化工学报 ›› 2021, Vol. 72 ›› Issue (8): 4267-4278.DOI: 10.11949/0438-1157.20210464

收稿日期:2021-04-02

修回日期:2021-05-23

出版日期:2021-08-05

发布日期:2021-08-05

通讯作者:

张炜

作者简介:陆俊杰(1990—),男,博士,讲师,基金资助:

Junjie LU1( ),Wei ZHANG1(

),Wei ZHANG1( ),Hao MA2

),Hao MA2

Received:2021-04-02

Revised:2021-05-23

Online:2021-08-05

Published:2021-08-05

Contact:

Wei ZHANG

摘要:

由于气浮密封薄膜引发的滑移流现象频发,本文针对一种新型柱面螺旋槽气浮密封,基于线性化Boltzmann方程(F-K 模型),引入流量因子,建立稀薄气体润滑的F-K滑移流模型。采用高精度八点差分法和Newton-Raphson迭代法求解气膜压力,解决了表面槽-台阶跃、径向偏心与极薄气膜三者耦合下对求解发散和计算精度的影响。将计算结果与现有研究对比,并考察了气体滑移流效应与运行参数的内在关联,研究结果验证了新型柱面螺旋槽气浮密封在高速、低压、小膜厚和大偏心下具有较为明显的滑移流效应;此外,虽然槽深、槽数和槽长的增加提高了气膜浮力,但是增强了槽内滑移流动的响应。研究结果为拓宽动压密封应用范围提供理论了基础。

中图分类号:

陆俊杰, 张炜, 马浩. 基于F-K滑移流模型的柱面微槽气浮密封浮升能力分析[J]. 化工学报, 2021, 72(8): 4267-4278.

Junjie LU, Wei ZHANG, Hao MA. Floating performance of cylindrical microgroove gas floating seal based on F-K slip flow model[J]. CIESC Journal, 2021, 72(8): 4267-4278.

| Parameters | Symbols | Values |

|---|---|---|

| outer diameter of rotating ring | R | 0.025 m |

| length of floating ring | L | 0.052 m |

| average gap | C | 4 × 10-6 m |

| eccentricity | ε | 0.5 |

| rotating speed | nr | 50000 r/min |

| groove depth | hc | 8 × 10-6 m |

| groove number | nc | 10 |

| spiral angle | β | 30° |

| groove length | lc | 0.025 m |

| gas pressure | p | 0.3 MPa |

表1 柱面气浮密封工况参数和螺旋槽结构参数

Table 1 Initial structural and operation parameters of spiral-grooved cylindrical gas-floating seal

| Parameters | Symbols | Values |

|---|---|---|

| outer diameter of rotating ring | R | 0.025 m |

| length of floating ring | L | 0.052 m |

| average gap | C | 4 × 10-6 m |

| eccentricity | ε | 0.5 |

| rotating speed | nr | 50000 r/min |

| groove depth | hc | 8 × 10-6 m |

| groove number | nc | 10 |

| spiral angle | β | 30° |

| groove length | lc | 0.025 m |

| gas pressure | p | 0.3 MPa |

| Parameters | Symbols | Values |

|---|---|---|

| outer diameter of floating ring | R | 0.0062 m |

| length of floating ring | L | 0.0144 m |

| initial film thickness | C | 6.5 × 10-5 m |

| eccentricity | ε | 0.5 |

| depth of groove | hc | 4 × 10-6 m |

| number of grooves | nc | 10 |

| spiral angle | β | 60° |

| length of groove | lc | 0.007 m |

表2 文献[27]中的密封实验参数

Table 2 The experimental parameters of Ref. [27]

| Parameters | Symbols | Values |

|---|---|---|

| outer diameter of floating ring | R | 0.0062 m |

| length of floating ring | L | 0.0144 m |

| initial film thickness | C | 6.5 × 10-5 m |

| eccentricity | ε | 0.5 |

| depth of groove | hc | 4 × 10-6 m |

| number of grooves | nc | 10 |

| spiral angle | β | 60° |

| length of groove | lc | 0.007 m |

图7 无滑移流与F-K滑移流模型在气膜厚度4 μm和偏心率0.5下气膜浮升力随转速和压力的变化规律

Fig.7 Variations of the floating forces of the gas film with rotating speed and pressure in the non-slipping flow model and the F-K model under gas film thickness 4 μm and eccentricity 0.5

