化工学报 ›› 2020, Vol. 71 ›› Issue (5): 2320-2332.DOI: 10.11949/0438-1157.20191419

宋艳培1,3( ),庄修政1,3,詹昊2,徐彬1,3,阴秀丽1(

),庄修政1,3,詹昊2,徐彬1,3,阴秀丽1( ),吴创之1,3

),吴创之1,3

收稿日期:2019-11-25

修回日期:2020-01-16

出版日期:2020-05-05

发布日期:2020-05-05

通讯作者:

阴秀丽

作者简介:宋艳培(1994—),女,硕士研究生,基金资助:

Yanpei SONG1,3( ),Xiuzheng ZHUANG1,3,Hao ZHAN2,Bin XU1,3,Xiuli YIN1(

),Xiuzheng ZHUANG1,3,Hao ZHAN2,Bin XU1,3,Xiuli YIN1( ),Chuangzhi WU1,3

),Chuangzhi WU1,3

Received:2019-11-25

Revised:2020-01-16

Online:2020-05-05

Published:2020-05-05

Contact:

Xiuli YIN

摘要:

污泥和褐煤通过共水热碳化预处理以制备高品质固体燃料,为污泥和低阶煤的有效处理提供了一种可行方案。本研究主要考察了城市污泥(SS)和褐煤(LC)在不同温度下(120,180,240和300℃)进行共水热碳化制得的固相产物(水热炭)的热化学转化特性和规律,包括燃烧、热解和半焦CO2气化过程,并分析了这些过程中的协同作用。结果表明,共水热碳化预处理对城市污泥和褐煤的热利用行为有显著影响。一方面,共水热碳化处理后的水热炭相对其计算值具有更高的产率、煤化程度、热值等,同时具有更低的灰分含量。另一方面,混合物水热炭在燃烧、热解和半焦CO2气化过程均表现出一定的协同作用(促进燃烧和热解行为,降低气化活性),且水热温度在240℃附近时,这种作用最为明显。鉴于热解和气化过程的协同效果均低于燃烧过程,共水热碳化产物被认为更适合用于燃烧。这些发现表明,将共水热碳化改性提质处理与后续热化学工艺相结合,对于能源的产生和有机废弃物的利用都有一定的积极意义。

中图分类号:

宋艳培, 庄修政, 詹昊, 徐彬, 阴秀丽, 吴创之. 城市污泥/褐煤共水热碳化产物的热化学转化特性及规律研究[J]. 化工学报, 2020, 71(5): 2320-2332.

Yanpei SONG, Xiuzheng ZHUANG, Hao ZHAN, Bin XU, Xiuli YIN, Chuangzhi WU. Investigation on thermochemical conversion characteristics and regularity of co-hydrothermal carbonization solid fuel from sewage sludge and lignite[J]. CIESC Journal, 2020, 71(5): 2320-2332.

| Sample | Yield /% | Proximate analysis /%(mass, db) | Ultimate analysis /%(mass, daf) | HHV/ (MJ·kg-1) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| (mass, db) | A | VM | FC | C | H | O | N | S | |||

| SS | SS-Raw | / | 56.24 | 39.15 | 4.61 | 48.53 | 8.07 | 34.49 | 7.52 | 1.40 | 9.38 |

| SS-120 | 88.34 | 61.22 | 34.30 | 4.48 | 49.77 | 8.16 | 34.19 | 6.42 | 1.45 | 8.23 | |

| SS-180 | 74.92 | 70.40 | 26.13 | 3.47 | 52.81 | 8.39 | 31.56 | 5.70 | 1.53 | 6.65 | |

| SS-240 | 70.45 | 76.21 | 20.27 | 3.52 | 56.18 | 8.83 | 27.90 | 5.44 | 1.64 | 5.70 | |

| SS-300 | 68.00 | 79.44 | 17.08 | 3.48 | 58.32 | 9.04 | 25.67 | 5.16 | 1.80 | 5.02 | |

| LC | LC-Raw | / | 6.97 | 50.65 | 42.38 | 65.10 | 5.68 | 27.37 | 1.41 | 0.43 | 23.95 |

| LC-120 | 95.41 | 6.59 | 50.07 | 43.34 | 65.67 | 5.28 | 27.32 | 1.36 | 0.36 | 24.38 | |

| LC-180 | 93.59 | 6.67 | 49.25 | 44.08 | 66.73 | 5.23 | 26.35 | 1.34 | 0.35 | 24.42 | |

| LC-240 | 89.46 | 6.81 | 48.95 | 44.24 | 67.60 | 5.23 | 25.53 | 1.33 | 0.31 | 24.74 | |

| LC-300 | 80.36 | 6.65 | 46.10 | 47.24 | 68.56 | 5.13 | 24.71 | 1.31 | 0.28 | 25.40 | |

| theoretical mixture | Mix-120(C) | 91.88 | 33.91 | 42.18 | 23.91 | 57.72 | 6.72 | 30.76 | 3.89 | 0.91 | 16.31 |

| Mix-180(C) | 84.26 | 38.53 | 37.69 | 23.77 | 59.77 | 6.81 | 28.95 | 3.52 | 0.94 | 15.55 | |

