化工学报 ›› 2024, Vol. 75 ›› Issue (2): 626-636.DOI: 10.11949/0438-1157.20231190

李浩文1( ), 兰昊1,3(

), 兰昊1,3( ), 郑幼丹1, 孙勇辉3, 杨子昕2, 宋谦石2, 汪小憨2(

), 郑幼丹1, 孙勇辉3, 杨子昕2, 宋谦石2, 汪小憨2( )

)

收稿日期:2023-11-17

修回日期:2024-01-29

出版日期:2024-02-25

发布日期:2024-04-10

通讯作者:

兰昊,汪小憨

作者简介:李浩文(1996—),男,博士,特别研究助理,hwli@gia.cas.cn

基金资助:

Haowen LI1( ), Hao LAN1,3(

), Hao LAN1,3( ), Youdan ZHENG1, Yonghui SUN3, Zixin YANG2, Qianshi SONG2, Xiaohan WANG2(

), Youdan ZHENG1, Yonghui SUN3, Zixin YANG2, Qianshi SONG2, Xiaohan WANG2( )

)

Received:2023-11-17

Revised:2024-01-29

Online:2024-02-25

Published:2024-04-10

Contact:

Hao LAN, Xiaohan WANG

摘要:

燃料分子结构是影响主动冷却通道内热解结焦过程的重要因素。在预氧化的STS304(Φ3.0 mm×0.5 mm×1.0 m)流动反应管内,600~800℃、1.0 MPa下对比了正庚烷(nC7H16)、异庚烷(iC7H16)、甲基环己烷(MCH)、正十二烷(nC12H26)、甲苯(A1CH3)的热解结焦行为。实验定量获取了热解气液产物并计算了燃料反应热沉,通过称重法对比了非稳态结焦特性和沿程结焦分布规律。结果表明,较低温度650℃下链烷烃的转化率较高,环烷烃次之,A1CH3在高于775℃转化率骤增。低温下MCH和nC12H26结焦速率较低,高温下MCH和A1CH3的结焦速率显著提高。直链烷烃裂解双烯含量最高,稳定的环状结构均有利于提供高热沉。iC7H16比nC7H16更稳定且结焦趋向更弱,但甲基的存在,产物烷烃化程度增加。五种典型燃料的结焦过程均呈现三阶段非稳态生长规律,低温下链烷烃结焦速率较大,高温下MCH和A1CH3结焦贡献显著提高。

中图分类号:

李浩文, 兰昊, 郑幼丹, 孙勇辉, 杨子昕, 宋谦石, 汪小憨. 热通道内典型碳氢燃料的热解结焦行为[J]. 化工学报, 2024, 75(2): 626-636.

Haowen LI, Hao LAN, Youdan ZHENG, Yonghui SUN, Zixin YANG, Qianshi SONG, Xiaohan WANG. Pyrolysis and coking behavior of typical liquid hydrocarbon fuels in hot pipe[J]. CIESC Journal, 2024, 75(2): 626-636.

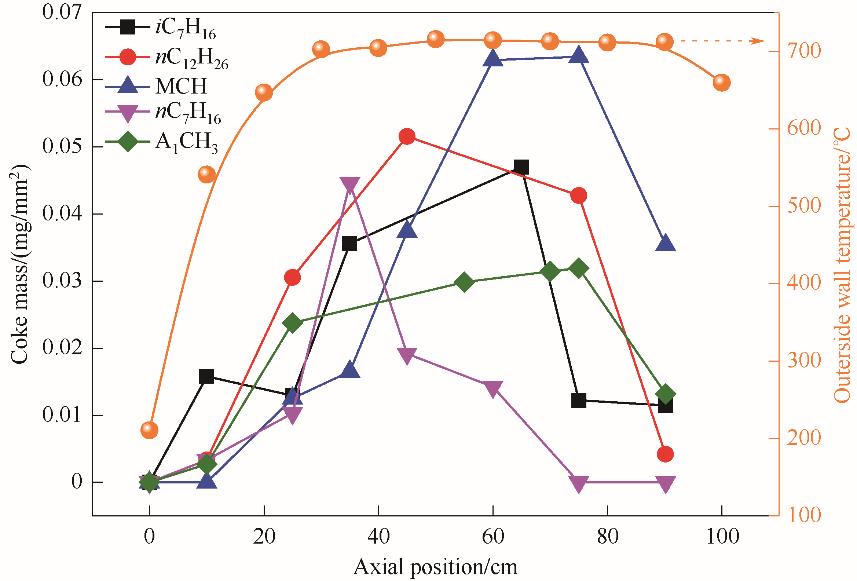

图10 不同燃料在700℃、40 min持续时间下沿程结焦分布规律对比及反应管外壁沿程温度分布

Fig.10 Comparison of coking spatial distribution of different fuels and temperature distribution along the reaction tube at 700℃, 40 min running time

