化工学报 ›› 2019, Vol. 70 ›› Issue (9): 3412-3420.DOI: 10.11949/0438-1157.20190232

收稿日期:2019-03-12

修回日期:2019-05-24

出版日期:2019-09-05

发布日期:2019-09-05

通讯作者:

姜晓滨

作者简介:李冠男(1992—),女,硕士研究生,基金资助:

Guannan LI( ),Gaohong HE,Xiaobin JIANG(

),Gaohong HE,Xiaobin JIANG( )

)

Received:2019-03-12

Revised:2019-05-24

Online:2019-09-05

Published:2019-09-05

Contact:

Xiaobin JIANG

摘要:

利用真空膜蒸馏-结晶耦合技术处理多元高盐废水(Na+、Mg2+//Cl--H2O),回收纯水和高品质NaCl晶体产品,考察不同操作温度和不同无机盐离子浓度对膜蒸馏性能和NaCl晶体产品性质调控作用。结果表明随着温度升高导致饱和蒸气压增大,增大了跨膜压差,膜的渗透通量逐渐升高;随着溶液中Mg2+浓度的逐渐升高,膜的渗透通量呈下降的趋势,主要是由于水的质量分数下降和溶液黏度增加;膜蒸馏过程中,通过对比实验,分析了疏水微孔膜表面在膜蒸馏操作条件下表面晶体颗粒沉积的程度,证实了使用的中空纤维膜性能稳定,重复使用20次后仍能保持稳定通量;操作温度为65℃时,不同离子浓度的饱和原料液(MgCl2质量占NaCl和MgCl2总质量的0%、5.0%和10.0%)得到NaCl晶体产品平均粒径分别为91.04、91.38和122.56 μm,粒度分布的变异系数C.V.值分别为28.78、30.63和36.77,粒径分布集中,表面相貌平整,呈完美的立方体形态,没有团聚现象;同时,膜蒸馏得到的水纯度较高,电导率均小于5 μS?m-1,采用选择性溶剂乙醇洗涤后的NaCl晶体产品纯度均大于98.15%。综上,通过膜蒸馏过程中渗透通量和膜界面的有效调控,在适宜的操作温度和较低的Mg2+含量下,膜蒸馏结晶过程从多元高盐废水(Na+、Mg2+//Cl--H2O)控制分离获得纯度较高、表面形貌完好、粒度均一的NaCl晶体产品。这一研究将为综合治理多元无机高盐废水,实现废水的近零排放和无机盐资源回用开拓新的思路。

中图分类号:

李冠男, 贺高红, 姜晓滨. 膜结晶处理高浓度Na+、Mg2+//Cl--H2O溶液的结晶调控[J]. 化工学报, 2019, 70(9): 3412-3420.

Guannan LI, Gaohong HE, Xiaobin JIANG. Treatment of high concentration Na+, Mg2+//Cl--H2O solution and crystallization control via membrane distillation crystallization[J]. CIESC Journal, 2019, 70(9): 3412-3420.