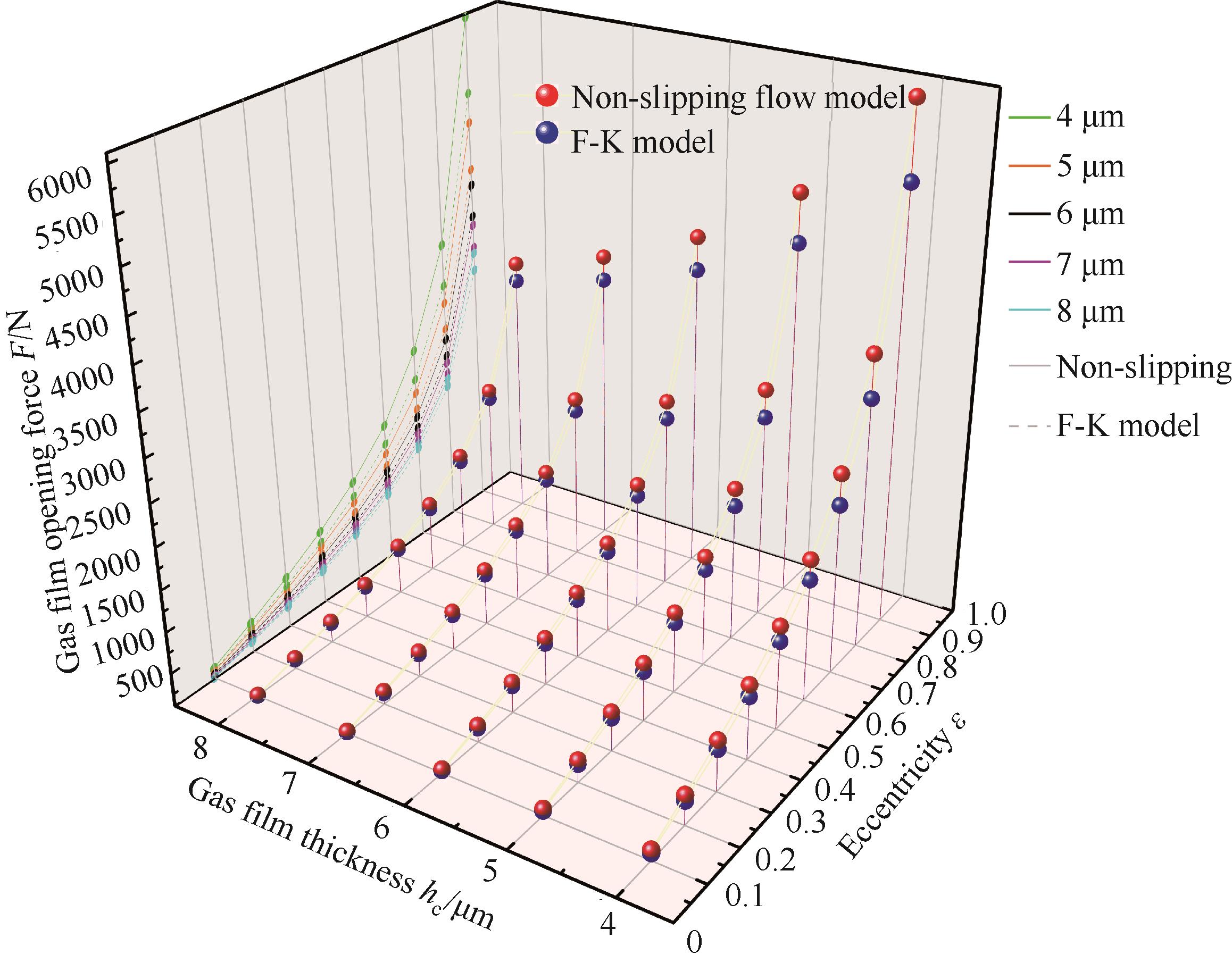

图8 无滑移流与F-K滑移流模型的气膜浮升力随膜厚与偏心率的变化规律

Fig.8 Variations of the floating forces of the gas film with eccentricity and gas film thickness in the non-slipping flow model and the F-K model

图10 无滑移流与F-K滑移流模型的气膜浮升力随槽数的变化规律

Fig.10 Variations of the floating forces of the gas film with the number of grooves in the non-slipping flow model and the F-K model

