化工学报 ›› 2021, Vol. 72 ›› Issue (7): 3716-3727.DOI: 10.11949/0438-1157.20210044

方丽君1( ),王景梅1,林巧靖1,陈建华1,2(

),王景梅1,林巧靖1,陈建华1,2( ),杨谦1,2

),杨谦1,2

收稿日期:2021-01-11

修回日期:2021-04-28

出版日期:2021-07-05

发布日期:2021-07-05

通讯作者:

陈建华

作者简介:方丽君(1994—),女,硕士研究生,基金资助:

FANG Lijun1( ),WANG Jingmei1,LIN Qiaojing1,CHEN Jianhua1,2(

),WANG Jingmei1,LIN Qiaojing1,CHEN Jianhua1,2( ),YANG Qian1,2

),YANG Qian1,2

Received:2021-01-11

Revised:2021-04-28

Online:2021-07-05

Published:2021-07-05

Contact:

CHEN Jianhua

摘要:

为提高聚醚嵌段酰胺 (PEBA)膜对水中苯酚的选择分离性能,采用二苯并-18-冠醚-6 (CE) 对PEBA膜进行改性制备了PEBA/CE渗透蒸发膜。通过FT-IR、SEM表征证实了CE与PEBA紧密结合且CE均匀分布在膜表面;AFM表征表明CE的修饰有效地提高了膜表面与苯酚的接触面积;水接触角测试表明CE的修饰极大地提高了PEBA/CE膜的疏水性。同时系统地研究了膜中CE含量、原料液苯酚浓度、进料温度对膜渗透汽化性能的影响,结果表明CE能显著提高PEBA膜对苯酚的选择性,在料液苯酚为0.8%(质量)及70℃操作温度条件下,当CE 的添加量为PEBA的6%(质量)时,PEBA/CE-6膜的分离因子和渗透通量分别为23.34和494.40 g/(m2·h),远超PEBA膜性能[分离因子8.46,总渗透通量547.48 g/(m2·h)]。长期性能稳定性测试表明所制备PEBA/CE-6膜具有良好稳定性,具有较好的工业运用潜力。

中图分类号:

方丽君, 王景梅, 林巧靖, 陈建华, 杨谦. 二苯并-18-冠醚-6/聚醚嵌段酰胺膜富集水中苯酚性能研究[J]. 化工学报, 2021, 72(7): 3716-3727.

FANG Lijun, WANG Jingmei, LIN Qiaojing, CHEN Jianhua, YANG Qian. Enrichment of phenol in water by dibenzo-18-crown ether-6/polyether block amide membrane[J]. CIESC Journal, 2021, 72(7): 3716-3727.