| 外径/μm | 膜厚/μm | 孔径/μm | 孔隙率 | 纯水的接触角/(°) |

|---|---|---|---|---|

| 403±5 | 35.4±0.6 | 0.17±0.02 | 0.503±0.05 | 115±2 |

表1 中空纤维膜的结构参数

Table 1 Membrane structure parameters of hollow fiber membrane

| 外径/μm | 膜厚/μm | 孔径/μm | 孔隙率 | 纯水的接触角/(°) |

|---|---|---|---|---|

| 403±5 | 35.4±0.6 | 0.17±0.02 | 0.503±0.05 | 115±2 |

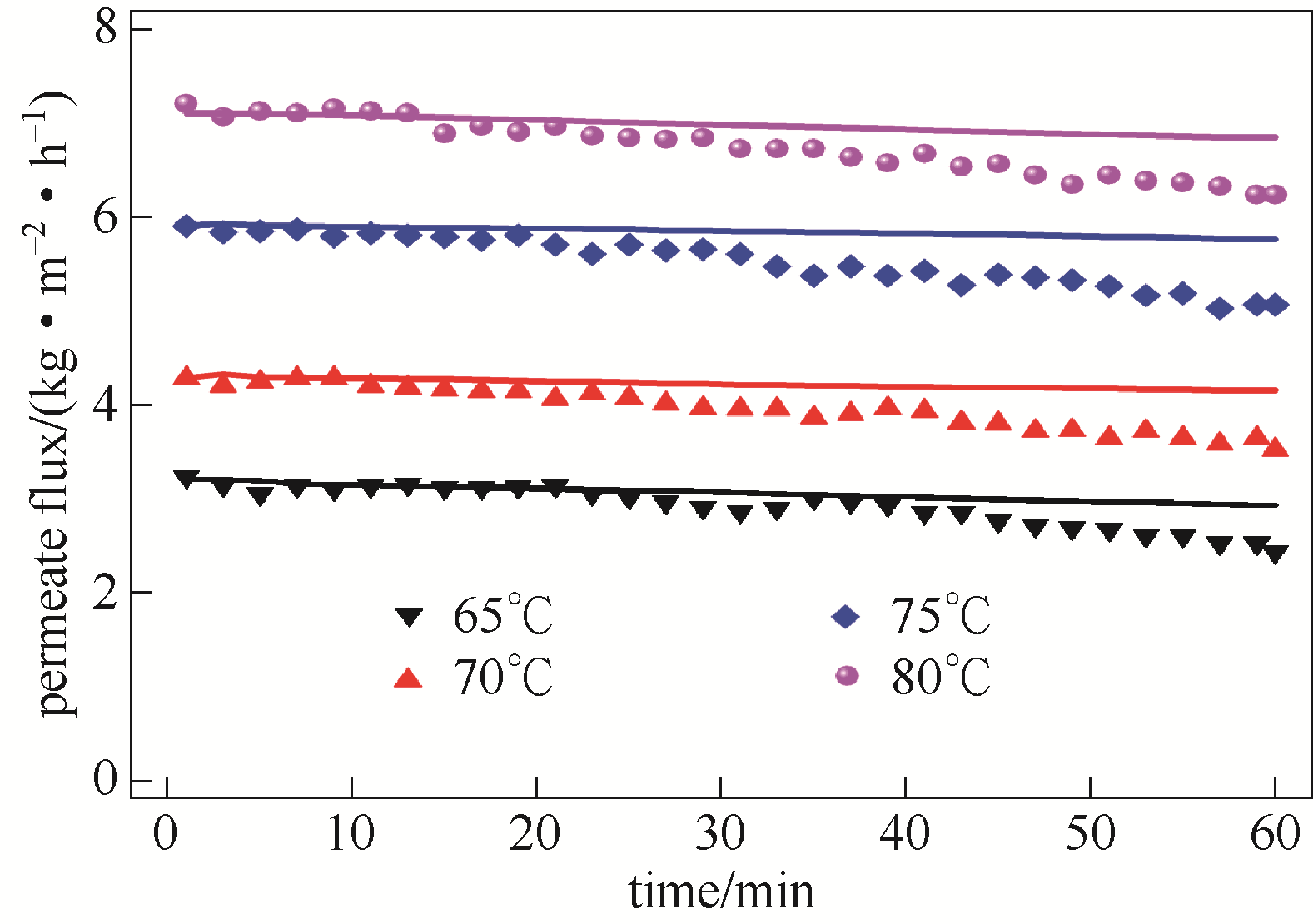

图3 不同操作温度对渗透通量的影响 ( W M g C l 2 / ( W M g C l 2 + W N a C l ) =5.0%,图中实线为实时通量预测值)

Fig.3 Permeate flux with different operation temperature ( W M g C l 2 / ( W M g C l 2 + W N a C l ) =5.0%,solid line is on-line predict permeate flux)

