化工学报 ›› 2025, Vol. 76 ›› Issue (5): 2070-2086.DOI: 10.11949/0438-1157.20241225

收稿日期:2024-10-31

修回日期:2024-12-24

出版日期:2025-05-25

发布日期:2025-06-13

通讯作者:

班宇杰,杨维慎

作者简介:张耀辉(1999—),男,博士研究生,zhangyaohui@dicp.ac.cn

基金资助:

Yaohui ZHANG1,2( ), Yujie BAN1,2(

), Yujie BAN1,2( ), Weishen YANG1,2(

), Weishen YANG1,2( )

)

Received:2024-10-31

Revised:2024-12-24

Online:2025-05-25

Published:2025-06-13

Contact:

Yujie BAN, Weishen YANG

摘要:

金属-有机框架(MOF)是由金属离子或金属离子簇与有机配体配位连接而成的一类高度有序的多孔材料。作为分离膜材料具有广泛的应用潜力。开发高效的MOF膜制备和修饰方法对获得连续、致密、结构可调控的MOF膜至关重要。相比传统液相合成过程,蒸气加工方法可大幅节省溶剂及前体用量,有效避免竞争性体相成核,降低后处理过程中因溶剂分子移除造成的膜层开裂风险,兼具效率高和环境友好的特点。系统总结了蒸气加工法用于MOF膜的直接合成与合成后修饰改性方面的研究进展以及蒸气加工方法对MOF膜分离性能的调控和强化作用,并展望了蒸气加工法未来的发展方向及其在MOF膜放大制备方面的应用潜力。

中图分类号:

张耀辉, 班宇杰, 杨维慎. 以蒸气加工法制备和修饰金属-有机框架膜[J]. 化工学报, 2025, 76(5): 2070-2086.

Yaohui ZHANG, Yujie BAN, Weishen YANG. Vapor-phase synthesis and post-synthetic modification of metal-organic framework membranes[J]. CIESC Journal, 2025, 76(5): 2070-2086.

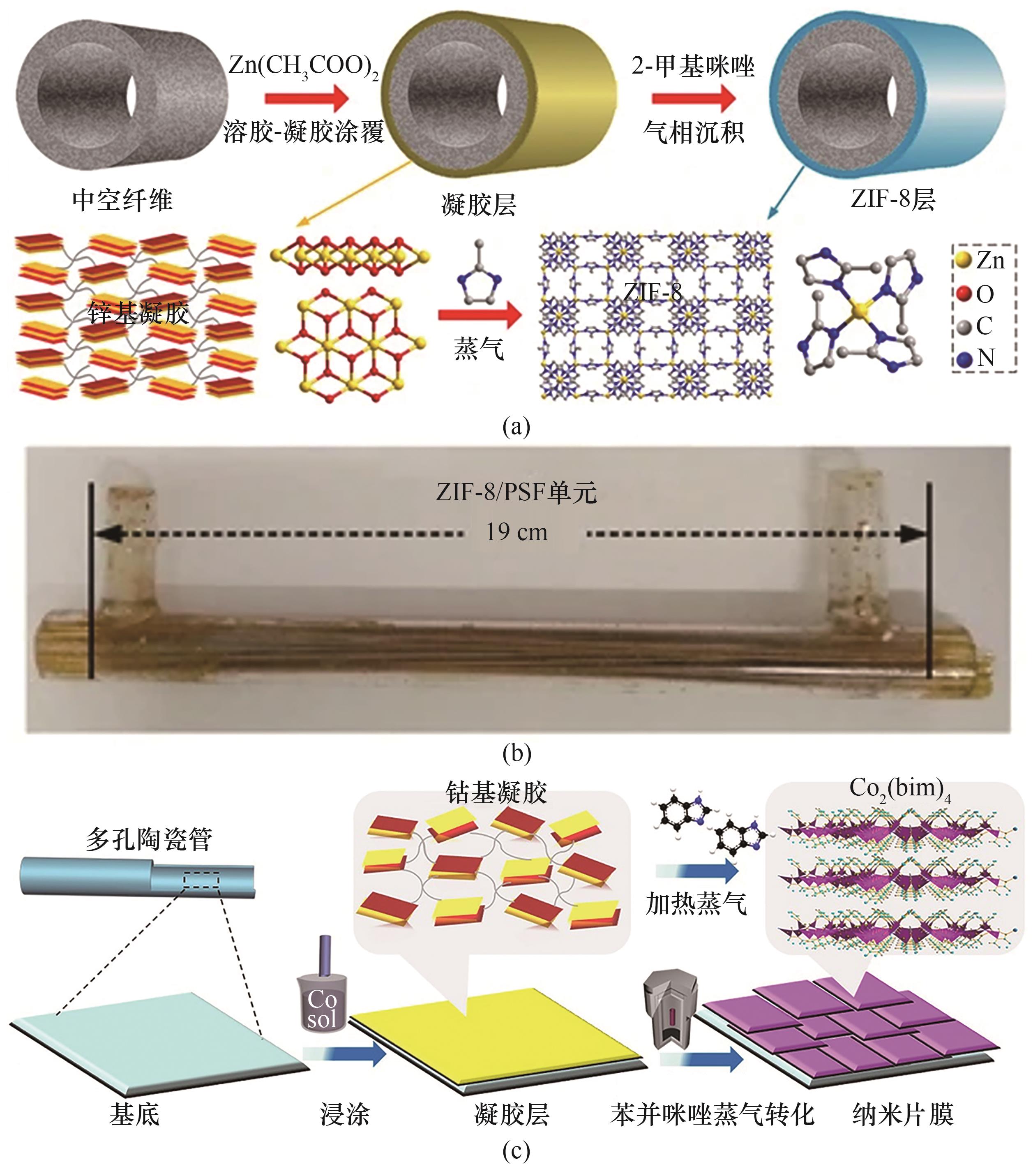

图2 (a) 锌基凝胶的气-固相转化[52];(b) ZIF-8中空纤维膜组件[52];(c) 钴基凝胶的气-固相转化[53]

Fig.2 (a) Gas-solid phase transformation of zinc-based gel[52]; (b) A ZIF-8 hollow fibre membrane module[52]; (c) Gas-solid phase transformation of cobalt-based gel[53]

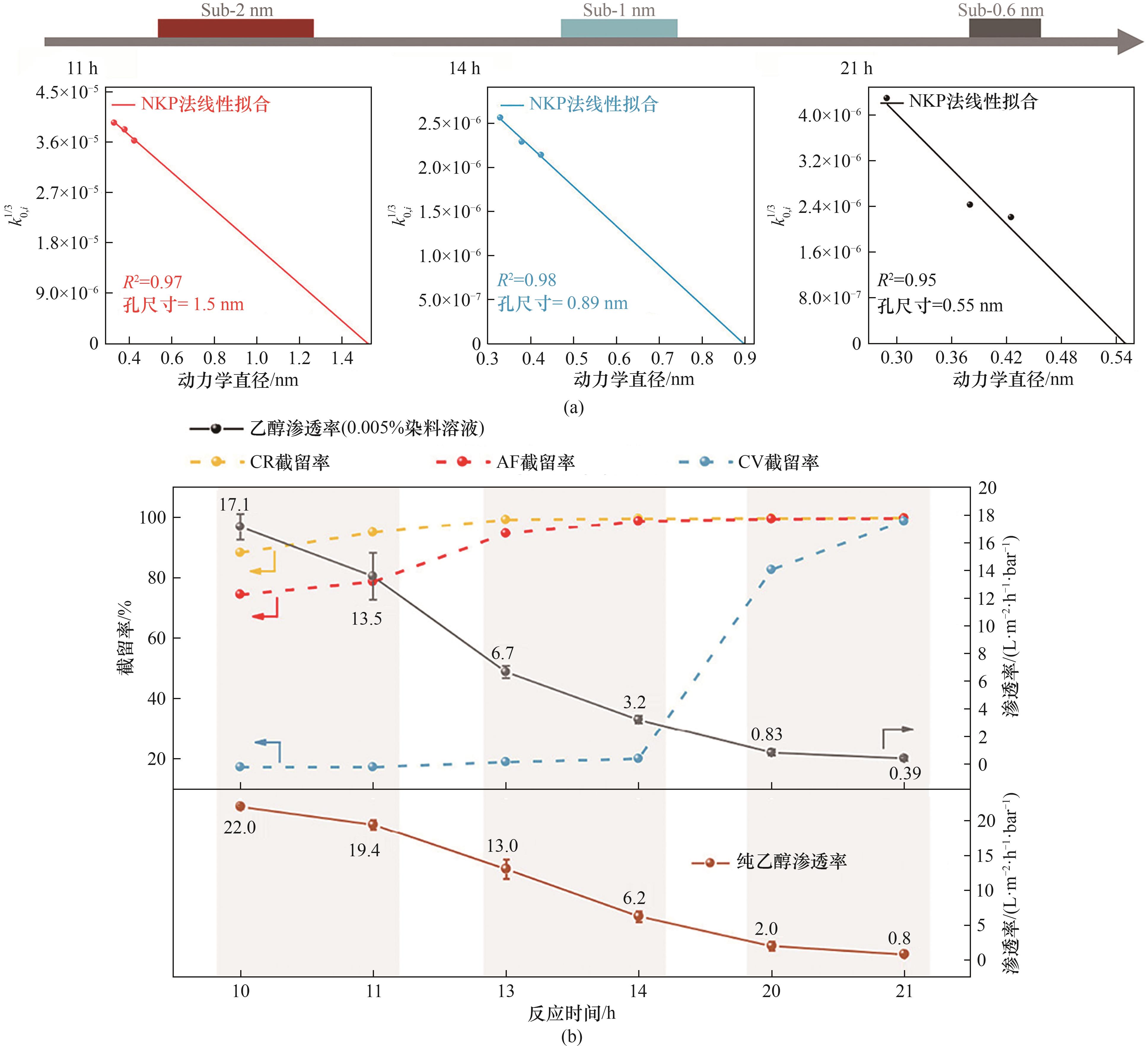

图3 (a) 不同反应时间晶间通道尺寸变化 (基于努森扩散原理计算)[54];(b) 不同反应时间下膜的染料截留能力及乙醇透量[54]