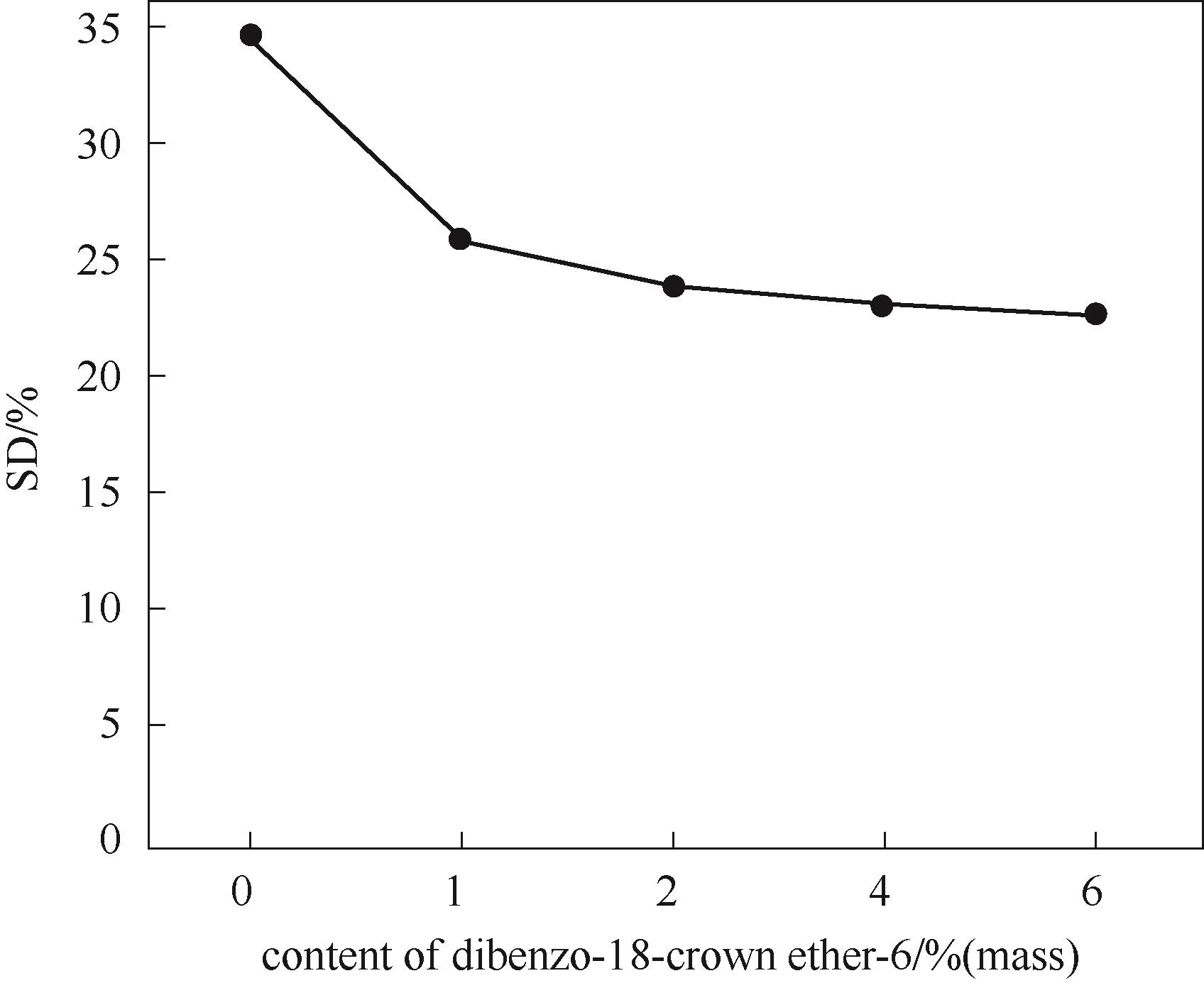

图10 在0.8%(质量)苯酚溶液、料液温度为70℃下冠醚含量对PEBA/CE 膜溶胀性的影响

Fig.10 The influence of CE content on PEBA/CE membrane swelling in 0.8%(mass) phenol dilute solution at 70℃