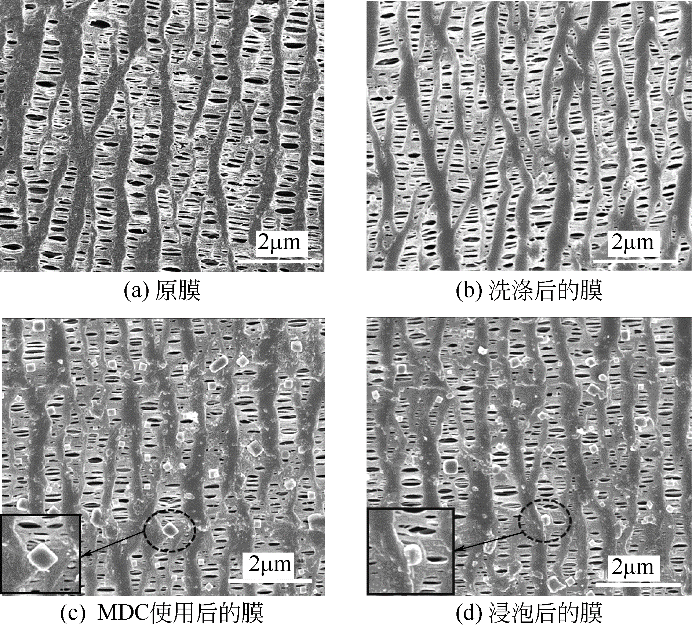

图4 原膜、使用后、洗涤后和浸泡对比实验的膜表面SEM图

Fig.4 SEM images of different membrane surface (original membrane, membrane after MDC, washed membrane after MDC, soaked membrane in comparative experiment)

