化工学报 ›› 2022, Vol. 73 ›› Issue (2): 904-913.DOI: 10.11949/0438-1157.20211287

收稿日期:2021-09-07

修回日期:2021-11-25

出版日期:2022-02-05

发布日期:2022-02-18

通讯作者:

宋英今

作者简介:王燕杉(1993—),女,博士研究生,基金资助:

Yanshan WANG( ),Xiaochao ZHU,Yingjin SONG(

),Xiaochao ZHU,Yingjin SONG( ),Yihang LI

),Yihang LI

Received:2021-09-07

Revised:2021-11-25

Online:2022-02-05

Published:2022-02-18

Contact:

Yingjin SONG

摘要:

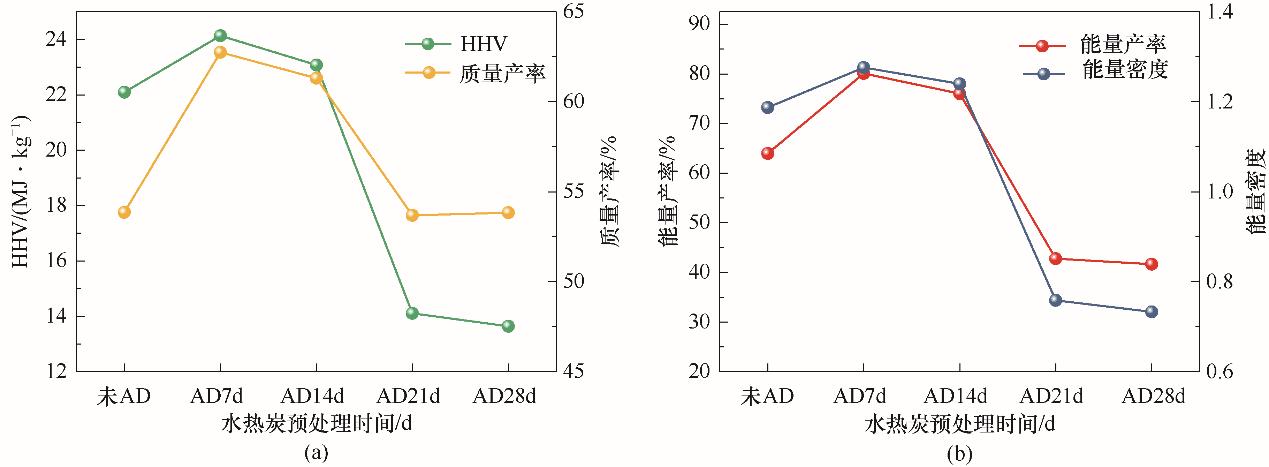

