化工学报 ›› 2025, Vol. 76 ›› Issue (5): 2055-2069.DOI: 10.11949/0438-1157.20241211

收稿日期:2024-10-31

修回日期:2025-01-25

出版日期:2025-05-25

发布日期:2025-06-13

通讯作者:

张国亮

作者简介:徐泽海(1991—),男,博士,副研究员,zhxu327@zjut.edu.cn

基金资助:

Zehai XU( ), Chao LIU, Guoliang ZHANG(

), Chao LIU, Guoliang ZHANG( )

)

Received:2024-10-31

Revised:2025-01-25

Online:2025-05-25

Published:2025-06-13

Contact:

Guoliang ZHANG

摘要:

渗透汽化是一种新兴的膜分离技术,广泛应用于溶剂回收和环境保护领域。通过选择性渗透和汽化过程,渗透汽化膜可有效分离水与有机溶剂,尤其适用于处理含水溶剂的废液,能减少环境污染,并实现资源的循环利用。立足于以聚合物材料作为基底的膜材料设计,综述疏水渗透汽化膜的研究进展,凝练出目前亟待解决的关键问题,为推动该技术领域的进一步发展提供指引。首先讨论了基于聚合物基底的渗透汽化膜的类型及特征,从提升材料疏水特性的角度,阐述了用于提升膜疏水性能的方法,如物理共混、表面结构控制和中间层构筑等,分析总结了具有所需微观结构和表面特性的聚合物基疏水渗透汽化膜的设计策略。其次,介绍了聚合物基疏水渗透汽化膜在溶剂回收领域的广泛应用及前景,包括醇类、脂类、烃类和酮类等溶剂的回收。再次,介绍了聚合物基疏水渗透汽化膜的热稳定性和中试案例。最后,对聚合物基疏水渗透汽化膜在实际应用中面临的挑战进行了分析,并概述了聚合物基疏水渗透汽化膜未来的研究和发展方向。

中图分类号:

徐泽海, 刘超, 张国亮. 聚合物基疏水渗透汽化膜及其溶剂回收应用[J]. 化工学报, 2025, 76(5): 2055-2069.

Zehai XU, Chao LIU, Guoliang ZHANG. Hydrophobic pervaporation membranes on polymer substrate for solvent recovery[J]. CIESC Journal, 2025, 76(5): 2055-2069.

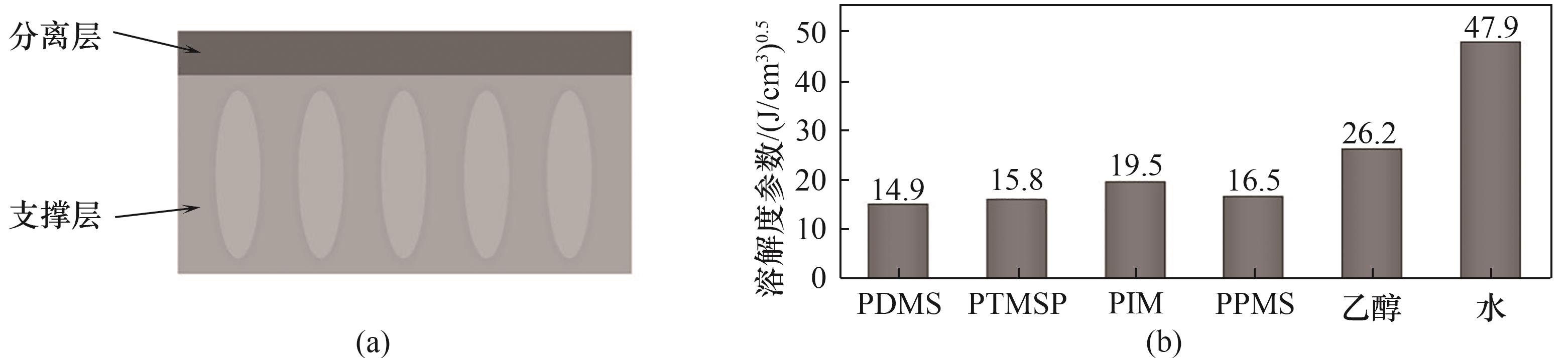

图2 (a)聚合物基复合膜示意;(b)部分疏水膜材料及乙醇/水的溶解度参数对比

Fig.2 (a) Schematic diagram of polymer-based composite membrane; (b) Comparison of solubility parameters of some hydrophobic film materials and ethanol/water

