化工学报 ›› 2023, Vol. 74 ›› Issue (5): 2123-2135.DOI: 10.11949/0438-1157.20230114

黄磊1,2( ), 孔令学1,3(

), 孔令学1,3( ), 白进1, 李怀柱1, 郭振兴1, 白宗庆1, 李平3, 李文1

), 白进1, 李怀柱1, 郭振兴1, 白宗庆1, 李平3, 李文1

收稿日期:2023-02-15

修回日期:2023-04-14

出版日期:2023-05-05

发布日期:2023-06-29

通讯作者:

孔令学

作者简介:黄磊(1995—),男,博士研究生,18361220739@163.com

基金资助:

Lei HUANG1,2( ), Lingxue KONG1,3(

), Lingxue KONG1,3( ), Jin BAI1, Huaizhu LI1, Zhenxing GUO1, Zongqing BAI1, Ping LI3, Wen LI1

), Jin BAI1, Huaizhu LI1, Zhenxing GUO1, Zongqing BAI1, Ping LI3, Wen LI1

Received:2023-02-15

Revised:2023-04-14

Online:2023-05-05

Published:2023-06-29

Contact:

Lingxue KONG

摘要:

准东煤中碱金属钠的含量高,在气化过程中生成的飞灰导致换热器积灰、腐蚀等问题的发生,对气化炉的安全稳定运行带来极大的挑战。煤灰的熔融行为是阐明飞灰沉积行为的重要参数,选取含Si、Al较高的油页岩为添加剂,研究了油页岩添加对准东高钠煤灰熔融行为的影响及机理,探讨使用油页岩解决准东高钠煤气化利用中的飞灰沉积问题。结果表明,随着油页岩添加量的增加,准东高钠煤红沙泉和将二矿煤灰的初始烧结温度与液相烧结温度区间长度增加,煤灰的沉积倾向减轻;矿物质分析显示,油页岩的添加降低了初始煤灰中硫酸钙的含量,提高石英的含量,同时熔融过程中生成大量夕线石,是准东高钠煤灰熔点升高的主要原因。对于红沙泉与将二矿煤,分别添加15%和20%的油页岩可有效提高煤灰的熔融特征温度,避免在气化过程中飞灰发生沉积。最后,基于神经网络模型,建立了准东高钠煤添加油页岩后的煤灰变形温度(DT)及流动温度(FT)的预测模型。

中图分类号:

黄磊, 孔令学, 白进, 李怀柱, 郭振兴, 白宗庆, 李平, 李文. 油页岩添加对准东高钠煤灰熔融行为影响的研究[J]. 化工学报, 2023, 74(5): 2123-2135.

Lei HUANG, Lingxue KONG, Jin BAI, Huaizhu LI, Zhenxing GUO, Zongqing BAI, Ping LI, Wen LI. Effect of oil shale addition on ash fusion behavior of Zhundong high-sodium coal[J]. CIESC Journal, 2023, 74(5): 2123-2135.

| Coal | Proximate analysis/ %(mass, air dried) | Ultimate analysis/ % (mass, dry ash free) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| M | A | V | FC | St | C | H | N | O* | ||

| HSQ | 2.10 | 13.04 | 27.72 | 57.14 | 1.89 | 79.00 | 4.14 | 0.90 | 14.07 | |

| JEK | 1.12 | 6.70 | 29.25 | 62.93 | 0.56 | 73.33 | 4.05 | 0.82 | 21.24 | |

| OS | 1.78 | 71.92 | 18.55 | 7.75 | 0.68 | 57.11 | 6.92 | 0.49 | 34.79 | |

表1 红沙泉、将军庙二矿煤与油页岩的工业分析及元素分析

Table 1 Proximate and ultimate analyses of HSQ, JEK and OS

| Coal | Proximate analysis/ %(mass, air dried) | Ultimate analysis/ % (mass, dry ash free) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| M | A | V | FC | St | C | H | N | O* | ||

| HSQ | 2.10 | 13.04 | 27.72 | 57.14 | 1.89 | 79.00 | 4.14 | 0.90 | 14.07 | |

| JEK | 1.12 | 6.70 | 29.25 | 62.93 | 0.56 | 73.33 | 4.05 | 0.82 | 21.24 | |

| OS | 1.78 | 71.92 | 18.55 | 7.75 | 0.68 | 57.11 | 6.92 | 0.49 | 34.79 | |

| Coal | 含量/%(mass) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | TiO2 | SO3 | K2O | Na2O | P2O5 | |