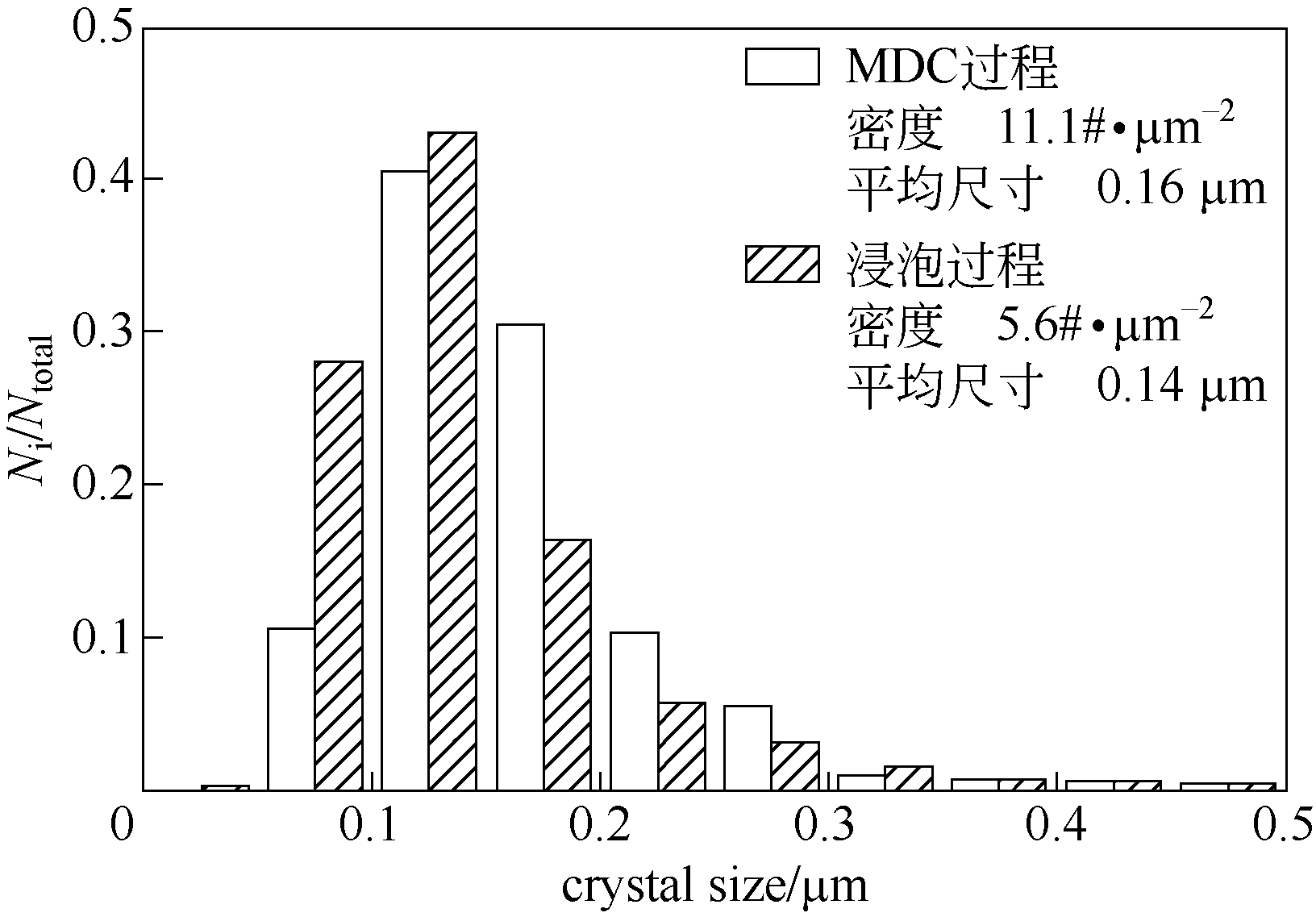

图5 MDC过程和浸泡对比实验的膜表面的晶体性质( W M g C l 2 / ( W M g C l 2 + W N a C l ) =5.0%, T=70℃)

Fig.5 Property of crystal on membrane surface with MDC process and soaking experiment ( W M g C l 2 / ( W M g C l 2 + W N a C l ) =5.0%, T=70℃)

图6 使用次数对膜渗透通量的影响 ( W M g C l 2 / ( W M g C l 2 + W N a C l ) =5.0%, T=70℃)

Fig.6 Permeate flux with reuse times ( W M g C l 2 / ( W M g C l 2 + W N a C l ) =5.0%, T=70℃)

图7 不同操作温度不同组分浓度下晶体的粒度分布(M.S.为平均粒度,C.V.为变异系数,σ为标准差,C.V.=标准差/均值)

Fig.7 Crystal size distribution with different operation temperature and component concentration (M.S. is average size and C.V. is coefficient of variation, C.V.=σ/M.S.)

| 操作 温度/℃ | | 水的电导率/ (μS?cm-1) | NaCl纯度(洗前)/%(mass) | NaCl纯度(洗后)/%(mass) |

|---|---|---|---|---|

| 65 | 0 | 4.68 | — | — |

| 5.0% | 4.37 | 95.95 | 99.10 | |

| 10.0% | 4.05 | 92.03 | 98.56 | |

| 80 | 0 | 4.89 | — | — |

| 5.0% | 4.63 | 92.82 | 98.80 | |

| 10.0% | 4.32 | 90.51 | 98.15 |

表2 不同温度下水和晶体产品的纯度

Table 2 Purity of water and crystal under different temperature

| 操作 温度/℃ | | 水的电导率/ (μS?cm-1) | NaCl纯度(洗前)/%(mass) | NaCl纯度(洗后)/%(mass) |

|---|---|---|---|---|

| 65 | 0 | 4.68 | — | — |

| 5.0% | 4.37 | 95.95 | 99.10 | |

| 10.0% | 4.05 | 92.03 | 98.56 | |

| 80 | 0 | 4.89 | — | — |

| 5.0% | 4.63 | 92.82 | 98.80 | |

| 10.0% | 4.32 | 90.51 | 98.15 |

图9 晶体洗涤前后表面的元素分析

Fig.9 Elemental mapping of crystal products surface before and after washing with ethanol ( W M g C l 2 / ( W M g C l 2 + W N a C l ) =10.0%, T = 80℃)

| 1 | Gupta V K , Ali I , Saleh T A , et al . Chemical treatment technologies for waste-water recycling—an overview[J]. RSC Advances, 2012, 2(16): 6380-6388. |

| 2 | Michael-Kordatou I , Michael C , Duan X , et al . Dissolved effluent organic matter: characteristics and potential implications in wastewater treatment and reuse applications[J]. Water Research, 2015, 77: 213-248. |

| 3 | Papageorgiou M , Kosma C , Lambropoulou D . Seasonal occurrence, removal, mass loading and environmental risk assessment of 55 pharmaceuticals and personal care products in a municipal wastewater treatment plant in Central Greece[J]. Science of the Total Environment, 2016, 543: 547-569. |