Fig.3 (a) Variation of intercrystalline channel size at different reaction times (measured based on Knudsen diffusion principle) [54];(b) Dye retention performances and ethanol permeances of membrane at different reaction times[54](1 bar=0.1 MPa)

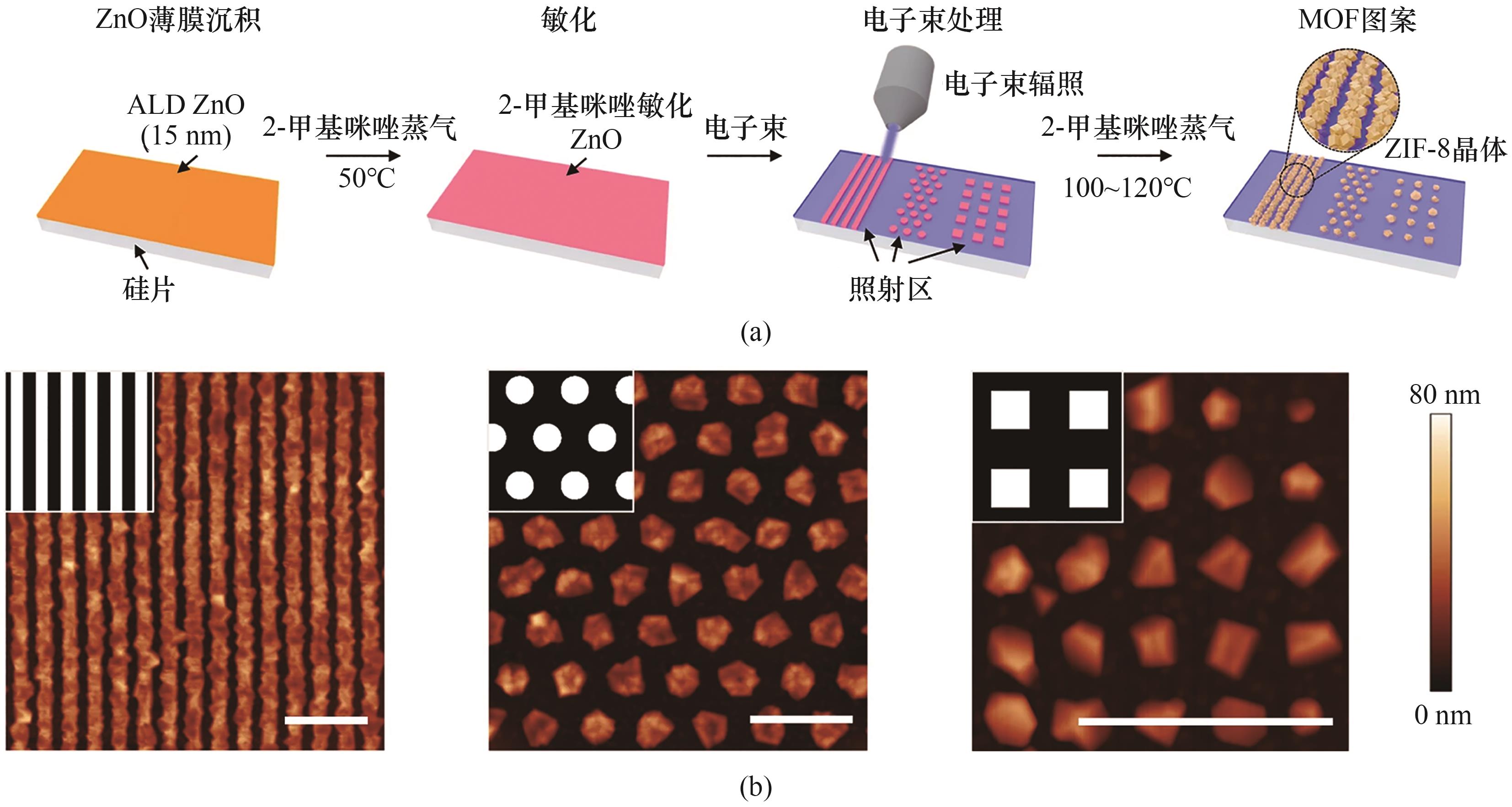

图4 (a) 电子束诱导氧化锌区域选择性转化为ZIF-8示意图[62];(b) 图案化ZIF-8的原子力显微镜图像[62]

Fig.4 (a) Schematic illustration of e-beam-induced area-selective transformation of ZnO into ZIF-8[62]; (b) Atomic force microscope image of patterned ZIF-8[62]

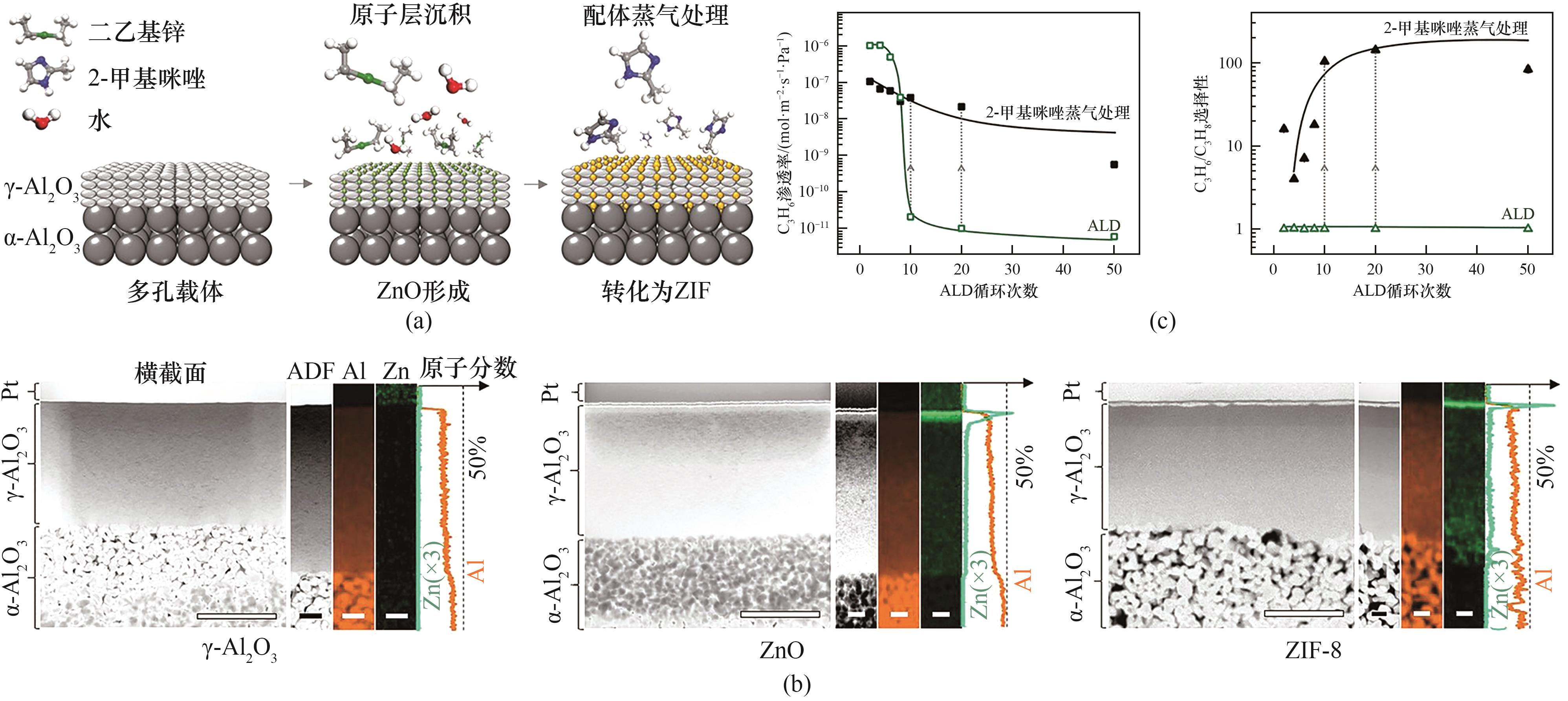

图5 (a) ZnO的ALD沉积与气-固相转化[63];(b) γ-Al2O3载体、ZnO层、ZIF-8膜的截面元素分布图[63];(c) ALD循环次数对气-固相转化前后膜的丙烯渗透率与丙烯/丙烷选择性的影响[63]