| 框架材料名称 | 孔尺寸/Å | BET比表面积/(m2/g) | 孔隙体积/(cm3/g) | 文献 |

|---|---|---|---|---|

| ZIF-8 | 3.4 | 1344 | 0.554 | [ |

| ZIF-71 | 4.8 | 1007 | 0.452 | [ |

| ZIF-67 | 4.51 | 1245 | 0.665 | [ |

| ZIF-90 | 2.86 | 1360 | 0.561 | [ |

| MAF-6 | 7.6 | 1343 | 0.63 | [ |

| MOF-808 | 14 | 2060 | 0.84 | [ |

| MIL-53 | 8 | 1294 | 0.65 | [ |

| MIL-101 | 12 | 2500 | 1.22 | [ |

| COF-300 | 0.7 | 1360 | 0.72 | [ |

| COF-DVA | 2.53 | 663 | — | [ |

| CuCOF | 1.89 | 515 | — | [ |

| COF-LZU1 | 74.5 | 583 | 0.48 | [ |

| COF- LZU8 | 12.3 | 454 | 0.36 | [ |

| COF-42 | 2.3 | 659 | 0.29 | [ |

表1 渗透汽化膜用MOFs和COFs结构参数

Table 1 Structural parameters of MOFs and COFs for pervaporation membranes

| 框架材料名称 | 孔尺寸/Å | BET比表面积/(m2/g) | 孔隙体积/(cm3/g) | 文献 |

|---|---|---|---|---|

| ZIF-8 | 3.4 | 1344 | 0.554 | [ |

| ZIF-71 | 4.8 | 1007 | 0.452 | [ |

| ZIF-67 | 4.51 | 1245 | 0.665 | [ |

| ZIF-90 | 2.86 | 1360 | 0.561 | [ |

| MAF-6 | 7.6 | 1343 | 0.63 | [ |

| MOF-808 | 14 | 2060 | 0.84 | [ |

| MIL-53 | 8 | 1294 | 0.65 | [ |

| MIL-101 | 12 | 2500 | 1.22 | [ |

| COF-300 | 0.7 | 1360 | 0.72 | [ |

| COF-DVA | 2.53 | 663 | — | [ |

| CuCOF | 1.89 | 515 | — | [ |

| COF-LZU1 | 74.5 | 583 | 0.48 | [ |

| COF- LZU8 | 12.3 | 454 | 0.36 | [ |

| COF-42 | 2.3 | 659 | 0.29 | [ |

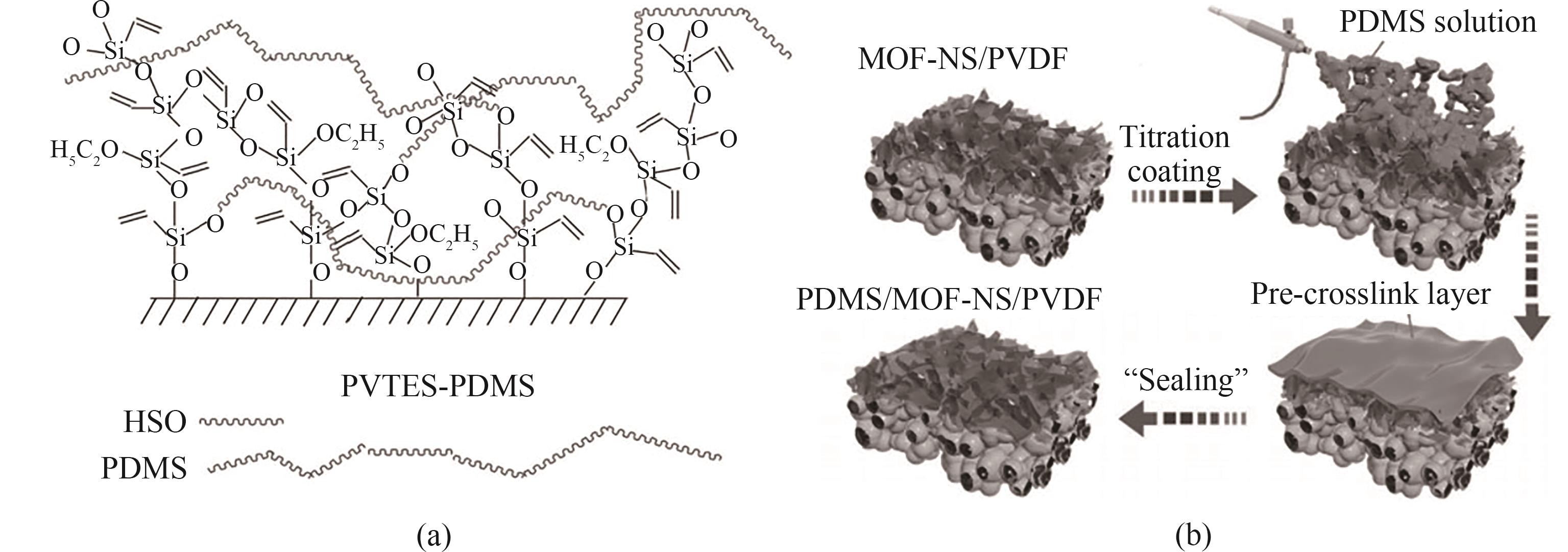

图4 (a)PVTES-PDMS渗透汽化膜结构示意[35];(b)MOF-NS/PVDF膜合成过程示意[37]

