化工学报 ›› 2022, Vol. 73 ›› Issue (12): 5648-5659.DOI: 10.11949/0438-1157.20220604

收稿日期:2022-08-21

修回日期:2022-09-04

出版日期:2022-12-05

发布日期:2023-01-17

通讯作者:

陈雪梅

作者简介:陈雪梅(1984—),女,博士,教授,xuemeichen@njust.edu.cn

基金资助:

Xuemei CHEN( ), Tong WANG, Yubo GAO, Dingcheng PENG, Yuting LUO

), Tong WANG, Yubo GAO, Dingcheng PENG, Yuting LUO

Received:2022-08-21

Revised:2022-09-04

Online:2022-12-05

Published:2023-01-17

Contact:

Xuemei CHEN

摘要:

传统的石墨烯制备方法过程复杂且环境严苛,本文使用激光诱导法制备石墨烯,并探索其在太阳能界面蒸发领域的应用。以商业隔热软木板(ICB板)为基底,在其表面通过激光刻蚀诱导生成石墨烯(laser-induced graphene, LIG)作为光热膜(ICB-LIG膜),辅以隔热装置和水输送通道,构建了一个新型的太阳能蒸发器。蒸发性能测试结果表明,该太阳能蒸发器能够在1个标准太阳光照射下实现高达1.33 kg·m-2·h-1的蒸发速率,相应的光热转化效率为86.0%。此外,该太阳能蒸发器还具有良好的耐久性,在7次循环实验中蒸发速率仅下降3.0%。

中图分类号:

陈雪梅, 王彤, 高玉箔, 彭鼎程, 罗雨婷. 利用激光诱导石墨烯实现高效太阳能界面蒸发[J]. 化工学报, 2022, 73(12): 5648-5659.

Xuemei CHEN, Tong WANG, Yubo GAO, Dingcheng PENG, Yuting LUO. Efficient solar interfacial evaporation using laser-induced graphene[J]. CIESC Journal, 2022, 73(12): 5648-5659.