| HSQ | 45.59 | 13.89 | 13.15 | 8.18 | 3.62 | 0.68 | 8.48 | 1.02 | 3.35 | 0.56 |

| JEK | 18.25 | 9.81 | 24.93 | 11.96 | 6.50 | 0.52 | 19.45 | 0.35 | 6.36 | 0.06 |

| OS | 63.32 | 28.12 | 2.25 | 2.05 | 0.31 | 1.22 | 0.40 | 0.22 | 0.40 | 0.09 |

表2 红沙泉、将军庙二矿煤和油页岩的灰化学组成

Table 2 Ash chemical compositions of HSQ, JEK and OS

| Coal | 含量/%(mass) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | TiO2 | SO3 | K2O | Na2O | P2O5 | |

| HSQ | 45.59 | 13.89 | 13.15 | 8.18 | 3.62 | 0.68 | 8.48 | 1.02 | 3.35 | 0.56 |

| JEK | 18.25 | 9.81 | 24.93 | 11.96 | 6.50 | 0.52 | 19.45 | 0.35 | 6.36 | 0.06 |

| OS | 63.32 | 28.12 | 2.25 | 2.05 | 0.31 | 1.22 | 0.40 | 0.22 | 0.40 | 0.09 |

| Element | 含量/(μg/g) | ||||

|---|---|---|---|---|---|

| Water-soluble | NH4Ac-soluble | HCl-soluble | Insoluble | ||

| HSQ | Na | 2645.00 | 1250.00 | 810.00 | 725.50 |

| Ca | 105.00 | 5027.50 | 1485.00 | 240.00 | |

| JEK | Na | 3797.50 | 2425.00 | 2122.50 | 880.00 |

| Ca | 52.50 | 6130.00 | 2857.50 | 310.00 | |

表3 红沙泉和将军庙二矿煤中Na与Ca的赋存形态

Table 3 Occurrence forms of Na and Ca in HSQ and JEK coals

| Element | 含量/(μg/g) | ||||

|---|---|---|---|---|---|

| Water-soluble | NH4Ac-soluble | HCl-soluble | Insoluble | ||

| HSQ | Na | 2645.00 | 1250.00 | 810.00 | 725.50 |

| Ca | 105.00 | 5027.50 | 1485.00 | 240.00 | |

| JEK | Na | 3797.50 | 2425.00 | 2122.50 | 880.00 |

| Ca | 52.50 | 6130.00 | 2857.50 | 310.00 | |

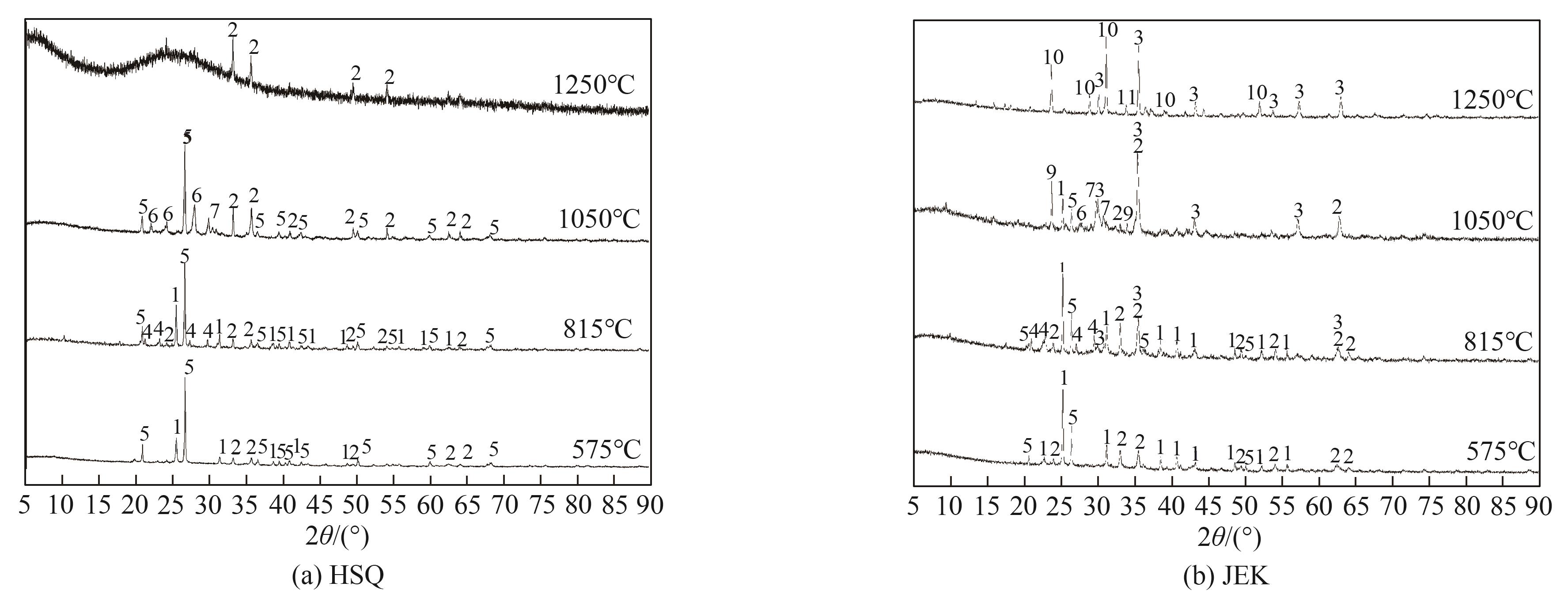

图3 不同温度下准东高钠煤灰的矿物质组成1—anhydrite (CaSO4); 2—hematite (Fe2O3); 3—magnetite (Fe3O4); 4—nepheline (NaAlSiO4); 5—quartz (SiO2); 6—feldspar (NaAlSi3O8, CaAl2Si2O8); 7—diopside (CaMgSi2O6); 8—sillimanite (Al2SiO5); 9—Na8Al6(SiO4)6SO4; 10—gehlenite (Ca2Al2SiO7); 11—rhodolite (Mg3Al2(SiO4)3)