| Mix-240(C) | 79.95 | 41.51 | 34.61 | 23.88 | 61.89 | 7.03 | 26.72 | 3.38 | 0.98 | 15.22 | |

| Mix-300(C) | 74.18 | 43.05 | 31.59 | 25.36 | 63.44 | 7.09 | 25.19 | 3.24 | 1.04 | 15.21 | |

| mixture | Mix-120(E) | 92.86 | 32.83 | 42.30 | 24.87 | 60.58 | 6.47 | 29.71 | 2.68 | 0.57 | 16.78 |

| Mix-180(E) | 86.81 | 34.69 | 39.91 | 25.39 | 63.26 | 6.35 | 27.22 | 2.62 | 0.56 | 16.79 | |

| Mix-240(E) | 82.82 | 36.39 | 37.97 | 25.64 | 65.27 | 6.26 | 25.42 | 2.55 | 0.50 | 16.93 | |

| Mix-300(E) | 74.88 | 40.38 | 32.70 | 26.92 | 67.11 | 6.14 | 23.84 | 2.46 | 0.46 | 16.62 | |

表1 原料和水热炭的理化特性

Table 1 Physicochemical properties of feedstocks and their derived hydrochars

| Sample | Yield /% | Proximate analysis /%(mass, db) | Ultimate analysis /%(mass, daf) | HHV/ (MJ·kg-1) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| (mass, db) | A | VM | FC | C | H | O | N | S | |||

| SS | SS-Raw | / | 56.24 | 39.15 | 4.61 | 48.53 | 8.07 | 34.49 | 7.52 | 1.40 | 9.38 |

| SS-120 | 88.34 | 61.22 | 34.30 | 4.48 | 49.77 | 8.16 | 34.19 | 6.42 | 1.45 | 8.23 | |

| SS-180 | 74.92 | 70.40 | 26.13 | 3.47 | 52.81 | 8.39 | 31.56 | 5.70 | 1.53 | 6.65 | |

| SS-240 | 70.45 | 76.21 | 20.27 | 3.52 | 56.18 | 8.83 | 27.90 | 5.44 | 1.64 | 5.70 | |

| SS-300 | 68.00 | 79.44 | 17.08 | 3.48 | 58.32 | 9.04 | 25.67 | 5.16 | 1.80 | 5.02 | |

| LC | LC-Raw | / | 6.97 | 50.65 | 42.38 | 65.10 | 5.68 | 27.37 | 1.41 | 0.43 | 23.95 |

| LC-120 | 95.41 | 6.59 | 50.07 | 43.34 | 65.67 | 5.28 | 27.32 | 1.36 | 0.36 | 24.38 | |

| LC-180 | 93.59 | 6.67 | 49.25 | 44.08 | 66.73 | 5.23 | 26.35 | 1.34 | 0.35 | 24.42 | |

| LC-240 | 89.46 | 6.81 | 48.95 | 44.24 | 67.60 | 5.23 | 25.53 | 1.33 | 0.31 | 24.74 | |

| LC-300 | 80.36 | 6.65 | 46.10 | 47.24 | 68.56 | 5.13 | 24.71 | 1.31 | 0.28 | 25.40 | |

| theoretical mixture | Mix-120(C) | 91.88 | 33.91 | 42.18 | 23.91 | 57.72 | 6.72 | 30.76 | 3.89 | 0.91 | 16.31 |

| Mix-180(C) | 84.26 | 38.53 | 37.69 | 23.77 | 59.77 | 6.81 | 28.95 | 3.52 | 0.94 | 15.55 | |

| Mix-240(C) | 79.95 | 41.51 | 34.61 | 23.88 | 61.89 | 7.03 | 26.72 | 3.38 | 0.98 | 15.22 | |

| Mix-300(C) | 74.18 | 43.05 | 31.59 | 25.36 | 63.44 | 7.09 | 25.19 | 3.24 | 1.04 | 15.21 | |

| mixture | Mix-120(E) | 92.86 | 32.83 | 42.30 | 24.87 | 60.58 | 6.47 | 29.71 | 2.68 | 0.57 | 16.78 |

| Mix-180(E) | 86.81 | 34.69 | 39.91 | 25.39 | 63.26 | 6.35 | 27.22 | 2.62 | 0.56 | 16.79 | |

| Mix-240(E) | 82.82 | 36.39 | 37.97 | 25.64 | 65.27 | 6.26 | 25.42 | 2.55 | 0.50 | 16.93 | |

| Mix-300(E) | 74.88 | 40.38 | 32.70 | 26.92 | 67.11 | 6.14 | 23.84 | 2.46 | 0.46 | 16.62 | |

| Sample | Residue / % (mass) | Characteristic temperatures /℃ | tb / min | (dw/dt)max / (%(mass)·min-1) | (dw/dt)mean / (%(mass)·min-1) | S×108 | ||

