,6-trimethylphenol oxidation in a rotating packed bed reactor[J]. Chemical Engineering and Processing: Process Intensification, 2020, 149: 107842. |

| 2 | Peer M, Weeranoppanant N, Adamo A, et al. Biphasic catalytic hydrogen peroxide oxidation of alcohols in flow: scale-up and extraction[J]. Organic Process Research & Development, 2016, 20(9): 1677-1685. |

| 3 | Wang S, Patehebieke Y, Zhou Z, et al. Catalyst-free biphasic oxidation of thiophenes in continuous-flow[J]. Journal of Flow Chemistry, 2020, 10(4): 597-603. |

| 4 | Xu J T, Zhang R W, Liu C S, et al. High efficient biosynthesis 2-ethylhexyl palmitate in a rotating packed bed reactor[J]. Applied Biochemistry and Biotechnology, 2021, 193(8): 2420-2429. |

| 5 | Huang T C, Qin H, Wang R Z, et al. Liquid-liquid equilibrium for the esterification system of acrylic acid with n-butanol catalyzed by ionic liquid [BMIm][HSO4] at atmospheric pressure[J]. Journal of Chemical & Engineering Data, 2021, 66(7): 2764-2772. |

| 6 | Rudelstorfer G, Neubauer M, Siebenhofer M, et al. Esterification of acetic acid with methanol and simultaneous product isolation by liquid-liquid extraction in a Taylor-Couette disc contactor[J]. Chemie Ingenieur Technik, 2022, 94(5): 671-680. |

| 7 | Guo S, Zhan L W, Zhu G K, et al. Scale-up and development of synthesis 2-ethylhexyl nitrate in microreactor using the Box-Behnken design[J]. Organic Process Research & Development, 2022, 26(1): 174-182. |

| 8 | Li L, Yao C Q, Jiao F J, et al. Experimental and kinetic study of the nitration of 2-ethylhexanol in capillary microreactors[J]. Chemical Engineering and Processing: Process Intensification, 2017, 117: 179-185. |

| 9 | Russo D, Tomaiuolo G, Andreozzi R, et al. Heterogeneous benzaldehyde nitration in batch and continuous flow microreactor[J]. Chemical Engineering Journal, 2019, 377: 120346. |

| 10 | Yang A M, Yue J C, Zheng S Q, et al. Experimental investigation of mononitrotoluene preparation in a continuous-flow microreactor[J]. Research on Chemical Intermediates, 2022, 48(10): 4373-4390. |

| 11 | Guo S, Zhu G K, Zhan L W, et al. Process design of two-step mononitration of m-xylene in a microreactor[J]. Journal of Flow Chemistry, 2022, 12(3): 327-336. |

| 12 | Cantillo D, Damm M, Dallinger D, et al. Sequential nitration/hydrogenation protocol for the synthesis of triaminophloroglucinol: safe generation and use of an explosive intermediate under continuous-flow conditions[J]. Organic Process Research & Development, 2014, 18(11): 1360-1366. |

| 13 | Sun B C, Zhang L L, Weng Z, et al. Sulfonation of alkylbenzene using liquid sulfonating agent in rotating packed bed: experimental and numerical study[J]. Chemical Engineering and Processing: Process Intensification, 2017, 119: 93-100. |

| 14 | Zhang D, Zhang P Y, Zou H K, et al. Synthesis of petroleum sulfonate surfactant by different sulfonating agent with application of HIGEE technology[J]. Chinese Journal of Chemical Engineering, 2010, 18(5): 848-855. |

| 97 | Yang K, Chu G W, Shao L, et al. Micromixing efficiency of rotating packed bed with premixed liquid distributor[J]. Chemical Engineering Journal, 2009, 153(1/2/3): 222-226. |

| 98 | Li Y B, Wen Z N, Sun B C, et al. Flow patterns, liquid holdup, and wetting behavior of viscous liquids in a disk-distributor rotating packed bed[J]. Chemical Engineering Science, 2022, 252: 117256. |

| 99 | Li Y B, Wen Z N, Xu H Z, et al. Flow pattern transition and liquid element characteristics in a disk-distributor rotating packed bed: a visual study for viscous fluid[J]. Chemical Engineering Science, 2022, 260: 117854. |