Fig.3 Minerals of HSQ and JEK coal ashes under different temperatures

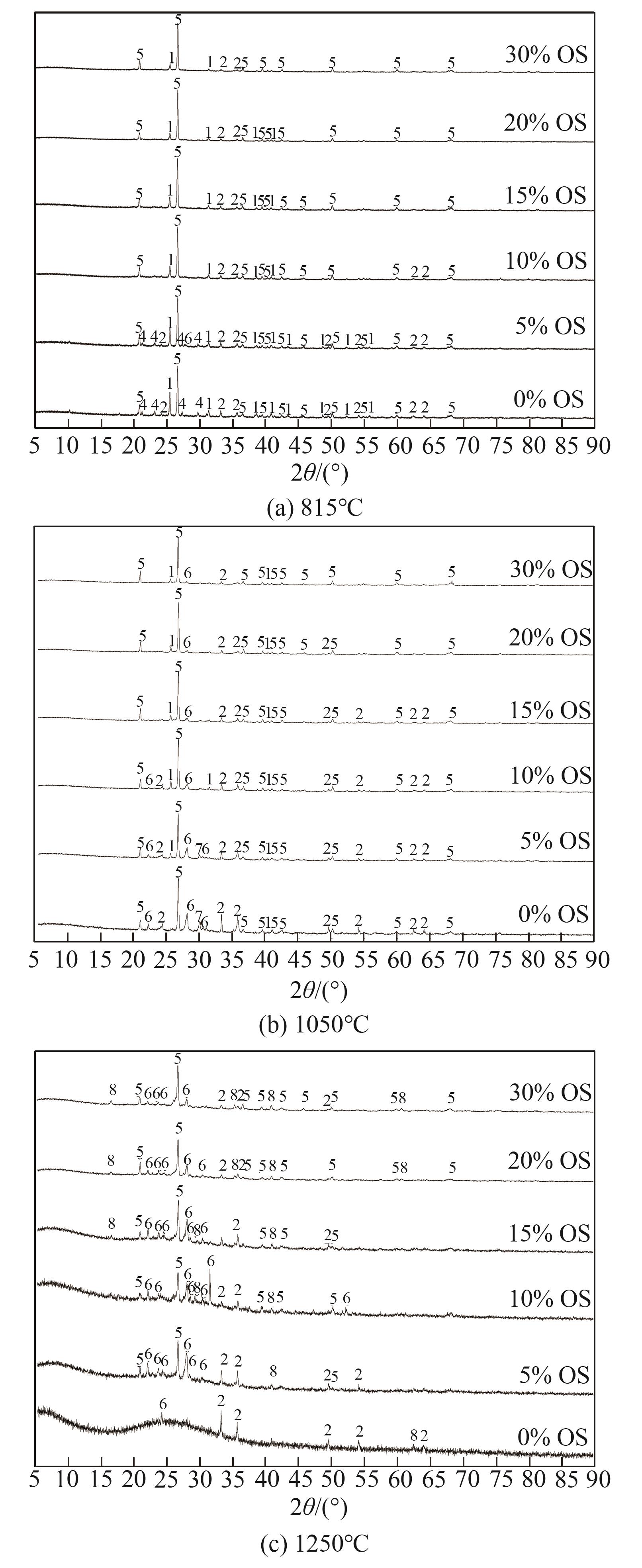

图6 添加不同比例油页岩时HSQ煤灰的XRD谱图1—anhydrite (CaSO4); 2—hematite (Fe2O3); 3—magnetite (Fe3O4); 4—nepheline (NaAlSiO4); 5—quartz (SiO2); 6—feldspar (NaAlSi3O8, CaAl2Si2O8); 7—diopside (CaMgSi2O6); 8—sillimanite (Al2SiO5)

Fig.6 XRD patterns of HSQ coal ash with different OS additions

图7 添加不同比例油页岩JEK煤灰的XRD谱图1—anhydrite (CaSO4); 2—hematite (Fe2O3); 3—magnetite (Fe3O4); 4—nepheline (NaAlSiO4); 5—quartz (SiO2); 6—feldspar (NaAlSi3O8, CaAl2Si2O8); 7—diopside (CaMgSi2O6); 8—sillimanite (Al2SiO5); 9—Na8Al6(SiO4)6SO4; 10—gehlenite (Ca2Al2SiO7); 11—rhodolite [Mg3Al2(SiO4)3]

Fig.7 XRD patterns of JEK coal ash with different OS additions

| No. | S+A | Fe2O3 | CaO | MgO | Na2O | K2O | SO3 | S/A | DT/℃ | FT/℃ |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 23.63 | 22.30 | 33.59 | 2.37 | 0.79 | 0.05 | 12.49 | 1.76 | 1272.00 | 1290.00 |

| 2 | 66.31 | 10.32 | 11.27 | 2.94 | 1.40 | 0.85 | 2.97 | 2.39 | 1243.00 | 1305.00 |

| 3 | 44.37 | 19.14 | 12.72 | 5.02 | 4.44 | 0.63 | 11.65 | 2.33 | 1162.00 | 1275.00 |

| 4 | 61.42 | 9.01 | 13.36 | 5.04 | 1.34 | 1.26 | 6.47 | 2.59 | 1204.00 | 1322.00 |

| 5 | 76.90 | 5.35 | 2.70 | 0.66 | 0.86 | 1.49 | 0.78 | 1.90 | 1500.00 | 1500.00 |

| 6 | 72.41 | 4.46 | 18.92 | 0.55 | 0.72 | 1.24 | 0.65 | 1.90 | 1335.00 | 1383.00 |