|---|---|---|---|---|---|---|---|---|

| Ti | Tm | Tb | ||||||

| SS-Raw | 57.95 | 215.43 | 318.46 | 708.24 | 49.28 | 1.80 | 0.48 | 2.65 |

| SS-120 | 63.57 | 219.87 | 315.88 | 712.55 | 49.27 | 1.64 | 0.42 | 1.99 |

| SS-180 | 70.61 | 223.59 | 318.47 | 715.35 | 49.18 | 1.57 | 0.34 | 1.48 |

| SS-240 | 77.66 | 247.57 | 383.97 | 717.72 | 47.02 | 0.91 | 0.26 | 0.53 |

| SS-300 | 78.83 | 262.92 | 389.35 | 730.65 | 46.77 | 0.95 | 0.24 | 0.46 |

| LC-Raw | 8.58 | 322.06 | 378.80 | 505.06 | 18.30 | 10.54 | 1.05 | 21.14 |

| LC-120 | 3.82 | 325.18 | 373.62 | 505.70 | 18.05 | 11.09 | 1.11 | 22.93 |

| LC-180 | 10.18 | 330.56 | 371.04 | 504.84 | 17.43 | 11.66 | 1.03 | 21.82 |

| LC-240 | 9.36 | 335.79 | 363.28 | 502.90 | 16.71 | 14.12 | 1.04 | 25.94 |

| LC-300 | 7.48 | 337.32 | 363.07 | 481.35 | 14.40 | 11.17 | 1.06 | 21.69 |

| Mix-120(C) | 34.63 | 312.78 | 368.37 | 520.88 | 20.81 | 6.42 | 0.75 | 9.47 |

| Mix-180(C) | 40.41 | 314.02 | 375.96 | 517.34 | 20.33 | 6.18 | 0.68 | 8.30 |

| Mix-240(C) | 43.47 | 319.56 | 363.42 | 510.33 | 19.08 | 7.54 | 0.65 | 9.40 |

| Mix-300(C) | 43.47 | 323.33 | 365.79 | 507.10 | 18.38 | 5.84 | 0.65 | 7.04 |

| Mix-120(E) | 30.44 | 312.78 | 370.74 | 520.97 | 20.82 | 6.09 | 0.80 | 9.55 |

| Mix-180(E) | 34.52 | 314.02 | 378.54 | 517.91 | 20.39 | 6.74 | 0.75 | 9.93 |

| Mix-240(E) | 33.84 | 324.17 | 378.93 | 514.65 | 19.05 | 7.74 | 0.76 | 10.88 |

| Mix-300(E) | 38.03 | 348.63 | 397.25 | 510.48 | 16.19 | 7.82 | 0.71 | 8.98 |

表2 原料及水热炭的特征温度点和综合燃烧指数

Table 2 Characteristic temperatures and combustibility indices of feedstocks and hydrochars

| Sample | Residue / % (mass) | Characteristic temperatures /℃ | tb / min | (dw/dt)max / (%(mass)·min-1) | (dw/dt)mean / (%(mass)·min-1) | S×108 | ||