Fig.5 (a) Schematic illustration of deposition of ZnO film through ALD and its further vapor transformation[63]; (b) Elemental distributions along cross sections of γ-Al2O3 support, ZnO film and ZIF-8 membrane[63]; (c) Influence of ALD cycles on propylene permeance and propylene/propane selectivity[63]

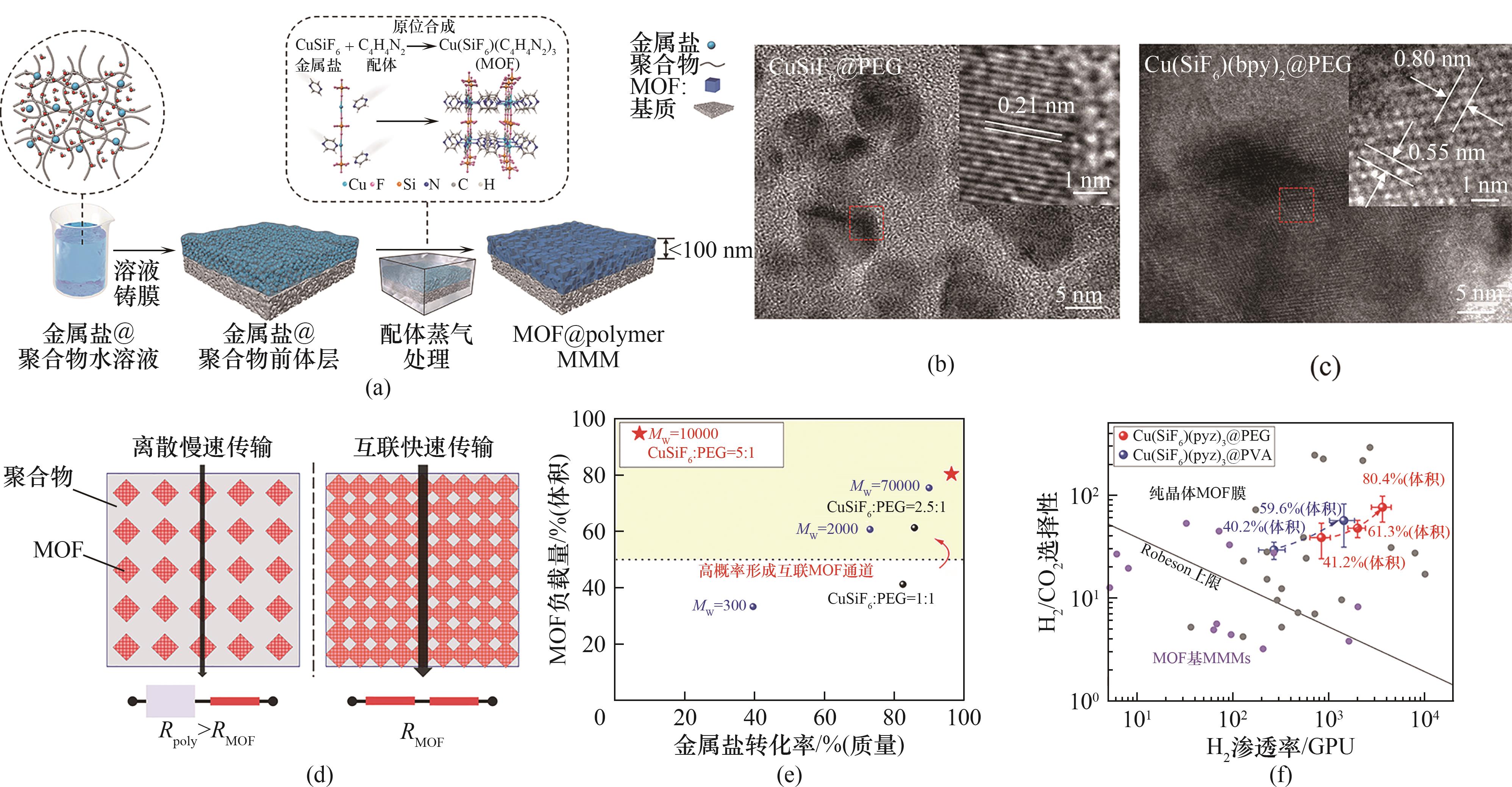

图6 (a) 固态溶剂策略制备混合基质膜;(b) CuSiF6@PEG前体的高分辨透射电子显微镜图像[64];(c) Cu(SiF6)(bpy)2@PEG混合基质膜的高分辨透射电子显微镜图像[64];(d) 不同MOF负载量的传质示意图[64];(e) MOF负载量与金属盐转化率的对应关系(Mw代表聚合物分子量)[64];(f) H2/CO2分离性能与文献对比[64]

Fig.6 (a) Mixed-matrix membrane (MMM) fabricated by a solid-solvent processing strategy[64]; (b) High-resolution transmission electron microscope image of the Cu(SiF6)(bpy)2@PEG MMM[64]; (c) High-resolution transmission electron microscope image of the Cu(SiF6)(bpy)2@PEG MMM[64]; (d) Schematic illustration of mass-transfer through MMM with different MOF loadings (Mw stands for the molecular mass of polymer) [64]; (e) MOF loadings varied with metal salt conversion ratios[64]; (f) Comparison of H2/CO2 separation performances between Cu(SiF6)(pyz)3@polymer MMMs and other membranes in literature[64]

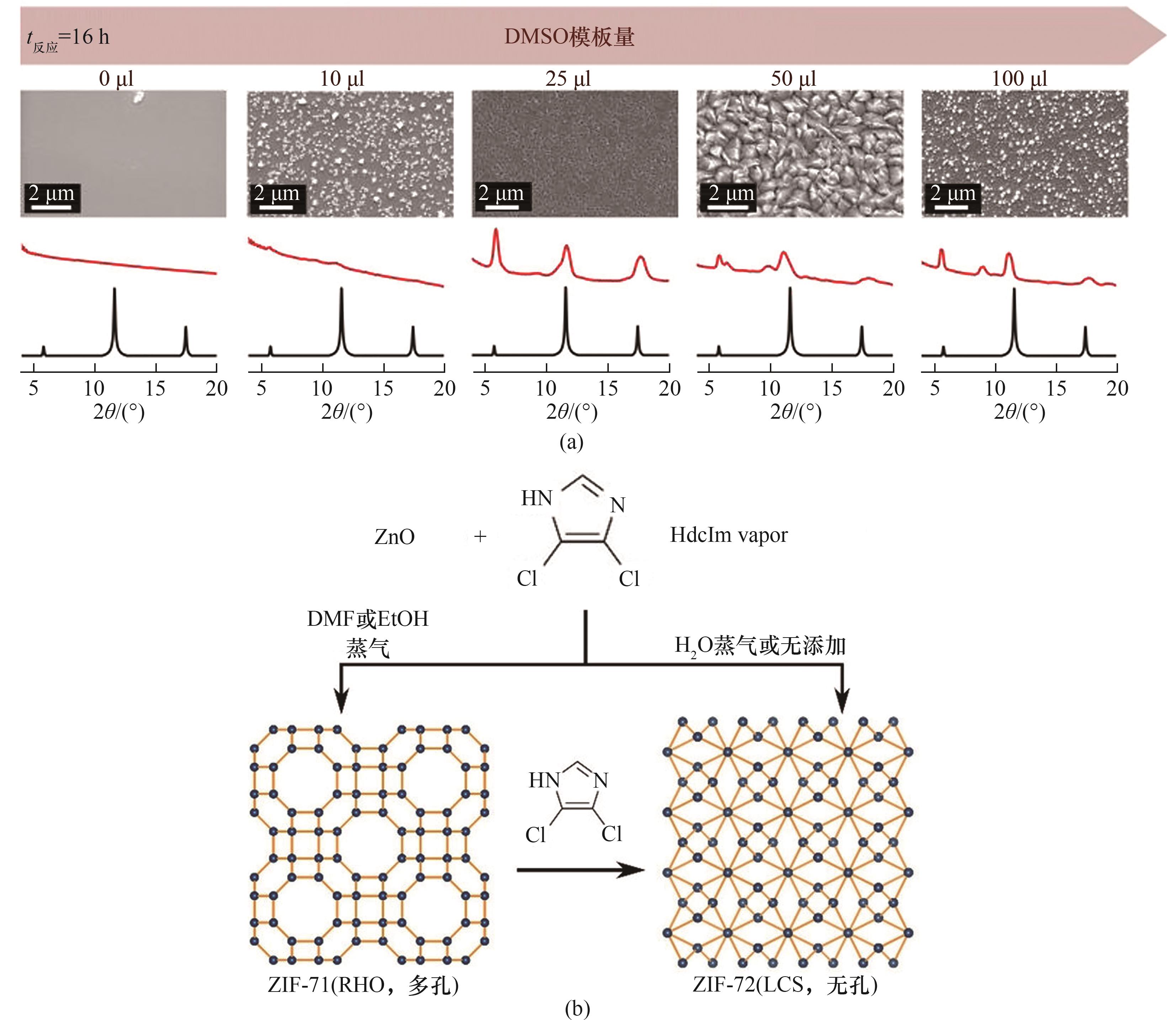

图7 (a) 扫描电子显微镜和略入射X射线衍射表征不同溶剂量对膜的表面形貌和结晶性的影响(红色线、黑色线分别代表实验和模拟谱图)[65];(b) 溶剂对气-固反应产物的影响[66]