Fig.4 (a) Structure diagram of PVTES-PDMS pervaporation membrane[35]; (b) Schematic diagram of the synthesis process of MOF-NS/PVDF membrane[37]

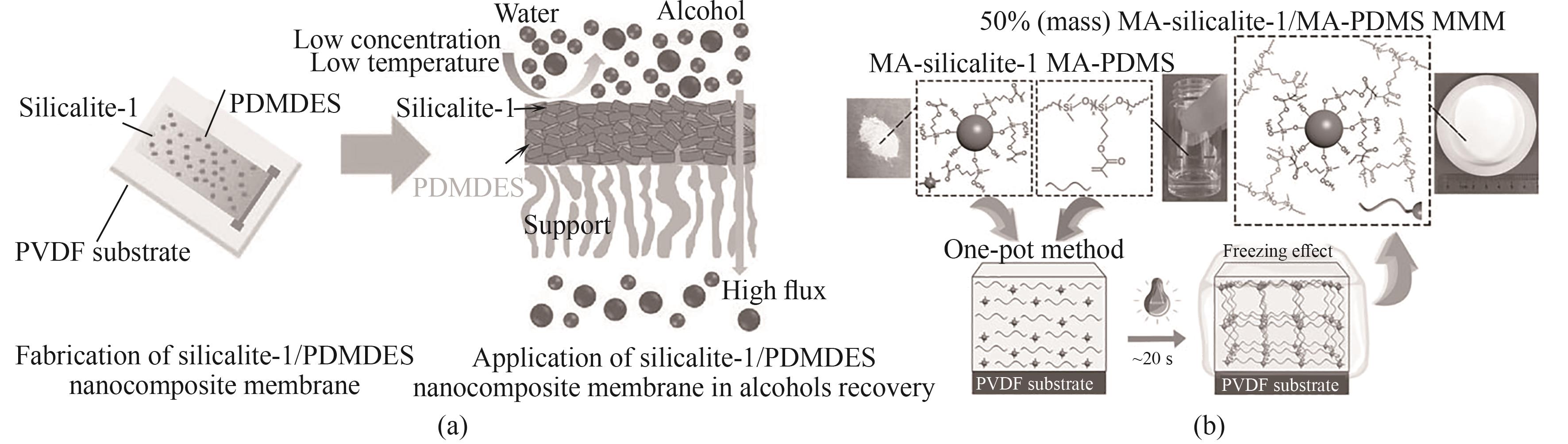

图5 (a)硅酸盐/PDMDES渗透汽化膜示意[38];(b)MA-silicalite-1/MA-PDMS膜合成过程示意[39]

Fig.5 (a) Structure diagram of silicalite-1/PDMDES pervaporation membrane[38]; (b) Schematic diagram of the synthesis process of MA-silicalite-1/MA-PDMS membrane[39]