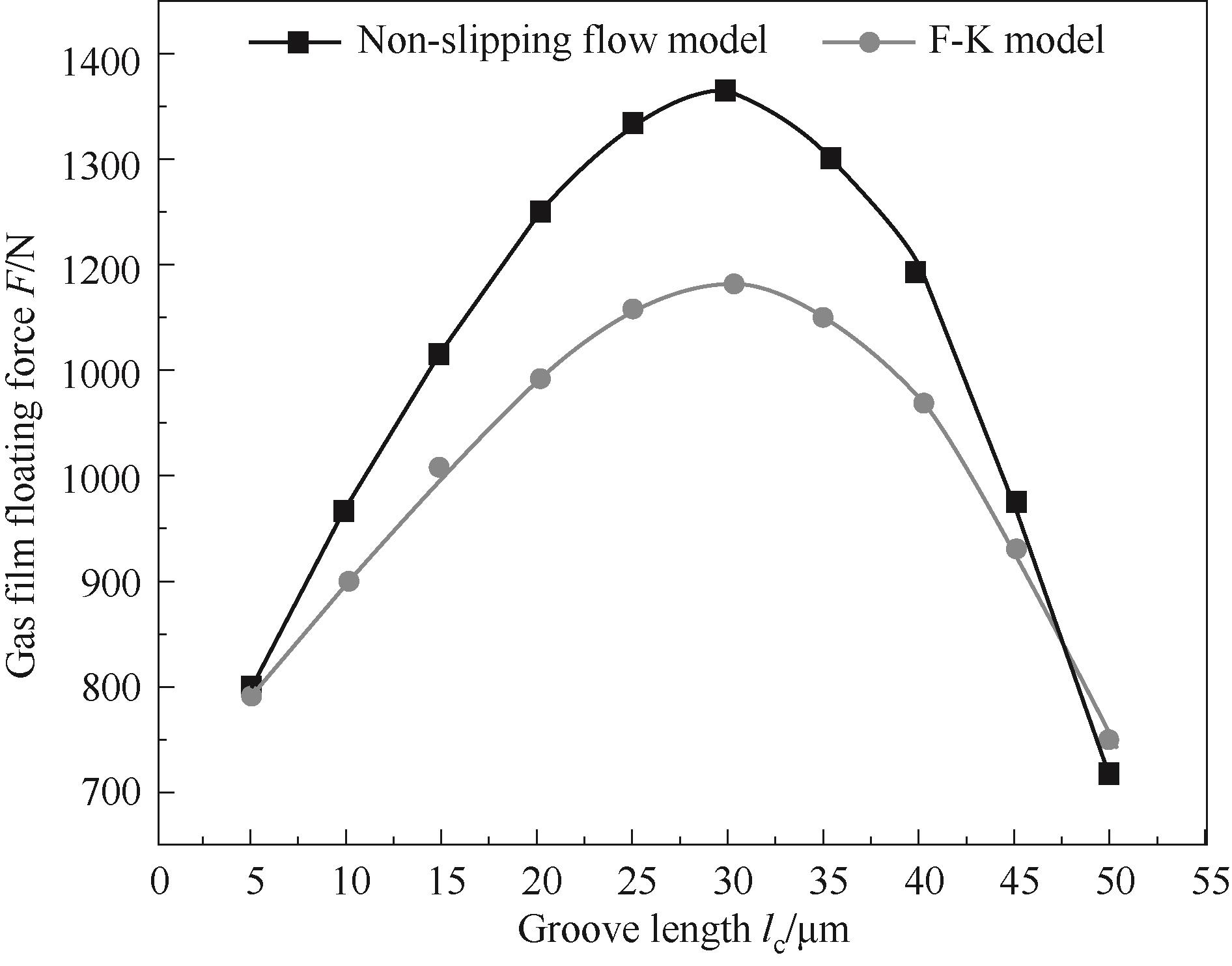

图11 无滑移流与F-K滑移流模型的气膜浮升力随槽长的变化规律

Fig.11 Variations of the floating forces of the gas film with the groove length in the non-slipping flow model and the F-K model

| 1 | Steinetz B M, Hendricks R C. Engine seal technology requirements to meet NASA's Advanced Subsonic Technology program goals[J]. Journal of Propulsion and Power, 1996, 12(4): 786-793. |

| 2 | Ludwig L, Johnson R. Sealing technology for aircraft gas turbine engines[C]//10th Propulsion Conference. Reston, Virigina: AIAA, 1974. |

| 3 | Liang A D, Shapiro W, Numerical Aggarwal B., analytical, experimental study of fluid dynamic forces in seals[R]. NASA CR, 2004 |

| 4 | Bird G A. Molecular Gas Dynamics and the Direct Simulation of Gas Flows[M]. New York: Oxford Science Publications, 1994. |

| 5 | Fan J, Shen C. Statistical simulation of low-speed rarefied gas flows[J]. Journal of Computational Physics, 2001, 167(2): 393-412. |