| 1 | Li F Q, Li Z Z, Jing K, et al. Thermal cracking of endothermic hydrocarbon fuel in regenerative cooling channels with different geometric structures[J]. Energy & Fuels, 2018, 32(6): 6524-6534. |

| 2 | Fakhroleslam M, Sadrameli S M. Thermal/catalytic cracking of hydrocarbons for the production of olefins: a state-of-the-art review(Ⅲ): Process modeling and simulation[J]. Fuel, 2019, 252: 553-566. |

| 3 | 蒋鹏飞, 宿伟毅, 罗灵力,等. 裂解炉长周期运行中的问题及优化措施[J]. 乙烯工业, 2020, 32(3): 22-28. |

| Jiang P F, Su W Y, Luo L L, et al. Problems in long-term operation of cracking furnace and the optimization measures [J]. Ethylene Industry, 2020, 32(3): 22-28. | |

| 4 | Liu Z H, Bi Q C, Feng J T. Evaluation of heat sink capability and deposition propensity of supercritical endothermic fuels in a minichannel[J]. Fuel, 2015, 158: 388-398. |

| 5 | Sun D A, Du Y M, Zhang J W, et al. Effects of molecular structures on the pyrolysis and anti-coking performance of alkanes for thermal management[J]. Fuel, 2017, 194: 266-273. |

| 6 | Zhou H, Gao X K, Liu P H, et al. An experimental and simulated investigation on pyrolysis of blended cyclohexane and benzene under supercritical pressure[J]. Petroleum Chemistry, 2017, 57(1): 71-78. |

| 7 | Sun D A, Li C Y, Du Y M, et al. Effects of endothermic hydrocarbon fuel composition on the pyrolysis and anti-coking performance under supercritical conditions[J]. Fuel, 2019, 239: 659-666. |

| 8 | Liu Y J, Gong S Y, Wang H Y, et al. Pyrolysis of C8—C16 hydrocarbons with different molecular structures using high-pressure micro-reactor with GC-MS/FID[J]. Journal of Analytical and Applied Pyrolysis, 2020, 149: 104864. |

| 9 | 范学军, 俞刚. 大庆RP-3航空煤油热物性分析[J]. 推进技术, 2006, 27(2): 187-192. |

| Fan X J, Yu G. Analysis of thermophysical properties of Daqing RP-3 aviation kerosene [J]. Journal of Propulsion Technology, 2006, 27(2): 187-192. | |

| 10 | 梁嘉麟, 林海, 曾兴业. 石脑油烃组成与主要裂解产物收率的关系[J]. 石化技术, 2021, 28(12): 18-19. |

| Liang J L, Lin H, Zeng X Y. Relationship between the composition of naphtha hydrocarbon and the yield of main cracking products[J]. Petrochemical Industry Technology, 2021, 28(12): 18-19. | |

| 11 | Pitz W J, Cernansky N P, Dryer F L, et al. Development of an experimental database and chemical kinetic models for surrogate gasoline fuels[C]//SAE Technical Paper Series. Warrendale, PA, United States: SAE International, 2007: 195-216. |

| 12 | McIlroy A, McRae G, Sick V, et al. Basic research needs for clean and efficient combustion of 21st century transportation fuels[R]. DOESC (USDOE Office of Science (SC)), 2006. |

| 13 | Sarathy S M, Farooq A, Kalghatgi G T. Recent progress in gasoline surrogate fuels[J]. Progress in Energy and Combustion Science, 2018, 65: 67-108. |

| 14 | Ranzi E. A wide-range kinetic modeling study of oxidation and combustion of transportation fuels and surrogate mixtures[J]. Energy & Fuels, 2006, 20(3): 1024-1032. |

| 15 | Wang X H, Song Q S, Wu Y, et al. Modelling and numerical simulation of n-heptane pyrolysis coking characteristics in a millimetre-sized tube reactor[J]. Combustion and Flame, 2019, 201: 44-56. |