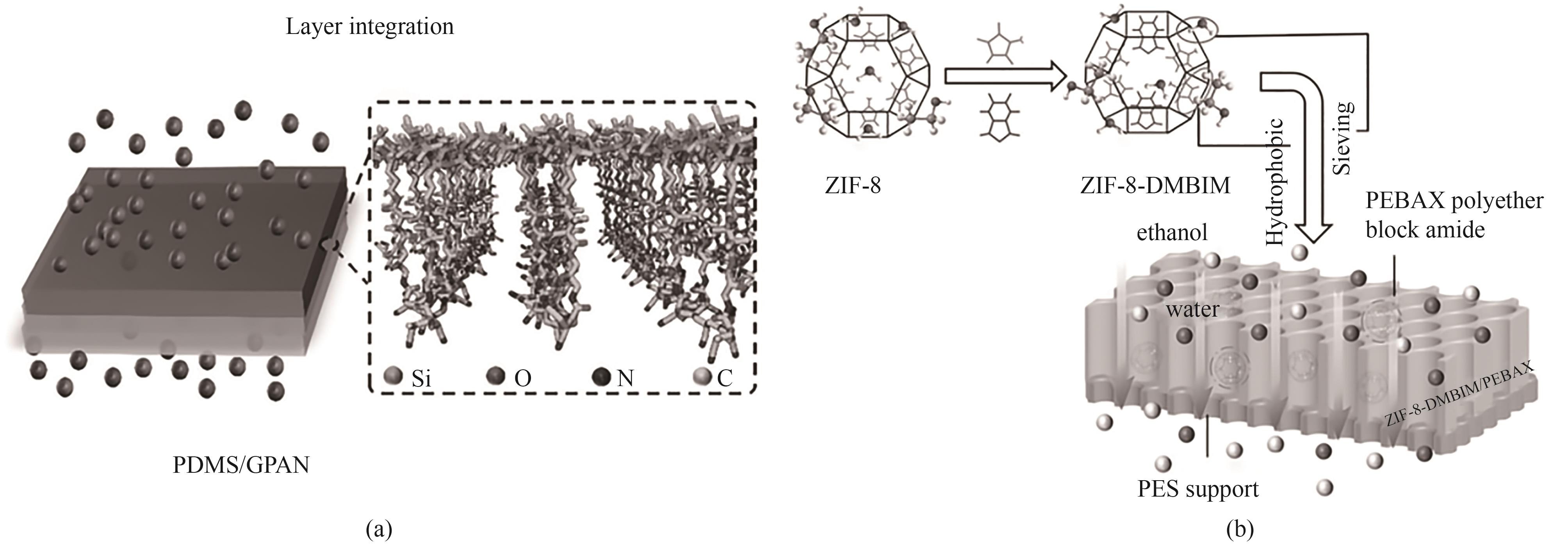

图7 (a)PDMS/GPAN膜结构示意[8];(b)ZIF-8-DMBIM/PEBAX膜制备流程示意[11]

Fig.7 (a) PDMS/GPAN membrane structure diagram[8]; (b) Schematic diagram of ZIF-8-DMBIM/PEBAX membrane preparation process[11]

| 膜 | 温度/℃ | 进料浓度/%(质量分数) | 回收溶剂 | 分离因子 | 渗透通量/(g/(m2·h)) | 文献 |

|---|---|---|---|---|---|---|

| POSS/PDMS | 50 | 10 | 乙醇 | 17.7 | 536 | [ |

| PVTES-HSO | 35 | 9 | 乙醇 | 6.6 | 8160 | [ |

| TMSC/PDMS | 24 | 5 | 乙醇 | 14 | 1600 | [ |

| UiO-66-NH2-TMS/PDMS | 40 | 5 | 乙醇 | 5.8 | 5277.9 | [ |

| 1173IPS-MA/PDMS | 40 | 5 | 乙醇 | 8.4 | 930 | [ |

| PMHS/PDMS | 60 | 5 | 乙醇 | 12 | 1204 | [ |

| MAF-6/PDMS | 40 | 5 | 乙醇 | 14.9 | 1200 | [ |

| LZU8/PDMS | 60 | 5 | 乙醇 | 11 | 5000 | [ |

| LDDLT-ZIF-L/PDMS | 40 | 5 | 乙醇 | 12.3 | 1120 | [ |

| MIL-53/PDMS | 70 | 5 | 乙醇 | 11.1 | 5467 | [ |

| DMDES/PDMS | 35 | 5 | 乙醇 | 6.5 | 7565.6 | [ |

| MOF-NS/PDMS | 40 | 5 | 乙醇 | 8.9 | 6800 | [ |

| Suspension-dispersed ZIF-8/PDMS | 40 | 5 | 丁醇 | 34 | 1358 | [ |

| PDMS-PMHS/ZIF-8 | 60 | 3 | 丁醇 | 64.59 | 2334.6 | [ |

| COF-LZU1/PEBA | 70 | 3.7 | 丁醇 | 22.2 | 611 | [ |

| PIM-1/PVDF 18-A3 (2% PIM-1) | 65 | 6 | 丁醇 | 13.3 | 9080 | [ |

| PIM-1/PDMS | 60 | 1 | 丁醇 | 30.7 | 1425.3 | [ |

| TAO/ZIF-8/K-PDMS | 70 | 1 | 丁醇 | 40.3 | 2890 | [ |

| PDMS/P-ZNC | 60 | 1 | 丁醇 | 40.7 | 1035.4 | [ |

| ZIF-8@ABT/PDMS | 70 | 1 | 丁醇 | 44 | 1074 | [ |

| ILTf2N@MIL-101/PEBA | 30 | 5 | 乙酸乙酯 | 207.6 | 2354 | [ |

| PEBA/ZSM-5-10 | 50 | 5 | 乙酸乙酯 | 185.5 | 199.5 | [ |

| PAN-C3-P3 | 50 | 1 | 乙酸乙酯 | 70 | 7850 | [ |

| 3%ZIF-67/ PVDF | 30 | 1.5 | 甲苯 | 41.2 | 467.6 | [ |

表2 聚合物基疏水渗透汽化膜在溶剂回收方面的应用

Table 2 Application of polymer-based hydrophobic pervaporation membranes in solvent recovery