| 6 | Alexander F J, Garcia A L. The direct simulation Monte Carlo method[J]. Computers in Physics, 1997, 11(6): 588-593. |

| 7 | Bhattacharya D K, Lie G C. Molecular-dynamics simulations of nonequilibrium heat and momentum transport in very dilute gases[J]. Physical Review Letters, 1989, 62(8): 897-900. |

| 8 | 陈东菊, 周帅, 杨智, 等. 稀薄效应对空气静压止推轴承性能影响[J]. 四川大学学报(工程科学版), 2016, 48(1): 194-199. |

| Chen D J, Zhou S, Yang Z, et al. Influence of flow factor in gas rarefied effects to aerostatic thrust bearing performance[J]. Journal of Sichuan University (Engineering Science Edition), 2016, 48(1): 194-199. | |

| 9 | Burgdorfer A. The influence of the molecular mean free path on the performance of hydrodynamic gas lubricated bearings[J]. Journal of Basic Engineering, 1959, 81(1): 94-98. |

| 10 | Hsia Y T, Domoto G A. An experimental investigation of molecular rarefaction effects in gas lubricated bearings at ultra-low clearances[J]. Journal of Lubrication Technology, 1983, 105(1): 120-129. |

| 11 | Mitsuya Y. Modified Reynolds equation for ultra-thin film gas lubrication using 1.5-order slip-flow model and considering surface accommodation coefficient[J]. Journal of Tribology, 1993, 115(2): 289-294. |

| 12 | Bahukudumbi P, Beskok A. A phenomenological lubrication model for the entire Knudsen regime[J]. Journal of Micromechanics and Microengineering, 2003, 13(6): 873-884. |

| 13 | Fukui S, Kaneko R. Analysis of ultra-thin gas film lubrication based on linearized Boltzmann equation (2): Influence of accommodation coefficient [J]. Transactions of the Japan Society of Mechanical Engineers Series C, 1987, 53(492): 1807-1814. |

| 14 | 黄平. 润滑数值计算方法[M]. 北京: 高等教育出版社, 2012. |

| Huang P. Numerical Calculation Method of Lubrication [M]. Beijing: Higher Education Press, 2012. | |

| 15 | Gu X J, Zhang H J, Emerson D R. A new extended Reynolds equation for gas bearing lubrication based on the method of moments[J]. Microfluidics and Nanofluidics, 2016, 20(1): 1-12. |

| 16 | Yamakiri H, Sasaki S, Kurita T, et al. Effects of laser surface texturing on friction behavior of silicon nitride under lubrication with water[J]. Tribology International, 2011, 44(5): 579-584. |

| 17 | Shi L P, Wang X Y, Su X, et al. Comparison of the load-carrying performance of mechanical gas seals textured with microgrooves and microdimples[J]. Journal of Tribology, 2016, 138(2): 021701. |

| 18 | Kovalchenko A, Ajayi O, Erdemir A, et al. The effect of laser surface texturing on transitions in lubrication regimes during unidirectional sliding contact[J]. Tribology International, 2005, 38(3): 219-225. |

| 19 | 张小青. 微涡轮发动机气体轴承-转子系统非线性动力学研究[D]. 北京: 北京理工大学, 2014. |

| Zhang X Q. Study on nonlinear dynamics of gas bearing-rotor system of micro-turbine engine [D]. Beijing: Beijing Institute of Technology, 2014. | |

| 20 | Childs D W, Leland T. Rotordynamic-coefficient and leakage characteristics for hole-pattern-stator annular gas seals—measurements versus predictions[J]. Journal of Tribology, 2004, 126(2): 326-333. |

| 21 | Nagai K, Kaneko S, Taura H, et al. Numerical and experimental analyses of static characteristics for liquid annular seals with helical grooves in seal stator[J]. Journal of Tribology, 2018, 140(3): 052201. |

| 22 | Nagai K, Kaneko S, Taura H, et al. Numerical and experimental analyses of dynamic characteristics for liquid annular seals with helical grooves in seal stator[J]. Journal of Tribology, 2018, 140(5): 0522011. |

| 23 | Zhang C W, Gu L, Wang J Y, et al. Effect of air rarefaction on the contact behaviors of air lubricated spiral-groove thrust micro-bearings[J]. Tribology International, 2017, 111: 167-175. |

| 24 | Ma C H, Bai S X, Peng X D. Thermoelastohydrodynamic characteristics of T-grooves gas face seals[J]. International Journal of Heat and Mass Transfer, 2016, 102: 277-286. |