| 16 | Wu Y, Wang X H, Song Q S, et al. The effect of temperature and pressure on n-heptane thermal cracking in regenerative cooling channel[J]. Combustion and Flame, 2018, 194: 233-244. |

| 17 | Montgomery C, Cannon S, Mawid M, et al. Reduced chemical kinetic mechanisms for JP-8 combustion[C]//Proceedings of the 40th AIAA Aerospace Sciences Meeting & Exhibit. Reston, Virigina: AIAA, 2002: AIAA2002-336. |

| 18 | Wang Z D, Ye L L, Yuan W H, et al. Experimental and kinetic modeling study on methylcyclohexane pyrolysis and combustion[J]. Combustion and Flame, 2014, 161(1): 84-100. |

| 19 | Bissoonauth T, Wang Z D, Mohamed S Y, et al. Methylcyclohexane pyrolysis and oxidation in a jet-stirred reactor[J]. Proceedings of the Combustion Institute, 2019, 37(1): 409-417. |

| 20 | Liu Y X, Richter S, Naumann C, et al. Combustion study of a surrogate jet fuel[J]. Combustion and Flame, 2019, 202: 252-261. |

| 21 | 谢文杰. 碳氢燃料裂解与结焦研究[D]. 杭州: 浙江大学, 2009. |

| Xie W J. The pyrolysis and coking of hydrocarbon fuels[D]. Hangzhou: Zhejiang University, 2009. | |

| 22 | Hou X, Ma Z Z, Chen B C, et al. Role of normal/cyclo-alkane in hydrocarbons pyrolysis process and product distribution[J]. Journal of Analytical and Applied Pyrolysis, 2021, 156: 105130. |

| 23 | Králíková U, Bajus M, Baxa J. Pyrolysis of methylcyclohexane[J]. Collection of Czechoslovak Chemical Communications, 1987, 52(6): 1527-1544. |

| 24 | Zámostný P, Bělohlav Z, Starkbaumová L, et al. Experimental study of hydrocarbon structure effects on the composition of its pyrolysis products[J]. Journal of Analytical and Applied Pyrolysis, 2010, 87(2): 207-216. |

| 25 | Lee T H, Mun S, Kim S H, et al. Effect of the mixing ratio of methylcyclohexane and n-dodecane on the product composition and coke formation in the catalytic decomposition reaction of blended fuels[J]. Journal of Industrial and Engineering Chemistry, 2021, 98: 389-396. |

| 26 | Feng Y, Cao Y, Liu S Y, et al. The influence of coking on heat transfer in turbulent reacting flow of supercritical hydrocarbon fuels[J]. International Journal of Heat and Mass Transfer, 2019, 144: 118623. |

| 27 | Tian K, Yang P, Tang Z C, et al. Effect of pyrolytic reaction of supercritical aviation kerosene RP-3 on heat and mass transfer in the near-wall region[J]. Applied Thermal Engineering, 2021, 197: 117401. |

| 28 | Li X, Zhang Y X, Zhang S L, et al. Effects of pyrolysis on heat transfer enhancement for hydrocarbon fuel flow in unilateral heated channels with dimples[J]. Applied Thermal Engineering, 2023, 218: 119301. |

| 29 | Li X, Ma Z H, Lv E Y, et al. Experimental and kinetic study of hydrocarbon fuel pyrolysis in a shock tube[J]. Fuel, 2021, 304: 121521. |

| 30 | 吴勇. 正庚烷高温热解和结焦动力学及影响机制[D]. 北京: 中国科学院大学, 2018. |

| Wu Y. Pyrolysis and coking kinetics and the effects mechanism during the pyrolysis process of n-heptane [D]. Beijing: University of Chinese Academy of Sciences, 2018. | |

| 31 | Jiang R P, Liu G Z, He X Y, et al. Supercritical thermal decompositions of normal- and iso-dodecane in tubular reactor[J]. Journal of Analytical and Applied Pyrolysis, 2011, 92(2): 292-306. |

| 32 | Yu W L, Zhou W X, Jia Z J, et al. Characteristics of scramjet regenerative cooling with endothermic chemical reactions[J]. Acta Astronautica, 2022, 195: 1-11. |

| 33 | Li H W, Wu Y, Yang Z X, et al. Effect of molecular structure on pyrolysis coking performances of hydrocarbons at different temperatures[J]. Fuel, 2022, 326: 125095. |