| 膜 | 温度/℃ | 进料浓度/%(质量分数) | 回收溶剂 | 分离因子 | 渗透通量/(g/(m2·h)) | 文献 |

|---|---|---|---|---|---|---|

| POSS/PDMS | 50 | 10 | 乙醇 | 17.7 | 536 | [ |

| PVTES-HSO | 35 | 9 | 乙醇 | 6.6 | 8160 | [ |

| TMSC/PDMS | 24 | 5 | 乙醇 | 14 | 1600 | [ |

| UiO-66-NH2-TMS/PDMS | 40 | 5 | 乙醇 | 5.8 | 5277.9 | [ |

| 1173IPS-MA/PDMS | 40 | 5 | 乙醇 | 8.4 | 930 | [ |

| PMHS/PDMS | 60 | 5 | 乙醇 | 12 | 1204 | [ |

| MAF-6/PDMS | 40 | 5 | 乙醇 | 14.9 | 1200 | [ |

| LZU8/PDMS | 60 | 5 | 乙醇 | 11 | 5000 | [ |

| LDDLT-ZIF-L/PDMS | 40 | 5 | 乙醇 | 12.3 | 1120 | [ |

| MIL-53/PDMS | 70 | 5 | 乙醇 | 11.1 | 5467 | [ |

| DMDES/PDMS | 35 | 5 | 乙醇 | 6.5 | 7565.6 | [ |

| MOF-NS/PDMS | 40 | 5 | 乙醇 | 8.9 | 6800 | [ |

| Suspension-dispersed ZIF-8/PDMS | 40 | 5 | 丁醇 | 34 | 1358 | [ |

| PDMS-PMHS/ZIF-8 | 60 | 3 | 丁醇 | 64.59 | 2334.6 | [ |

| COF-LZU1/PEBA | 70 | 3.7 | 丁醇 | 22.2 | 611 | [ |

| PIM-1/PVDF 18-A3 (2% PIM-1) | 65 | 6 | 丁醇 | 13.3 | 9080 | [ |

| PIM-1/PDMS | 60 | 1 | 丁醇 | 30.7 | 1425.3 | [ |

| TAO/ZIF-8/K-PDMS | 70 | 1 | 丁醇 | 40.3 | 2890 | [ |

| PDMS/P-ZNC | 60 | 1 | 丁醇 | 40.7 | 1035.4 | [ |

| ZIF-8@ABT/PDMS | 70 | 1 | 丁醇 | 44 | 1074 | [ |

| ILTf2N@MIL-101/PEBA | 30 | 5 | 乙酸乙酯 | 207.6 | 2354 | [ |

| PEBA/ZSM-5-10 | 50 | 5 | 乙酸乙酯 | 185.5 | 199.5 | [ |

| PAN-C3-P3 | 50 | 1 | 乙酸乙酯 | 70 | 7850 | [ |

| 3%ZIF-67/ PVDF | 30 | 1.5 | 甲苯 | 41.2 | 467.6 | [ |

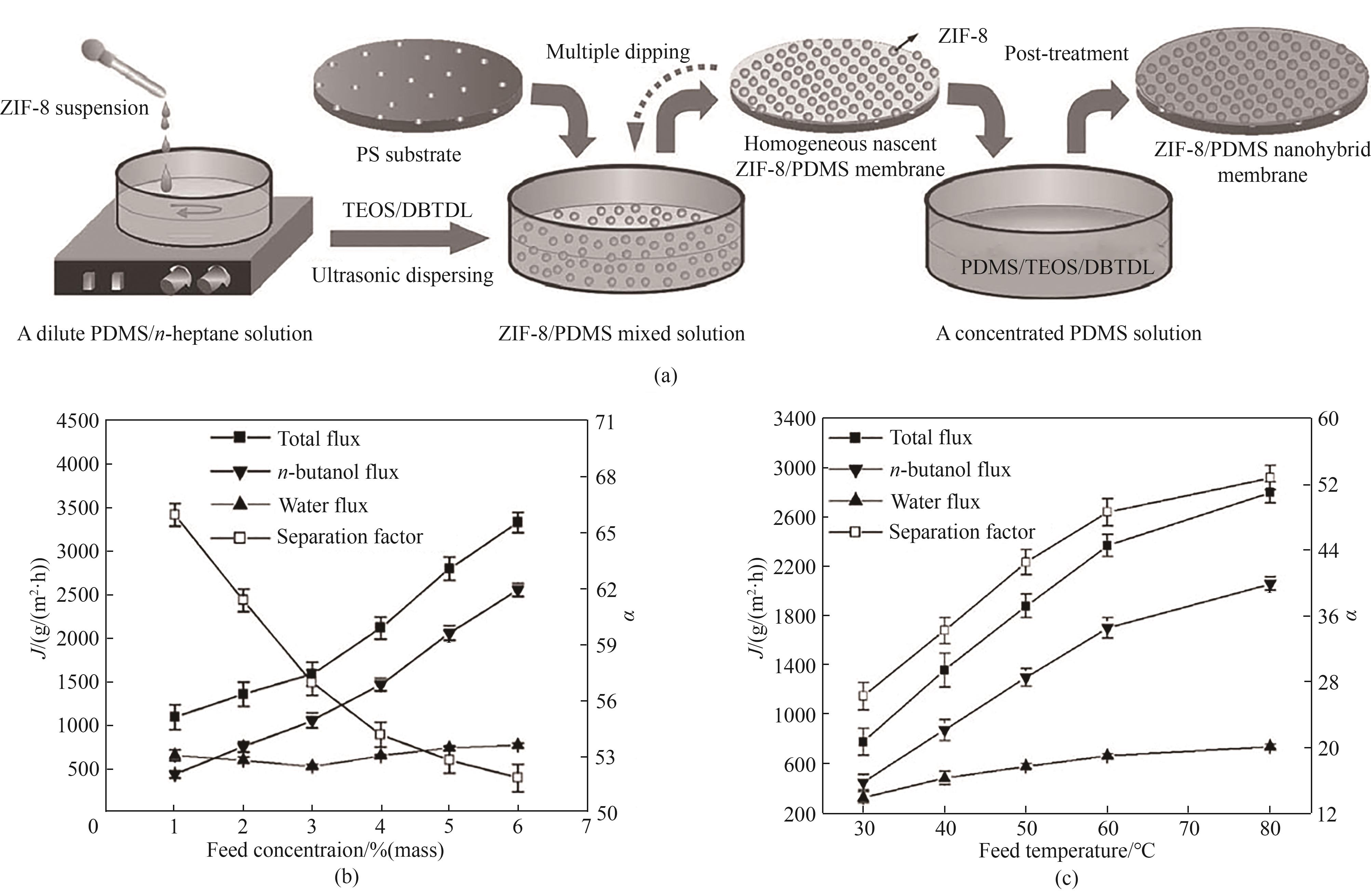

图8 (a)悬浮分散ZIF-8/PDMS混合基质膜的制备示意;进料浓度(b)和温度(c)对渗透汽化性能的影响[52]

Fig.8 (a) Preparation diagram of suspended dispersed ZIF-8/PDMS mixed matrix membrane; Influence of feed concentration (b) and temperature (c) on pervaporation performance[52]

| 1 | Park H B, Kamcev J, Robeson L M, et al. Maximizing the right stuff: the trade-off between membrane permeability and selectivity[J]. Science, 2017, 356(6343): eaab0530. |

| 2 | Wang Q, Qian C, Li Y N, et al. Preparation and application of highly oriented MFI zeolite membranes for efficient pervaporation recovery of organic solvents[J]. Journal of Membrane Science, 2024, 709: 123117. |

