化工学报 ›› 2023, Vol. 74 ›› Issue (7): 3010-3017.DOI: 10.11949/0438-1157.20230492

收稿日期:2023-05-18

修回日期:2023-06-23

出版日期:2023-07-05

发布日期:2023-08-31

通讯作者:

翁志焕

作者简介:赵婧(1998—),女,硕士研究生,1464432197@qq.com

基金资助:

Jing ZHAO( ), Chengwen GU, Xigao JIAN, Zhihuan WENG(

), Chengwen GU, Xigao JIAN, Zhihuan WENG( )

)

Received:2023-05-18

Revised:2023-06-23

Online:2023-07-05

Published:2023-08-31

Contact:

Zhihuan WENG

摘要:

以环氧氯丙烷和生物基化合物厚朴酚为原料,通过一步反应制得厚朴酚环氧树脂(DGEM),以聚醚胺D230为固化剂制备含云母粉的防腐涂层。采用红外光谱仪、耐磨试验仪、热失重分析仪、差示扫描量热仪、电化学工作站、铅笔硬度、冲击试验器等对涂层进行分析表征和性能测试,研究了云母粉填料用量对涂层的耐腐蚀等相关性能的影响。结果表明:相比于纯DGEM-D230涂层,添加3%(质量)云母粉填料的涂层DGEM-D230-3%表现出更好的力学性能和耐腐蚀性能,其铅笔硬度为4H,冲击强度为30 cm,低频阻抗模值达到8.47×108 Ω∙cm2,氮气氛围下800℃时的残炭率为37.1%,柔韧性达到0.5 mm,附着力达到0级。

中图分类号:

赵婧, 顾程文, 蹇锡高, 翁志焕. 厚朴酚基环氧树脂防腐涂层的制备及性能评价[J]. 化工学报, 2023, 74(7): 3010-3017.

Jing ZHAO, Chengwen GU, Xigao JIAN, Zhihuan WENG. Preparation and performance evaluation of magnolol-based epoxy resin anti-corrosion coatings[J]. CIESC Journal, 2023, 74(7): 3010-3017.

图3 不同组分DGEM-D230涂层在3.5% (质量) NaCl溶液中浸泡1、7、15、30 d时的Nyquist曲线

Fig.3 Nyquist plots of different composite DGEM-D230 coatings immersed in 3.5% (mass) NaCl solution for 1, 7, 15, 30 d