| 100 | Li Y B, Wen Z N, Xu H Z, et al. Mass transfer modeling for viscous fluids in a disk-distributor rotating packed bed[J]. Chemical Engineering Journal, 2023, 453: 139604. |

| 101 | Wenzel D, Gerdes N, Steinbrink M, et al. Liquid distribution and mixing in rotating packed beds[J]. Industrial & Engineering Chemistry Research, 2018, 58(15): 5919-5928. |

| 102 | Bai Y, Zhao Q, Zhang Z H, et al. A new rotor structural design method of rotating packed bed based on hydrodynamic performance analysis[J]. Chemical Engineering and Processing-Process Intensification, 2022, 181: 109145. |

| 103 | Liu W, Luo Y, Liu Y Z, et al. Scale-up of a rotating packed bed reactor with a mesh-pin rotor (Ⅰ): Hydrodynamic studies[J]. Industrial & Engineering Chemistry Research, 2020, 59(11): 5114-5123. |

| 104 | Wen Z N, Li Y B, Xu H Z, et al. Liquid flow behavior in the concentric mesh packing with novel fiber cross-sectional shape in a rotating packed bed[J]. Chemical Engineering Journal, 2023, 451: 139094. |

| 105 | Wen Z N, Wu W, Luo Y, et al. Novel wire mesh packing with controllable cross-sectional area in a rotating packed bed: mass transfer studies[J]. Industrial & Engineering Chemistry Research, 2020, 59(36): 16043-16051. |

| 106 | Yang P F, Luo S, Zhang D S, et al. Extraction of nitrobenzene from aqueous solution in impinging stream-rotating packed bed[J]. Chemical Engineering and Processing-Process Intensification, 2018, 124: 255-260. |

| 107 | Chang J, Zhang L B, Du Y, et al. Separation of indium from iron in a rotating packed bed contactor using di-2-ethylhexylphosphoric acid[J]. Separation and Purification Technology, 2016, 164: 12-18. |

| 108 | Jiao W Z, Liu Y Z, Qi G S. A new impinging stream-rotating packed bed reactor for improvement of micromixing iodide and iodate[J]. Chemical Engineering Journal, 2010, 157(1): 168-173. |

| 109 | Lin C C, Tsai C H. Micromixing in a rotating packed bed with blade packings[J]. Journal of the Taiwan Institute of Chemical Engineers, 2016, 63: 33-38. |

| 110 | Ma C, Wen Z N, Sun B C, et al. Mass transfer intensification mechanism of Al2O3 sphere packing in a rotating packed bed[J]. Chemical Engineering Journal, 2022, 428: 130953. |

| 15 | Xu Y M, Liu S L, Meng W J, et al. Continuous sulfonation of hexadecylbenzene in a microreactor[J]. Green Processing and Synthesis, 2021, 10(1): 219-229. |

| 16 | Pu X, Li G X, Song Y, et al. Droplet coalescence phenomena during liquid-liquid heterogeneous reactions in microreactors[J]. Industrial & Engineering Chemistry Research, 2017, 56(43): 12316-12325. |

| 17 | Breen J R, Sandford G, Yufit D S, et al. Continuous gas/liquid-liquid/liquid flow synthesis of 4-fluoropyrazole derivatives by selective direct fluorination[J]. Beilstein Journal of Organic Chemistry, 2011, 7: 1048-1054. |

| 18 | Joshi A V, Baidossi M, Mukhopadhyay S, et al. Oxidative bromination of activated aromatic compounds using aqueous nitric acid as an oxidant[J]. Organic Process Research & Development, 2004, 8(4): 568-570. |

| 19 | Tian Y T, Li Z X, Mei S J, et al. Alkylation of isobutane and 2-butene by concentrated sulfuric acid in a rotating packed bed reactor[J]. Industrial & Engineering Chemistry Research, 2018, 57(40): 13362-13371. |

| 20 | Liu Y, Liu G L, Wu G Q, et al. Alkylation of isobutane and 2-butene in rotating packed-bed reactors: using ionic liquid and solid acid as catalysts[J]. Industrial & Engineering Chemistry Research, 2020, 59(33): 14767-14775. |