| 7 | 72.41 | 8.63 | 14.75 | 0.55 | 0.72 | 1.24 | 0.65 | 1.90 | 1332.00 | 1369.00 |

| 8 | 72.41 | 12.79 | 10.58 | 0.55 | 0.72 | 1.24 | 0.65 | 1.90 | 1298.00 | 1331.00 |

| 9 | 72.41 | 16.96 | 6.42 | 0.55 | 0.72 | 1.24 | 0.65 | 1.90 | 1317.00 | 1359.00 |

| 10 | 72.41 | 21.23 | 2.25 | 0.55 | 0.72 | 1.24 | 0.65 | 1.90 | 1381.00 | 1425.00 |

| 11 | 75.16 | 10.28 | 11.03 | 0.27 | 0.17 | 0.35 | 0.36 | 1.20 | 1408.00 | 1430.00 |

| 12 | 75.16 | 18.62 | 2.69 | 0.27 | 0.17 | 0.35 | 0.36 | 1.20 | 1510.00 | 1540.00 |

| 13 | 75.16 | 1.95 | 19.36 | 0.27 | 0.17 | 0.35 | 0.36 | 1.20 | 1474.00 | 1493.00 |

| 14 | 90.19 | 2.34 | 3.23 | 0.23 | 0.20 | 0.42 | 0.43 | 1.20 | 1510.00 | 1540.00 |

| 15 | 75.16 | 18.62 | 2.69 | 0.27 | 0.17 | 0.35 | 0.36 | 1.20 | 1483.00 | 1515.00 |

| 16 | 75.16 | 14.45 | 6.86 | 0.27 | 0.17 | 0.35 | 0.36 | 1.20 | 1463.00 | 1487.00 |

| 17 | 75.16 | 10.28 | 11.03 | 0.27 | 0.17 | 0.35 | 0.36 | 1.20 | 1408.00 | 1430.00 |

| 18 | 75.16 | 6.12 | 15.19 | 0.27 | 0.17 | 0.35 | 0.36 | 1.20 | 1405.00 | 1427.00 |

| 19 | 75.16 | 1.95 | 19.36 | 0.27 | 0.17 | 0.35 | 0.36 | 1.20 | 1438.00 | 1456.00 |

| 20 | 75.16 | 1.95 | 19.36 | 0.27 | 0.17 | 0.35 | 0.36 | 1.20 | 1474.00 | 1493.00 |

| 21 | 23.63 | 22.30 | 33.59 | 2.37 | 0.79 | 0.05 | 12.49 | 1.76 | 1272.00 | 1290.00 |