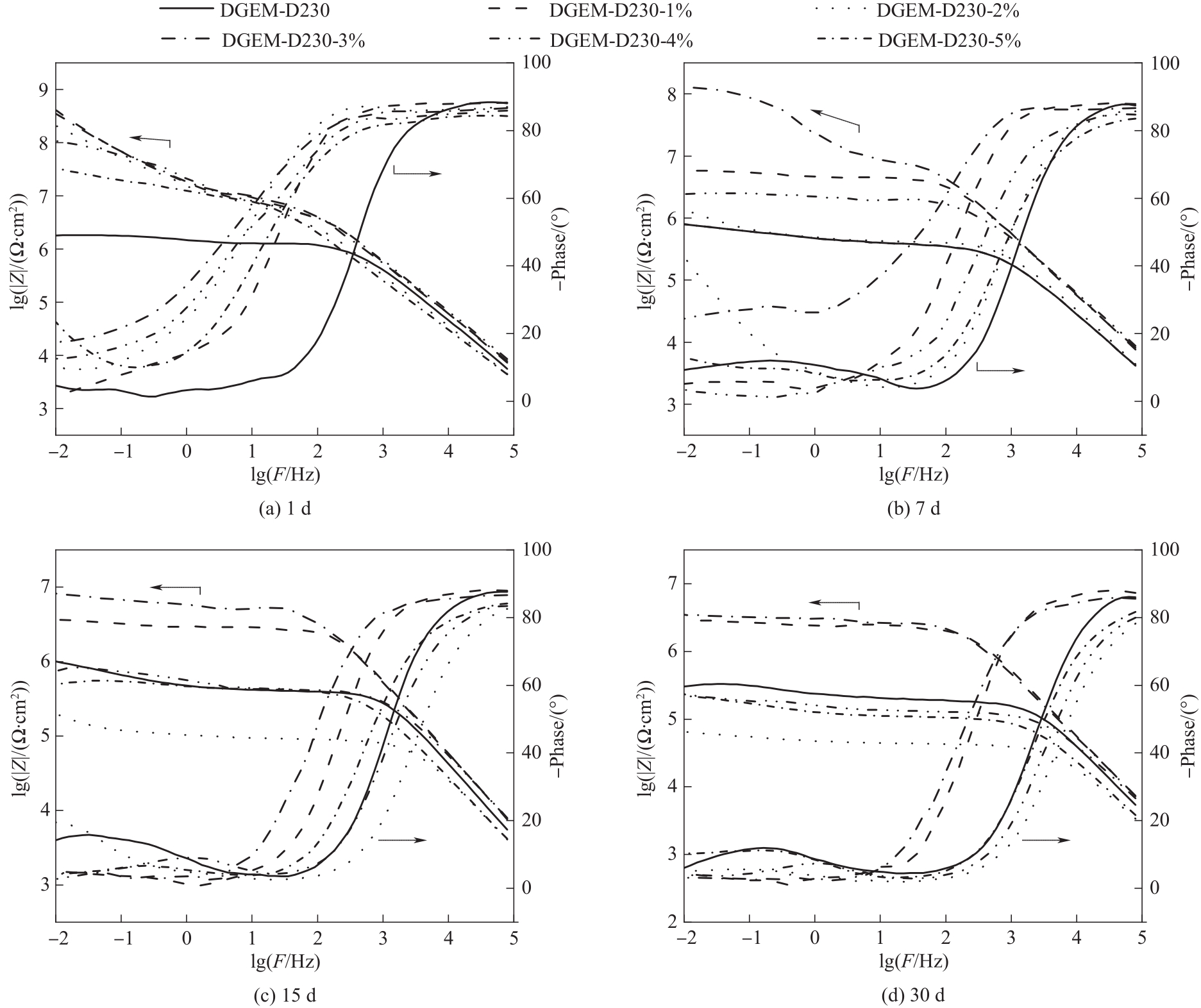

图4 不同组分DGEM-D230涂层在3.5% (质量) NaCl溶液中浸泡1, 7, 15, 30 d时的Bode曲线

Fig.4 Bode plots of different composite DGEM-D230 coatings immersed in 3.5% (mass) NaCl solution for 1, 7, 15, 30 d

| 1 | Matthiesen J E, Carraher J M, Vasiliu M, et al. Electrochemical conversion of muconic acid to biobased diacid monomers[J]. ACS Sustainable Chemistry & Engineering, 2016, 4(6): 3575-3585. |

| 2 | Wang W L, Xue L W, Zhang T S, et al. The influence of MgO/ZrO2/Al2O3 refractories on the refining process of Ti-containing steel based on kinetic study[J]. Ceramics International, 2020, 46(11): 17561-17568. |

| 3 | Chen B, Wu Q, Li J, et al. A novel and green method to synthesize a epoxidized biomass eucommia gum as the nanofiller in the epoxy composite coating with excellent anticorrosive performance[J]. Chemical Engineering Journal, 2020, 379: 122323. |

| 4 | Nabipour H, Wang X, Song L, et al. Facile synthesis of a novel zinc-triazole complex for simultaneous improvement in fire safety and mechanical properties of epoxy resins[J]. Composites Part A: Applied Science and Manufacturing, 2021, 143: 106284. |

| 5 | Waśkiewicz S, Zenkner K, Langer E W, et al. Organic coatings based on new Schiff base epoxy resins[J]. Progress in Organic Coatings, 2013, 76(7/8): 1040-1045. |