| 3 | 赵静, 金万勤. 基于三维多孔填料的聚二甲基硅氧烷混合基质渗透汽化膜研究进展[J]. 华东理工大学学报(自然科学版), 2024, 50(5): 633-644. |

| Zhao J, Jin W Q. Research progress of polydimethylsiloxane mixed matrix pervaporation membranes based on three-dimensional porous fillers[J]. Journal of East China University of Science and Technology, 2024, 50(5): 633-644. | |

| 4 | Jia Z Q, Wu G R. Metal-organic frameworks based mixed matrix membranes for pervaporation[J]. Microporous and Mesoporous Materials, 2016, 235: 151-159. |

| 5 | Xu X, Nikolaeva D, Hartanto Y, et al. MOF-based membranes for pervaporation[J]. Separation and Purification Technology, 2021, 278: 119233. |

| 6 | 张浩, 伍艳辉. MOF-聚合物混合基质膜的制备、改性及其在渗透汽化中的应用[J]. 化学进展, 2023, 35(8): 1154-1167. |

| Zhang H, Wu Y H. Preparation and modification of MOF-polymer mixed matrix membrane and its application in pervaporation[J]. Progress in Chemistry, 2023, 35(8): 1154-1167. | |

| 7 | 李妍, 吴芹, 陈康成, 等. 聚酰亚胺渗透汽化膜用于有机溶剂脱水的改性研究进展[J]. 化工进展, 2024, 43(6): 2915-2927. |

| Li Y, Wu Q, Chen K C, et al. Modified polyimide pervaporation membranes for dehydration of organic solvent[J]. Chemical Industry and Engineering Progress, 2024, 43(6): 2915-2927. | |

| 8 | Sang C, Zhang S Y, Si Z H, et al. Design of PDMS/PAN composite membranes with ultra-interfacial stability via layer integration[J]. Materials Horizons, 2024, 11(19): 4681-4688. |

| 9 | Grimaldi J, Imbrogno J, Kilduff J C, et al. New class of synthetic membranes: organophilic pervaporation brushes for organics recovery[J]. Chemistry of Materials, 2015, 27(11): 4142-4148. |

| 10 | 张琪, 王泽众, 李盈莹, 等. 用于醇脱水的渗透汽化有机膜的改性研究进展[J]. 膜科学与技术, 2023, 43(4): 184-195. |

| Zhang Q, Wang Z Z, Li Y Y, et al. Research progress in the modification of pervaporation organic membranes for alcohol dehydration[J]. Membrane Science and Technology, 2023, 43(4): 184-195. | |