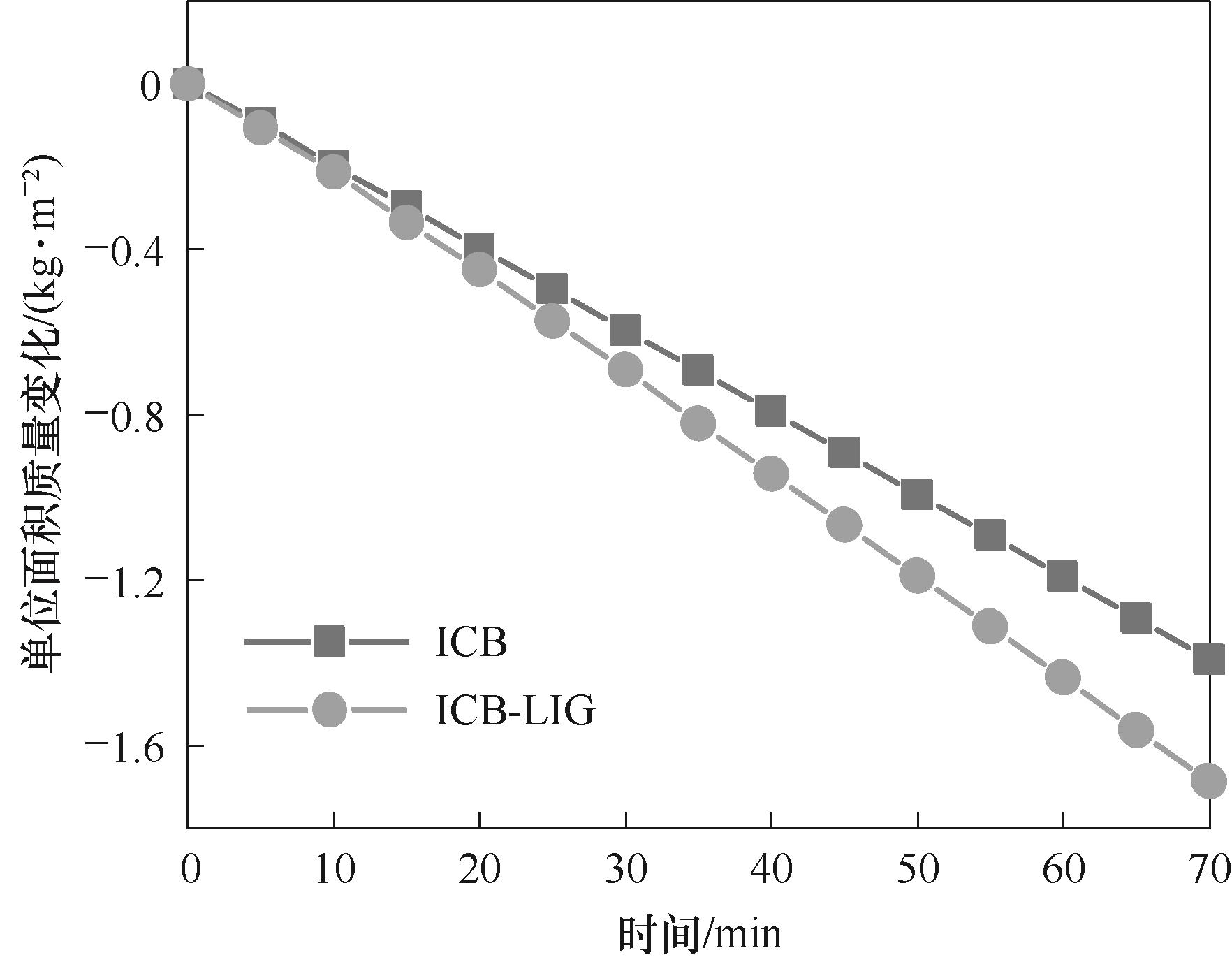

图9 1倍太阳光强下3.5%(质量)的NaCl溶液中ICB板和ICB-LIG膜蒸发系统的质量变化

Fig.9 Mass change of evaporation system of ICB plate and ICB-LIG membrane in 3.5%(mass) NaCl solution under 1 sun illumination

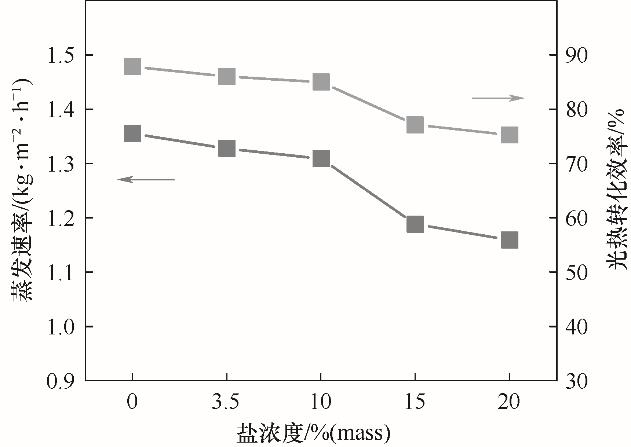

图10 1倍太阳光强下不同质量分数的NaCl溶液(0、3.5%、10%、15%、20%)中ICB-LIG膜的蒸发速率和光热转化效率

Fig.10 Evaporation rate and photothermal conversion efficiency of ICB-LIG membrane in different mass fraction of NaCl solution (0, 3.5%, 10%, 15%, 20%) under 1 sun illumination

图11 不同光强下3.5%(质量) NaCl溶液中蒸发系统的各项数据变化以及1倍光强下膜温与水温随时间的变化

Fig.11 The data changes of the evaporation system in the 3.5%(mass) NaCl solution under different light intensities and change of membrane temperature and water temperature under 1 sun illumination