| 6 | Wan J T, Zhao J Q, Gan B, et al. Ultrastiff biobased epoxy resin with high Tg and low permittivity: from synthesis to properties[J]. ACS Sustainable Chemistry & Engineering, 2016, 4(5): 2869-2880. |

| 7 | Xin J N, Li M, Li R, et al. Green epoxy resin system based on lignin and tung oil and its application in epoxy asphalt[J]. ACS Sustainable Chemistry & Engineering, 2016, 4(5): 2754-2761. |

| 8 | Dai J Y, Teng N, Shen X B, et al. Synthesis of biobased benzoxazines suitable for vacuum-assisted resin transfer molding process via introduction of soft silicon segment[J]. Industrial & Engineering Chemistry Research, 2018, 57(8): 3091-3102. |

| 9 | Wang X, Leng W Q, Oshani Nayanathara R M, et al. Anticorrosive epoxy coatings from direct epoxidation of bioethanol fractionated lignin[J]. International Journal of Biological Macromolecules, 2022, 221: 268-277. |

| 10 | Li M L, Hao X H, Hu M L, et al. Synthesis of vanillin-based flame retardant epoxy coating on wood surface[J]. Progress in Organic Coatings, 2022, 172: 107161. |

| 11 | Zheng S L, Bellido-Aguilar D A, Hu J, et al. Waterborne bio-based epoxy coatings for the corrosion protection of metallic substrates[J]. Progress in Organic Coatings, 2019, 136: 105265. |

| 12 | Wang X, Nabipour H, Kan Y C, et al. A fully bio-based, anti-flammable and non-toxic epoxy thermosetting network for flame-retardant coating applications[J]. Progress in Organic Coatings, 2022, 172: 107095. |

| 13 | Huang J, Zhang J S, Zhu G Q, et al. Self-healing, high-performance, and high-biobased-content UV-curable coatings derived from rubber seed oil and itaconic acid[J]. Progress in Organic Coatings, 2021, 159: 106391. |

| 14 | Jiang H, Sun L, Zhang Y R, et al. Novel biobased epoxy resin thermosets derived from eugenol and vanillin[J]. Polymer Degradation and Stability, 2019, 160: 45-52. |

| 15 | Zhang Y T, Pang H, Wei D D, et al. Preparation and characterization of chemical grouting derived from lignin epoxy resin[J]. European Polymer Journal, 2019, 118: 290-305. |

| 16 | Ammar S, Iling A W M, Ramesh K, et al. Development of fully organic coating system modified with epoxidized soybean oil with superior corrosion protection performance[J]. Progress in Organic Coatings, 2020, 140: 105523. |

| 17 | 何吉喆, 刘明言, 徐杨书函. 环氧豆油树脂涂层的防腐性能研究[J]. 化工学报, 2021, 72(2): 1067-1077. |

| He J Z, Liu M Y, Xu Y S H. Study on anticorrosive properties of epoxy soybean oil resin coating[J]. CIESC Journal, 2021, 72(2): 1067-1077. | |

| 18 | 赵晓磊, 侯桂香, 于守武. 植物酚型生物基环氧树脂研究进展[J]. 高分子材料科学与工程, 2022, 38(9): 167-175. |

| Zhao X L, Hou G X, Yu S W. Progress on research of plant phenolic bio-based epoxy resin[J]. Polymer Materials Science & Engineering, 2022, 38(9): 167-175. | |

| 19 | 翁志焕, 李佳惠, 戚裕, 等. 生物基环氧树脂高性能化和功能化的研究进展[J]. 中国材料进展, 2019, 38(10): 999-1008, 1016. |

| Weng Z H, Li J H, Qi Y, et al. Progress on high performance and functionalization of bio-based epoxy resins[J]. Materials China, 2019, 38(10): 999-1008, 1016. | |

| 20 | 宋乐群, 戚裕, 曹旗, 等. 高性能和厚朴酚生物基环氧树脂的性能调控[J]. 高分子材料科学与工程, 2022, 38(2): 1-7, 16. |