| 11 | Xiong Y, Shu Y F, Deng N Y, et al. A novel modified ZIF-8 nanoparticle with enhanced interfacial compatibility and pervaporation performance in a mixed matrix membrane for de-alcoholization in low-concentration solutions[J]. Molecules, 2024, 29(18): 4465. |

| 12 | Luo R W, Fu H Y, Li Y L, et al. In situ fabrication of metal-organic framework thin films with enhanced pervaporation performance[J]. Advanced Functional Materials, 2023, 33(18): 2213221. |

| 13 | Li W B, Su P C, Li Z J, et al. Ultrathin metal-organic framework membrane production by gel-vapour deposition[J]. Nature Communications,2017, 8: 406. |

| 14 | Li W B, Zhang Y F, Zhang C Y, et al. Transformation of metal-organic frameworks for molecular sieving membranes[J]. Nature Communications, 2016, 7: 11315. |

| 15 | Choudhury S, Ray S K. Synthesis of polymer nanoparticles based highly selective membranes by mini-emulsion polymerization for dehydration of 1,4-dioxane and recovery of ethanol from water by pervaporation[J]. Journal of Membrane Science, 2021, 617: 118646. |

| 16 | Si Z H, Wu H Z, Qin P Y, et al. Polydimethylsiloxane based membranes for biofuels pervaporation[J]. Separation and Purification Technology, 2022, 298: 121612. |

| 17 | Lin Z H, Yuan Z Y, Dai Z D, et al. A review from material functionalization to process feasibility on advanced mixed matrix membranes for gas separations[J]. Chemical Engineering Journal, 2023, 475: 146075. |

| 18 | Ryder M R, Zeng Z X, Sun Y T, et al. Dielectric properties of metal-organic frameworks probed via synchrotron infrared reflectivity[J/OL]. arXiv, 2018: 1802.06702. . |

| 19 | Khan A, Ali M, Ilyas A, et al. ZIF-67 filled PDMS mixed matrix membranes for recovery of ethanol via pervaporation[J]. Separation and Purification Technology, 2018, 206: 50-58. |

| 20 | He C T, Jiang L, Ye Z M, et al. Exceptional hydrophobicity of a large-pore metal-organic zeolite[J]. Journal of the American Chemical Society, 2015, 137(22): 7217-7223. |

| 21 | Knozowska K, Thür R, Kujawa J, et al. Fluorinated MOF-808 with various modulators to fabricate high-performance hybrid membranes with enhanced hydrophobicity for organic-organic pervaporation[J]. Separation and Purification Technology, 2021, 264: 118315. |

| 22 | Chanut N, Ghoufi A, Coulet M V, et al. Tailoring the separation properties of flexible metal-organic frameworks using mechanical pressure[J]. Nature Communications, 2020, 11(1): 1216. |

| 23 | Férey G, Mellot-Draznieks C, Serre C, et al. A chromium terephthalate-based solid with unusually large pore volumes and surface area[J]. Science, 2005, 309(5743): 2040-2042. |

| 24 | Wu Y X, Tian Y H, He X P, et al. Preparation of covalent organic framework/PDMS mixed matrix membranes for efficient ethanol recovery via pervaporation[J]. Industrial & Engineering Chemistry Research, 2024, 63(45): 19756-19766. |

| 25 | Guo H K, Fang Y J, Li J Q, et al. Continuous covalent organic framework membranes with ordered nanochannels as tunable transport layers for fast butanol/water separation[J]. Nano Letters, 2024, 24(37): 11438-11445. |

| 26 | Du J, Liang S W, Wang M D, et al. Metal-covalent organic framework nanosheets engineered facilitated transport membranes for toluene/n-heptane separation[J]. Journal of Membrane Science, 2023, 683: 121840. |

| 27 | Banjerdteerakul K, Peng H, Li K. Covalent organic frameworks based membranes for separation of azeotropic solvent mixtures by pervaporation[J]. Journal of Membrane Science, 2023, 678: 121679. |

| 28 | Zhang L L, Wang L, Wang N X, et al. Covalent organic frameworks hybird membrane with optimized mass transport nanochannel for aromatic/aliphatic mixture pervaporation[J]. Journal of Membrane Science, 2020, 598: 117652. |

| 29 | Fan H W, Xie Y F, Li J C, et al. Ultra-high selectivity COF-based membranes for biobutanol production[J]. Journal of Materials Chemistry A, 2018, 6(36): 17602-17611. |

| 30 | Feng X Q, Zhu J Y, Jin J, et al. Polymers of intrinsic microporosity for membrane-based precise separations[J]. Progress in Materials Science, 2024, 144: 101285. |

| 31 | Zhuang Y, Si Z H, Pang S Y, et al. Recent progress in pervaporation membranes for furfural recovery: a mini review[J]. Journal of Cleaner Production, 2023, 396: 136481. |