| 4 | Wu H , Zhang J , Ngo H H , et al . A review on the sustainability of constructed wetlands for wastewater treatment: design and operation[J]. Bioresource Technology, 2015, 175: 594-601. |

| 5 | Fisher J B , Melton F , Middleton E , et al . The future of evapotranspiration: global requirements for ecosystem functioning, carbon and climate feedbacks, agricultural management, and water resources[J]. Water Resources Research, 2017, 53(4): 2618-2626. |

| 6 | Loganathan K , Chelme-Ayala P , El-Din M G . Pilot-scale study on the treatment of basal aquifer water using ultrafiltration, reverse osmosis and evaporation/crystallization to achieve zero-liquid discharge[J]. Journal of Environmental Management, 2016, 165: 213-223. |

| 7 | Li Y , Wang Z , He T . Morphological control of polymer spherulites via manipulating radial lamellar organization upon evaporative crystallization: a mini review[J]. Crystals, 2017, 7(4): 115. |

| 8 | McBride S A , Dash S , Varanasi K K . Evaporative crystallization in drops on superhydrophobic and liquid-impregnated surfaces[J]. Langmuir, 2018, 34(41): 12350-12358. |

| 9 | Lu H , Wang J , Wang T , et al . Crystallization techniques in wastewater treatment: an overview of applications[J]. Chemosphere, 2017, 173: 474-484. |

| 10 | Shokri‐Kuehni S M S , Vetter T , Webb C , et al . New insights into saline water evaporation from porous media: complex interaction between evaporation rates, precipitation, and surface temperature[J]. Geophysical Research Letters, 2017, 44(11): 5504-5510. |

| 11 | Anisi F , Thomas K M , Kramer H J M . Membrane-assisted crystallization: membrane characterization, modelling and experiments[J]. Chemical Engineering Science, 2017, 158: 277-286. |

| 12 | 关云山, 武警, 程文婷, 等 . 膜蒸馏-结晶耦合从高浓度 KCl-MgCl2-H2O 溶液中回收KCl[J]. 化工学报, 2015, 66(5): 1767-1776. |

| Guan Y S , Wu J , Cheng W T , et al . Recovery of KCl crystalline product from highly concentrated KCl-MgCl2-H2O solution with membrane distillation crystallization[J]. CIESC Journal, 2015, 66(5): 1767-1776. | |

| 13 | Pantoja C E , Nariyoshi Y N , Seckler M M . Membrane distillation crystallization applied to brine desalination: a hierarchical design procedure[J]. Industrial & Engineering Chemistry Research, 2015, 54(10): 2776-2793. |

| 14 | Creusen R , van Medevoort J , Roelands M , et al . Integrated membrane distillation-crystallization: process design and cost estimations for seawater treatment and fluxes of single salt solutions[J]. Desalination, 2013, 323: 8-16. |

| 15 | 游文婷, 董哲勤, 张觅, 等 . 高浓度NaCl溶液真空膜蒸馏传递阻力分布的研究[J]. 膜科学与技术, 2014, 34(6): 1-5. |

| You W T , Dong Z Q , Zhang M , et al . The research about transfer resistance distribution of high concentration NaCl solution via vacuum membrane distillation[J]. Membrane Science and Technology, 2014, 34(6): 1-5. | |

| 16 | 王平, 秦英杰, 刘晶, 等 . 多效膜蒸馏技术用于深度浓缩多种无机盐水溶液[J]. 膜科学与技术, 2014, 4: 39-44. |

| Wang P , Qin Y J , Liu J , et al . Deep concentration of various aqueous solutions of inorganic salts by using multiple-effect membrane distillation[J]. Membrane Science and Technology, 2014, 4: 39-44. | |

| 17 | 李卜义, 王建友, 王济虎, 等 . 中空纤维空气隙式膜蒸馏海水淡化过程的性能模拟与优化[J]. 化工学报, 2015, 66(2): 597-604. |