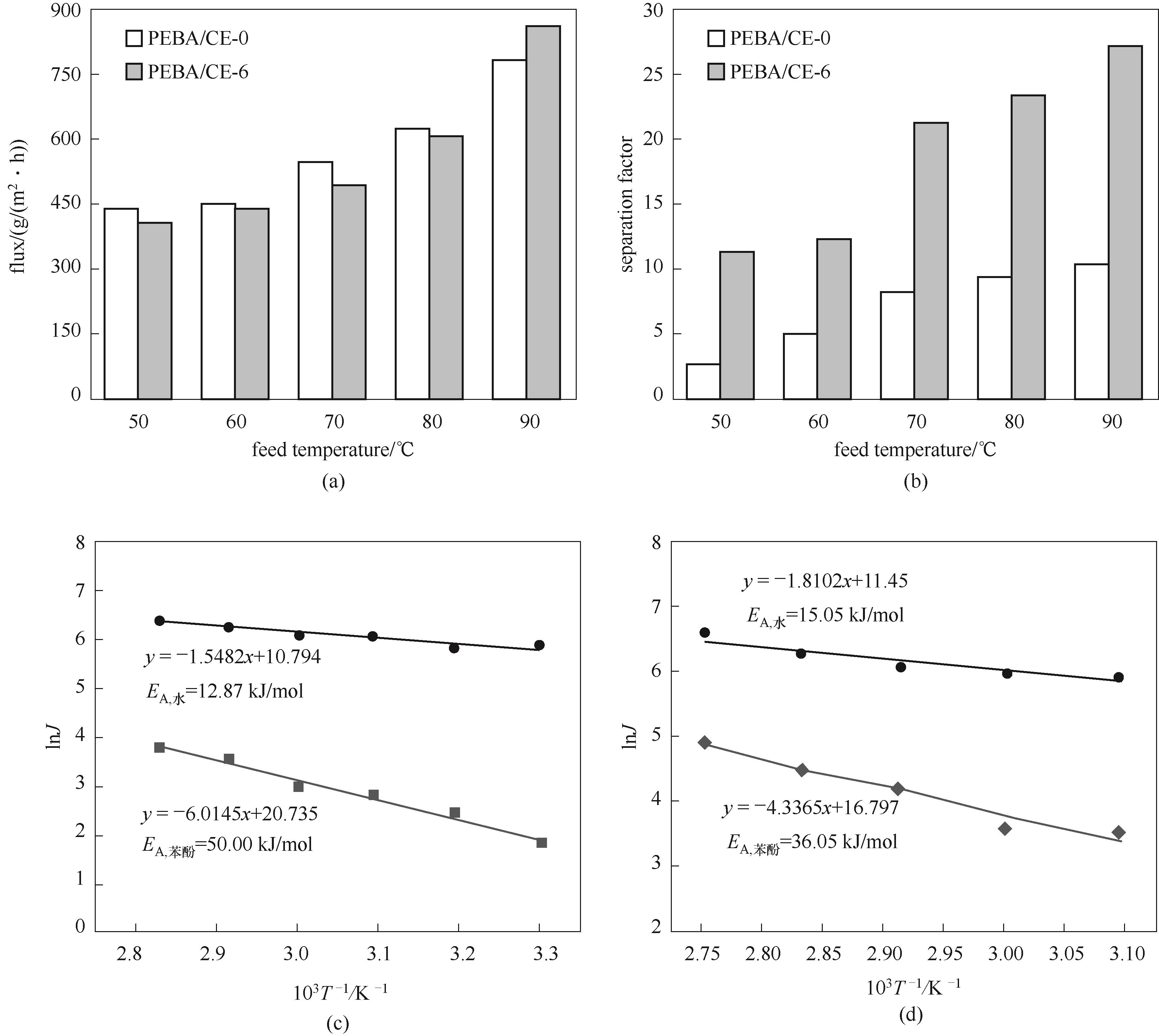

图13 料液温度对PEBA/CE-0和PEBA/CE-6膜渗透汽化性能的影响总渗透通量(a); 分离因子(b); 料液温度对 PEBA/CE-0膜通量的影响(c); 料液温度对PEBA/CE-6膜通量的影响(d)

Fig.13 The influence of feed temperature on the pervaporation performance of PEBA/CE-0 membrane and PEBA/CE-6 membranetotal permeation flux (a); separation factor (b); flux of PEBA/CE-0 membrane (c); flux of PEBA/CE-6 membrane (d)

| 1 | Babich H, Davis D L. Phenol: a review of environmental and health risks[J]. Regulatory Toxicology and Pharmacology, 1981, 1(1): 90-109. |

| 2 | 盛怡. 苯酚的危害及应对策略[J]. 化工管理, 2019, (14): 25-26. |

| Sheng Y. The harm of phenol and countermeasures [J]. Chemical Enterprise Management, 2019, (14): 25-26. | |

| 3 | 王红娟, 奚红霞, 夏启斌, 等. 含酚废水处理技术的现状与开发前景[J]. 工业水处理, 2002, 22(6): 6-9. |

| Wang H J, Xi H X, Xia Q B, et al. Present situation and future development of phenol-containing wastewater treatment[J]. Industrial Water Treatment, 2002, 22(6): 6-9. | |

| 4 | Jeong Y S, Chung J S. Simultaneous removal of COD, thiocyanate, cyanide and nitrogen from coal process wastewater using fluidized biofilm process[J]. Process Biochemistry, 2006, 41(5): 1141-1147. |