表4 样本煤灰的化学组成

Table 4 Chemical compositions of coal ash samples

| No. | S+A | Fe2O3 | CaO | MgO | Na2O | K2O | SO3 | S/A | DT/℃ | FT/℃ |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 23.63 | 22.30 | 33.59 | 2.37 | 0.79 | 0.05 | 12.49 | 1.76 | 1272.00 | 1290.00 |

| 2 | 66.31 | 10.32 | 11.27 | 2.94 | 1.40 | 0.85 | 2.97 | 2.39 | 1243.00 | 1305.00 |

| 3 | 44.37 | 19.14 | 12.72 | 5.02 | 4.44 | 0.63 | 11.65 | 2.33 | 1162.00 | 1275.00 |

| 4 | 61.42 | 9.01 | 13.36 | 5.04 | 1.34 | 1.26 | 6.47 | 2.59 | 1204.00 | 1322.00 |

| 5 | 76.90 | 5.35 | 2.70 | 0.66 | 0.86 | 1.49 | 0.78 | 1.90 | 1500.00 | 1500.00 |

| 6 | 72.41 | 4.46 | 18.92 | 0.55 | 0.72 | 1.24 | 0.65 | 1.90 | 1335.00 | 1383.00 |

| 7 | 72.41 | 8.63 | 14.75 | 0.55 | 0.72 | 1.24 | 0.65 | 1.90 | 1332.00 | 1369.00 |

| 8 | 72.41 | 12.79 | 10.58 | 0.55 | 0.72 | 1.24 | 0.65 | 1.90 | 1298.00 | 1331.00 |

| 9 | 72.41 | 16.96 | 6.42 | 0.55 | 0.72 | 1.24 | 0.65 | 1.90 | 1317.00 | 1359.00 |

| 10 | 72.41 | 21.23 | 2.25 | 0.55 | 0.72 | 1.24 | 0.65 | 1.90 | 1381.00 | 1425.00 |

| 11 | 75.16 | 10.28 | 11.03 | 0.27 | 0.17 | 0.35 | 0.36 | 1.20 | 1408.00 | 1430.00 |

| 12 | 75.16 | 18.62 | 2.69 | 0.27 | 0.17 | 0.35 | 0.36 | 1.20 | 1510.00 | 1540.00 |

| 13 | 75.16 | 1.95 | 19.36 | 0.27 | 0.17 | 0.35 | 0.36 | 1.20 | 1474.00 | 1493.00 |

| 14 | 90.19 | 2.34 | 3.23 | 0.23 | 0.20 | 0.42 | 0.43 | 1.20 | 1510.00 | 1540.00 |

| 15 | 75.16 | 18.62 | 2.69 | 0.27 | 0.17 | 0.35 | 0.36 | 1.20 | 1483.00 | 1515.00 |

| 16 | 75.16 | 14.45 | 6.86 | 0.27 | 0.17 | 0.35 | 0.36 | 1.20 | 1463.00 | 1487.00 |

| 17 | 75.16 | 10.28 | 11.03 | 0.27 | 0.17 | 0.35 | 0.36 | 1.20 | 1408.00 | 1430.00 |

| 18 | 75.16 | 6.12 | 15.19 | 0.27 | 0.17 | 0.35 | 0.36 | 1.20 | 1405.00 | 1427.00 |

| 19 | 75.16 | 1.95 | 19.36 | 0.27 | 0.17 | 0.35 | 0.36 | 1.20 | 1438.00 | 1456.00 |

| 20 | 75.16 | 1.95 | 19.36 | 0.27 | 0.17 | 0.35 | 0.36 | 1.20 | 1474.00 | 1493.00 |

| 21 | 23.63 | 22.30 | 33.59 | 2.37 | 0.79 | 0.05 | 12.49 | 1.76 | 1272.00 | 1290.00 |