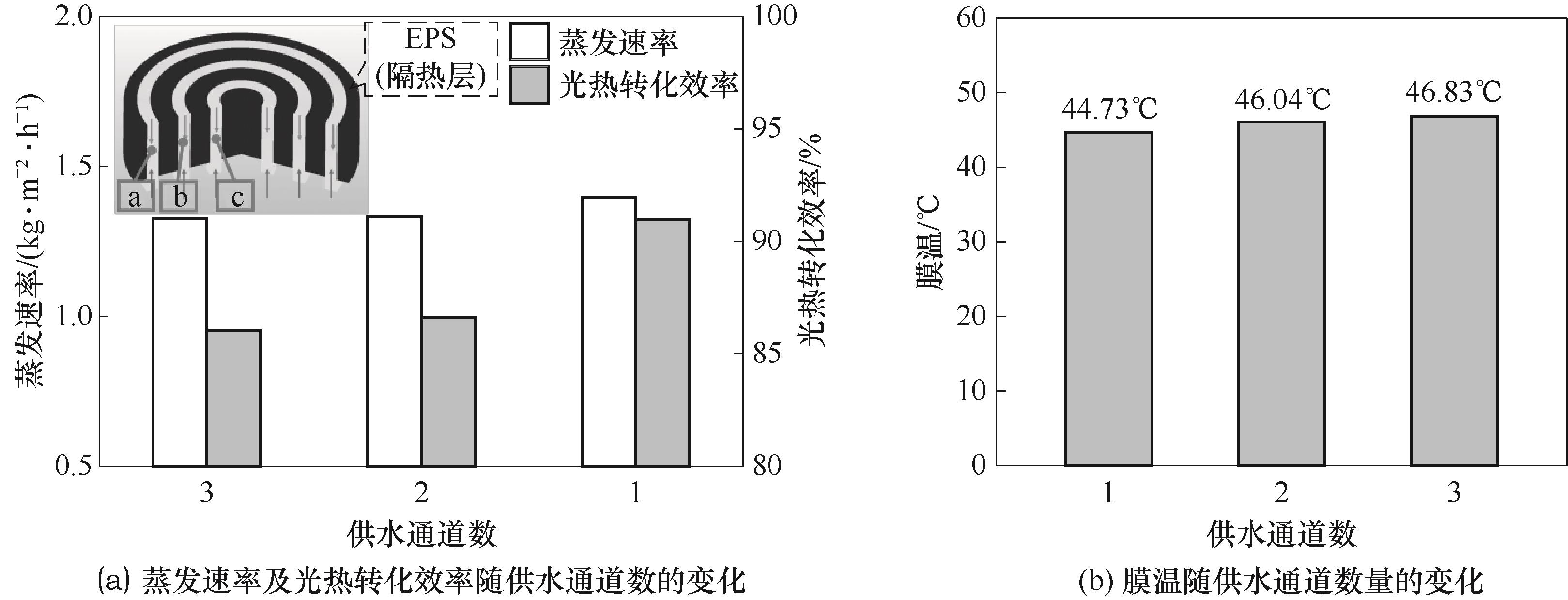

图14 1倍太阳光照下3.5%(质量)NaCl溶液中不同供水通道数下ICB-LIG膜的蒸发性能

Fig.14 The evaporation performance of ICB-LIG membrane with different number of water supply channels in 3.5% (mass) NaCl solution under 1 sun illumination

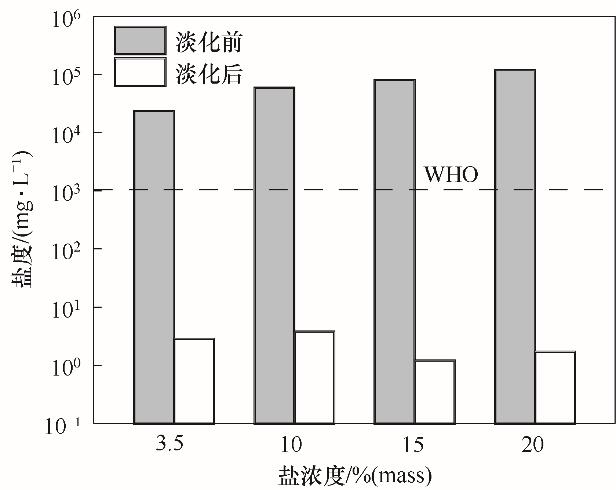

图17 不同质量分数的NaCl溶液淡化前后的盐度[虚线代表WHO定义的饮用水标准盐度(1000 mg·L-1)]