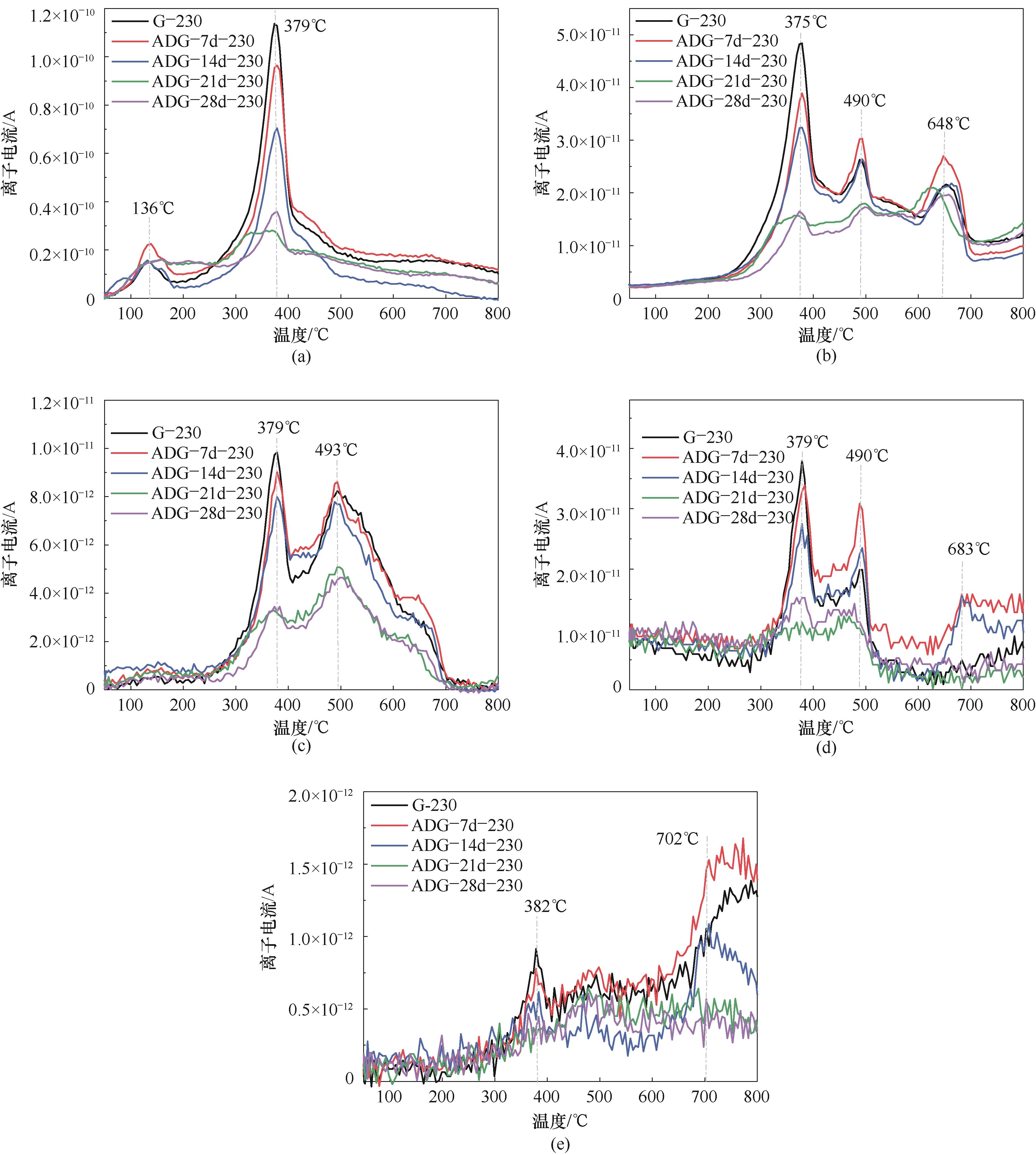

厌氧消化(AD)耦合水热炭化(HTC)技术对园林废弃物的可持续资源化利用具有显著优势和意义。采用草为研究对象,进行了7~28 d的AD预处理,深入探究了AD预处理耦合HTC对水热炭特性及其热解和产物释放特性的影响。其中,AD促进HTC过程主要发生脱羧反应;通过改变木质纤维素构成比例和结构特征有效调控水热炭的功能特性。此外,AD打破了生物质内部致密的刚性结构,促进了水热炭丰富孔隙的形成和比表面积的增加。在生物可降解程度为17.52%(AD 7 d)时,水热炭性能最佳,质量产率、高位热值(HHV)、能量产率和能量密度分别达62.75%、23.81 MJ·kg-1、80.31%和1.28。此外, TG-MS分析结果揭示了AD预处理提高了炭的热稳定性以及热解产物中能源气体的生成,有助于热解气的提质和利用。

中图分类号:

王燕杉, 朱小超, 宋英今, 李易航. 草屑厌氧消化预处理耦合水热炭化研究[J]. 化工学报, 2022, 73(2): 904-913.