| 25 | Bai S X. Thermoelastohydrodynamic gas lubrication of spiral-groove face seals: modeling and analysis of vapor condensation[J]. Tribology Transactions, 2017, 60(4): 719-728. |

| 26 | 陆俊杰, 张炜, 谢方民, 等. 一种自适应柱状密封气膜特性分析[J]. 化工学报, 2020, 71: 346-354. |

| Lu J J, Zhang W, Xie F M, et al. Performance analysis of gas film of adaptive cylindrical seal[J]. CIESC Journal, 2020, 71: 346-354. | |

| 27 | Choi W C, Shin Y H, Choi J H. Numerical analysis of stiffness of self-acting air bearings of various curvatures[J]. JSME International Journal Series C, 2001, 44(2): 470-475. |

| 28 | Ruan B. Finite element analysis of the spiral groove gas face seal at the slow speed and the low pressure conditions—slip flow consideration[J]. Tribology Transactions, 2000, 43(3): 411-418. |

| 29 | Zhang W M, Meng G, Huang H, et al. Characteristics analysis and dynamic responses of micro-gas-lubricated journal bearings with a new slip model[J]. Journal of Physics D: Applied Physics, 2008, 41(15): 155305. |

| [1] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [2] | 张伟政, 赵吉军, 马学忠, 张琦璇, 庞益祥, 张俊涛. 湍流效应对高速机械密封端面型槽冷却性能影响分析[J]. 化工学报, 2023, 74(3): 1228-1238. |

| [3] | 徐洁, 俞树荣, 丁雪兴, 蒋海涛, 丁俊华. 基于波箔片变形的浮动式箔片气膜密封性能分析[J]. 化工学报, 2022, 73(5): 2083-2093. |

| [4] | 王学良, 刘美红, 熊忠汾, 李鑫. 考虑表面粗糙度的柔性箔柱面气膜密封紊流特性分析[J]. 化工学报, 2022, 73(4): 1683-1694. |

| [5] | 刘献飞, 王恒, 王方, 李志强, 朱彩霞, 张浩飞. 单螺杆膨胀机螺旋槽道内液膜分布均匀特性[J]. 化工学报, 2021, 72(S1): 336-341. |

| [6] | 商浩, 陈源, 李孝禄, 王冰清, 李运堂, 彭旭东. 膜厚扰动下的非线性效应对干气密封性能影响研究[J]. 化工学报, 2021, 72(4): 2213-2222. |

| [7] | 于辰,江锦波,赵文静,李纪云,彭旭东,王玉明. 基于微段组合的干气密封端面型槽结构模型及其参数影响[J]. 化工学报, 2021, 72(10): 5294-5309. |

| [8] | 陆俊杰, 张炜, 谢方民, 焦永峰. 一种自适应柱状密封气膜特性分析[J]. 化工学报, 2020, 71(S1): 346-354. |

| [9] | 俞树荣, 丁俊华, 王世鹏, 刘红, 丁雪兴, 孙宝财. 柱面密封气膜动压效应模拟及试验[J]. 化工学报, 2020, 71(7): 3220-3228. |

| [10] | 孟祥铠, 江莹莹, 赵文静, 彭旭东. 螺旋槽液膜密封热流体动力润滑性能分析[J]. 化工学报, 2019, 70(4): 1512-1521. |

| [11] | 陈传刚, 丁雪兴, 陆俊杰, 张伟政, 陈金林. 摩擦副界面微造型序列对气体密封性能的影响[J]. 化工学报, 2019, 70(3): 1016-1026. |

| [12] | 杨文静, 郝木明, 曹恒超, 袁俊马, 李晗. 基于质量守恒边界条件的下游泵送螺旋槽液膜密封空化分析[J]. 化工学报, 2018, 69(9): 3932-3943. |

| [13] | 曹恒超, 郝木明, 杨文静, 汪艳红, 李勇凡, 徐鲁帅. 双列螺旋槽液膜密封相变现象及性能[J]. 化工学报, 2018, 69(5): 2110-2119. |

| [14] | 马学忠, 孟祥铠, 王玉明, 赵文静, 沈明学, 彭旭东. 机械端面密封反向螺旋槽空化效应与泄漏控制机理[J]. 化工学报, 2018, 69(4): 1558-1568. |

| [15] | 丁雪兴, 贺振泓, 张伟政, 陆俊杰, 苗春昊. 柱面螺旋槽气膜密封微尺度流动场稳态特性分析[J]. 化工学报, 2018, 69(4): 1537-1546. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号