Fig.17 Salinity before and after desalting NaCl solutions with different mass fraction [dotted line represents the WHO standard salinity for drinking water (1000 mg·L-1)]

| 1 | 徐炜超. Janus吸收体在太阳能海水淡化方面的研究[D]. 南京: 南京大学, 2018. |

| Xu W C. Janus absorber for solar desalination[D]. Nanjing: Nanjing University, 2018. | |

| 2 | Al-Shammiri M, Safar M. Multi-effect distillation plants: state of the art[J]. Desalination, 1999, 126(1/2/3): 45-59. |

| 3 | Alhazmy M M. Economic and thermal feasibility of multi stage flash desalination plant with brine-feed mixing and cooling[J]. Energy, 2014, 76: 1029-1035. |

| 4 | Garelick H, Dybowska A, Valsami-Jones E, et al. Remediation technologies for arsenic contaminated drinking waters[J]. Journal of Soils and Sediments, 2005, 5(3): 182-190. |

| 5 | 魏天骐, 李秀强, 李金磊, 等. 界面光蒸汽转化研究进展[J]. 科学通报, 2018, 63(14): 1405-1416, 1404. |

| Wei T Q, Li X Q, Li J L, et al. Interfacial solar vapor generation[J]. Chinese Science Bulletin, 2018, 63(14): 1405-1416, 1404 | |

| 6 | 王峥, 任毅. 我国太阳能资源的利用现状与产业发展[J]. 资源与产业, 2010, 12(2): 89-92. |

| Wang Z, Ren Y. Utilization and development of solar energy industry in China[J]. Resources & Industries, 2010, 12(2): 89-92. | |

| 7 | Xu Z Y, Zhang L N, Zhao L, et al. Ultrahigh-efficiency desalination via a thermally-localized multistage solar still[J]. Energy & Environmental Science, 2020, 13(3): 830-839. |

| 8 | Ghasemi H, Ni G, Marconnet A M, et al. Solar steam generation by heat localization[J]. Nature Communications, 2014, 5: 4449. |

| 9 | Zhu M W, Li Y J, Chen F J, et al. Plasmonic wood for high-efficiency solar steam generation[J]. Advanced Energy Materials, 2018, 8(4): 1701028. |

| 10 | Traver E, Karaballi R A, Monfared Y E, et al. TiN, ZrN, and HfN nanoparticles on nanoporous aluminum oxide membranes for solar-driven water evaporation and desalination[J]. ACS Applied Nano Materials, 2020, 3(3): 2787-2794. |

| 11 | Chala T F, Wu C M, Chou M H, et al. Melt electrospun reduced tungsten oxide /polylactic acid fiber membranes as a photothermal material for light-driven interfacial water evaporation[J]. ACS Applied Materials & Interfaces, 2018, 10(34): 28955-28962. |

| 12 | Jiang Q S, Tian L M, Liu K K, et al. Bilayered biofoam for highly efficient solar steam generation[J]. Advanced Materials, 2016, 28(42): 9400-9407. |

| 13 | Hu X Z, Xu W C, Zhou L, et al. Tailoring graphene oxide-based aerogels for efficient solar steam generation under one Sun[J]. Advanced Materials, 2017, 29(5): 1604031. |

| 14 | Zhou X Y, Zhao F, Guo Y H, et al. A hydrogel-based antifouling solar evaporator for highly efficient water desalination[J]. Energy & Environmental Science, 2018, 11(8): 1985-1992. |

| 15 | Guo Y H, Zhao F, Zhou X Y, et al. Tailoring nanoscale surface topography of hydrogel for efficient solar vapor generation[J]. Nano Letters, 2019, 19(4): 2530-2536. |

| 16 | Wu X, Chen G Y, Zhang W, et al. A plant-transpiration-process-inspired strategy for highly efficient solar evaporation[J]. Advanced Sustainable Systems, 2017, 1(6): 1700046. |

| 17 | 李岳, 李炯利, 朱巧思, 等. 石墨烯导热材料研究进展[J]. 材料工程, 2021(11): 1-13. |

| Li Y, Li J L, Zhu Q S, et al. Research progress in graphene based thermal conductivity materials[J]. Journal of Materials Engineering, 2021(11): 1-13. | |