Yanshan WANG, Xiaochao ZHU, Yingjin SONG, Yihang LI. Study on anaerobic digestion pretreatment coupled with hydrothermal carbonization of grass[J]. CIESC Journal, 2022, 73(2): 904-913.

| 参数 | 草 | 接种污泥 |

|---|---|---|

| TS/% | 97.39 ± 0.50 | 2.65 ± 0.30 |

| VS/% | 85.66 ± 0.40 | 1.53 ± 0.40 |

| C/% | 39.40 | 23.72 |

| N/% | 2.68 | 3.70 |

| H/% | 7.69 | 5.02 |

| S/% | 0.10 | 0.63 |

表1 原料及接种物的特性

Table 1 Properties of the feedstock and inoculum

| 参数 | 草 | 接种污泥 |

|---|---|---|

| TS/% | 97.39 ± 0.50 | 2.65 ± 0.30 |

| VS/% | 85.66 ± 0.40 | 1.53 ± 0.40 |

| C/% | 39.40 | 23.72 |

| N/% | 2.68 | 3.70 |

| H/% | 7.69 | 5.02 |

| S/% | 0.10 | 0.63 |

图5 经AD预处理前后的草屑水热炭的质量产率和热值(a),能量产率和能量密度(b)的变化

Fig.5 Mass yields and HHV(a), energy densification and energy yields (b) of hydrochar derived from untreated and pretreated with AD

| 样品 | 比表面积/ (m2·g-1) | 平均孔径/nm | 总孔体积/ (cm3·g-1) |

|---|---|---|---|

| G-230 | 23.98 | 6.21 | 0.037 |

| ADG-7d-230 | 34.46 | 7.78 | 0.067 |

| ADG-14d-230 | 27.28 | 11.84 | 0.076 |

| ADG-21d-230 | 54.41 | 20.55 | 0.280 |

| ADG-28d-230 | 44.82 | 21.87 | 0.25 |

表2 AD预处理前后水热炭的SSA和孔隙结构参数

Table 2 SSA and pore structure parameters of hydrochar pretreated and untreated with AD

| 样品 | 比表面积/ (m2·g-1) | 平均孔径/nm | 总孔体积/ (cm3·g-1) |

|---|---|---|---|

| G-230 | 23.98 | 6.21 | 0.037 |

| ADG-7d-230 | 34.46 | 7.78 | 0.067 |

| ADG-14d-230 | 27.28 | 11.84 | 0.076 |

| ADG-21d-230 | 54.41 | 20.55 | 0.280 |

| ADG-28d-230 | 44.82 | 21.87 | 0.25 |

| 参数/(mg·kg-1) | G-230 | ADG-7d-230 |

|---|---|---|

| 无机元素 | ||

| K | 720.67 | 869.95 |

| Ca | 22323.20 | 25444.37 |

| Na | 133.42 | 240.95 |

| Mg | 2586.22 | 3327.14 |

| P | 5350.21 | 6157.90 |

| Al | 1554.11 | 6758.90 |

| Si | 4920.62 | 4801.05 |

| Cu | 90.44 | 104.36 |

| Zn | 326.45 | 246.50 |

| Fe | 3211.70 | 7804.13 |

| 重金属元素 | ||

| As | 0.76 | 0.21 |

| Hg | 0.54 | 0.62 |

| Pb | 9.90 | 20.05 |

| Cd | 0.08 | 0.11 |

| Cr | 19.12 | 45.23 |

表3 AD预处理前后水热炭的无机和重金属元素

Table 3 Inorganic and heavy metal elements of hydrochar derived from pretreated and untreated with AD

| 参数/(mg·kg-1) | G-230 | ADG-7d-230 |

|---|---|---|

| 无机元素 | ||

| K | 720.67 | 869.95 |

| Ca | 22323.20 | 25444.37 |

| Na | 133.42 | 240.95 |

| Mg | 2586.22 | 3327.14 |

| P | 5350.21 | 6157.90 |

| Al | 1554.11 | 6758.90 |

| Si | 4920.62 | 4801.05 |

| Cu | 90.44 | 104.36 |

| Zn | 326.45 | 246.50 |

| Fe | 3211.70 | 7804.13 |

| 重金属元素 | ||

| As | 0.76 | 0.21 |

| Hg | 0.54 | 0.62 |

| Pb | 9.90 | 20.05 |

| Cd | 0.08 | 0.11 |

| Cr | 19.12 | 45.23 |

图9 经AD预处理和未预处理的草屑水热炭的产物释放特性质谱图(a) H2O, m/z = 18; (b) CO2, m/z = 44; (c) CH4, m/z = 16; (d) CO, m/z = 28; (e) H2, m/z = 2