| 1 | Li J, Zhuang X G, Querol X, et al. Environmental geochemistry of the feed coals and their combustion by-products from two coal-fired power plants in Xinjiang Province, Northwest China[J]. Fuel, 2012, 95: 446-456. |

| 2 | Li G Y, Wang C A, Yan Y, et al. Release and transformation of sodium during combustion of Zhundong coals[J]. Journal of the Energy Institute, 2016, 89(1): 48-56. |

| 3 | 段晓丽, 张彦迪, 朱晨钊, 等. 五彩湾煤在O2/CO2燃烧条件下的积灰特性[J]. 洁净煤技术, 2019, 25(2): 53-61. |

| Duan X L, Zhang Y D, Zhu C Z, et al. Ash deposition characteristics of Wucaiwan coal under the combustion condition of O2/CO2 [J]. Clean Coal Technology, 2019, 25(2): 53-61. | |

| 4 | Liu X, Yu G S, Xu J L, et al. Viscosity fluctuation behaviors of coal ash slags with high content of calcium and low content of silicon[J]. Fuel Processing Technology, 2017, 158: 115-122. |

| 5 | 郑忆南, 陆海峰, 郭晓镭, 等. 气流床煤气化细灰流动特性研究[J]. 高校化学工程学报, 2018, 32(1): 108-116. |

| Zheng Y N, Lu H F, Guo X L, et al. Study on flow properties of fine ash from entrained-flow coal gasification[J]. Journal of Chemical Engineering of Chinese Universities, 2018, 32(1): 108-116. | |

| 6 | Laxminarayan Y, Jensen P, Wu H, et al. Biomass fly ash deposition in an entrained flow reactor[J]. Proceedings of the Combustion Institute, 2019, 37(3): 2689-2696. |

| 7 | Yang X, Ingham D, Ma L, et al. Prediction of particle sticking efficiency for fly ash deposition at high temperatures[J]. Proceedings of the Combustion Institute, 2019, 37(3): 2995-3003. |

| 8 | 兰泽全, 曹欣玉, 刘建忠, 等. 灰污热流探针模拟锅炉受热面灰沉积的研究[J]. 燃料化学学报, 2008, 36(1): 30-35. |

| Lan Z Q, Cao X Y, Liu J Z, et al. Simulation of ash depositing in heat transfer surface with heat flux probe[J]. Journal of Fuel Chemistry and Technology, 2008, 36(1): 30-35. | |

| 9 | Huang L, Zhang X X, Kong L X, et al. Formation of fine particles (PM10) from Zhundong high-sodium coal at entrained flow gasification condition in a flat-flame burner reactor[J]. Fuel Processing Technology, 2022, 231: 107225. |

| 10 | Ruan R H, Tan H Z, Wang X B, et al. Characteristic of particulate matter from combustion of Zhundong lignite: a comparison between air and oxy-fuel atmospheres[J]. Energy & Fuels, 2019, 33: 12260-12269. |

| 11 | Kleinhans U, Wieland C, Frandsen F J, et al. Ash formation and deposition in coal and biomass fired combustion systems: progress and challenges in the field of ash particle sticking and rebound behavior[J]. Progress in Energy and Combustion Science, 2018, 68: 65-168. |

| 12 | 盛新, 纪明俊, 韩启元, 等. Shell煤气化飞灰粘附特性影响因素探讨[J]. 安徽理工大学学报(自然科学版), 2009, 29(2): 42-46. |

| Sheng X, Ji M J, Han Q Y, et al. Study on the factors influencing fly ash deposition in shell coal gasification process[J]. Journal of Anhui University of Science and Technology (Natural Science), 2009, 29(2): 42-46. | |

| 13 | Shi W J, Laabs M, Reinmöller M, et al. In-situ analysis of the effect of CaO/Fe2O3 addition on ash melting and sintering behavior for slagging-type applications[J]. Fuel, 2021, 285: 119090. |

| 14 | 杨鑫, 黄戒介, 房倚天, 等. 无烟煤流化床气化飞灰的结渣特性[J]. 燃料化学学报, 2013, 41(1): 1-8. |

| Yang X, Huang J J, Fang Y T, et al. Slagging characteristics of fly ash from anthracite gasification in fluidized bed[J]. Journal of Fuel Chemistry and Technology, 2013, 41(1): 1-8. | |

| 15 | Yang Y P, Lin X C, Chen X J, et al. The formation of deposits and their evolutionary characteristics during pressurized gasification of Zhundong coal char[J]. Fuel, 2018, 224: 469-480. |