|---|---|---|---|---|---|---|---|---|

| Ti | Tm | Tb | ||||||

| SS-Raw | 57.95 | 215.43 | 318.46 | 708.24 | 49.28 | 1.80 | 0.48 | 2.65 |

| SS-120 | 63.57 | 219.87 | 315.88 | 712.55 | 49.27 | 1.64 | 0.42 | 1.99 |

| SS-180 | 70.61 | 223.59 | 318.47 | 715.35 | 49.18 | 1.57 | 0.34 | 1.48 |

| SS-240 | 77.66 | 247.57 | 383.97 | 717.72 | 47.02 | 0.91 | 0.26 | 0.53 |

| SS-300 | 78.83 | 262.92 | 389.35 | 730.65 | 46.77 | 0.95 | 0.24 | 0.46 |

| LC-Raw | 8.58 | 322.06 | 378.80 | 505.06 | 18.30 | 10.54 | 1.05 | 21.14 |

| LC-120 | 3.82 | 325.18 | 373.62 | 505.70 | 18.05 | 11.09 | 1.11 | 22.93 |

| LC-180 | 10.18 | 330.56 | 371.04 | 504.84 | 17.43 | 11.66 | 1.03 | 21.82 |

| LC-240 | 9.36 | 335.79 | 363.28 | 502.90 | 16.71 | 14.12 | 1.04 | 25.94 |

| LC-300 | 7.48 | 337.32 | 363.07 | 481.35 | 14.40 | 11.17 | 1.06 | 21.69 |

| Mix-120(C) | 34.63 | 312.78 | 368.37 | 520.88 | 20.81 | 6.42 | 0.75 | 9.47 |

| Mix-180(C) | 40.41 | 314.02 | 375.96 | 517.34 | 20.33 | 6.18 | 0.68 | 8.30 |

| Mix-240(C) | 43.47 | 319.56 | 363.42 | 510.33 | 19.08 | 7.54 | 0.65 | 9.40 |

| Mix-300(C) | 43.47 | 323.33 | 365.79 | 507.10 | 18.38 | 5.84 | 0.65 | 7.04 |

| Mix-120(E) | 30.44 | 312.78 | 370.74 | 520.97 | 20.82 | 6.09 | 0.80 | 9.55 |

| Mix-180(E) | 34.52 | 314.02 | 378.54 | 517.91 | 20.39 | 6.74 | 0.75 | 9.93 |

| Mix-240(E) | 33.84 | 324.17 | 378.93 | 514.65 | 19.05 | 7.74 | 0.76 | 10.88 |

| Mix-300(E) | 38.03 | 348.63 | 397.25 | 510.48 | 16.19 | 7.82 | 0.71 | 8.98 |

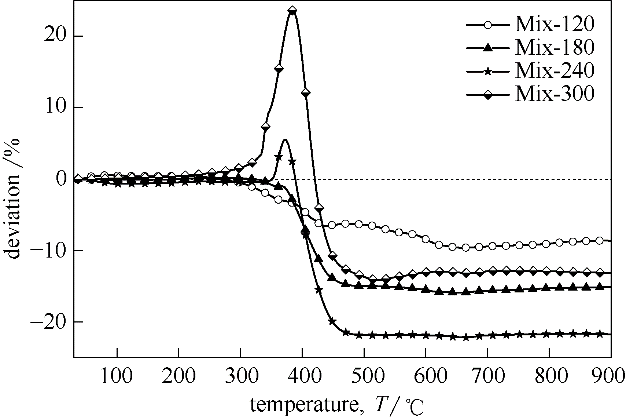

图3 混合物燃烧过程的实验与计算TG曲线偏差分析

Fig.3 Comparison between experimental and calculated TG curves of four blends for deviation profiles during combustion process

| Sample | Residue/ %(mass) | Characteristic temperatures /℃ | tb / min | (dw/dt)max / (% (mass)·min-1) | (dw/dt)mean / (% (mass)·min-1) | ΔT1/2 / ℃ | D×107 | ||

|---|---|---|---|---|---|---|---|---|---|

| Ti | Tm | Tb | |||||||

| SS-Raw | 56.35 | 216.83 | 280.48 | 1086.06 | 86.92 | 1.54 | 0.41 | 198.74 | 22.69 |

| SS-120 | 58.95 | 234.46 | 331.94 | 1088.34 | 85.39 | 1.49 | 0.38 | 168.83 | 17.86 |

| SS-180 | 67.89 | 246.66 | 345.37 | 1089.35 | 84.27 | 1.01 | 0.30 | 228.14 | 5.01 |

| SS-240 | 73.90 | 253.98 | 454.12 | 1100.00 | 84.60 | 0.65 | 0.24 | 211.66 | 1.70 |

| SS-300 | 76.74 | 283.81 | 456.65 | 1100.00 | 81.62 | 0.61 | 0.22 | 152.34 | 1.56 |

| LC-Raw | 48.66 | 283.81 | 421.67 | 946.89 | 66.31 | 1.59 | 0.48 | 191.89 | 17.06 |

| LC-120 | 47.96 | 293.57 | 417.11 | 921.55 | 62.80 | 1.62 | 0.49 | 186.31 | 17.97 |

| LC-180 | 49.23 | 296.01 | 423.95 | 919.26 | 62.33 | 1.54 | 0.47 | 184.79 | 16.00 |

| LC-240 | 50.72 | 300.89 | 431.05 | 916.98 | 61.61 | 1.59 | 0.46 | 179.72 | 15.48 |

| LC-300 | 54.18 | 315.53 | 440.18 | 914.70 | 59.92 | 1.45 | 0.43 | 188.35 | 10.88 |

| Mix-120(C) | 53.54 | 239.34 | 422.47 | 1085.81 | 84.65 | 1.19 | 0.43 | 253.42 | 9.37 |

| Mix-180(C) | 59.51 | 258.58 | 430.97 | 1089.36 | 83.08 | 1.08 | 0.38 | 223.77 | 6.64 |

| Mix-240(C) | 61.45 | 283.54 | 433.25 | 1100.00 | 81.65 | 1.09 | 0.36 | 179.17 | 6.88 |

| Mix-300(C) | 64.98 | 302.77 | 444.91 | 1100.00 | 79.72 | 1.03 | 0.33 | 152.36 | 5.75 |

| Mix-120(E) | 55.37 | 244.22 | 424.89 | 1076.87 | 83.27 | 1.16 | 0.42 | 261.78 | 7.95 |

| Mix-180(E) | 59.16 | 268.62 | 433.25 | 1080.99 | 81.24 | 1.18 | 0.38 | 210.85 | 7.50 |

| Mix-240(E) | 60.29 | 288.42 | 437.81 | 1085.81 | 79.74 | 1.25 | 0.37 | 167.77 | 8.70 |

| Mix-300(E) | 63.55 | 310.65 | 448.45 | 1090.37 | 77.97 | 1.15 | 0.34 | 141.15 | 7.26 |