| 5 | Araki S, Gondo D, Imasaka S, et al. Permeation properties of organic compounds from aqueous solutions through hydrophobic silica membranes with different functional groups by pervaporation[J]. Journal of Membrane Science, 2016, 514: 458-466. |

| 6 | 高超, 王启山. 吸附法处理含酚废水的研究进展[J]. 水处理技术, 2011, 37(1): 1-4. |

| Gao C, Wang Q S. Progresses of phenol wastewater based on adsorption method[J]. Technology of Water Treatment, 2011, 37(1): 1-4. | |

| 7 | Tri N L M, Thang P Q, van Tan L, et al. Removal of phenolic compounds from wastewaters by using synthesized Fe-nano zeolite[J]. Journal of Water Process Engineering, 2020, 33: 101070. |

| 8 | Wu D S, Chen G Q, Hu B S, et al. Feasibility and energy consumption analysis of phenol removal from salty wastewater by electro-electrodialysis[J]. Separation and Purification Technology, 2019, 215: 44-50. |

| 9 | Guo C, Cao Q, Chen B K, et al. Development of synergistic extraction process for highly efficient removal of phenols from coal gasification wastewater[J]. Journal of Cleaner Production, 2019, 211: 380-386. |

| 10 | Ye H, Zhang X, Zhao Z X, et al. Pervaporation performance of surface-modified zeolite/PU mixed matrix membranes for separation of phenol from water[J]. Iranian Polymer Journal, 2017, 26(3): 193-203. |

| 11 | 张时雨, 邹昀, 韦藤幼, 等. β-环糊精/聚醚共聚乙酰胺填充膜的制备及渗透汽化分离水中微量苯酚[J]. 化工学报, 2016, 67(11): 4662-4670. |

| Zhang S Y, Zou Y, Wei T Y, et al. Preparation of β-cyclodextrin filled PEBA membranes and pervaporation separation of phenol from dilute solution[J]. CIESC Journal, 2016, 67(11): 4662-4670. | |

| 12 | 左成业, 涂睿, 丁晓斌, 等. PDMS复合膜回收酯化反应废水中的异丁醇[J]. 化工学报, 2020, 71(9): 4189-4199. |

| Zuo C Y, Tu R, Ding X B, et al. DMS composite membrane for recovery of isobutanol in esterification wastewater[J]. CIESC Journal, 2020, 71(9): 4189-4199. | |

| 13 | 那沙沙, 李卫星, 邢卫红. 无机杂化海藻酸钠渗透汽化膜的制备与分离性能对比[J]. 化工学报, 2016, 67(9): 3730-3737. |

| Na S S, Li W X, Xing W H. Development of inorganic nano particles modified sodium alginate hybrid membranes for pervaporation[J]. CIESC Journal, 2016, 67(9): 3730-3737. | |

| 14 | Song Y M, Jiang Z Y, Gao B X, et al. Embedding hydrophobic MoS2 nanosheets within hydrophilic sodium alginate membrane for enhanced ethanol dehydration[J]. Chemical Engineering Science, 2018, 185: 231-242. |

| 15 | Hao X G, Pritzker M, Feng X S. Use of pervaporation for the separation of phenol from dilute aqueous solutions[J]. Journal of Membrane Science, 2009, 335(1/2): 96-102. |

| 16 | Li D, Yao J, Sun H, et al. Recycling of phenol from aqueous solutions by pervaporation with ZSM-5/PDMS/PVDF hollow fiber composite membrane[J]. Applied Surface Science, 2018, 427: 288-297. |

| 17 | 王敏敏, 张新儒, 李馨然, 等. PEBA/MCM-41杂化膜的制备及其对苯酚/水渗透汽化分离性能的研究[J]. 膜科学与技术, 2015, 35(6): 40-47. |

| Wang M M, Zhang X R, Li X R, et al. Preparation of hybrid PEBA/MCM-41 membranes and its pervaporation performance for separating phenol/water mixture[J]. Membrane Science and Technology, 2015, 35(6): 40-47. | |