| Song L Q, Qi Y, Cao Q, et al. Rational regulation of performance on high-performance bio-based epoxy resin bearing honokiol moiety[J]. Polymer Materials Science & Engineering, 2022, 38(2): 1-7, 16. | |

| 21 | 戚裕. 耐高温本征阻燃高性能生物基环氧树脂的制备及性能研究[D]. 大连: 大连理工大学, 2021. |

| Qi Y. Preparation and properties of high-temperature resistant intrinsic flame retardant high-performance bio-based epoxy resin[D]. Dalian: Dalian University of Technology, 2021. | |

| 22 | Qi Y, Weng Z H, Zhang K W, et al. Magnolol-based bio-epoxy resin with acceptable glass transition temperature, processability and flame retardancy[J]. Chemical Engineering Journal, 2020, 387: 124115. |

| 23 | Xu M Z, Lei Y X, Ren D X, et al. Thermal stability of allyl-functional phthalonitriles-containing benzoxazine/bismaleimide copolymers and their improved mechanical properties[J]. Polymers, 2018, 10(6): 596. |

| 24 | 刘立立. 颜填料的特性及其对隔热涂料性能的影响[D]. 武汉: 武汉科技大学, 2015. |

| Liu L L. Characteristics of fillers and its effect on the properties of thermal insulation coatings[D]. Wuhan: Wuhan University of Science and Technology, 2015. | |

| 25 | da Silva L R R, Carvalho B A, Pereira R C S, et al. Bio-based one-component epoxy resin: novel high-performance anticorrosive coating from agro-industrial byproduct[J]. Progress in Organic Coatings, 2022, 167: 106861. |

| 26 | Zhang Y Y, Chu L Y, Dai Z S, et al. Synergistically enhancing the performance of cardanol-rich epoxy anticorrosive coatings using cardanol-based reactive diluent and its functionalized graphene oxide[J]. Progress in Organic Coatings, 2022, 171: 107060. |

| 27 | Margarit-Mattos I C P. EIS and organic coatings performance: revisiting some key points[J]. Electrochimica Acta, 2020, 354: 136725. |

| 28 | Xing C, Wang W, Qu S, et al. Degradation of zinc-rich epoxy coating in 3.5% NaCl solution and evolution of its EIS parameters[J]. Journal of Coatings Technology and Research, 2021, 18(3): 843-860. |

| 29 | 陈绪蕾, 彭强, 邓志强, 等. 氟化石墨烯硅烷功能化对环氧复合涂层耐腐蚀性的影响[J]. 涂料工业, 2022, 52(12): 1-8. |

| Chen X L, Peng Q, Deng Z Q, et al. Effect of fluorinated graphene silane functionalization on the corrosion resistance of epoxy composite coatings[J]. Paint & Coatings Industry, 2022, 52(12): 1-8. | |

| 30 | 莫梦婷. 聚氨酯/石墨烯复合涂层的制备及其防腐耐磨性能[D]. 北京: 中国科学院大学, 2016. |

| Mo M T. Preparation of polyurethane/graphene composite coating and its corrosion and wear resistance[D]. Beijing: University of Chinese Academy of Sciences, 2016. | |

| 31 | 刘雷, 徐萍. 跑合试验对螺杆变幅机构的必要性的实例分析[J]. 内燃机与配件, 2021(12): 57-58. |

| Liu L, Xu P. Example analysis of the necessity of running-in test for screw luffing mechanism[J]. Internal Combustion Engine & Parts, 2021(12): 57-58. | |

| 32 | 姜秀杰, 冷晓飞, 白杨, 等. 高耐划伤性航空耐磨涂料的研制[J]. 涂料工业, 2021, 51(6): 69-74. |

| Jiang X J, Leng X F, Bai Y, et al. Development of highly scratch resistant aviation wear-resistant coatings[J]. Paint & Coatings Industry, 2021, 51(6): 69-74. | |