| 18 | Liu Y M, Chen J W, Guo D W, et al. Floatable, self-cleaning, and carbon-black-based superhydrophobic gauze for the solar evaporation enhancement at the air-water interface[J]. ACS Applied Materials & Interfaces, 2015, 7(24): 13645-13652. |

| 19 | 陈瑞灿, 王海燕, 韩永刚, 等. 氧化还原法制备石墨烯及其表征[J]. 材料导报, 2012, 26(12): 114-117. |

| Chen R C, Wang H Y, Han Y G, et al. Synthesis and characterization of graphene via oxidation reduction[J]. Material Review, 2012, 26(12): 114-117. | |

| 20 | Novoselov K S, Geim A K, Morozov S V, et al. Electric field effect in atomically thin carbon films[J]. Science, 2004, 306(5696): 666-669. |

| 21 | Berger C, Song Z M, Li T B, et al. Ultrathin epitaxial graphite: 2D electron gas properties and a route toward graphene-based nanoelectronics[J]. The Journal of Physical Chemistry B, 2004, 108(52): 19912-19916. |

| 22 | Lin J, Peng Z W, Liu Y Y, et al. Laser-induced porous graphene films from commercial polymers[J]. Nature Communications, 2014, 5: 5714. |

| 23 | Luo Y T, Chen Z C, Li Q, et al. Laser-induced porous graphene on a polyimide membrane with a melamine sponge framework (PI@MS) for long-term stable steam generation[J]. ACS Applied Energy Materials, 2021, 4(9): 9766-9774. |

| 24 | Chyan Y, Ye R Q, Li Y L, et al. Laser-induced graphene by multiple lasing: toward electronics on cloth, paper, and food[J]. ACS Nano, 2018, 12(3): 2176-2183. |

| 25 | Le T S D, Park S, An J N, et al. Ultrafast laser pulses enable one-step graphene patterning on woods and leaves for green electronics[J]. Advanced Functional Materials, 2019, 29(33): 1902771. |

| 26 | Chen J Y, Wang Y N, Liu F, et al. Laser-induced graphene paper heaters with multimodally patternable electrothermal performance for low-energy manufacturing of composites[J]. ACS Applied Materials & Interfaces, 2020, 12(20): 23284-23297. |

| 27 | Wang Y N, Wang Y, Zhang P P, et al. Laser-induced freestanding graphene papers: a new route of scalable fabrication with tunable morphologies and properties for multifunctional devices and structures[J]. Small, 2018, 14(36): e1802350. |

| 28 | Wang H, Zhao Z F, Liu P P, et al. Laser-induced graphene based flexible electronic devices[J]. Biosensors, 2022, 12(2): 55. |

| 29 | Ye R Q, Peng Z W, Wang T, et al. In situ formation of metal oxide nanocrystals embedded in laser-induced graphene[J]. ACS Nano, 2015, 9(9): 9244-9251. |

| 30 | Zhang C, Peng Z X, Huang C L, et al. High-energy all-in-one stretchable micro-supercapacitor arrays based on 3D laser-induced graphene foams decorated with mesoporous ZnP nanosheets for self-powered stretchable systems[J]. Nano Energy, 2021, 81: 105609. |

| 31 | Inagaki M, Kang F Y. Graphene derivatives: graphane, fluorographene, graphene oxide, graphyne and graphdiyne[J]. Jourmal of Materials Chemistry A, 2014, 2: 13193-13206. |

| 32 | 吴娟霞, 徐华, 张锦. 拉曼光谱在石墨烯结构表征中的应用[J]. 化学学报, 2014, 72(3): 301-318. |

| Wu J X, Xu H, Zhang J. Raman spectroscopy of graphene[J]. Acta Chimica Sinica, 2014, 72(3): 301-318. | |

| 33 | Fesenko O, Dovbeshko G, Dementjev A, et al. Graphene-enhanced Raman spectroscopy of thymine adsorbed on single-layer graphene[J]. Nanoscale Research Letters, 2015, 10: 163. |