| 21 | Song Y, Liu S E, Wang B Y, et al. Continuous and controllable preparation of polyaniline with different reaction media in microreactors for supercapacitor applications[J]. Chemical Engineering Science, 2019, 207: 820-828. |

| 22 | Song Y, Song J N, Shang M J, et al. Hydrodynamics and mass transfer performance during the chemical oxidative polymerization of aniline in microreactors[J]. Chemical Engineering Journal, 2018, 353: 769-780. |

| 23 | Visscher F, van der Schaaf J, Nijhuis T A, et al. Rotating reactors—a review[J]. Chemical Engineering Research and Design, 2013, 91(10): 1923-1940. |

| 24 | 骆培成, 程易, 汪展文, 等. 液-液快速混合设备研究进展[J]. 化工进展, 2005, 24(12): 1319-1326. |

| Luo P C, Cheng Y, Wang Z W, et al. Research progress of liquid-liquid fast mixing equipment[J]. Chemical Industry and Engineering Progress, 2005, 24(12): 1319-1326. | |

| 25 | Wernersson Stahl, Tragardh C. Scale-up of Rushton turbine-agitated tanks[J]. Chemical Engineering Science, 1999, 54(19): 4245-4256. |

| 111 | Zheng X H, Chu G W, Kong D J, et al. Mass transfer intensification in a rotating packed bed with surface-modified nickel foam packing[J]. Chemical Engineering Journal, 2016, 285: 236-242. |

| 112 | Zhang W, Xie P, Li Y X, et al. 3D CFD simulation of the liquid flow in a rotating packed bed with structured wire mesh packing[J]. Chemical Engineering Journal, 2022, 427: 130874. |

| 113 | 张傑. 氯铝酸离子液体催化异丁烷和丁烯烷基化反应的研究[D]. 北京: 北京化工大学, 2008. |

| Zhang J. Study on the alkylation of isobutane with butene using chloroaluminate ionic liquids as the catalysts[D]. Beijing: Beijing University of Chemical Technology, 2008. | |

| 114 | Zhang Y D, Zhang L L, Wang Z X, et al. Liquid-liquid heterogeneous mixing efficiency in a rotating packed bed reactor[J]. AIChE Journal, 2023, 69(6): e18000. |

| 115 | Hiraoka S, Tada Y, Suzuki H, et al. Correlation of mass transfer volumetric coefficient with power input in stirred liquid-liquid dispersions[J]. Journal of Chemical Engineering of Japan, 1990, 23(4): 468-474. |

| 116 | Wilhelm A M, Laugier F, Kidak R, et al. Ultrasound to enhance a liquid-liquid reaction [J]. Journal of Chemical Engineering of Japan, 2010, 43(9): 751-756. |

| 117 | Martínez A N M, Assirelli M, Schaaf J V D. Droplet size and liquid-liquid mass transfer with reaction in a rotor-stator spinning disk reactor[J]. Chemical Engineering Science, 2021, 242: 116706. |

| 118 | Sattari Najafabadi M, Nasr Esfahany M, Wu Z, et al. The effect of the size of square microchannels on hydrodynamics and mass transfer during liquid‐liquid slug flow[J]. AIChE Journal, 2017, 63(11): 5019-5028. |

| 119 | 初广文. 定-转子反应器开发研究[D]. 北京: 北京化工大学, 2007. |

| Chu G W. Development of rotor-stator reactor[D]. Beijing: Beijing University of Chemical Technology, 2007. | |

| 120 | 王思文. 定-转子反应器中的流体流动和可视化研究[D]. 北京: 北京化工大学, 2016. |

| 26 | Rave K, Hermes M, Wirz D, et al. Experiments and fully transient coupled CFD-PBM 3D flow simulations of disperse liquid-liquid flow in a baffled stirred tank[J]. Chemical Engineering Science, 2022, 253: 117518. |

| 27 | Kumaresan T, Joshi J B. Effect of impeller design on the flow pattern and mixing in stirred tanks[J]. Chemical Engineering Journal, 2006, 115(3): 173-193. |

| 28 | Xu W T, Tan Y B, Li M, et al. Effects of surface vortex on the drawdown and dispersion of floating particles in stirred tanks[J]. Particuology, 2020, 49: 159-168. |