Fig.9 Mass spectra of product release characteristics of hydrochar pretreated and unpretreated with AD

| 1 | Song Y J, Meng S Y, Chen G Y, et al. Co-digestion of garden waste, food waste, and tofu residue: effects of mixing ratio on methane production and microbial community structure[J]. Journal of Environmental Chemical Engineering, 2021, 9(5): 105901. |

| 2 | Panigrahi S, Sharma H B, Dubey B K. Anaerobic co-digestion of food waste with pretreated yard waste: a comparative study of methane production, kinetic modeling and energy balance[J]. Journal of Cleaner Production, 2020, 243: 118480. |

| 3 | Huang C, Xiong L, Guo H J, et al. Anaerobic digestion of elephant grass hydrolysate: biogas production, substrate metabolism and outlet effluent treatment[J]. Bioresource Technology, 2019, 283: 191-197. |

| 4 | Sharma H B, Panigrahi S, Sarmah A K, et al. Downstream augmentation of hydrothermal carbonization with anaerobic digestion for integrated biogas and hydrochar production from the organic fraction of municipal solid waste: a circular economy concept[J]. Science of the Total Environment, 2020, 706: 135907. |

| 5 | Mumme J, Eckervogt L, Pielert J, et al. Hydrothermal carbonization of anaerobically digested maize silage[J]. Bioresource Technology, 2011, 102(19): 9255-9260. |

| 6 | Libra J A, Ro K S, Kammann C, et al. Hydrothermal carbonization of biomass residuals: a comparative review of the chemistry, processes and applications of wet and dry pyrolysis[J]. Biofuels, 2011, 2(1): 71-106. |

| 7 | Kang S M, Li X L, Fan J, et al. Characterization of hydrochars produced by hydrothermal carbonization of lignin, cellulose, D-xylose, and wood meal[J]. Industrial & Engineering Chemistry Research, 2012, 51(26): 9023-9031. |

| 8 | Sheng K C, Zhang S, Liu J L, et al. Hydrothermal carbonization of cellulose and xylan into hydrochars and application on glucose isomerization[J]. Journal of Cleaner Production, 2019, 237: 117831. |

| 9 | Chen G Y, Guo X, Liu F, et al. Gasification of lignocellulosic biomass pretreated by anaerobic digestion (AD) process: an experimental study[J]. Fuel, 2019, 247: 324-333. |

| 10 | Wang T P, Ye X N, Yin J, et al. Effects of biopretreatment on pyrolysis behaviors of corn stalk by methanogen[J]. Bioresource Technology, 2014, 164: 416-419. |

| 11 | Funke A, Mumme J, Koon M, et al. Cascaded production of biogas and hydrochar from wheat straw: energetic potential and recovery of carbon and plant nutrients[J]. Biomass and Bioenergy, 2013, 58: 229-237. |

| 12 | Sawatdeenarunat C, Nam H, Adhikari S, et al. Decentralized biorefinery for lignocellulosic biomass: integrating anaerobic digestion with thermochemical conversion[J]. Bioresource Technology, 2018, 250: 140-147. |

| 13 | Erdogan E, Atila B, Mumme J, et al. Characterization of products from hydrothermal carbonization of orange pomace including anaerobic digestibility of process liquor[J]. Bioresource Technology, 2015, 196: 35-42. |

| 14 | Pagés-Díaz J, Cerda Alvarado A O, Montalvo S, et al. Anaerobic bio-methane potential of the liquors from hydrothermal carbonization of different lignocellulose biomasses[J]. Renewable Energy, 2020, 157: 182-189. |

| 15 | Choe U, Mustafa A M, Lin H J, et al. Anaerobic co-digestion of fish processing waste with a liquid fraction of hydrothermal carbonization of bamboo residue[J]. Bioresource Technology, 2020, 297: 122542. |