| 34 | 姜晓琳, 李君, 刘臻, 等. 石墨烯炭材料的结构表征方法研究[J]. 洁净煤技术, 2022, DOI:10.13226/j.issn.1006-6772. 22010701 . |

| Jiang X L, Li J, Liu Z, et al. Study on structural characterization of graphene carbon materials[J]. Clean Coal Technology, 2022, DOI:10.13226/j.issn.1006-6772.22010701 .. | |

| 35 | Xue G B, Liu K, Chen Q, et al. Robust and low-cost flame-treated wood for high-performance solar steam generation[J]. ACS Applied Materials & Interfaces, 2017, 9(17): 15052-15057. |

| 36 | 张德旭. 高速太阳能水蒸发体系的构建及其性能研究[D]. 青岛: 青岛科技大学, 2021. |

| Zhang D X. Construction and performance of high efficient solar water evaporation system[D]. Qingdao: Qingdao University of Science and Technology, 2021. | |

| 37 | Chen Z C, Li Q, Chen X M. Porous graphene/polyimide membrane with a three-dimensional architecture for rapid and efficient solar desalination via interfacial evaporation[J]. ACS Sustainable Chemistry & Engineering, 2020, 8(36): 13850-13858. |

| 38 | Liu G H, Chen T, Xu J L, et al. Salt-rejecting solar interfacial evaporation[J]. Cell Reports Physical Science, 2021, 2(1): 100310. |

| [1] | 吴馨, 龚建英, 靳龙, 王宇涛, 黄睿宁. 超声波激励下铝板表面液滴群输运特性的研究[J]. 化工学报, 2023, 74(S1): 104-112. |

| [2] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [3] | 毕丽森, 刘斌, 胡恒祥, 曾涛, 李卓睿, 宋健飞, 吴翰铭. 粗糙界面上纳米液滴蒸发模式的分子动力学研究[J]. 化工学报, 2023, 74(S1): 172-178. |

| [4] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [5] | 于宏鑫, 邵双全. 水结晶过程的分子动力学模拟分析[J]. 化工学报, 2023, 74(S1): 250-258. |

| [6] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [7] | 张化福, 童莉葛, 张振涛, 杨俊玲, 王立, 张俊浩. 机械蒸汽压缩蒸发技术研究现状与发展趋势[J]. 化工学报, 2023, 74(S1): 8-24. |

| [8] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [9] | 杨越, 张丹, 郑巨淦, 涂茂萍, 杨庆忠. NaCl水溶液喷射闪蒸-掺混蒸发的实验研究[J]. 化工学报, 2023, 74(8): 3279-3291. |

| [10] | 徐文杰, 贾献峰, 王际童, 乔文明, 凌立成, 王任平, 余子舰, 张寅旭. 有机硅/酚醛杂化气凝胶的制备和性能研究[J]. 化工学报, 2023, 74(8): 3572-3583. |

| [11] | 傅予, 刘兴翀, 王瀚雨, 李海敏, 倪亚飞, 邹文静, 雷月, 彭永姗. F3EACl修饰层对钙钛矿太阳能电池性能提升的研究[J]. 化工学报, 2023, 74(8): 3554-3563. |

| [12] | 张媛媛, 曲江源, 苏欣欣, 杨静, 张锴. 循环流化床燃煤机组SNCR脱硝过程气液传质和反应特性[J]. 化工学报, 2023, 74(6): 2404-2415. |

| [13] | 李正涛, 袁志杰, 贺高红, 姜晓滨. 疏水界面上的NaCl液滴蒸发过程内环流调控机制研究[J]. 化工学报, 2023, 74(5): 1904-1913. |

| [14] | 苏晓丹, 朱干宇, 李会泉, 郑光明, 孟子衡, 李防, 杨云瑞, 习本军, 崔玉. 湿法磷酸半水工艺考察与石膏结晶过程研究[J]. 化工学报, 2023, 74(4): 1805-1817. |

| [15] | 张生安, 刘桂莲. 高效太阳能电解水制氢系统及其性能的多目标优化[J]. 化工学报, 2023, 74(3): 1260-1274. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号