表3 原料及水热炭的特征温度点和综合热解指数

Table 3 Characteristic temperatures and pyrolysis indices of feedstocks and hydrochars

| Sample | Residue/ %(mass) | Characteristic temperatures /℃ | tb / min | (dw/dt)max / (% (mass)·min-1) | (dw/dt)mean / (% (mass)·min-1) | ΔT1/2 / ℃ | D×107 | ||

|---|---|---|---|---|---|---|---|---|---|

| Ti | Tm | Tb | |||||||

| SS-Raw | 56.35 | 216.83 | 280.48 | 1086.06 | 86.92 | 1.54 | 0.41 | 198.74 | 22.69 |

| SS-120 | 58.95 | 234.46 | 331.94 | 1088.34 | 85.39 | 1.49 | 0.38 | 168.83 | 17.86 |

| SS-180 | 67.89 | 246.66 | 345.37 | 1089.35 | 84.27 | 1.01 | 0.30 | 228.14 | 5.01 |

| SS-240 | 73.90 | 253.98 | 454.12 | 1100.00 | 84.60 | 0.65 | 0.24 | 211.66 | 1.70 |

| SS-300 | 76.74 | 283.81 | 456.65 | 1100.00 | 81.62 | 0.61 | 0.22 | 152.34 | 1.56 |

| LC-Raw | 48.66 | 283.81 | 421.67 | 946.89 | 66.31 | 1.59 | 0.48 | 191.89 | 17.06 |

| LC-120 | 47.96 | 293.57 | 417.11 | 921.55 | 62.80 | 1.62 | 0.49 | 186.31 | 17.97 |

| LC-180 | 49.23 | 296.01 | 423.95 | 919.26 | 62.33 | 1.54 | 0.47 | 184.79 | 16.00 |

| LC-240 | 50.72 | 300.89 | 431.05 | 916.98 | 61.61 | 1.59 | 0.46 | 179.72 | 15.48 |

| LC-300 | 54.18 | 315.53 | 440.18 | 914.70 | 59.92 | 1.45 | 0.43 | 188.35 | 10.88 |

| Mix-120(C) | 53.54 | 239.34 | 422.47 | 1085.81 | 84.65 | 1.19 | 0.43 | 253.42 | 9.37 |

| Mix-180(C) | 59.51 | 258.58 | 430.97 | 1089.36 | 83.08 | 1.08 | 0.38 | 223.77 | 6.64 |

| Mix-240(C) | 61.45 | 283.54 | 433.25 | 1100.00 | 81.65 | 1.09 | 0.36 | 179.17 | 6.88 |

| Mix-300(C) | 64.98 | 302.77 | 444.91 | 1100.00 | 79.72 | 1.03 | 0.33 | 152.36 | 5.75 |

| Mix-120(E) | 55.37 | 244.22 | 424.89 | 1076.87 | 83.27 | 1.16 | 0.42 | 261.78 | 7.95 |

| Mix-180(E) | 59.16 | 268.62 | 433.25 | 1080.99 | 81.24 | 1.18 | 0.38 | 210.85 | 7.50 |

| Mix-240(E) | 60.29 | 288.42 | 437.81 | 1085.81 | 79.74 | 1.25 | 0.37 | 167.77 | 8.70 |

| Mix-300(E) | 63.55 | 310.65 | 448.45 | 1090.37 | 77.97 | 1.15 | 0.34 | 141.15 | 7.26 |

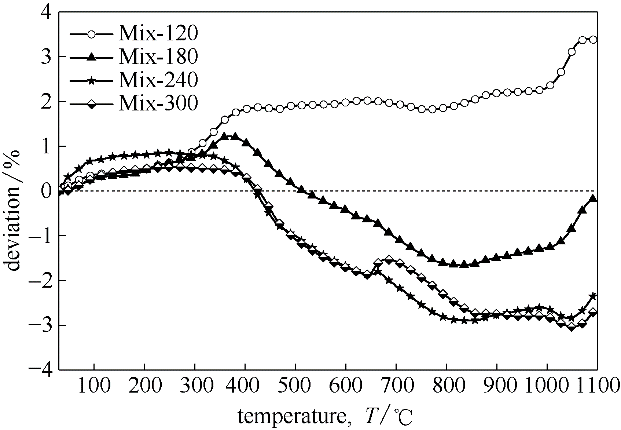

图5 混合物热解过程的实验与计算TG曲线偏差分析

Fig.5 Comparison between experimental and calculated TG curves of four blends for deviation profiles during pyrolysis process

| Sample | Time X50/min | Rmax/min-1 | Sample | Time X50/min | Rmax/min-1 | Sample | Time X50/min | Rmax/min-1 | Sample | Time X50/min | Rmax/min-1 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SS-Raw | 12.84 | 0.45 | LC-Raw | 0.66 | 1.13 | ||||||

| SS-120 | 3.63 | 0.49 | LC-120 | 0.65 | 1.15 | Mix-120(C) | 0.67 | 1.03 | Mix-120(E) | 0.85 | 0.94 |

| SS-180 | 12.85 | 0.26 | LC-180 | 0.70 | 1.05 | Mix-180(C) | 0.72 | 1.02 | Mix-180(E) | 0.93 | 0.81 |

| SS-240 | 14.63 | 0.22 | LC-240 | 0.68 | 1.08 | Mix-240(C) | 0.70 | 0.95 | Mix-240(E) | 0.93 | 0.83 |

| SS-300 | 16.41 | 0.25 | LC-300 | 0.69 | 1.06 | Mix-300(C) | 0.71 | 1.04 | Mix-300(E) | 1.13 | 0.71 |