Fig.7 (a) Influence of different template amounts on film morphology (characterized by scanning electron microscope) and crystallinity (characterized by grazing incidence X-ray diffraction), red and black lines represent experimental and simulated patterns, respectively[65]; (b) Effect of solvent on topologies of products[66]

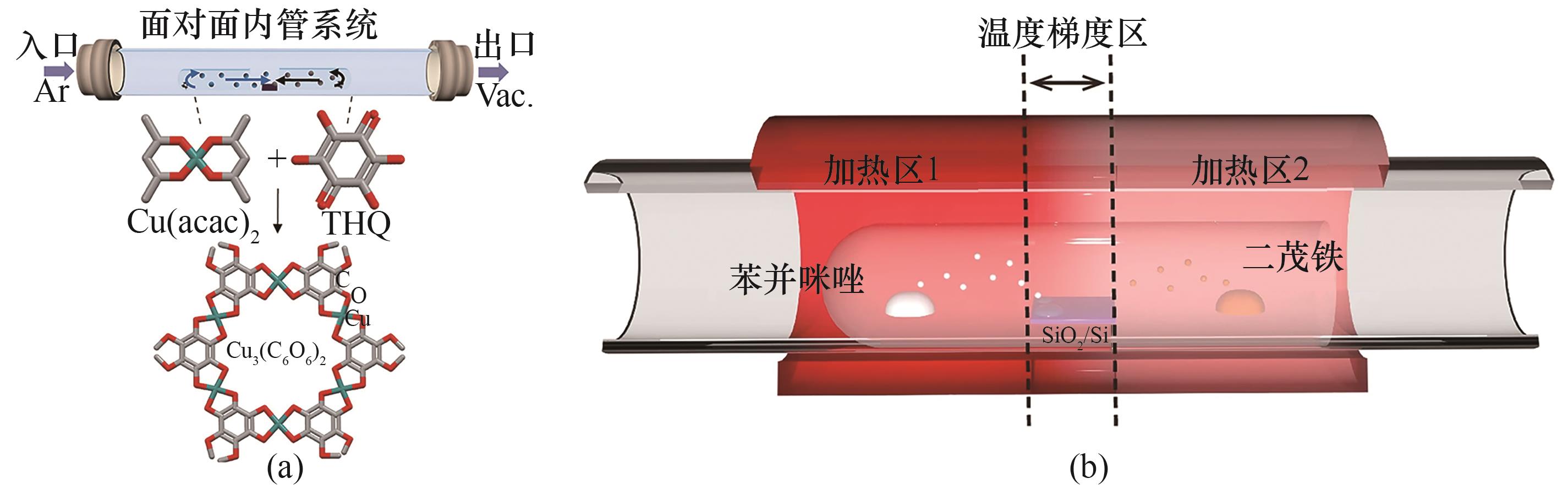

图9 (a) Cu3(C6O6)2的一步全气相转化策略[70];(b) 双加热气相转化系统[71]

Fig.9 (a) Single-step all-vapor-phase conversion strategy for Cu3(C6O6)2[70]; (b) A typical vapor conversion device with dual heating zones[71]

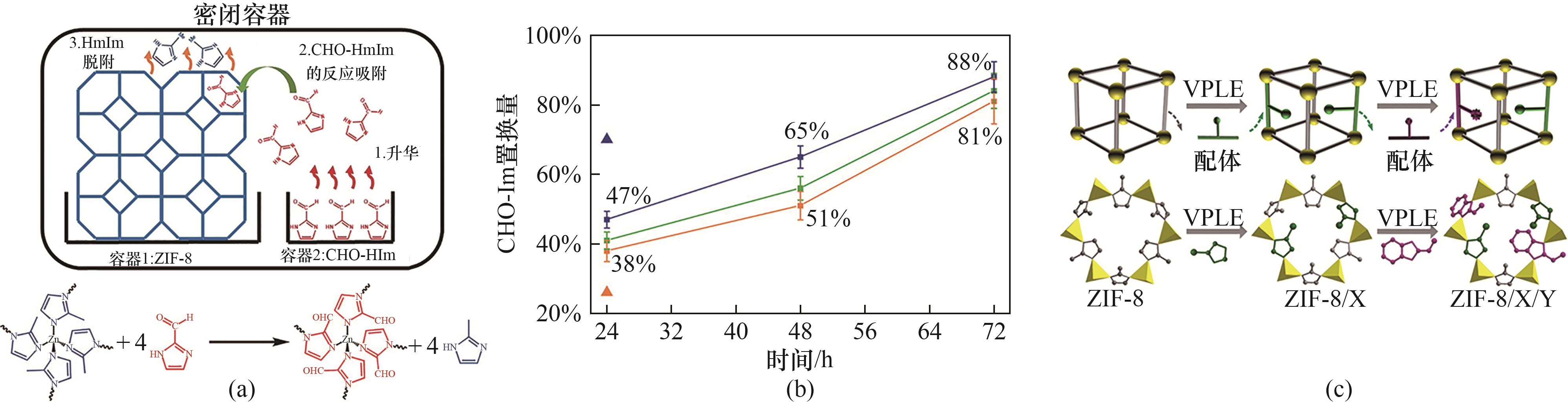

图10 (a) ZIF-8的气相配体置换过程示意图[73];(b) 置换比例随时间的变化 (蓝色线、绿色线、橙色线分别代表粒径为90 nm、15 μm、150 μm的ZIF-8)[73];(c) ZIF-8的二次气相配体置换示意图[74]

Fig.10 (a) Schematic illustration of vapor-phase linker exchange process of ZIF-8[73]; (b) Vapor-phase linker exchange ratio as a function of time (blue, green, and orange lines represent ZIF-8 particles with sizes of 90 nm, 15 μm, and 150 μm, respectively ) [73]; (c) Schematic illustration of the secondary vapor-phase linker exchange process of ZIF-8[74]

图11 (a) ZIF-8膜的气相配体置换与孔径变化[75];(b) 配体置换后膜的单组分气体渗透行为变化[75];(c) 配体置换后膜的选择性变化[75];(d) 部分无定形ZIF-8膜的制备示意图[76];(e) 具有晶间缺陷的多晶膜与部分无定形膜的气体传输路径示意图[76];(f) 配体置换后膜的选择性变化[76]