| 29 | Soares L L, Biserni C, da Rosa Costa R, et al. Numerical study and geometric investigation of the influence of rectangular baffles over the mixture of turbulent flows into stirred tanks[J]. Applied Sciences, 2022, 12(10): 4827. |

| 30 | Shen Y Y, Qin B, Li X, et al. Investigation of the flow characteristics of liquid-liquid two-phase mixing in an agitator equipped with a “V-shaped” horizontal baffle[J]. Environment, Development and Sustainability, 2021, 23(2): 2298-2313. |

| 31 | Zhou S Q, Yang Q Z, Lu L F, et al. CFD analysis of sine baffles on flow mixing and power consumption in stirred tank[J]. Applied Sciences, 2022, 12(11): 5743. |

| 32 | Soliman M S, Nosier S A, Hussein M, et al. Mass and heat transfer behavior of a new heterogeneous stirred tank reactor with serpentine tube baffles[J]. Chemical Engineering Research and Design, 2017, 124: 211-221. |

| 33 | Abdel-Gawad E H, Taha M M, Abdel-Kawi M A, et al. Mass and heat transfer in stirred tank equipped with a horizontal tubular cruciform baffle[J]. Chemical Engineering Research and Design, 2022, 178: 514-522. |

| 34 | Tamburini A, Gagliano G, Micale G, et al. Direct numerical simulations of creeping to early turbulent flow in unbaffled and baffled stirred tanks[J]. Chemical Engineering Science, 2018, 192: 161-175. |

| 35 | Busciglio A, Scargiali F, Grisafi F, et al. Oscillation dynamics of free vortex surface in uncovered unbaffled stirred vessels[J]. Chemical Engineering Journal, 2016, 285: 477-486. |

| 36 | Zhao S C, Guo J H, Dang X H, et al. Energy consumption, flow characteristics and energy-efficient design of cup-shape blade stirred tank reactors: computational fluid dynamics and artificial neural network investigation[J]. Energy, 2022, 240: 122474. |

| 37 | Gu D Y, Mei Y, Wen L, et al. Chaotic mixing and mass transfer characteristics of fractal impellers in gas-liquid stirred tank[J]. Journal of the Taiwan Institute of Chemical Engineers, 2021, 121: 20-28. |

| 38 | Kamla Y, Ameur H, Karas A, et al. Performance of new designed anchor impellers in stirred tanks[J]. Chemical Papers, 2020, 74(3): 779-785. |

| 39 | Dai Y X, Wang Z H, Fan Y W, et al. Analysis of mixing effect and power consumption of cone-bottom dual Rushton turbines stirred tank[J]. Chemical Papers, 2022, 76(4): 2177-2191. |

| 40 | Yao H, Tang J J, Liu Z H, et al. Chaotic mixing intensification and flow field evolution mechanism in a stirred reactor using a dual-shaft eccentric impeller[J]. Industrial & Engineering Chemistry Research, 2022, 61(26): 9498-9513. |

| 41 | Liang Y Y, Shi D E, Xu B H, et al. Turbulent flow field in a stirred vessel agitated by an Impeller with flexible blades[J]. AIChE Journal, 2018, 64(11): 4148-4161. |

| 42 | Chen L M, Bo C, Yuan M Y, et al. Enhancement of turbulent liquid-liquid dispersions in a round-bottom stirred tank equipped by a flexible impeller[J]. Chemical Engineering and Processing- Process Intensification, 2021, 169: 108652. |

| 43 | Afshar G R, Abdul Raman A A, Ibrahim S. The effect of various designs of six-curved blade impellers on reaction rate analysis in liquid-liquid mixing vessel[J]. Measurement, 2016, 91: 440-450. |

| 44 | Bliatsiou C, Malik A, Böhm L, et al. Influence of impeller geometry on hydromechanical stress in stirred liquid/liquid dispersions[J]. Industrial & Engineering Chemistry Research, 2019, 58(7): 2537-2550. |

| 45 | Vashisth S, Kumar V, Nigam K D P. A review on the potential applications of curved geometries in process industry[J]. Industrial & Engineering Chemistry Research, 2008, 47(10): 3291-3337. |

| 46 | Dean W R. XVI.Note on the motion of fluid in a curved pipe[J]. The London, Edinburgh, and Dublin Philosophical Magazine and Journal of Science, 1927, 4(20): 208-223. |