表4 原料及水热炭的气化特征参数

Table 4 Gasification characteristic parameters of feedstocks and hydrochars

| Sample | Time X50/min | Rmax/min-1 | Sample | Time X50/min | Rmax/min-1 | Sample | Time X50/min | Rmax/min-1 | Sample | Time X50/min | Rmax/min-1 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SS-Raw | 12.84 | 0.45 | LC-Raw | 0.66 | 1.13 | ||||||

| SS-120 | 3.63 | 0.49 | LC-120 | 0.65 | 1.15 | Mix-120(C) | 0.67 | 1.03 | Mix-120(E) | 0.85 | 0.94 |

| SS-180 | 12.85 | 0.26 | LC-180 | 0.70 | 1.05 | Mix-180(C) | 0.72 | 1.02 | Mix-180(E) | 0.93 | 0.81 |

| SS-240 | 14.63 | 0.22 | LC-240 | 0.68 | 1.08 | Mix-240(C) | 0.70 | 0.95 | Mix-240(E) | 0.93 | 0.83 |

| SS-300 | 16.41 | 0.25 | LC-300 | 0.69 | 1.06 | Mix-300(C) | 0.71 | 1.04 | Mix-300(E) | 1.13 | 0.71 |

图7 半焦CO2气化过程的实验与计算TG曲线偏差分析

Fig.7 Comparison between experimental and calculated TG curves of four blends for deviation profiles during char CO2-gasification process

| 1 | Mun T Y, Tumsa T Z, Yang W, et al. Performance evaluation of co-firing various kinds of biomass with low rank coals in a 500 MWe coal-fired power plant[J]. Energy, 2016, 115: 954-962. |

| 2 | 庄修政, 宋艳培, 詹昊, 等. 水热污泥与煤在混燃过程中的协同效应特性研究[J]. 燃料化学学报, 2018, 46(12): 1237-1446. |

| Zhuang X Z, Song Y P, Zhan H, et al. Synergistic effects in co-combusting of hydrochar derived from sewage sludge with different-rank coals[J]. Journal of Fuel Chemistry and Technology, 2018, 46(12): 1237-1446. | |

| 3 | Xie C D, Liu J Y, Xie W M, et al. Quantifying thermal decomposition regimes of textile dyeing sludge, pomelo peel, and their blends[J]. Renewable Energy, 2018, 122: 55-64. |

| 4 | Parshetti G K, Liu Z G, Jain A, et al. Hydrothermal carbonization of sewage sludge for energy production with coal[J]. Fuel, 2013, 111: 201-210. |

| 5 | 葛立超, 张彦威, 应芝, 等. 水热处理对我国典型褐煤气化特性的影响[J]. 中国电机工程学报, 2013, 33(32): 14-20. |

| Ge L C, Zhang Y W, Ying Z, et al. Influence of the hydrothermal dewatering on the gasification characteristics of typical chinese lignite[J]. Proceedings of the CSEE, 2013, 33(32): 14-20. | |

| 6 | Nonaka M, Hirajima T, Sasaki K. Upgrading of low rank coal and woody biomass mixture by hydrothermal treatment[J]. Fuel, 2011, 90(8): 2578-2584. |

| 7 | Zhuang X Z, Zhan H, Huang Y Q, et al. Conversion of industrial biowastes to clean solid fuels via hydrothermal carbonization (HTC): upgrading mechanism in relation to coalification process and combustion behavior[J]. Bioresource Technology, 2018, 267: 17-29. |

| 8 | Zhuang X Z, Huang Y Q, Liu H C, et al. Relationship between physicochemical properties and dewaterability of hydrothermal sludge derived from different source[J]. J. Environ. Sci. (China), 2018, 69: 261-270. |

| 9 | Liao J J, Fei Y, Marshall M, et al. Hydrothermal dewatering of a Chinese lignite and properties of the solid products[J]. Fuel, 2016, 180: 473-480. |

| 10 | Wu J, Wang J, Liu J, et al. Moisture removal mechanism of low-rank coal by hydrothermal dewatering: physicochemical property analysis and DFT calculation[J]. Fuel, 2017, 187: 242-249. |

| 11 | Saba A, Saha P, Reza M T. Co-hydrothermal carbonization of coal-biomass blend: influence of temperature on solid fuel properties[J]. Fuel Processing Technology, 2017, 167: 711-720. |

| 12 | He C, Wang K, Yang Y H, et al. Utilization of sewage-sludge-derived hydrochars toward efficient cocombustion with different-rank coals: effects of subcritical water conversion and blending scenarios[J]. Energy & Fuels, 2014, 28(9): 6140-6150. |

| 13 | Zhuang X Z, Song Y P, Zhan H, et al. Synergistic effects on the co-combustion of medicinal biowastes with coals of different ranks[J]. Renewable Energy, 2019, 140: 380-389. |

| 14 | Lin Y S, Ma X Q, Peng X W, et al. Combustion, pyrolysis and char CO2-gasification characteristics of hydrothermal carbonization solid fuel from municipal solid wastes[J]. Fuel, 2016, 181: 905-915. |