| 34 | Dong G L, Hüttinger K J. Consideration of reaction mechanisms leading to pyrolytic carbon of different textures[J]. Carbon, 2002, 40(14): 2515-2528. |

| 35 | Wang Y, Raj A, Chung S H. A PAH growth mechanism and synergistic effect on PAH formation in counterflow diffusion flames[J]. Combustion and Flame, 2013, 160(9): 1667-1676. |

| 36 | Li H W, Wang X H, Song Q S, et al. Experimental investigation of n-heptane unsteady-state pyrolysis coking characteristics in microchannel[J]. Journal of Analytical and Applied Pyrolysis, 2022, 161: 105384. |

| [1] | 吴雷, 刘姣, 李长聪, 周军, 叶干, 刘田田, 朱瑞玉, 张秋利, 宋永辉. 低阶粉煤催化微波热解制备含碳纳米管的高附加值改性兰炭末[J]. 化工学报, 2023, 74(9): 3956-3967. |

| [2] | 杨峥豪, 何臻, 常玉龙, 靳紫恒, 江霞. 生物质快速热解下行式流化床反应器研究进展[J]. 化工学报, 2023, 74(6): 2249-2263. |

| [3] | 衣思敏, 马亚丽, 刘伟强, 张金帅, 岳岩, 郑强, 贾松岩, 李雪. 微晶菱镁矿蒸氨及水化动力学研究[J]. 化工学报, 2023, 74(4): 1578-1586. |

| [4] | 陈瑞哲, 程磊磊, 顾菁, 袁浩然, 陈勇. 纤维增强树脂复合材料化学回收技术研究进展[J]. 化工学报, 2023, 74(3): 981-994. |

| [5] | 张家庆, 蒋榕培, 史伟康, 武博翔, 杨超, 刘朝晖. 煤基/石油基火箭煤油高参数黏温特性与组分特性研究[J]. 化工学报, 2023, 74(2): 653-665. |

| [6] | 张娜, 潘鹤林, 牛波, 张亚运, 龙东辉. 酚醛树脂热裂解反应机理的密度泛函理论研究[J]. 化工学报, 2023, 74(2): 843-860. |

| [7] | 刘世君, 郑安庆, 陈晓丽, 付娟, 苏秋成. 纤维素增强环氧树脂复合材料热解特性研究[J]. 化工学报, 2023, 74(12): 4968-4978. |

| [8] | 钟声亮, 张军, 单锐, 孙勇. 废海绵衍生碳基固体酸催化热解木薯渣制备左旋葡萄糖酮[J]. 化工学报, 2023, 74(11): 4559-4569. |

| [9] | 何笑, 刘晶晶, 李文瑶, 刘永卓, 郭庆杰. 玉米秸秆化学链热解过程铁基复合载氧体的载氧-催化性能[J]. 化工学报, 2023, 74(10): 4153-4163. |

| [10] | 江丙友, 丁大伟, 苏明清, 鲁昆仑. 聚磷酸铵对聚乙烯粉尘爆炸特性及热解动力学影响研究[J]. 化工学报, 2023, 74(10): 4352-4366. |

| [11] | 张金鹏, 王强, 王艳美, 严舒, 吴建波, 张慧, 白红存. 镍基载氧体化学链燃烧过程中宁夏QH和YCW煤分子结构演化特征及对比分析[J]. 化工学报, 2023, 74(10): 4252-4266. |

| [12] | 陈睿哲, 刘永峰, 殷晨阳, 王龙, 张璐, 宋金瓯. 1-硝基丙烷引发正己烷热解的机理研究[J]. 化工学报, 2023, 74(10): 4319-4329. |

| [13] | 韩修远, 张守玉, 徐嘉庆, 陈旭阳, 张邢佳, 徐梓航, 胡南, 吴玉新. 水热过程中杉木屑组分的演变对木醋液的影响[J]. 化工学报, 2023, 74(10): 4311-4318. |

| [14] | 陈晨, 杨倩, 陈云, 张睿, 刘冬. 不同氧浓度下煤挥发分燃烧的化学动力学研究[J]. 化工学报, 2022, 73(9): 4133-4146. |

| [15] | 郝泽光, 张乾, 高增林, 张宏文, 彭泽宇, 杨凯, 梁丽彤, 黄伟. 生物质与催化裂化油浆共热解协同作用研究[J]. 化工学报, 2022, 73(9): 4070-4078. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号