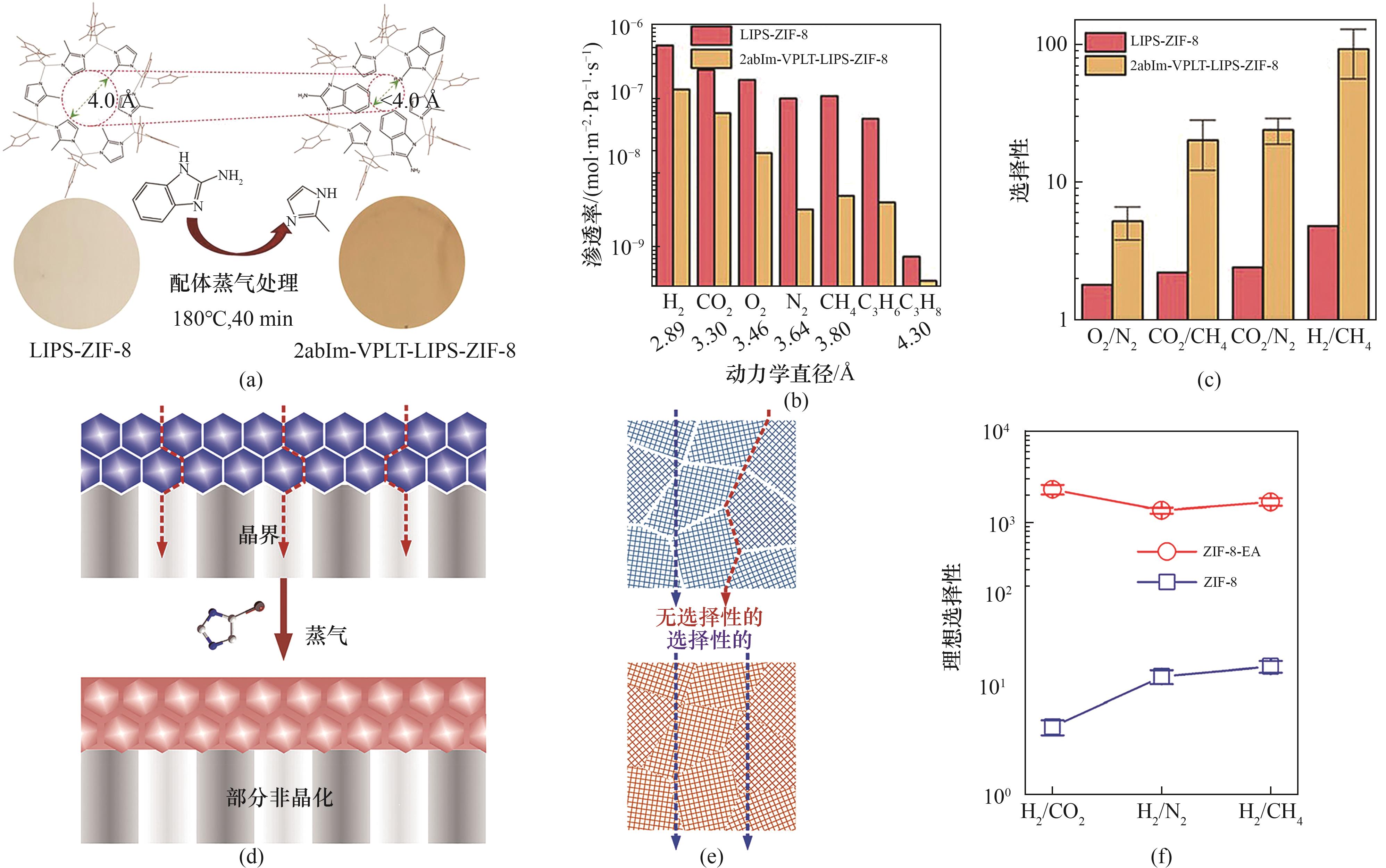

Fig.11 (a) Vapor-phase linker exchange process of ZIF-8 membrane and its pore size variation[75]; (b) Gas permeation properties of membrane after linker exchange[75]; (c) Permselectivity of gas pairs before and after linker exchange[75]; (d) Schematic of preparation of partially amorphous ZIF-8 membrane[76]; (e) Schematic of gas transport through polycrystalline membranes with grain boundary defects and partially amorphous membrane[76]; (f) Permselectivity of gas pairs before and after linker exchange[76](1 Å=0.1 nm)

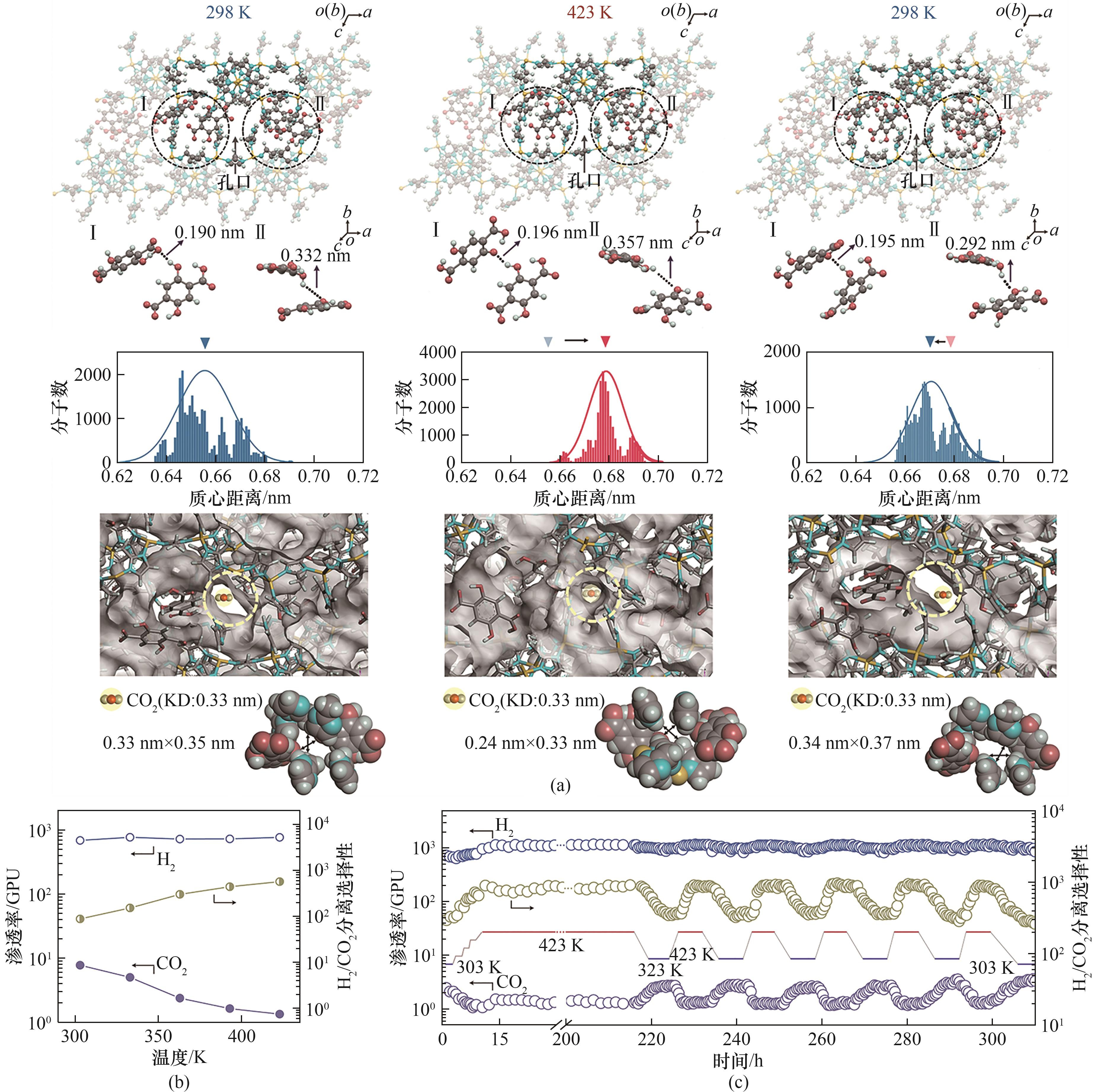

图12 (a) 升降温过程中分子守门员质心距离与相应孔径变化[77];(b) 升温后的气体渗透特性[77];(c) 升降温循环下膜的稳定性[77]

Fig.12 (a) Change in centroid distance of molecular gatekeepers during a heating-cooling cycle and corresponding pore size evolutions[77]; (b) Gas permeation properties varied with temperatures[77]; (c) Stability of membrane during a heating-cooling cycle[77]

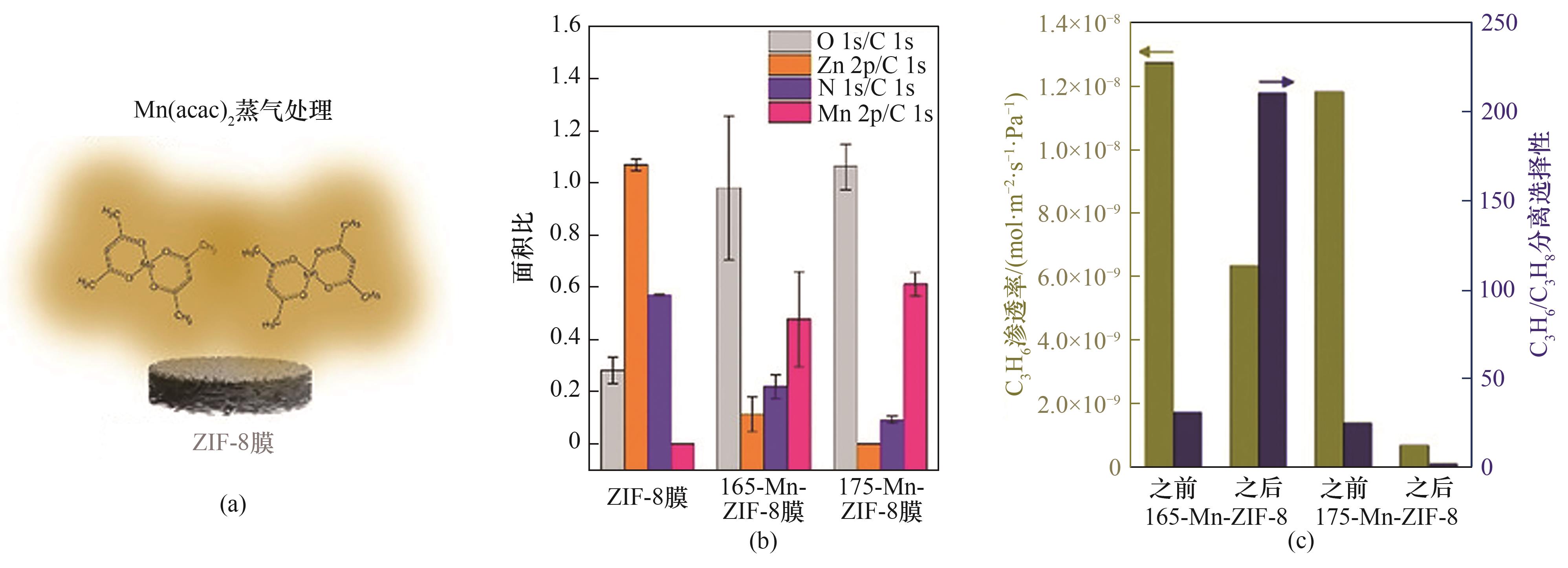

图14 (a) 以Mn(acac)2蒸气处理ZIF-8膜示意图[81];(b) 蒸气处理前后O、Zn、N、Mn的比例变化(X射线光电子能谱表征) [81];(c) 气相处理前后的气体渗透行为[81]

