化工学报 ›› 2022, Vol. 73 ›› Issue (10): 4769-4779.DOI: 10.11949/0438-1157.20220850

裴蓓1,2( ), 徐梦娇2, 韦双明2, 郭佳琪2, 李世梁2, 胡紫维2

), 徐梦娇2, 韦双明2, 郭佳琪2, 李世梁2, 胡紫维2

收稿日期:2022-06-16

修回日期:2022-07-12

出版日期:2022-10-05

发布日期:2022-11-02

通讯作者:

裴蓓

作者简介:裴蓓(1982—),女,博士,副教授, smart128@126.com

基金资助:

Bei PEI1,2( ), Mengjiao XU2, Shuangming WEI2, Jiaqi GUO2, Shiliang LI2, Ziwei HU2

), Mengjiao XU2, Shuangming WEI2, Jiaqi GUO2, Shiliang LI2, Ziwei HU2

Received:2022-06-16

Revised:2022-07-12

Online:2022-10-05

Published:2022-11-02

Contact:

Bei PEI

摘要:

借助20 L球形爆炸系统研究了甲烷/石墨粉和甲烷/煤粉复合体系爆炸特性异同,结果表明:甲烷浓度对甲烷/石墨粉和甲烷/煤粉两相体系的爆炸特性有重要影响,当甲烷的浓度为6%(体积)时,随着石墨粉粒径的增加,甲烷/石墨粉体系的压力曲线由单峰转为双峰,三种粒径的石墨粉(D50:7、18、75 μm)浓度分别在60、200、30 g/m3达到爆炸压力最大值0.691、0.657、0.611 MPa;甲烷/煤粉体系则在400 g/m3达到最大值0.724 MPa,高于甲烷/石墨粉体系。当甲烷浓度接近当量比时,三种粒径石墨粉的爆炸压力峰值均呈现逐渐减小的趋势,石墨粉的粒径越小,甲烷/石墨粉两相体系的爆炸压力峰值越小,甲烷/石墨粉体系在质量浓度为10 g/m3时达到最大值;甲烷/煤粉体系的爆炸压力则在60 g/m3时达到最大值0.776 MPa。甲烷浓度由6%增加至9%时,甲烷/石墨粉和甲烷/煤粉的爆炸火焰由不规则形状转为近似球形发展,火焰表面褶皱消失,同时两相体系的爆燃指数显著增高,当粉尘质量浓度大于30 g/m3时,甲烷/煤粉的爆燃指数大于甲烷/石墨粉体系,这是由于煤粉挥发分含量高,燃烧更为充分,且焦炭参与了爆炸过程;石墨粉本身的挥发分含量低,含碳量远超过煤粉,爆炸中仅有少部分石墨粉参与了爆炸。研究结果将对气粉两相混合物爆炸防治提供指导。

中图分类号:

裴蓓, 徐梦娇, 韦双明, 郭佳琪, 李世梁, 胡紫维. 甲烷/石墨粉与甲烷/煤粉爆炸特性对比研究[J]. 化工学报, 2022, 73(10): 4769-4779.

Bei PEI, Mengjiao XU, Shuangming WEI, Jiaqi GUO, Shiliang LI, Ziwei HU. Comparison of explosion characteristics of methane/graphite powder and methane/pulverized coal[J]. CIESC Journal, 2022, 73(10): 4769-4779.