| 47 | 骆江洲. 螺旋盘管反应器强化液-液混合及应用研究[D]. 北京: 北京化工大学, 2017. |

| Luo J Z. Enhancement of liquid-liquid mixing in a helical tube reactor and its application[D]. Beijing: Beijing University of Chemical Technology, 2017. | |

| 48 | Sharma M, Acharya R B, Kulkarni A A. Exploring the steady operation of a continuous pilot plant for the di-nitration reaction[J]. Chemical Engineering & Technology, 2019, 42(10): 2241-2251. |

| 49 | Kulkarni A A, Nivangune N T, Joshi R R, et al. Continuous flow multipoint dosing approach for selectivity engineering in sulfoxidation[J]. Organic Process Research & Development, 2013, 17(10): 1293-1299. |

| 50 | Somnuk K, Prasit T, Prateepchaikul G. Effects of mixing technologies on continuous methyl ester production: comparison of using plug flow, static mixer, and ultrasound clamp[J]. Energy Conversion and Management, 2017, 140: 91-97. |

| 51 | Weatherley L R, Rooney D. Enzymatic catalysis and electrostatic process intensification for processing of natural oils[J]. Chemical Engineering Journal, 2008, 135(1/2): 25-32. |

| 52 | Keil F J. Process intensification[J]. Reviews in Chemical Engineering, 2018, 34(2): 135-200. |

| 53 | Thakur R K, Vial C, Nigam K D P, et al. Static mixers in the process industries—a review[J]. Chemical Engineering Research and Design, 2003, 81(7): 787-826. |

| 54 | Lobry E, Theron F, Gourdon C, et al. Turbulent liquid-liquid dispersion in SMV static mixer at high dispersed phase concentration[J]. Chemical Engineering Science, 2011, 66(23): 5762-5774. |

| 55 | Theron F, Le Sauze N. Comparison between three static mixers for emulsification in turbulent flow[J]. International Journal of Multiphase Flow, 2011, 37(5): 488-500. |

| 56 | Lebaz N, Sheibat-Othman N. A population balance model for the prediction of breakage of emulsion droplets in SMX+ static mixers[J]. Chemical Engineering Journal, 2019, 361: 625-634. |

| 57 | Abou Hweij K, Azizi F. Hydrodynamics and residence time distribution of liquid flow in tubular reactors equipped with screen-type static mixers[J]. Chemical Engineering Journal, 2015, 279: 948-963. |

| 58 | Al Taweel A M, Azizi F, Sirijeerachai G. Static mixers: effective means for intensifying mass transfer limited reactions[J]. Chemical Engineering and Processing: Process Intensification, 2013, 72: 51-62. |

| 59 | Sungwornpatansakul P, Hiroi J, Nigahara Y, et al. Enhancement of biodiesel production reaction employing the static mixing[J]. Fuel Processing Technology, 2013, 116: 1-8. |

| 60 | Bayareh M, Ashani M N, Usefian A. Active and passive micromixers: a comprehensive review[J]. Chemical Engineering and Processing: Process Intensification, 2020, 147: 107771. |

| 61 | Zhao Y C, Su Y H, Chen G W, et al. Effect of surface properties on the flow characteristics and mass transfer performance in microchannels[J]. Chemical Engineering Science, 2010, 65(5): 1563-1570. |

| 62 | Dessimoz A L, Cavin L, Renken A, et al. Liquid-liquid two-phase flow patterns and mass transfer characteristics in rectangular glass microreactors[J]. Chemical Engineering Science, 2008, 63(16): 4035-4044. |

| 63 | Kashid M N, Renken A, Kiwi-Minsker L. Influence of flow regime on mass transfer in different types of microchannels[J]. Industrial & Engineering Chemistry Research, 2011, 50(11): 6906-6914. |

| 64 | Kashid M N, Agar D W. Hydrodynamics of liquid-liquid slug flow capillary microreactor: flow regimes, slug size and pressure drop[J]. Chemical Engineering Journal, 2007, 131(1): 1-13. |

| 65 | Ghaini A, Kashid M N, Agar D W. Effective interfacial area for mass transfer in the liquid-liquid slug flow capillary microreactors[J]. Chemical Engineering and Processing: Process Intensification, 2010, 49(4): 358-366. |