| 15 | Zhang X J, Zhang L, Li A M. Hydrothermal co-carbonization of sewage sludge and pinewood sawdust for nutrient-rich hydrochar production: synergistic effects and products characterization[J]. J. Environ. Manage., 2017, 201: 52-62. |

| 16 | 宋艳培, 庄修政, 詹昊, 等. 污泥与褐煤共水热碳化的协同特性研究[J]. 化工学报, 2019, 70(8): 3132-3141. |

| Song Y P, Zhuang X Z, Zhan H, et al. Investigation on synergistic characteristics of sludge and lignite during co-hydrothermal carbonization[J]. CIESC Journal, 2019, 70(8): 3132-3141. | |

| 17 | Li L W, Huang Y Q, Zhang D Y, et al. Uncovering structure-reactivity relationships in pyrolysis and gasification of biomass with varying severity of torrefaction[J]. ACS Sustainable Chemistry & Engineering, 2018, 6(5): 6008-6017. |

| 18 | 庄修政, 詹昊, 黄艳琴, 等. 两类药渣的水热提质效果及其燃烧特性研究[J]. 燃料化学学报, 2018, 46(8): 940-949. |

| Zhuang X Z, Zhan H, Huang Y Q, et al. Influence of hydrothermal upgrading on the fuel characteristics and combustion behavior of herb wastes[J]. Journal of Fuel Chemistry and Technology, 2018, 46(8): 940-949. | |

| 19 | Ul Saqib N, Sarmah A K, Baroutian S. Effect of temperature on the fuel properties of food waste and coal blend treated under co-hydrothermal carbonization[J]. Waste Manag., 2019, 89: 236-246. |

| 20 | Otero M, Gomez X, Garcia A I, et al. Effects of sewage sludge blending on the coal combustion: a thermogravimetric assessment[J]. Chemosphere, 2007, 69(11): 1740-1750. |

| 21 | Xie C D, Liu J Y, Zhang X C, et al. Co-combustion thermal conversion characteristics of textile dyeing sludge and pomelo peel using TGA and artificial neural networks[J]. Applied Energy, 2018, 212: 786-795. |

| 22 | Yao Z L, Ma X Q. Characteristics of co-hydrothermal carbonization on polyvinyl chloride wastes with bamboo[J]. Bioresource Technology, 2018, 247: 302-309. |

| 23 | 刁韩杰, 张进, 王敏艳, 等. 高温热解对污泥炭特性及其重金属形态变化的影响[J]. 环境工程, 2019, 37(3): 29-34. |

| Diao H J, Zhang J, Wang M Y, et al. Effect of high temperature pyrolysis of sewage sludge on characteristics of residual biochar and speciation changes of heavy metals[J]. Environmental Engineering, 2019, 37(3): 29-34. | |

| 24 | Xie Z Q, Ma X Q. The thermal behaviour of the co-combustion between paper sludge and rice straw[J]. Bioresource Technology, 2013, 146: 611-618. |

| 25 | Kambo H S, Dutta A. A comparative review of biochar and hydrochar in terms of production, physico-chemical properties and applications[J]. Renewable and Sustainable Energy Reviews, 2015, 45: 359-378. |

| 26 | Deb-Choudhury S, Haines S, Harland D, et al. Effect of cooking on meat proteins: mapping hydrothermal protein modification as a potential indicator of bioavailability[J]. J. Agric. Food Chem., 2014, 62(32): 8187-8196. |

| 27 | Basso D, Patuzzi F, Castello D, et al. Agro-industrial waste to solid biofuel through hydrothermal carbonization[J]. Waste Manag., 2016, 47(Pt A): 114-121. |

| 28 | 冯钰. 煤热解半焦气化反应活性和燃烧特性研究[D]. 大连: 大连理工大学, 2016. |

| Feng Y. Gasification reactivity and combustion characteristic of chars from coal pyrolysis[D]. Dalian: Dalian University of Technology, 2016. | |

| 29 | 李少华, 车德勇, 张学斌. 松木屑与褐煤共热解特性及动力学分析[J]. 华北电力大学学报, 2013, 40(4): 90-95. |

| Li S H, Che D Y, Zhang X B. Co-pyrolysis characteristics and kinetics analysis of pine sawdust with lignite[J]. Journal of North China Electric Power University, 2013, 40(4): 90-95. | |

| 30 | 易霜, 何选明, 郑辉, 等. 甘蔗渣与褐煤共热解半焦的特性[J]. 化工进展, 2016, 35(10): 3149-3154. |

| Yi S, He X M, Zheng H, et al. Characteristics of co-pyrolysis char of sugarcane bagasse and lignite[J]. Chemical Industry and Engineering Progress, 2016, 35(10): 3149-3154. | |

| 31 | Yuan S, Dai Z H, Zhou Z J, et al. Rapid co-pyrolysis of rice straw and a bituminous coal in a high-frequency furnace and gasification of the residual char[J]. Bioresource Technology, 2012, 109: 188-197. |