Fig.14 (a) Schematic illustration of treatment of ZIF-8 using Mn(acac)2 vapor[81]; (b) Ratio of integrated area of O, Zn, N, and Mn for ZIF-8 films before and after Mn(acac)2 treatment (characterized by X-ray photoelectron spectroscopy) [81]; (c) Permselectivity of gas pairs before and after vapor-treatment[81]

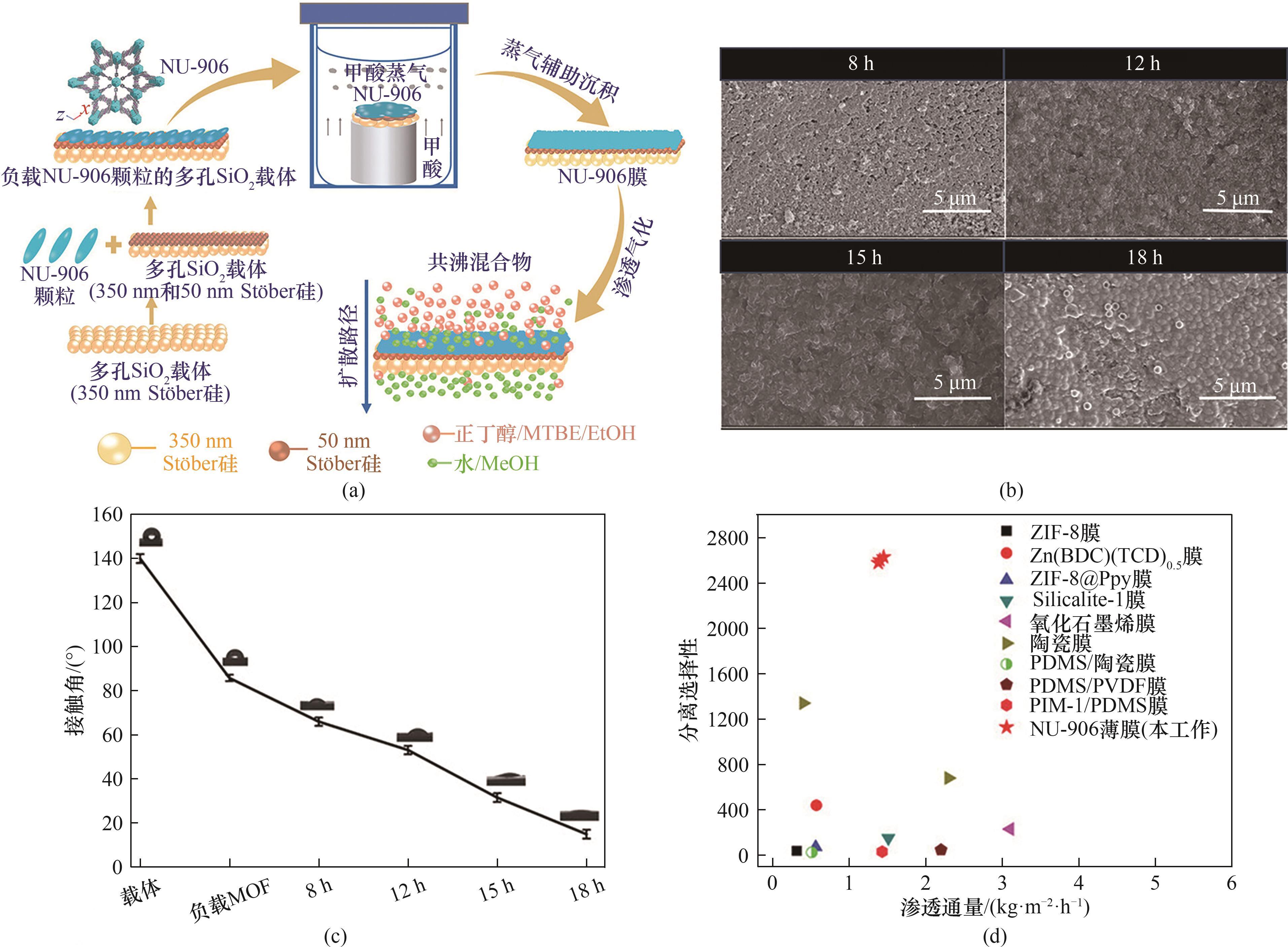

图15 (a) 甲酸蒸气诱导NU-906原位重结晶示意图[82];(b) 不同反应时间对表面形貌的影响[82];(c) 不同时间的甲酸蒸气处理后接触角的变化[82];(d) 正丁醇/水的渗透气化性能[82]

Fig.15 (a) Schematic illustration of fabrication process of NU-906 membrane by in situ recrystallization under formic acid vapor[82]; (b) Effect of different reaction times on membrane surface morphology[82]; (c) Variation of contact angles over vapor treatment times[82]; (d) Pervaporation performance of NU-906 film for n-butanol/water feed solution[82]

| 1 | Furukawa H, Cordova K E, O’Keeffe M, et al. The chemistry and applications of metal-organic frameworks[J]. Science, 2013, 341(6149): 1230444. |

| 2 | Li J R, Kuppler R J, Zhou H C. Selective gas adsorption and separation in metal-organic frameworks[J]. Chemical Society Reviews, 2009, 38(5): 1477-1504. |

| 3 | Qiu S L, Xue M, Zhu G S. Metal-organic framework membranes: from synthesis to separation application[J]. Chemical Society Reviews, 2014, 43(16): 6116-6140. |

| 4 | Cui Y J, Li B, He H J, et al. Metal-organic frameworks as platforms for functional materials[J]. Accounts of Chemical Research, 2016, 49(3): 483-493. |

| 5 | Lee J, Farha O K, Roberts J, et al. Metal-organic framework materials as catalysts[J]. Chemical Society Reviews, 2009, 38(5): 1450-1459. |

| 6 | Liu J W, Chen L F, Cui H, et al. Applications of metal-organic frameworks in heterogeneous supramolecular catalysis[J]. Chemical Society Reviews, 2014, 43(16): 6011-6061. |

| 7 | Wang Q, Astruc D. State of the art and prospects in metal-organic framework (MOF)-based and MOF-derived nanocatalysis[J]. Chemical Reviews, 2020, 120(2): 1438-1511. |

| 8 | Xia W, Mahmood A, Zou R Q, et al. Metal-organic frameworks and their derived nanostructures for electrochemical energy storage and conversion[J]. Energy & Environmental Science, 2015, 8(7): 1837-1866. |

| 9 | Wang L, Han Y Z, Feng X, et al. Metal-organic frameworks for energy storage: batteries and supercapacitors[J]. Coordination Chemistry Reviews, 2016, 307: 361-381. |

| 10 | Wu H B, Lou X W. Metal-organic frameworks and their derived materials for electrochemical energy storage and conversion: promises and challenges[J]. Science Advances, 2017, 3(12): eaap9252. |

| 11 | Hu Z C, Deibert B J, Li J. Luminescent metal-organic frameworks for chemical sensing and explosive detection[J]. Chemical Society Reviews, 2014, 43(16): 5815-5840. |

| 12 | Lustig W P, Mukherjee S, Rudd N D, et al. Metal-organic frameworks: functional luminescent and photonic materials for sensing applications[J]. Chemical Society Reviews, 2017, 46(11): 3242-3285. |

| 13 | Zhang Y M, Yuan S, Day G, et al. Luminescent sensors based on metal-organic frameworks[J]. Coordination Chemistry Reviews, 2018, 354: 28-45. |

| 14 | Huxford R C, Della Rocca J, Lin W B. Metal-organic frameworks as potential drug carriers[J]. Current Opinion in Chemical Biology, 2010, 14(2): 262-268. |

| 15 | Wu M X, Yang Y W. Metal-organic framework (MOF)-based drug/cargo delivery and cancer therapy[J]. Advanced Materials, 2017, 29(23): 1606134. |

| 16 | Lawson H D, Walton S P, Chan C. Metal-organic frameworks for drug delivery: a design perspective[J]. ACS Applied Materials & Interfaces, 2021, 13(6): 7004-7020. |

| 17 | Ban Y, Yang W. Multidimensional building blocks for molecular sieve membranes[J]. Accounts of Chemical Research, 2022, 55(21): 3162-3177. |

| 18 | Venna S R, Carreon M A. Metal-organic framework membranes for carbon dioxide separation[J]. Chemical Engineering Science, 2015, 124: 3-19. |