| 33 | 李鹏. 基于衣康酸和大豆油的环保型光固化涂料的研究[D]. 太原: 中北大学, 2016. |

| Li P. Environment friendly UV-cured coatings based on itaconic acid and soybean oil[D]. Taiyuan: North University of China, 2016. | |

| 34 | 冯江波. 基于PANI/SiO2环氧防防腐涂层的制备及性能的研究[D]. 西安: 陕西科技大学, 2021. |

| Feng J B. Research on preparation and performance of epoxy anticorrosive coating based on PANI/SiO2 [D]. Xi'an: Shaanxi University of Science & Technology, 2021. |

| [1] | 王帅, 杨富凯, 徐新宇. 阻燃型全生物基多元醇聚氨酯泡沫的制备及性能研究[J]. 化工学报, 2023, 74(3): 1399-1408. |

| [2] | 郑杰元, 张先伟, 万金涛, 范宏. 丁香酚环氧有机硅树脂的制备及其固化动力学研究[J]. 化工学报, 2023, 74(2): 924-932. |

| [3] | 王哲, 祖愿, 胡方圆, 蹇锡高. 含杂萘联苯结构的环氧树脂固化动力学分析[J]. 化工学报, 2022, 73(2): 681-688. |

| [4] | 韩维辰, 王佳铭, 贺曼罗, 贺高红, 焉晓明, 阮雪华. 潜伏型环氧固化剂甲基异丁基酮二亚胺的合成及工艺优化[J]. 化工学报, 2021, 72(7): 3832-3838. |

| [5] | 金晶, 安秋凤, 杨博文, 史书源, 田华鹏. 环氧基POSS改性环氧树脂的研制与性能研究[J]. 化工学报, 2020, 71(5): 2432-2439. |

| [6] | 徐彦芹, 杨锡智, 罗若诗, 黄玉红, 霍锋, 王丹. 合成生物学在生物基塑料制造中的应用[J]. 化工学报, 2020, 71(10): 4520-4531. |

| [7] | 于守武, 肖淑娟, 赵泽文, 霍晓文, 魏俊富. 蜜胺-环氧树脂双层包覆聚磷酸铵及其阻燃PP的研究[J]. 化工学报, 2019, 70(6): 2370-2376. |

| [8] | 张继宗, 常厚春, 常建民, 龙金星, 李雪辉. 生物油对生物油基淀粉胶黏剂性能的影响[J]. 化工学报, 2018, 69(S1): 123-128. |

| [9] | 倪卓, 林煜豪, 黄苇颖, 林丽蓉. 环氧树脂微胶囊合成及其反应动力学[J]. 化工学报, 2018, 69(4): 1790-1798. |

| [10] | 张继宗, 常厚春, 常建民, 龙金星, 李雪辉. 生物油淀粉胶黏剂固化特性研究[J]. 化工学报, 2018, 69(12): 5309-5315. |

| [11] | 陈杨, 史铁钧, 钱莹, 何涛. 新型含硼苯并噁嗪的合成及其与环氧树脂共混热性能[J]. 化工学报, 2017, 68(6): 2604-2610. |

| [12] | 杜朋亚, 边锋, 姚蒙蒙, 常达, 唐二军. 高阻尼性涂层用环氧-丙烯酸酯复合乳液的合成[J]. 化工学报, 2016, 67(10): 4508-4513. |

| [13] | 俞坚, Pradeep Munasinghe, 康世民. 基于二氧化碳、水、太阳能的绿色化工精炼[J]. 化工学报, 2015, 66(8): 3225-3232. |

| [14] | 王权, 史铁钧, 张焱, 虞伕, 刘建华. 聚双胍/环氧树脂体系潜伏性固化过程[J]. 化工学报, 2015, 66(1): 464-470. |

| [15] | 王权, 史铁钧, 虞伕, 刘建华, 周讯. 新型潜伏性固化剂的合成及性能[J]. 化工学报, 2014, 65(9): 0-0. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号