| 32 | Salema A A, Afzal M T, Motasemi F. Is there synergy between carbonaceous material and biomass during conventional pyrolysis? A TG-FTIR approach[J]. Journal of Analytical and Applied Pyrolysis, 2014, 105: 217-226. |

| 33 | Krerkkaiwan S, Fushimi C, Tsutsumi A, et al. Synergetic effect during co-pyrolysis/gasification of biomass and sub-bituminous coal[J]. Fuel Processing Technology, 2013, 115: 11-18. |

| 34 | Johannes I, Tiikma L, Luik H. Synergy in co-pyrolysis of oil shale and pine sawdust in autoclaves[J]. Journal of Analytical and Applied Pyrolysis, 2013, 104: 341-352. |

| 35 | Aboyade A O, Görgens J F, Carrier M, et al. Thermogravimetric study of the pyrolysis characteristics and kinetics of coal blends with corn and sugarcane residues[J]. Fuel Processing Technology, 2013, 106: 310-320. |

| 36 | Zhang L, Xu S P, Zhao W, et al. Co-pyrolysis of biomass and coal in a free fall reactor[J]. Fuel, 2007, 86(3): 353-359. |

| 37 | Lin Y S, Ma X Q, Yu Z S, et al. Investigation on thermochemical behavior of co-pyrolysis between oil-palm solid wastes and paper sludge[J]. Bioresource Technology, 2014, 166: 444-450. |

| 38 | Salavati S, Zhang C T, Zhang S, et al. Cross-interaction during co-gasification of wood, weed, plastic, tire and carton[J]. Journal of Environmental Management, 2019, 250: 109467. |

| [1] | 程伟江, 汪何琦, 高翔, 李娜, 马赛男. 锂离子电池硅基负极电解液成膜添加剂的研究进展[J]. 化工学报, 2023, 74(2): 571-584. |

| [2] | 郝泽光, 张乾, 高增林, 张宏文, 彭泽宇, 杨凯, 梁丽彤, 黄伟. 生物质与催化裂化油浆共热解协同作用研究[J]. 化工学报, 2022, 73(9): 4070-4078. |

| [3] | 杨晓阳, 王宝凤, 宋旭涛, 杨凤玲, 程芳琴. 污泥与高硫煤共水热碳化过程中硫氮形态转化规律[J]. 化工学报, 2022, 73(11): 5211-5219. |

| [4] | 王润涛, 罗泽军, 王储, 朱锡锋. 生物油蒸馏残渣与废弃塑料催化共热解协同作用的研究[J]. 化工学报, 2022, 73(11): 5088-5097. |

| [5] | 周烨, 肖慧霞, 王亦飞, 于广锁. 基于配煤和表面修饰改善褐煤成浆性的研究[J]. 化工学报, 2021, 72(4): 2233-2240. |

| [6] | 朱新宇, 张光义, 张建伟, 温宏炎, 李运甲, 张建岭, 许光文. 醇提中药渣与废弃活性焦共燃特性及动力学分析[J]. 化工学报, 2021, 72(2): 1116-1124. |

| [7] | 杨珍, 曹景沛, 朱陈, 刘天龙, 赵小燕. B-ZSM-5酸调控及催化褐煤热解挥发分制轻质芳烃研究[J]. 化工学报, 2021, 72(11): 5633-5642. |

| [8] | 王博阳, 夏吉利, 董晓玲, 郭行, 李文翠. 不同变质程度煤衍生硬炭的储钠行为研究[J]. 化工学报, 2021, 72(11): 5738-5750. |

| [9] | 温宏炎, 张玉明, 纪德馨, 张光义. 油泥焦与褐煤共燃特性及动力学[J]. 化工学报, 2020, 71(2): 755-765. |

| [10] | 宋艳培, 庄修政, 詹昊, 王南涛, 阴秀丽, 吴创之. 污泥与褐煤共水热碳化的协同特性研究[J]. 化工学报, 2019, 70(8): 3132-3141. |

| [11] | 辛善志, 黄芳, 刘晓烨, 许庆利, 米铁. 烘焙中药渣的热解与燃烧特性及其动力学分析[J]. 化工学报, 2019, 70(8): 3142-3150. |

| [12] | 吴渊默, 张守玉, 张华, 慕晨, 李昊, 宋晓冰, 吕俊复. 高温干燥对褐煤孔隙结构及水分复吸的影响[J]. 化工学报, 2019, 70(1): 199-206. |

| [13] | 周新志, 邵伦, 崔岢, 杨阳, 周余, 张若彬. 褐煤微波干燥提质生产线的多级功率控制系统研究[J]. 化工学报, 2018, 69(S2): 274-282. |

| [14] | 耿莉莉, 杨凯旭, 张诺伟, 陈秉辉. Ru和Cu协同催化湿式氧化处理氨氮废水[J]. 化工学报, 2018, 69(9): 3869-3878. |

| [15] | 曲洋, 初茉, 朱书全, 张超, 郝成亮, 徐芳. 回转窑内利用液化残渣共热褐煤以抑制其粉化的影响因素分析[J]. 化工学报, 2018, 69(5): 2166-2174. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号