石墨粉/ 粉煤 | 水分/%(mass) | 灰分/%(mass) | 可燃基挥发分/%(mass) | 固定碳/%(mass) |

|---|---|---|---|---|

| 石墨粉 | 0.15 | 0.51 | 0.82 | 98.53 |

| 煤粉 | 7.08 | 12.98 | 48.38 | 51.25 |

表1 石墨粉、煤粉的工业分析

Table 1 Industrial analysis of graphite powder and pulverized coal

石墨粉/ 粉煤 | 水分/%(mass) | 灰分/%(mass) | 可燃基挥发分/%(mass) | 固定碳/%(mass) |

|---|---|---|---|---|

| 石墨粉 | 0.15 | 0.51 | 0.82 | 98.53 |

| 煤粉 | 7.08 | 12.98 | 48.38 | 51.25 |

图2 三种粒径下甲烷/石墨粉爆炸压力峰值随质量浓度的变化

Fig.2 Variation curve of explosion pressure peak value of methane/graphite powder with mass concentration of three particle sizes

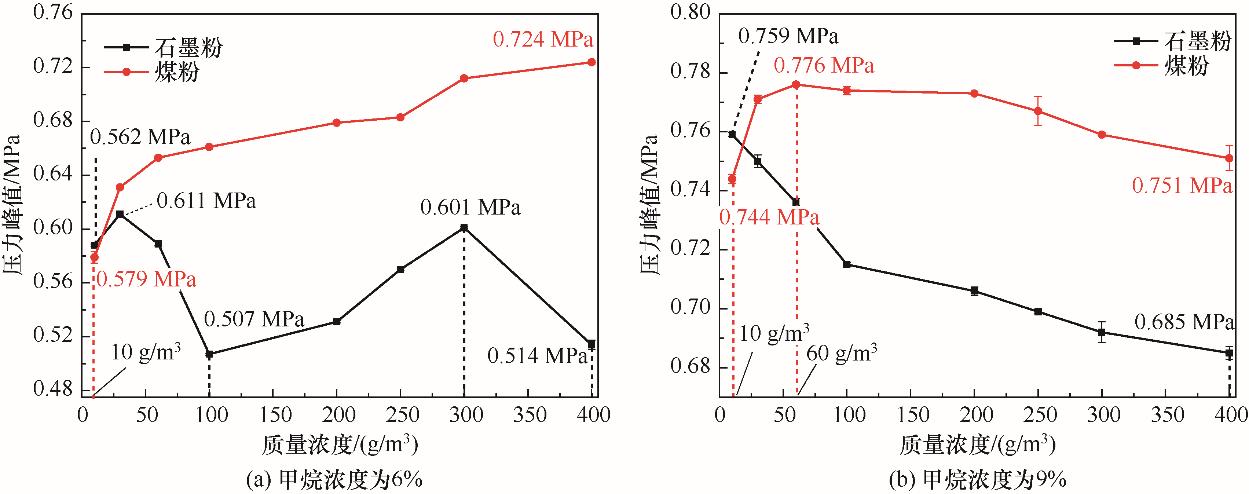

图3 甲烷/石墨粉与甲烷/煤粉爆炸压力峰值随质量浓度变化对比(煤粉D50:83 μm,石墨粉D50:75 μm)

Fig.3 Comparison of peak explosion pressure of methane/graphite powder and methane/pulverized coal with mass concentration(pulverized coal D50: 83 μm, graphite powder D50: 75 μm)

图4 三种粒径甲烷/石墨粉爆炸压升速率峰值随质量浓度的变化

Fig.4 Variation curve of peak pressure rise rate of three particle sizes of methane/graphite powder with mass concentration