| 16 | Panigrahi S, Dubey B K. Electrochemical pretreatment of yard waste to improve biogas production: understanding the mechanism of delignification, and energy balance[J]. Bioresource Technology, 2019, 292: 121958. |

| 17 | Reza M T, Werner M, Pohl M, et al. Evaluation of integrated anaerobic digestion and hydrothermal carbonization for bioenergy production[J]. Journal of Visualized Experiments, 2014(88): 51734. |

| 18 | Zhang D L, Wang F, Shen X L, et al. Comparison study on fuel properties of hydrochars produced from corn stalk and corn stalk digestate[J]. Energy, 2018, 165: 527-536. |

| 19 | Huang S M, Wang T, Chen K, et al. Engineered biochar derived from food waste digestate for activation of peroxymonosulfate to remove organic pollutants[J]. Waste Management, 2020, 107: 211-218. |

| 20 | Chen Y D, Bai S W, Li R X, et al. Magnetic biochar catalysts from anaerobic digested sludge: production, application and environment impact[J]. Environment International, 2019, 126: 302-308. |

| 21 | Moodley P, Sewsynker-Sukai Y, Gueguim Kana E B. Progress in the development of alkali and metal salt catalysed lignocellulosic pretreatment regimes: potential for bioethanol production[J]. Bioresource Technology, 2020, 310: 123372. |

| 22 | Guan R L, Li X J, Wachemo A C, et al. Enhancing anaerobic digestion performance and degradation of lignocellulosic components of rice straw by combined biological and chemical pretreatment[J]. Science of the Total Environment, 2018, 637/638: 9-17. |

| 23 | Dai X H, Hua Y, Liu R, et al. Biomethane production by typical straw anaerobic digestion: deep insights of material compositions and surface properties[J]. Bioresource Technology, 2020, 313: 123643. |

| 24 | Wang Y S, Song Y J, Li N, et al. Tunable active sites on biogas digestate derived biochar for sulfanilamide degradation by peroxymonosulfate activation[J]. Journal of Hazardous Materials, 2022, 421: 126794. |

| 25 | López Barreiro D, Samorì C, Terranella G, et al. Assessing microalgae biorefinery routes for the production of biofuels via hydrothermal liquefaction[J]. Bioresource Technology, 2014, 174: 256-265. |

| 26 | Heilmann S M, Molde J S, Timler J G, et al. Phosphorus reclamation through hydrothermal carbonization of animal manures[J]. Environmental Science & Technology, 2014, 48(17): 10323-10329. |

| 27 | Aragón-Briceño C I, Pozarlik A K, Bramer E A, et al. Hydrothermal carbonization of wet biomass from nitrogen and phosphorus approach: a review[J]. Renewable Energy, 2021, 171: 401-415. |

| 28 | Zhao X, Becker G C, Faweya N, et al. Fertilizer and activated carbon production by hydrothermal carbonization of digestate[J]. Biomass Conversion and Biorefinery, 2018, 8(2): 423-436. |

| 29 | Wang T, Chen Y C, Li J P, et al. Co-pyrolysis behavior of sewage sludge and rice husk by TG-MS and residue analysis[J]. Journal of Cleaner Production, 2020, 250: 119557. |

| 30 | Yang H P, Yan R, Chen H P, et al. Characteristics of hemicellulose, cellulose and lignin pyrolysis[J]. Fuel, 2007, 86(12/13): 1781-1788. |

| 31 | Zhou Y C, Chen Z Z, Gong H J, et al. Characteristics of dehydration during rice husk pyrolysis and catalytic mechanism of dehydration reaction with NiO/γ-Al2O3 as catalyst[J]. Fuel, 2019, 245: 131-138. |

| 32 | Minh Loy A C, Yusup S, Chin B L F, et al. Comparative study of in situ catalytic pyrolysis of rice husk for syngas production: kinetics modelling and product gas analysis[J]. Journal of Cleaner Production, 2018, 197: 1231-1243. |