| 66 | Kashid M N, Renken A, Kiwi-Minsker L. Gas-liquid and liquid-liquid mass transfer in microstructured reactors[J]. Chemical Engineering Science, 2011, 66(17): 3876-3897. |

| 67 | Hessel V, Löwe H, Schönfeld F. Micromixers—a review on passive and active mixing principles[J]. Chemical Engineering Science, 2005, 60(8/9): 2479-2501. |

| 68 | Deshmukh A A, Liepmann D, Pisano A P. Continuous micromixer with pulsatile micropumps[C]//2000 Solid-State, Actuators, and Microsystems Workshop Technical Digest. San Diego: Transducer Research Foundation, Inc., 2000: 73-76. |

| 69 | Aljbour S, Tagawa T, Yamada H. Ultrasound-assisted capillary microreactor for aqueous-organic multiphase reactions[J]. Journal of Industrial and Engineering Chemistry, 2009, 15(6): 829-834. |

| 70 | Zhao S N, Yao C Q, Zhang Q, et al. Acoustic cavitation and ultrasound-assisted nitration process in ultrasonic microreactors: the effects of channel dimension, solvent properties and temperature[J]. Chemical Engineering Journal, 2019, 374: 68-78. |

| 71 | Owen D, Ballard M, Alexeev A, et al. Rapid microfluidic mixing via rotating magnetic microbeads[J]. Sensors and Actuators A: Physical, 2016, 251: 84-91. |

| 120 | Wang S W. Study on fluid flow and visualization in rotor-stator reactor[D]. Beijing: Beijing University of Chemical Technology, 2016. |

| 121 | Li Y W, Wang S W, Sun B C, et al. Visual study of liquid flow in a rotor-stator reactor[J]. Chemical Engineering Science, 2015, 134: 521-530. |

| 122 | Wang Y B, Li J, Jin Y, et al. Visual study on the characteristics of liquid and droplet in a novel rotor-stator reactor[J]. Chinese Journal of Chemical Engineering, 2019, 27(11): 2643-2652. |

| 123 | Manzano Martínez A N, van Eeten K M P, Schouten J C, et al. Micromixing in a rotor-stator spinning sisc reactor[J]. Industrial & Engineering Chemistry Research, 2017, 56(45): 13454-13460. |

| 124 | Kleiner J, Hinrichsen O. Epoxidation of methyl oleate in a rotor-stator spinning disc reactor[J]. Chemical Engineering and Processing: Process Intensification, 2019, 136: 152-162. |

| 125 | Chaudhuri A, Backx W G, Moonen L L C, et al. Kinetics and intensification of tertiary amine N-oxidation: towards a solventless, continuous and sustainable process[J]. Chemical Engineering Journal, 2021, 416: 128962. |

| 126 | Zhao S N, Dong Z Y, Yao C Q, et al. Liquid-liquid two-phase flow in ultrasonic microreactors: cavitation, emulsification, and mass transfer enhancement[J]. AIChE Journal, 2018, 64(4): 1412-1423. |

| 127 | Zhao H, Shao L, Chen J F. High-gravity process intensification technology and application[J]. Chemical Engineering Journal, 2010, 156(3): 588-593. |

| 128 | Liang C, Cai Y, Li K, et al. Using dielectric barrier discharge and rotating packed bed reactor for NO x removal[J]. Separation and Purification Technology, 2020, 235: 116141. |

| 129 | 徐涵卓, 刘志浩, 孙宝昌, 等. 流体驱动旋转装备应用与数值模拟方法研究进展[J]. 化工进展, 2022, 41(6): 2806-2817. |

| Xu H Z, Liu Z H, Sun B C, et al. Research progress in applications and numerical simulation of fluid-driven rotating equipment[J]. Chemical Industry and Engineering Progress, 2022, 41(6): 2806-2817. |

| [1] | Juan WANG, Xiuming LI, Weitao SHAO, Xu DING, Ying HUO, Lianchao FU, Yunyu BAI, Di LI. Numerical simulation of flow and mass transfer characteristics in porous plate bubbling column reactor [J]. CIESC Journal, 2024, 75(3): 801-814. |