| 18 | Ding C, Zhang X R, Li C C, et al. ZIF-8 incorporated polyether block amide membrane for phenol permselective pervaporation with high efficiency[J]. Separation and Purification Technology, 2016, 166: 252-261. |

| 19 | Khan R, Ul Haq I, Mao H, et al. Enhancing the pervaporation performance of PEBA/PVDF membrane by incorporating MAF-6 for the separation of phenol from its aqueous solution[J]. Separation and Purification Technology, 2021, 256: 117804. |

| 20 | 马克. PDMS渗透蒸发膜的制备及其处理含酚废水的研究[D]. 上海: 东华大学, 2010. |

| Ma K. Study on the preparation and phenols wastewater treatment of PDMS pervaporation membranes[D]. Shanghai: Donghua University, 2010. | |

| 21 | 王维, 姜雪迎, 李悦, 等. 亲水型ZSM-5分子筛填充PVA膜及分离乙酸乙酯/水的应用[J]. 化工学报, 2020, 71(8): 3807-3818. |

| Wang W, Jiang X Y, Li Y, et al. Application of PVA membrane filled with hydrophilic ZSM-5 molecular sieve on separation of water from ethyl acetate[J]. CIESC Journal, 2020, 71(8): 3807-3818. | |

| 22 | 张锐, 邵琦, 张华宇, 等. 硼掺杂二氧化硅杂化膜的制备及渗透汽化脱盐性能[J]. 化工学报, 2021, 72(4): 2317-2327. |

| Zhang R, Shao Q, Zhang H Y, et al. Fabrication of boron-doped hybrid silica membranes for pervaporation desalination[J]. CIESC Journal, 2021, 72(4): 2317-2327. | |

| 23 | 杨同华, 姜延林, 陈桂英, 等. 二苯并-18冠-6的热中子散射谱和红外光谱[J]. 原子能科学技术, 1986, 20(3): 376-378. |

| Yang T H, Jiang Y L, Chen G Y, et al. Thermal neutron scattering and infrared spectrum for dibenzo-18-crown-6[J]. Atomic Energy Science and Technology, 1986, 20(3): 376-378. | |

| 24 | 付新梅, 汪磊, 戴树桂. 红外光谱法和量子化学法对离子液体提取水中壬基酚的机理研究[J]. 光谱学与光谱分析, 2011, 31(3): 625-629. |

| Fu X M, Wang L, Dai S G. Mechanism study on the extraction of nonylphenol by ionic liquids in water through IR spectroscopy and quantum chemical calculation[J]. Spectroscopy and Spectral Analysis, 2011, 31(3): 625-629. | |

| 25 | Amirkhani F, Mosadegh M, Asghari M, et al. The beneficial impacts of functional groups of CNT on structure and gas separation properties of PEBA mixed matrix membranes[J]. Polymer Testing, 2020, 82: 106285. |

| 26 | Lalia B S, Ahmed F E, Shah T, et al. Electrically conductive membranes based on carbon nanostructures for self-cleaning of biofouling[J]. Desalination, 2015, 360: 8-12. |

| 27 | Baker R W. Membrane Technology and Applications[M]. Chichester, UK: John Wiley & Sons Ltd., 2012. |

| 28 | Bai Y X, Dong L L, Zhang C F, et al. ZIF-8 filled polydimethylsiloxane membranes for pervaporative separation of n-butanol from aqueous solution[J]. Separation Science and Technology, 2013, 48(17): 2531-2539. |

| 29 | Feng X S, Huang R Y M. Concentration polarization in pervaporation separation processes[J]. Journal of Membrane Science, 1994, 92(3): 201-208. |

| 30 | Groß A, Heintz A. Sorption isotherms of aromatic compounds in organophilic polymer membranes used in pervaporation[J]. Journal of Solution Chemistry, 1999, 28(10): 1159-1174. |

| 31 | Borisov I L, Kujawska A, Knozowska K, et al. Influence of feed flow rate, temperature and feed concentration on concentration polarization effects during separation of water-methyl acetate solutions with high permeable hydrophobic pervaporation PDMS membrane[J]. Journal of Membrane Science, 2018, 564: 1-9. |