| Li B Y , Wang J Y , Wang J H , et al . Modeling and optimization of hollow fiber air gap membrane distillation for seawater desalination[J]. CIESC Journal, 2015, 66(2): 597-604. | |

| 18 | Cho H , Choi Y , Lee S , et al . Membrane distillation of high salinity wastewater from shale gas extraction: effect of antiscalants[J]. Desalination and Water Treatment, 2016, 57(55): 26718-26729. |

| 19 | McGaughey A L , Gustafson R D , Childress A E . Effect of long-term operation on membrane surface characteristics and performance in membrane distillation[J]. Journal of Membrane Science, 2017, 543: 143-150. |

| 20 | Politano A , Argurio P , Di Profio G , et al . Photothermal membrane distillation for seawater desalination[J]. Advanced Materials, 2017, 29(2): 1603504. |

| 21 | Wang P , Chung T S . Recent advances in membrane distillation processes: membrane development, configuration design and application exploring[J]. Journal of Membrane Science, 2015, 474: 39-56. |

| 22 | Kim J , Kwon H , Lee S , et al . Membrane distillation (MD) integrated with crystallization (MDC) for shale gas produced water (SGPW) treatment[J]. Desalination, 2017, 403: 172-178. |

| 23 | Eykens L , Hitsov I , De Sitter K , et al . Influence of membrane thickness and process conditions on direct contact membrane distillation at different salinities[J]. Journal of Membrane Science, 2016, 498: 353-364. |

| 24 | Choi Y , Naidu G , Jeong S , et al . Experimental comparison of submerged membrane distillation configurations for concentrated brine treatment[J]. Desalination, 2017, 420: 54-62. |

| 25 | Jiang X , Li G , Lu D , et al . Hybrid control mechanism of crystal morphology modification for ternary solution treatment via membrane assisted crystallization[J]. Crystal Growth & Design, 2017, 18(2): 934-943. |

| 26 | Julian H , Meng S , Li H , et al . Effect of operation parameters on the mass transfer and fouling in submerged vacuum membrane distillation crystallization (VMDC) for inland brine water treatment[J]. Journal of Membrane Science, 2016, 520: 679-692. |

| 27 | Di Profio G , Curcio E , Ferraro S , et al . Effect of supersaturation control and heterogeneous nucleation on porous membrane surfaces in the crystallization of L-glutamic acid polymorphs[J]. Crystal Growth and Design, 2009, 9(5): 2179-2186. |

| 28 | Trifkovic M , Sheikhzadeh M , Rohani S . Determination of metastable zone width for combined anti-solvent/cooling crystallization[J]. Journal of Crystal Growth 2009, 311(14): 3640-3650. |

| 29 | Myerson A . Handbook of Industrial Crystallization[M]. America: Butterworth-Heinemann, 2002. |

| 30 | Edwie F , Chung T S . Development of hollow fiber membranes for water and salt recovery from highly concentrated brine via direct contact membrane distillation and crystallization[J]. Journal of Membrane Science, 2012, 421: 111-123. |

| 31 | Lu D , Li P , Xiao W , et al . Simultaneous recovery and crystallization control of saline organic wastewater by membrane distillation crystallization[J]. AIChE Journal, 2017, 63(6): 2187-2197. |

| 32 | Quist-Jensen C A , Macedonio F , Horbez D , et al . Reclamation of sodium sulfate from industrial wastewater by using membrane distillation and membrane crystallization[J]. Desalination, 2017, 401: 112-119. |

| 33 | Kurdian A R , Bahreini M , Montazeri G H , et al . Modeling of direct contact membrane distillation process: flux prediction of sodium sulfate and sodium chloride solutions[J]. Desalination, 2013, 323: 75-82. |

| 34 | Jiang X , Lu D , Xiao W , et al . Interface-based crystal particle autoselection via membrane crystallization: from scaling to process control[J]. AIChE Journal, 2019, 65: 723-733. |

| 35 | Bao L , Ma J , Long W , et al . Fractal analysis in particle dissolution: a review[J]. Rev. Chem. Eng., 2014, 30(3): 261-287. |

| 36 | Tromelin A , Hautbout G , Pourcelot Y . Application of fractal geometry to dissolution kinetic study of a sweetener excipient[J]. Int. J. Pharm ., 2001, 224: 131-140. |