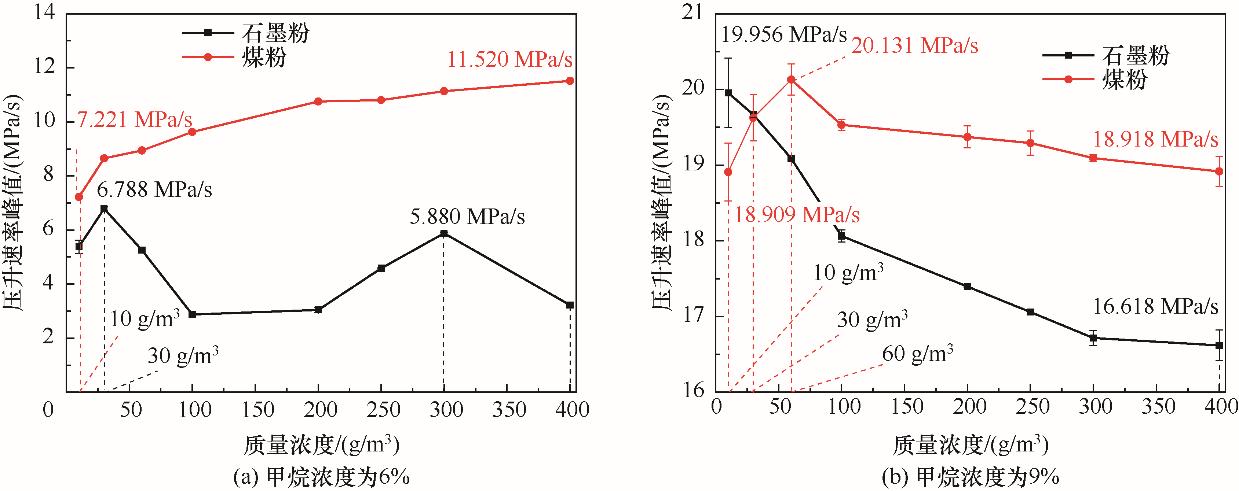

图5 甲烷/石墨粉与甲烷/煤粉爆炸压力峰值随质量浓度变化对比(煤粉D50:83 μm,石墨粉D50:75 μm)

Fig.5 Comparison of peak explosion pressure of methane/graphite powder and methane/pulverized coal with mass concentration(pulverized coal D50:83 μm, graphite powder D50:75 μm)

| 1 | 国家统计局. 中国统计年鉴. 2021[M]. 北京: 中国统计出版社, 2021: 288. |

| National Bureau of Statistics of China. China Statistical Yearbook. 2021[M]. Beijing: China Statistics Press, 2021: 288. | |

| 2 | Torrado D, Buitrago V, Glaude P A, et al. Explosions of methane/air/nanoparticles mixtures: comparison between carbon black and inert particles[J]. Process Safety and Environmental Protection, 2017, 110: 77-88. |

| 3 | Denkevits A, Dorofeev S. Explosibility of fine graphite and tungsten dusts and their mixtures[J]. Journal of Loss Prevention in the Process Industries, 2006, 19(2/3): 174-180. |

| 4 | 杨劲松, 张佳心. 石墨粒的着火燃烧实验研究[J]. 应用科技, 1992, 19(2): 24-28. |

| Yang J S, Zhang J X. Experimental study on ignition and combustion of graphite particles[J]. Applied Science and Technology, 1992, 19(2): 24-28. | |

| 5 | Kosinski P, Nyheim R, Asokan V, et al. Explosions of carbon black and propane hybrid mixtures[J]. Journal of Loss Revention in the Process Industries, 2013, 26(1): 45-51. |

| 6 | 王景伟, 关杰, 吴雯杰, 等. 打印机墨粉燃烧特性的热分析[J]. 环境工程, 2009, 27(4): 109-112. |

| Wang J W, Guan J, Wu W J, et al. Thermal analysis study on combustibility of printer toner[J]. Environmental Engineering, 2009, 27(4): 109-112. | |

| 7 | 吴月浩. 墨粉爆炸危险性研究与安全措施[D]. 南京: 南京理工大学, 2012. |

| Wu Y H. The study on explosion risk and safety measures of toner dust[D]. Nanjing: Nanjing University of Science and Technology, 2012. | |

| 8 | 李秀丽, 王景伟. 废弃硒鼓残留墨粉的爆炸参数研究[J]. 工业安全与环保, 2012, 38(8): 20-22. |

| Li X L, Wang J W. Study on toner dust explosion characteristic of waste toner cartridge[J]. Industrial Safety and Environmental Protection, 2012, 38(8): 20-22. | |