| 16 | 曾宪鹏. 准东煤燃烧过程中灰的生成、沉积及控制机理研究[D]. 武汉: 华中科技大学, 2019. |

| Zeng X P. Study on formation, deposition and control mechanism of ash in Zhundong coal combustion process[D]. Wuhan: Huazhong University of Science and Technology, 2019. | |

| 17 | 周上坤, 王萌, 谭厚章, 等. 蛭石对高钠高钙准东煤结渣特性影响研究[J]. 燃料化学学报, 2019, 47(4): 419-427. |

| Zhou S K, Wang M, Tan H Z, et al. Effect of vermiculite on the slagging characteristics of high sodium and high calcium Zhundong coal[J]. Journal of Fuel Chemistry and Technology, 2019, 47(4): 419-427. | |

| 18 | Xu L L, Liu J, Kang Y, et al. Safely burning high alkali coal with Kaolin additive in a pulverized fuel boiler[J]. Energy & Fuels, 2014, 28(9): 5640-5648. |

| 19 | 曾宪鹏, 于敦喜, 徐静颖, 等. 添加高岭土对准东煤燃烧PM1生成影响的研究[J]. 工程热物理学报, 2015, 36(11): 2522-2526. |

| Zeng X P, Yu D X, Xu J Y, et al. Study on the effect of kaolin addition on the PM1 formation during a Zhundong coal combustion[J]. Journal of Engineering Thermophysics, 2015, 36(11): 2522-2526. | |

| 20 | Niu Y Q, Gong Y H, Zhang X, et al. Effects of leaching and additives on the ash fusion characteristics of high-Na/Ca Zhundong coal[J]. Journal of the Energy Institute, 2019, 92(4): 1115-1122. |

| 21 | Binner E, Jiao F C, Chen L G, et al. Effect of coal drying on the behavior of inorganic species during Victorian brown coal pyrolysis and combustion[J]. Energy & Fuels, 2011, 25: 2764-2771. |

| 22 | Zhou S K, Wang M, Tan H Z, et al. Evaluation of aluminum ash in alleviating the ash deposition of high-sodium and high-iron coal[J]. Fuel, 2020, 273: 117701. |

| 23 | 魏博, 谭厚章, 王学斌, 等. 煤燃烧过程中复杂气氛下的灰熔融特性[J]. 燃烧科学与技术, 2017, 23(4): 320-324. |

| Wei B, Tan H Z, Wang X B, et al. Ash fusion characteristics under complex atmosphere in coal combustion process[J]. Journal of Combustion Science and Technology, 2017, 23(4): 320-324. | |

| 24 | Li D F, Deng Q K, Lee D, et al. Prediction of attrition rate of coal ash for fluidized bed based on chemical composition with an artificial neural network model[J]. Fuel Processing Technology, 2022, 225: 107024. |

| 25 | 邱钱粮, 白向飞. 基于遗传算法优化的BP神经网络气化用煤灰流动温度预测模型[J]. 煤炭转化, 2023, 46(2): 109-118. |

| Qiu Q L, Bai X F. Prediction model of fusion temperature of coal ash for gasification based on GA-BP neural network[J]. Coal Conversion, 2023, 46(2): 109-118. | |

| 26 | Yan T G, Kong L X, Bai J, et al. Thermomechanical analysis of coal ash fusion behavior[J]. Chemical Engineering Science, 2016, 147(22): 74-82. |

| 27 | Shi W J, Bai J, Kong L X, et al. Effect of CaO/Fe2O3 ratio on fusibility of coal ashes with high silica and alumina levels and prediction[J]. Fuel, 2020, 260:116369. |

| 28 | Mclennan A R, Bryant G W, Bailey C W, et al. An experimental comparison of the ash formed from coals containing pyrite and siderite mineral in oxidizing and reducing conditions[J]. Energy & Fuels, 2000, 14(2): 308-315. |

| 29 | Fan H L, Li F H. Ash fusion temperature regulation mechanism of Xiangyang coal by coal blending[J]. Journal of Thermal Analysis and Calorimetry, 2020, 139(3): 2055-2066. |

| 30 | Qi X B, Song G L, Song W J, et al. Effect of bed materials on slagging and fouling during Zhundong coal gasification[J]. Energy Exploration & Exploitation, 2017, 35(5): 558-578. |

| 31 | Yuan Z S, Wang J, Kong L X, et al. Comparison study of fusibility between coal ash and synthetic ash[J]. Fuel Processing Technology, 2021, 211:106593. |

| 32 | Zhao B T, Zhang Z X, Wu X J. Prediction of coal ash fusion temperature by least-squares support vector machine model[J]. Energy & Fuels, 2010, 24: 3066-3071. |