| 37 | Jiang X , Lu D , Xiao W , et al . Membrane assisted cooling crystallization: process model, nucleation, metastable zone, and crystal size distribution[J]. AIChE Journal, 2016, 62(3): 829-841. |

| 38 | Jiang X , Lu D , Xiao W , et al . Interface-based crystal particle autoselection via membrane crystallization: from scaling to process control[J]. AIChE Journal, 2019, 65(2):723-733. |

| [1] | 于宏鑫, 邵双全. 水结晶过程的分子动力学模拟分析[J]. 化工学报, 2023, 74(S1): 250-258. |

| [2] | 张佳怡, 何佳莉, 谢江鹏, 王健, 赵鹬, 张栋强. 渗透汽化技术用于锂电池生产中N-甲基吡咯烷酮回收的研究进展[J]. 化工学报, 2023, 74(8): 3203-3215. |

| [3] | 傅予, 刘兴翀, 王瀚雨, 李海敏, 倪亚飞, 邹文静, 雷月, 彭永姗. F3EACl修饰层对钙钛矿太阳能电池性能提升的研究[J]. 化工学报, 2023, 74(8): 3554-3563. |

| [4] | 苏晓丹, 朱干宇, 李会泉, 郑光明, 孟子衡, 李防, 杨云瑞, 习本军, 崔玉. 湿法磷酸半水工艺考察与石膏结晶过程研究[J]. 化工学报, 2023, 74(4): 1805-1817. |

| [5] | 周璇, 李孟亚, 孙杰, 岑振凯, 吕强三, 周立山, 王海涛, 韩丹丹, 龚俊波. 添加剂对氨基酸晶体生长的影响[J]. 化工学报, 2023, 74(2): 500-510. |

| [6] | 陈毓明, 历伟, 严翔, 王靖岱, 阳永荣. 初生态聚乙烯聚集态结构调控研究进展[J]. 化工学报, 2023, 74(2): 487-499. |

| [7] | 苏伟怡, 丁佳慧, 李春利, 王洪海, 姜艳军. 酶促反应结晶研究进展[J]. 化工学报, 2023, 74(2): 617-629. |

| [8] | 乃学瑛, 吴鹏, 程远, 肖剑飞, 刘鑫, 董亚萍. 水热生长碱式硫酸镁纳米线结晶动力学研究[J]. 化工学报, 2022, 73(7): 3038-3044. |

| [9] | 孙国鑫, 苟萌萱, 周诚, 常佩, 贺高红, 姜晓滨. 高浓度Na+//NO |

| [10] | 殷海青, 马祎明, 万旭兴, 董伟兵, 张玉龙, 吴送姑. 碳酸锂气液固三相反应结晶过程研究[J]. 化工学报, 2022, 73(3): 1207-1220. |

| [11] | 陈雪梅, 王彤, 高玉箔, 彭鼎程, 罗雨婷. 利用激光诱导石墨烯实现高效太阳能界面蒸发[J]. 化工学报, 2022, 73(12): 5648-5659. |

| [12] | 敬鹏程, 陈立涛, 闫传梁, 姜传祥, 夏煜翔, 于常宏, 王昊天. 超声波悬浮TBAB溶液液滴表面半笼型水合物生长过程研究[J]. 化工学报, 2022, 73(11): 4893-4902. |

| [13] | 贺冲, 白进, 郭晶, 孔令学, 鲁浩, 李怀柱, 秦育红, 李文. 气氛和化学组成对高铁煤灰熔融特性的影响机理[J]. 化工学报, 2022, 73(10): 4648-4658. |

| [14] | 郑海峰, 贾晟哲, 王崧成, 韩瑞, 韩丹丹, 高振国, 龚俊波. 超细晶体的研究进展[J]. 化工学报, 2022, 73(10): 4285-4297. |

| [15] | 丰闪闪, 刘晓斌, 郭石麟, 何兵兵, 高振国, 陈明洋, 龚俊波. 锂枝晶的成核、生长与抑制[J]. 化工学报, 2022, 73(1): 97-109. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号