| 9 | 毕明树, 王洪雨. 甲烷-煤尘复合爆炸威力实验[J]. 煤炭学报, 2008, 33(7): 784-788. |

| Bi M S, Wang H Y. Experiment on methane-coal dust explosions[J]. Journal of China Coal Society, 2008, 33(7): 784-788. | |

| 10 | 裴蓓, 张子阳, 潘荣锟, 等. 不同强度冲击波诱导沉积煤尘爆炸火焰传播特性[J]. 煤炭学报, 2021, 46(2): 498-506. |

| Pei B, Zhang Z Y, Pan R K, et al. Flame propagation characteristics of deposited coal dust explosion induced by shock waves of different intensities[J]. Journal of China Coal Society, 2021, 46(2): 498-506. | |

| 11 | 田野, 王保民, 李利国. 甲烷浓度和煤粉粒径对混合爆炸火焰传播速度的影响[J]. 科学技术与工程, 2017, 17(9): 321-324. |

| Tian Y, Wang B M, Li L G. Effect of methane concentration and coal dust particle size on the speed of flame[J]. Science Technology and Engineering, 2017, 17(9): 321-324. | |

| 12 | 曲志明, 王育德. 甲烷煤尘燃烧爆炸试验研究[J]. 中国安全科学学报, 2012, 22(11): 55-61. |

| Qu Z M, Wang Y D. Experimental study on methane and coal dust combustion and explosion[J]. China Safety Science Journal, 2012, 22(11): 55-61. | |

| 13 | 陈东梁, 孙金华, 刘义, 等. 甲烷、煤尘复合体系燃烧特性及火焰结构的实验研究[J]. 自然科学进展, 2007, 17(4): 494-499. |

| Chen D L, Sun J H, Liu Y, et al. Experimental study on combustion characteristics and flame structure of methane and coal dust composite system[J]. Progress in Natural Science, 2007, 17(4): 494-499. | |

| 14 | 陈东梁, 孙金华, 刘义, 等. 甲烷/煤尘复合体系燃烧反应特性研究[J]. 工程热物理学报, 2008, 29(7): 1243-1247. |

| Chen D L, Sun J H, Liu Y, et al. Study on combustion characteristics of methane/coal dust mixture[J]. Journal of Engineering Thermophysics, 2008, 29(7): 1243-1247. | |

| 15 | 王晓彬. 点火延迟时间对甲烷煤尘爆炸特性的影响[J]. 煤矿安全, 2020, 51(3): 23-27. |

| Wang X B. Effect of ignition delay time on explosion characteristics of methane and coal dust hybrid mixtures[J]. Safety in Coal Mines, 2020, 51(3): 23-27. | |

| 16 | 李庆钊, 翟成, 吴海进, 等. 基于20L球形爆炸装置的煤尘爆炸特性研究[J]. 煤炭学报, 2011, 36(S1): 119-124. |

| Li Q Z, Zhai C, Wu H J, et al. Investigation on coal dust explosion characteristics using 20 L explosion sphere vessels[J]. Journal of China Coal Society, 2011, 36(S1): 119-124. | |

| 17 | 李润之. 瓦斯煤尘共存条件下的煤尘云爆炸下限[J]. 爆炸与冲击, 2018, 38(4): 913-917. |

| Li R Z. Minimum explosive concentration of coal dust cloud in the coexistence of gas and coal dust[J]. Explosion and Shock Waves, 2018, 38(4): 913-917. | |

| 18 | 司荣军, 李润之, 苏岱峰. 煤尘云质量浓度对瓦斯爆炸压力影响的试验研究[J]. 安全与环境学报, 2018, 18(5): 1796-1798. |

| Si R J, Li R Z, Su D F. Investigation of the influence of the coal dust cloud on the gas explosion pressure[J]. Journal of Safety and Environment, 2018, 18(5): 1796-1798. | |

| 19 | 王博, 苟瑞君, 阚润哲. 煤尘粒径对瓦斯煤尘爆炸的影响研究[J]. 中北大学学报(自然科学版), 2019, 40(1): 79-83, 89. |