| [2] | Wenkai CHENG, Jinyu YAN, Jiajun WANG, Lianfang FENG. Research progress of horizontal kneading reactor and its application in polymerization industry [J]. CIESC Journal, 2024, 75(3): 768-781. |

| [3] | Rao CHEN, Xin ZHAO, Daixin CHEN, Shengkun JIANG, Yingjiang LIAN, Jinbo WANG, Mei YANG, Guangwen CHEN. Continuous dinitration of toluene to dinitrotoluene in a microreactor [J]. CIESC Journal, 2024, 75(3): 867-876. |

| [4] | Hong CHEN, Kun JIANG, Tingjiang TANG, Yiyuan HUANG, Bin CHI, Shijun LIAO. Research on membrane electrode assembly consistency of high-power proton exchange membrane fuel cell stack [J]. CIESC Journal, 2024, 75(2): 637-646. |

| [5] | Xueyi MA, Keqin LIU, Jijiang HU, Zhen YAO. CFD studies on the mixing and reaction in a solution polymerization reactor for POE production [J]. CIESC Journal, 2024, 75(1): 322-337. |

| [6] | Ting WANG, Zhongdong WANG, Xingyu XIANG, Chengxiang HE, Chunying ZHU, Youguang MA, Taotao FU. Advances in synthesis of cyclic ester additives for lithium batteries in microreactors [J]. CIESC Journal, 2024, 75(1): 95-109. |

| [7] | Yizhou CUI, Chengxiang LI, Linxiao ZHAI, Shuyu LIU, Xiaogang SHI, Jinsen GAO, Xingying LAN. Comparative study on the flow and mass transfer characteristics of sub-millimeter bubbles and conventional bubbles in gas-liquid two-phase flow [J]. CIESC Journal, 2024, 75(1): 197-210. |

| [8] | Junnan WANG, Chengxiang HE, Zhongdong WANG, Chunying ZHU, Youguang MA, Taotao FU. Numerical simulation of homogeneous mixing in T-junction micromixers [J]. CIESC Journal, 2024, 75(1): 242-254. |

| [9] | Yuyuan ZHENG, Zhiwei GE, Xiangyu HAN, Liang WANG, Haisheng CHEN. Progress and prospect of medium and high temperature thermochemical energy storage of calcium-based materials [J]. CIESC Journal, 2023, 74(8): 3171-3192. |

| [10] | Zhenghao YANG, Zhen HE, Yulong CHANG, Ziheng JIN, Xia JIANG. Research progress in downer fluidized bed reactor for biomass fast pyrolysis [J]. CIESC Journal, 2023, 74(6): 2249-2263. |

| [11] | Xiaowen ZHOU, Jie DU, Zhanguo ZHANG, Guangwen XU. Study on the methane-pulsing reduction characteristics of Fe2O3-Al2O3 oxygen carrier [J]. CIESC Journal, 2023, 74(6): 2611-2623. |

| [12] | Yongyao SUN, Qiuying GAO, Wenguang ZENG, Jiaming WANG, Yifei CHEN, Yongzhe ZHOU, Gaohong HE, Xuehua RUAN. Design and optimization of membrane-based integration process for advanced utilization of associated gases in N2-EOR oilfields [J]. CIESC Journal, 2023, 74(5): 2034-2045. |

| [13] | Zedong WANG, Zhiping SHI, Liyan LIU. Numerical simulation and optimization of acoustic streaming considering inhomogeneous bubble cloud dissipation in rectangular reactor [J]. CIESC Journal, 2023, 74(5): 1965-1973. |

| [14] | Lanhe ZHANG, Qingyi LAI, Tiezheng WANG, Xiaozhuo GUAN, Mingshuang ZHANG, Xin CHENG, Xiaohui XU, Yanping JIA. Effect of H2O2 on nitrogen removal and sludge properties in SBR [J]. CIESC Journal, 2023, 74(5): 2186-2196. |

| [15] | Jianhua ZHANG, Mengmeng CHEN, Yawen SUN, Yongzhen PENG. Efficient nitrogen and phosphorus removal from domestic wastewater via simultaneous partial nitritation and phosphorus removal combined Anammox [J]. CIESC Journal, 2023, 74(5): 2147-2156. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||