| 19 | Jayaramulu K, Mukherjee S, Morales D M, et al. Graphene-based metal-organic framework hybrids for applications in catalysis, environmental, and energy technologies[J]. Chemical Reviews, 2022, 122(24): 17241-17338. |

| 20 | Dechnik J, Gascon J, Doonan C J, et al. Mixed-matrix membranes[J]. Angewandte Chemie International Edition, 2017, 56(32): 9292-9310. |

| 21 | Peng Y, Li Y, Ban Y, et al. Metal-organic framework nanosheets as building blocks for molecular sieving membranes[J]. Science, 2014, 346(6215): 1356-1359. |

| 22 | Yang K, Hu S, Ban Y, et al. ZIF-L membrane with a membrane-interlocked-support composite architecture for H2/CO2 separation[J]. Science Bulletin, 2021, 66(18): 1869-1876. |

| 23 | Hong X L, Lu Z, Zhao Y L, et al. Fast fabrication of freestanding MXene-ZIF-8 dual-layered membranes for H2/CO2 separation[J]. Journal of Membrane Science, 2022, 642: 119982. |

| 24 | Jin C X, Liu S, Chen X F, et al. Oriented growth of large-area metal-organic framework ZIF-8 membrane for hydrogen separation[J]. Journal of Membrane Science, 2024, 711: 123163. |

| 25 | Bae T H, Long J R. CO2/N2 separations with mixed-matrix membranes containing Mg2(dobdc) nanocrystals[J]. Energy & Environmental Science, 2013, 6(12): 3565-3569. |

| 26 | Ban Y, Li Z, Li Y, et al. Confinement of ionic liquids in nanocages: tailoring the molecular sieving properties of ZIF-8 for membrane-based CO2 capture[J]. Angewandte Chemie International Edition, 2015, 54(51): 15483-15487. |

| 27 | Li C E, Qi A H, Ling Y, et al. Establishing gas transport highways in MOF-based mixed matrix membranes[J]. Science Advances, 2023, 9(13): eadf5087. |

| 28 | Sun Y W, Yan J H, Gao Y L, et al. Fabrication of highly oriented ultrathin zirconium metal-organic framework membrane from nanosheets towards unprecedented gas separation[J]. Angewandte Chemie International Edition, 2023, 62(15): e202216697. |

| 29 | Rodenas T, Luz I, Prieto G, et al. Metal-organic framework nanosheets in polymer composite materials for gas separation[J]. Nature Materials, 2015, 14(1): 48-55. |

| 30 | Wang Y H, Jin H, Ma Q, et al. A MOF glass membrane for gas separation[J]. Angewandte Chemie International Edition, 2020, 59(11): 4365-4369. |

| 31 | Kwon H T, Jeong H K. In situ synthesis of thin zeolitic-imidazolate framework ZIF-8 membranes exhibiting exceptionally high propylene/propane separation[J]. Journal of the American Chemical Society, 2013, 135(29): 10763-10768. |

| 32 | Sun Y W, Hu S, Yan J H, et al. Oriented ultrathin π-complexation MOF membrane for ethylene/ethane and flue gas separations[J]. Angewandte Chemie International Edition, 2023, 62(43): e202311336. |

| 33 | Wang Y, Ban Y, Hu Z, et al. A LDH template triggers the formation of a highly compact MIL-53 metal-organic framework membrane for acid upgrading[J]. Angewandte Chemie International Edition, 2023, 62(16): e202302181. |

| 34 | Wang Y, Ban Y, Hu Z, et al. Adaptive healing of stress-induced dynamic cracks in a metal-organic framework membrane using nanoparticles[J]. Science Advances, 2024, 10(31): eado7331. |

| 35 | Wang Q, Zhou C C, Shen L, et al. Co-gallate MOF membrane for efficient pervaporation separation of MeOH from MTBE[J]. Journal of Membrane Science, 2024, 698: 122621. |

| 36 | Herm Z R, Wiers B M, Mason J A, et al. Separation of hexane isomers in a metal-organic framework with triangular channels[J]. Science, 2013, 340(6135): 960-964. |

| 37 | Wang Y, Ban Y, Hu Z, et al. Energy-efficient extraction of linear alkanes from various isomers using structured metal-organic framework membrane[J]. Nature Communications, 2023, 14(1): 6617. |

| 38 | Cong S Z, Zhou Y Q, Luo C L, et al. Designing metal-organic framework (MOF) membranes for isomer separation[J]. Angewandte Chemie, 2024, 63(15): e202319894. |

| 39 | Liu X L, Demir N K, Wu Z T, et al. Highly water-stable zirconium metal-organic framework UiO-66 membranes supported on alumina hollow fibers for desalination[J]. Journal of the American Chemical Society, 2015, 137(22): 6999-7002. |

| 40 | Cong S Z, Yuan Y, Wang J X, et al. Highly water-permeable metal-organic framework MOF-303 membranes for desalination[J]. Journal of the American Chemical Society, 2021, 143(48): 20055-20058. |

| 41 | Zhang R, Ji S L, Wang N X, et al. Coordination-driven in situ self-assembly strategy for the preparation of metal-organic framework hybrid membranes[J]. Angewandte Chemie International Edition, 2014, 53(37): 9775-9779. |

| 42 | Bux H, Liang F Y, Li Y S, et al. Zeolitic imidazolate framework membrane with molecular sieving properties by microwave-assisted solvothermal synthesis[J]. Journal of the American Chemical Society, 2009, 131(44): 16000-16001. |

| 43 | Pejman M, Dadashi Firouzjaei M, Aghapour Aktij S, et al. In situ Ag-MOF growth on pre-grafted zwitterions imparts outstanding antifouling properties to forward osmosis membranes[J]. ACS Applied Materials & Interfaces, 2020, 12(32): 36287-36300. |

| 44 | Li Y S, Bux H, Feldhoff A, et al. Controllable synthesis of metal-organic frameworks: from MOF nanorods to oriented MOF membranes[J]. Advanced Materials, 2010, 22(30): 3322-3326. |

| 45 | Hu Y X, Dong X L, Nan J P, et al. Metal-organic framework membranes fabricated via reactive seeding[J]. Chemical Communications, 2011, 47(2): 737-739. |

| 46 | Yao J F, Dong D H, Li D, et al. Contra-diffusion synthesis of ZIF-8 films on a polymer substrate[J]. Chemical Communications, 2011, 47(9): 2559-2561. |

| 47 | Li X Y, Zhang H C, Yu H, et al. Unidirectional and selective proton transport in artificial heterostructured nanochannels with nano-to-subnano confined water clusters[J]. Advanced Materials, 2020, 32(24): 2001777. |

| 48 | Gao J, Wei W, Yin Y, et al. Continuous ultrathin UiO-66-NH2 coatings on a polymeric substrate synthesized by a layer-by-layer method: a kind of promising membrane for oil-water separation[J]. Nanoscale, 2020, 12(12): 6658-6663. |

| 49 | Pichon A, Lazuen-Garay A, James S L. Solvent-free synthesis of a microporous metal-organic framework[J]. CrystEngComm, 2006, 8(3): 211-214. |

| 50 | Beldon P J, Fábián L, Stein R S, et al. Rapid room-temperature synthesis of zeolitic imidazolate frameworks by using mechanochemistry[J]. Angewandte Chemie, 2010, 49(50): 9640-9643. |

| 51 | Chen Y F, Li S Q, Pei X K, et al. A solvent-free hot-pressing method for preparing metal-organic-framework coatings[J]. Angewandte Chemie International Edition, 2016, 55(10): 3419-3423. |

| 52 | Li W B, Su P C, Li Z J, et al. Ultrathin metal-organic framework membrane production by gel-vapour deposition[J]. Nature Communications, 2017, 8(1): 406. |

| 53 | Nian P, Liu H O, Zhang X F. Bottom-up fabrication of two-dimensional Co-based zeolitic imidazolate framework tubular membranes consisting of nanosheets by vapor phase transformation of Co-based gel for H2/CO2 separation[J]. Journal of Membrane Science, 2019, 573: 200-209. |

| 54 | Shi D C, Li H, Yu X, et al. Intercrystalline channels at subnanometer scale for precise molecular nanofiltration[J]. Journal of the American Chemical Society, 2023, 145(29): 15848-15858. |

| 55 | Han S, Ciufo R A, Meyerson M L, et al. Solvent-free vacuum growth of oriented HKUST-1 thin films[J]. Journal of Materials Chemistry A, 2019, 7(33): 19396-19406. |

| 56 | Zhang X F, Liu Y G, Li S H, et al. New membrane architecture with high performance: ZIF-8 membrane supported on vertically aligned ZnO nanorods for gas permeation and separation[J]. Chemistry of Materials, 2014, 26(5): 1975-1981. |

| 57 | Hou J M, Hong X L, Zhou S, et al. Solvent-free route for metal-organic framework membranes growth aiming for efficient gas separation[J]. AIChE Journal, 2019, 65(2): 712-722. |

| 58 | Bo R H, Taheri M, Liu B R, et al. Hierarchical metal-organic framework films with controllable meso/macroporosity[J]. Advanced Science, 2020, 7(24): 2002368. |