| 32 | Shao P, Huang R Y M. Polymeric membrane pervaporation[J]. Journal of Membrane Science, 2007, 287(2): 162-179. |

| [1] | 张佳怡, 何佳莉, 谢江鹏, 王健, 赵鹬, 张栋强. 渗透汽化技术用于锂电池生产中N-甲基吡咯烷酮回收的研究进展[J]. 化工学报, 2023, 74(8): 3203-3215. |

| [2] | 肖川宝, 李林洋, 刘武锋, 钟年丙, 解泉华, 钟登杰, 常海星. 光催化与离子交换吸附耦合有效去除2,4,6-三氯苯酚[J]. 化工学报, 2023, 74(4): 1587-1597. |

| [3] | 刘鑫, 潘阳, 刘公平, 方静, 李春利, 李浩. 渗透汽化-隔壁塔精馏耦合初步分离费托合成水的过程研究[J]. 化工学报, 2022, 73(5): 2020-2030. |

| [4] | 毛恒, 王月, 王森, 刘伟民, 吕静, 陈甫雪, 赵之平. APTES改性ZIF-L/PEBA混合基质膜强化渗透汽化分离苯酚研究[J]. 化工学报, 2022, 73(3): 1389-1402. |

| [5] | 丁婉月, 马晓华. 合成次数及硅铝比调控SAPO-34分子筛膜的乙醇脱水性能[J]. 化工学报, 2021, 72(8): 4410-4417. |

| [6] | 黄文媛, 孙士杰, 唐宏震, 苏智芳, 钟秦迪, 刘幽燕, 李青云. 聚氨酯泡沫固定化Alcaligenes sp.DN25去除苯酚的研究[J]. 化工学报, 2021, 72(5): 2783-2791. |

| [7] | 李超凡, 温玉娟, 曹楠, 孙东, 宋晓明, 杨悦锁. 耐低温对硝基苯酚降解菌的降解动力学研究[J]. 化工学报, 2021, 72(3): 1692-1701. |

| [8] | 周毅,王永洪,张新儒,李晋平. PEBA/氮硫共掺杂多孔碳球混合基质膜的制备及CO2分离性能研究[J]. 化工学报, 2021, 72(10): 5237-5246. |

| [9] | 左成业, 涂睿, 丁晓斌, 邢卫红. PDMS复合膜回收酯化反应废水中的异丁醇[J]. 化工学报, 2020, 71(9): 4189-4199. |

| [10] | 马珊宏, 叶枫, 王燕鸿, 郎雪梅, 樊栓狮, 李刚. ZSM-5沸石膜用于生物油的脱水分离及其再生过程研究[J]. 化工学报, 2020, 71(7): 3345-3353. |

| [11] | 杨霁豪,耿莉莉,叶松寿,谢建榕,张诺伟,陈秉辉. 稳定高效Ru/TiO2-ZrO2催化剂处理苯酚磺酸废水[J]. 化工学报, 2020, 71(12): 5561-5567. |

| [12] | 洪迪昆, 操政, 杨昌敏, 刘亮, 郭欣. 钙催化苯酚反应的分子动力学模拟[J]. 化工学报, 2019, 70(5): 1788-1794. |

| [13] | 王家德, 袁通斌, 周丹飞, 周栩乐, 甘永平. 基于原位红外光谱的水相苯酚电氧化机理研究[J]. 化工学报, 2019, 70(12): 4821-4827. |

| [14] | 金浩, 陆佳伟, 汤吉海, 张竹修, 费兆阳, 刘清, 陈献, 崔咪芬, 乔旭. 带侧线反应精馏-渗透汽化生产乙酸乙酯集成过程模拟与分析[J]. 化工学报, 2018, 69(8): 3469-3478. |

| [15] | 岳东敏, 张欠之, 孙德, 李冰冰, 毛钦烨, 彭从康. PVA/SO42--AAO催化-渗透汽化双功能复合膜合成乙酸乙酯[J]. 化工学报, 2018, 69(6): 2775-2781. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号