| 33 | Tripathi H S, Mukherjee B, Das S K, et al. Effect of sillimanite beach sand composition on mullitization and properties of Al2O3-SiO2 system[J]. Bulletin of Materials Science, 2003, 26(2): 217-220. |

| 34 | 李珍, 许东明, 阳雅丽, 等. 硅线石及其尾矿利用研究[J]. 中国陶瓷, 2016, 52(5): 1-5. |

| Li Z, Xu D M, Yang Y L, et al. Research on sillimanite and applications of its tailings[J]. China Ceramics, 2016, 52(5): 1-5. | |

| 35 | 曹希. 高温下水蒸气对煤灰流动性的影响规律及机理研究[D]. 北京:中国科学院大学,2020. |

| Cao X. Study on the influence law and mechanism of steam on the fluidity of coal ash at high temperature[D]. Beijing: University of Chinese Academy of Sciences, 2020. | |

| 36 | 石文举, 白进, 孔令学, 等. 不同气氛下Ca-Fe二元助剂改变高硅铝煤灰熔融温度的规律和机制[J]. 化工学报, 2022, 73(10): 4638-4647. |

| Shi W J, Bai J, Kong L X, et al. Law and mechanism of Ca-Fe binary additives changing the melting temperature of high silicon aluminum coal ash in different atmospheres [J]. CIESC Journal, 2022, 73(10): 4638-4647. |

| [1] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [2] | 温凯杰, 郭力, 夏诏杰, 陈建华. 一种耦合CFD与深度学习的气固快速模拟方法[J]. 化工学报, 2023, 74(9): 3775-3785. |

| [3] | 尹刚, 李伊惠, 何飞, 曹文琦, 王民, 颜非亚, 向禹, 卢剑, 罗斌, 卢润廷. 基于KPCA和SVM的铝电解槽漏槽事故预警方法[J]. 化工学报, 2023, 74(8): 3419-3428. |

| [4] | 诸程瑛, 王振雷. 基于改进深度强化学习的乙烯裂解炉操作优化[J]. 化工学报, 2023, 74(8): 3429-3437. |

| [5] | 闫琳琦, 王振雷. 基于STA-BiLSTM-LightGBM组合模型的多步预测软测量建模[J]. 化工学报, 2023, 74(8): 3407-3418. |

| [6] | 徐野, 黄文君, 米俊芃, 申川川, 金建祥. 多源信息融合的离心式压缩机喘振诊断方法[J]. 化工学报, 2023, 74(7): 2979-2987. |

| [7] | 高学金, 姚玉卓, 韩华云, 齐咏生. 基于注意力动态卷积自编码器的发酵过程故障监测[J]. 化工学报, 2023, 74(6): 2503-2521. |

| [8] | 贠程, 王倩琳, 陈锋, 张鑫, 窦站, 颜廷俊. 基于社团结构的化工过程风险演化路径深度挖掘[J]. 化工学报, 2023, 74(4): 1639-1650. |

| [9] | 张江淮, 赵众. 碳三加氢装置鲁棒最小协方差约束控制及应用[J]. 化工学报, 2023, 74(3): 1216-1227. |

| [10] | 吴心远, 刘奇磊, 曹博渊, 张磊, 都健. Group2vec:基于无监督机器学习的基团向量表示及其物性预测应用[J]. 化工学报, 2023, 74(3): 1187-1194. |

| [11] | 吴选军, 王超, 曹子健, 蔡卫权. 数据与物理信息混合驱动的固定床吸附穿透深度学习模型[J]. 化工学报, 2023, 74(3): 1145-1160. |

| [12] | 王雅琳, 潘雨晴, 刘晨亮. 基于GSA-LSTM动态结构特征提取的间歇过程监测方法[J]. 化工学报, 2022, 73(9): 3994-4002. |

| [13] | 高学金, 程琨, 韩华云, 高慧慧, 齐咏生. 基于中心损失的条件生成式对抗网络的冷水机组故障诊断[J]. 化工学报, 2022, 73(9): 3950-3962. |

| [14] | 孙哲, 金华强, 李康, 顾江萍, 黄跃进, 沈希. 基于知识数据化表达的制冷空调系统故障诊断方法[J]. 化工学报, 2022, 73(7): 3131-3144. |

| [15] | 周乐, 沈程凯, 吴超, 侯北平, 宋执环. 深度融合特征提取网络及其在化工过程软测量中的应用[J]. 化工学报, 2022, 73(7): 3156-3165. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号