| 59 | Tanaka S, Sakamoto K, Inada H, et al. Vapor-phase synthesis of ZIF-8 MOF thick film by conversion of ZnO nanorod array[J]. Langmuir, 2018, 34(24): 7028-7033. |

| 60 | Stassen I, Styles M, Grenci G, et al. Chemical vapour deposition of zeolitic imidazolate framework thin films[J]. Nature Materials, 2016, 15(3): 304-310. |

| 61 | Lausund K B, Nilsen O. All-gas-phase synthesis of UiO-66 through modulated atomic layer deposition[J]. Nature Communications, 2016, 7: 13578. |

| 62 | Miao Y R, Lee D T, de Mello M D, et al. Solvent-free bottom-up patterning of zeolitic imidazolate frameworks[J]. Nature Communications,2022, 13(1): 420. |

| 63 | Ma X L, Kumar P, Mittal N, et al. Zeolitic imidazolate framework membranes made by ligand-induced permselectivation[J]. Science, 2018, 361(6406): 1008-1011. |

| 64 | Chen G N, Chen C L, Guo Y N, et al. Solid-solvent processing of ultrathin, highly loaded mixed-matrix membrane for gas separation[J]. Science, 2023, 381(6664): 1350-1356. |

| 65 | Rodríguez-Hermida S, Kravchenko D E, Wauteraerts N, et al. Vapor-assisted powder synthesis and oriented MOF-CVD thin films of the metal-organic framework HKUST-1[J]. Inorganic Chemistry, 2022, 61(45): 17927-17931. |

| 66 | Tu M, Kravchenko D E, Xia B Z, et al. Template-mediated control over polymorphism in the vapor-assisted formation of zeolitic imidazolate framework powders and films[J]. Angewandte Chemie International Edition, 2021, 60(14): 7553-7558. |

| 67 | Shi Q, Chen Z F, Song Z W, et al. Synthesis of ZIF-8 and ZIF-67 by steam-assisted conversion and an investigation of their tribological behaviors[J]. Angewandte Chemie International Edition, 2011, 50(3): 672-675. |

| 68 | Ma X X, Wan Z, Li Y H, et al. Anisotropic gas separation in oriented ZIF-95 membranes prepared by vapor-assisted in-plane epitaxial growth[J]. Angewandte Chemie International Edition, 2020, 59(47): 20858-20862. |

| 69 | Wang X, Yao R, Zhu H, et al. Solvent-vapor-triggered crystallization of a ZIF-90 membrane with versatile separation properties towards light hydrocarbons[J]. Chemical Engineering Journal, 2024, 496: 153737. |

| 70 | Choe M, Koo J Y, Park I, et al. Chemical vapor deposition of edge-on oriented 2D conductive metal-organic framework thin films[J]. Journal of the American Chemical Society, 2022, 144(37): 16726-16731. |

| 71 | Luo L X, Hou L X, Cui X P, et al. Self-condensation-assisted chemical vapour deposition growth of atomically two-dimensional MOF single-crystals[J]. Nature Communications, 2024, 15(1): 3618. |

| 72 | Claire F J, Solomos M A, Kim J, et al. Structural and electronic switching of a single crystal 2D metal-organic framework prepared by chemical vapor deposition[J]. Nature Communications, 2020, 11(1): 5524. |

| 73 | Marreiros J, Van Dommelen L, Fleury G, et al. Vapor-phase linker exchange of the metal-organic framework ZIF-8: a solvent-free approach to post-synthetic modification[J]. Angewandte Chemie International Edition, 2019, 58(51): 18471-18475. |

| 74 | Wu W F, Su J Y, Jia M M, et al. Vapor-phase linker exchange of metal-organic frameworks[J]. Science Advances, 2020, 6(18): eaax7270. |

| 75 | Eum K, Hayashi M, De Mello M D, et al. ZIF-8 membrane separation performance tuning by vapor phase ligand treatment[J]. Angewandte Chemie International Edition, 2019, 58(46): 16390-16394. |

| 76 | Su P C, Tang H Y, Jia M M, et al. Vapor linker exchange of partially amorphous metal-organic framework membranes for ultra-selective gas separation[J]. AIChE Journal, 2022, 68(5): e17576. |

| 77 | Zhao M, Zhou D, Chen P, et al. Heat-driven molecule gatekeepers in MOF membrane for record-high H2 selectivity[J]. Science Advances, 2023, 9(24): eadg2229. |

| 78 | Zhao M, Ban Y, Chang Z, et al. Pyrazine-interior-embodied MOF-74 for selective CO2 adsorption[J]. AIChE Journal, 2022, 68(3): e17528. |

| 79 | Rong S Y, Chen S Z, Su P C, et al. Postsynthetic modification of metal-organic frameworks by vapor-phase grafting[J]. Inorganic Chemistry, 2021, 60(16): 11745-11749. |

| 80 | Zhou Y, Ban Y, Yang W. Reversibly phase-transformative zeolitic imidazolate framework-108 and the membrane separation utility[J]. Inorganic Chemistry, 2022, 61(43): 17342-17352. |

| 81 | Hayashi M, Lee D T, de Mello M D, et al. ZIF-8 membrane permselectivity modification by manganese(Ⅱ) acetylacetonate vapor treatment[J]. Angewandte Chemie International Edition, 2021, 60(17): 9316-9320. |

| 82 | Luo R W, Fu H Y, Li Y L, et al. In situ fabrication of metal-organic framework thin films with enhanced pervaporation performance[J]. Advanced Functional Materials, 2023, 33(18): 2213221. |

| [1] | 高冰冰, 许诺, 白云翔, 张春芳, 杨永强, 董亮亮. 氦气分离聚合物膜[J]. 化工学报, 2025, 76(5): 2119-2135. |

| [2] | 何燎, 李俊, 高梦舒, 刘东阳, 张宇豪, 赵亮, 高金森, 徐春明. 石油烃中芳烃分离技术研究进展[J]. 化工学报, 2025, 76(5): 1909-1926. |

| [3] | 徐泽海, 刘超, 张国亮. 聚合物基疏水渗透汽化膜及其溶剂回收应用[J]. 化工学报, 2025, 76(5): 2055-2069. |

| [4] | 郭彭涛, 王婷, 薛波, 应允攀, 刘大欢. 用于CH4/N2分离的多吸附位点超微孔MOF[J]. 化工学报, 2025, 76(5): 2304-2312. |

| [5] | 李紫鹃, 谭晓艳, 吴永盛, 杨陈怡, 陈红, 毕小刚, 刘捷, 喻发全. 分子模拟研究三维扭曲催化芳烃-降冰片烯环化聚合物膜的CO2/N2分离机理[J]. 化工学报, 2025, 76(5): 2348-2357. |

| [6] | 花敬贤, 罗宇荣, 顾亚伟, 吴婷婷, 潘宜昌, 邢卫红. 超薄取向ZIF-8膜的制备及乙烯/乙烷高效分离[J]. 化工学报, 2025, 76(5): 2209-2218. |

| [7] | 李艳, 雷美丽, 李鑫钢. 基于分离性能的顺序式模拟移动床结构调控策略[J]. 化工学报, 2025, 76(5): 2219-2229. |

| [8] | 刘鑫, 郑皓仁, 陈强, 丁静怡, 黄康, 徐至. 全钒液流电池用纤维素纳米晶掺杂混合基质膜[J]. 化工学报, 2025, 76(5): 2294-2303. |

| [9] | 巴雅琪, 吴涛, 邸安頔, 陆安慧. 多孔炭材料用于低碳烃分离的研究进展[J]. 化工学报, 2025, 76(5): 2136-2157. |

| [10] | 谈朋, 李雪梅, 刘晓勤, 孙林兵. 基于柔性MOFs的磁响应复合材料及其丙烯吸附性能研究[J]. 化工学报, 2025, 76(5): 2230-2240. |

| [11] | 向昕辰, 鲁丹, 赵影, 姚之侃, 寇瑞强, 郑丹军, 周志军, 张林. 聚酰胺纳滤膜表面季铵化提高荷正电性及其锂镁分离性能[J]. 化工学报, 2025, 76(5): 2377-2386. |

| [12] | 王金月, 谢恩泽, 马翰泽, 袁晟, 何光伟, 姜忠义. 单原子层分离膜:进展与展望[J]. 化工学报, 2025, 76(5): 1943-1959. |

| [13] | 陆艳秋, 狄扬, 石文博, 殷聪聪, 汪勇. 基于新型有机多孔聚合物的智能响应膜研究进展[J]. 化工学报, 2025, 76(5): 2101-2118. |

| [14] | 陶春珲, 李印辉, 傅钰, 段然, 赵泽一, 唐羽丰, 张罡, 马和平. 不同吸附剂对低浓度Kr气的选择性吸附与纯化[J]. 化工学报, 2025, 76(5): 2358-2366. |

| [15] | 赵浩帆, 任豪杰, 刘宗凯, 董冠英, 张亚涛. MOFs玻璃膜在气体分离领域的研究进展[J]. 化工学报, 2025, 76(5): 2042-2054. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号