| Wang B, Gou R J, Kan R Z. Study on the influence of particle size of coal dust on gas and coal dust explosion[J]. Journal of North University of China (Natural Science Edition), 2019, 40(1): 79-83, 89. | |

| 20 | 宋佰超, 李雨成, 罗红波. 挥发分对煤尘爆炸特性影响研究[J]. 数学的实践与认识, 2019, 49(1): 118-123. |

| Song B C, Li Y C, Luo H B. Study on the influence of volatile matter on coal dust explosion characteristics[J]. Mathematics in Practice and Theory, 2019, 49(1): 118-123. | |

| 21 | 宋春香. 煤质成分对煤尘爆炸特性影响实验研究[J]. 煤炭技术, 2015, 34(2): 189-191. |

| Song C X. Experimental study on coal dust explosion characteristics under impact of coal elemental composition[J]. Coal Technology, 2015, 34(2): 189-191. | |

| 22 | 马祯, 刘佳. 煤质成分对煤尘爆炸特性影响实验分析[J]. 当代化工研究, 2018(6): 2-3. |

| Ma Z, Liu J. Experimental analysis on the influence of coal quality composition on coal dust explosion characteristics[J]. Modern Chemical Research, 2018(6): 2-3. | |

| 23 | 王世昌. 中国动力煤挥发分发热量分布规律[J]. 电站系统工程, 2012, 28(3): 26-28, 30. |

| Wang S C. Distribution laws of volatile heating value for Chinese power coals[J]. Power System Engineering, 2012, 28(3): 26-28, 30. | |

| 24 | 刘仁生, 何英杰, 钟雪晴. 府谷长焰煤挥发分析出温度的探讨[J]. 煤质技术, 2010(3): 7-8, 11. |

| Liu R S, He Y J, Zhong X Q. The study on the volatile precipitation temperature of Fugu long flame coal[J]. Coal Quality Technology, 2010(3): 7-8, 11. | |

| 25 | 张廷尧, 胡中发, 周月桂. 单颗粒煤粉着火特性的数值分析[J]. 燃烧科学与技术, 2022, 28(1): 36-41. |

| Zhang T Y, Hu Z F, Zhou Y G. Numerical analysis of the ignition characteristics of single coal particle[J]. Journal of Combustion Science and Technology, 2022, 28(1): 36-41. | |

| 26 | 刘丹, 司荣军, 李润之. 环境湿度对瓦斯爆炸特性的影响[J]. 高压物理学报, 2015, 29(4): 307-312. |

| Liu D, Si R J, Li R Z. Ambient humidity influence on explosion characteristics of methane-air mixture[J]. Chinese Journal of High Pressure Physics, 2015, 29(4): 307-312. | |

| 27 | 李志宏. 可视化火焰测量系统的开发及应用[D]. 北京: 中国科学院研究生院(工程热物理研究所), 2006. |

| Li Z H. Visual method of flame's development and application[D]. Beijing: Graduate School of Chinese Academy of Sciences (Institute of Engineering Thermophysics), 2006. | |

| 28 | Khatami R, Levendis Y A. An overview of coal rank influence on ignition and combustion phenomena at the particle level[J]. Combustion and Flame, 2016, 164: 22-34. |

| 29 | National Fire Protection Association. NFPA 68: Guide for Venting of Deflagrations[Z]. National Fire Protection Association, 2002. |

| 30 | 来诚锋, 段滋华, 张永发, 等. 煤粉末的爆炸机理[J]. 爆炸与冲击, 2010, 30(3): 325-328. |

| Lai C F, Duan Z H, Zhang Y F, et al. Explosion mechanism of carbon powder[J]. Explosion and Shock Waves, 2010, 30(3): 325-328. | |