| 33 | Sanchez-Silva L, López-González D, Villaseñor J, et al. Thermogravimetric-mass spectrometric analysis of lignocellulosic and marine biomass pyrolysis[J]. Bioresource Technology, 2012, 109: 163-172. |

| 34 | Yu J L, Lucas J A, Wall T F. Formation of the structure of chars during devolatilization of pulverized coal and its thermoproperties: a review[J]. Progress in Energy and Combustion Science, 2007, 33(2): 135-170. |

| 35 | Luo L, Liu J X, Zhang H, et al. TG-MS-FTIR study on pyrolysis behavior of superfine pulverized coal[J]. Journal of Analytical and Applied Pyrolysis, 2017, 128: 64-74. |

| [1] | 吕龙义, 及文博, 韩沐达, 李伟光, 高文芳, 刘晓阳, 孙丽, 王鹏飞, 任芝军, 张光明. 铁基导电材料强化厌氧去除卤代有机污染物:研究进展及未来展望[J]. 化工学报, 2023, 74(8): 3193-3202. |

| [2] | 黄玉龙, 吕凡, 仇俊杰, 章骅, 何品晶. 易腐垃圾厌氧消化沼液理化性质及VOCs分子特征[J]. 化工学报, 2023, 74(3): 1275-1285. |

| [3] | 刘海波, 王楠, 刘洪周, 陈铁柱, 李建昌. 电压扰动对EAD代谢通量中微生物与关键酶活性的影响[J]. 化工学报, 2022, 73(10): 4603-4612. |

| [4] | 毛政中, 孙怡, 黄志鹏, 李超超, 黄浩斌, 成少安. 微生物电解池产甲烷技术研究进展[J]. 化工学报, 2019, 70(7): 2411-2425. |

| [5] | 赵博玮, 李建政, 邓凯文, 孟佳. 木质框架土壤渗滤系统处理养猪废水厌氧消化液的效能[J]. 化工学报, 2015, 66(6): 2248-2255. |

| [6] | 李恒, 柯蓝婷, 王海涛, 郑艳梅, 王远鹏, 何宁, 李清彪. 低劣生物质厌氧产甲烷过程的模拟研究进展[J]. 化工学报, 2014, 65(5): 1577-1586. |

| [7] | 王定美, 王跃强, 袁浩然, 余震, 徐荣险, 周顺桂. 水热炭化制备污泥生物炭的碳固定[J]. 化工学报, 2013, 64(7): 2625-2632. |

| [8] | 刘华杰,杨殿海,薛勇刚,段妮娜,戴晓虎. 含油废水处理厂污泥的厌氧消化试验[J]. 化工进展, 2013, 32(10): 2501-2506. |

| [9] | 高 鹏,张 栋,贾舒婷,董 滨,戴晓虎. 污水厂污泥厌氧消化产短链脂肪酸研究进展[J]. 化工进展, 2013, 32(09): 2227-2232. |

| [10] | 池勇志1,2,刘晓敏1,李玉友3,张 昱2,费学宁1,王愉晨1. 微波预处理剩余污泥的研究进展[J]. 化工进展, 2013, 32(09): 2221-2226. |

| [11] | 张 珏,邢保山,马 春,王 慧,金仁村. 厌氧消化泡沫形成的影响因素探究[J]. 化工进展, 2013, 32(05): 1152-1156. |

| [12] | 张 辉1,胡勤海1,吴祖成1,潘慧云2. 城市污泥能源化利用研究进展[J]. 化工进展, 2013, 32(05): 1145-1151. |

| [13] | 金 效 齐 . 利用TG-MS研究NO气体在酰胺化碳纳米管吸附-脱附的性能[J]. 化工进展, 2013, 32(05): 1091-1096. |

| [14] | 何品晶, 管冬兴, 吴铎, 吕凡, 邵立明. 氨氮和林可霉素对有机物厌氧消化的抑制效应 [J]. 化工学报, 2011, 62(5): 1389-1394. |

| [15] | 徐贵华,陈少华,石建稳. 超声促进污泥厌氧消化效能及其机理 [J]. CIESC Journal, 2010, 29(11): 2198-. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号