| 31 | 高尔新, 周中一, 韩三楼, 等. 高灰分煤尘对冲击波作用响应的微观研究[J]. 煤炭技术, 2005, 24(9): 1-2. |

| Gao E X, Zhou Z Y, Han S L, et al. The experiment research on explosive characteristic of coal dust by shock wave[J]. Coal Technology, 2005, 24(9): 1-2. |

| [1] | 李珍宝, 李超, 王虎, 王绍瑞, 黎泉. MPP抑制铝镁合金粉尘爆炸微观机理研究[J]. 化工学报, 2023, 74(8): 3608-3614. |

| [2] | 郑默, 李晓霞. ReaxFF MD模拟揭示的煤热解挥发分自由基反应的竞争与协调[J]. 化工学报, 2022, 73(6): 2732-2741. |

| [3] | 马萌, 白永辉, 卫俊涛, 闫伦靖, 吕鹏, 王焦飞, 宋旭东, 苏暐光, 于广锁. 生物质与煤(共)热解/气化过程中挥发分-半焦交互作用研究与进展[J]. 化工学报, 2022, 73(11): 5186-5200. |

| [4] | 刘洁妤, 龚岩, 吴晓翔, 郭庆华, 于广锁, 王辅臣. 多喷嘴对置式气化炉内颗粒挥发分火焰可视化研究[J]. 化工学报, 2021, 72(3): 1275-1282. |

| [5] | 梅振飞, 陈明, 陈德珍, 洪鎏, 胡雨燕. 垃圾热解-挥发分重整过程中基于产物导向的催化剂选择[J]. 化工学报, 2019, 70(8): 3104-3112. |

| [6] | 余明高, 袁晨樵, 郑凯. 管道内障碍物对加氢甲烷爆炸特性的影响[J]. 化工学报, 2016, 67(12): 5311-5319. |

| [7] | 冯冬冬, 赵义军, 刘鹏, 张宇, 张海楠, 孙绍增. 挥发分-半焦交互反应对生物质热解半焦特性的影响[J]. 化工学报, 2016, 67(11): 4787-4794. |

| [8] | 万丽花, 姚忠, 倪芳, 韦敏, 周治, 王浩绮, 孙芸, 仲兆祥. 两相体系中β-葡萄糖苷酶催化栀子苷水解制备京尼平[J]. 化工学报, 2014, 65(9): 3583-3591. |

| [9] | 万丽花, 姚忠, 倪芳, 韦敏, 周治, 王浩绮, 孙芸, 仲兆祥. 两相体系中β-葡萄糖苷酶催化栀子苷水解制备京尼平[J]. 化工学报, 2014, 65(9): 0-0. |

| [10] | 王擎1,隋义1,迟铭书1,隋岩2. 油页岩中矿物质对挥发分不凝气释放过程的影响[J]. 化工进展, 2014, 33(10): 2613-2618. |

| [11] | 汪 云1, 王利群1,2,何玉财1,2,朱 劼1,卿 青1,王明慧1. 两相体系中固定化黏红酵母CCZU-G5催化合成 (R)-2-羟基-4-苯基丁酸乙酯[J]. 化工进展, 2013, 32(03): 661-665. |

| [12] | 李沃源,毋 伟,邹海魁,初广文,邵 磊,陈建峰. 超重力旋转填充床用于高黏聚合物脱挥的研究进展 [J]. CIESC Journal, 2010, 29(2): 211-. |

| [13] | 双玥;吴昌宁;颜彬航;程易. 煤粉高温快速裂解过程的颗粒内部传递行为 [J]. CIESC Journal, 2010, 61(12): 3072-3079. |

| [14] | 陆 军,张伟国. 两相体系生物转化L-苯丙氨酸生成2-苯乙醇 [J]. CIESC Journal, 2008, 27(3): 417-. |

| [15] | 张涛, 黄哲, 林章凛. 固定化β-葡萄糖苷酶双相体系中水解大豆异黄酮 [J]. 化工学报, 2008, 59(2): 387-392. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号