| 32 | Fatima S, Govardhan B, Kalyani S, et al. Extraction of volatile organic compounds from water and wastewater by vacuum-driven membrane process: a comprehensive review[J]. Chemical Engineering Journal, 2022, 434: 134664. |

| 33 | Zhou L, Li S Y, Chen L, et al. MOFs and COFs based pervaporation membranes for alcohols/water separation: a review[J]. Separation and Purification Technology, 2024, 330: 125324. |

| 34 | Liu H X, Wang N X, Zhao C, et al. Membrane materials in the pervaporation separation of aromatic/aliphatic hydrocarbon mixtures: a review[J]. Chinese Journal of Chemical Engineering, 2018, 26(1): 1-16. |

| 35 | Jia W, Sun W, Xia C J, et al. Copolymerization modification of poly(vinyltriethoxysilane) membranes for ethanol recovery by pervaporation[J]. RSC Advances, 2017, 7(86): 54441-54452. |

| 36 | Yin H D, Cay-Durgun P, Lai T M, et al. Effect of ZIF-71 ligand-exchange surface modification on biofuel recovery through pervaporation[J]. Polymer, 2020, 195: 122379. |

| 37 | Xu L H, Li S H, Mao H, et al. Highly flexible and superhydrophobic MOF nanosheet membrane for ultrafast alcohol-water separation[J]. Science, 2022, 378(6617): 308-313. |

| 38 | Chen X L, Li N, Wu C Y, et al. Enhancing pervaporation performance for alcohol recovery from aqueous solutions with silicalite-1/polydimethyldiethoxysilane (PDMDES) nanocomposite membranes[J]. Industrial & Engineering Chemistry Research, 2024, 63(1): 508-524. |

| 39 | Si Z H, Li G Z, Wang Z, et al. A particle-driven, ultrafast-cured strategy for tuning the network cavity size of membranes with outstanding pervaporation performance[J]. ACS Applied Materials & Interfaces, 2020, 12(28): 31887-31895. |

| 40 | Liu S, Liu G Z, Zhao B J, et al. Methanol/dimethyl carbonate separation using graphene oxide membrane via cationic control of molecular transport channels[J]. Journal of Membrane Science, 2022, 650: 120457. |

| 41 | Zhang X, Xiao L L, Zhang G L, et al. Preparation of stable multilayer PDMS composite pervaporation membrane incorporated with in situ transformed metal organic frameworks for enhanced butanol recovery[J]. Journal of Membrane Science, 2024, 700: 122727. |

| 42 | Wang H, Tang S H, Ni Y X, et al. Covalent cross-linking for interface engineering of high flux UiO-66-TMS/PDMS pervaporation membranes[J]. Journal of Membrane Science, 2020, 598: 117791. |

| 43 | Zhan X, Wang M Y, Gao T, et al. A highly selective sorption process in POSS-g-PDMS mixed matrix membranes for ethanol recovery via pervaporation[J]. Separation and Purification Technology, 2020, 236: 116238. |

| 44 | Puspasari T, Chakrabarty T, Genduso G, et al. Unique cellulose/polydimethylsiloxane blends as an advanced hybrid material for organic solvent nanofiltration and pervaporation membranes[J]. Journal of Materials Chemistry A, 2018, 6(28): 13685-13695. |

| 45 | Si Z H, Liu C, Xue T L, et al. Polymeric membranes through self-initiation and self-polymerization for high-performance bioethanol pervaporation[J]. Journal of Materials Chemistry A, 2022, 10(34): 17699-17709. |

| 46 | Fan H W, Wang R, Shan L L, et al. One-step assembly of molecular separation membranes by direct atomizing oligomers[J]. ACS Applied Materials & Interfaces, 2017, 9(4): 4074-4083. |

| 47 | Li Q Q, Cheng L, Shen J, et al. Improved ethanol recovery through mixed-matrix membrane with hydrophobic MAF-6 as filler[J]. Separation and Purification Technology, 2017, 178: 105-112. |

| 48 | Song D Y, Li C, Li J, et al. Incorporating COFs into PDMS matrix for accelerated crosslinking and efficient ethanol recovery[J]. Journal of Membrane Science, 2024, 696: 122529. |

| 49 | Pei C, Mao H, Wang Y J, et al. Boosting pervaporation performance of ZIF-L/PDMS mixed matrix membranes by surface plasma etching for ethanol/water separation[J]. Separation and Purification Technology, 2023, 318: 124025. |

| 50 | Zhang G J, Li J, Wang N X, et al. Enhanced flux of polydimethylsiloxane membrane for ethanol permselective pervaporation via incorporation of MIL-53 particles[J]. Journal of Membrane Science, 2015, 492: 322-330. |

| 51 | Jia W, Sun W, Yu Y P, et al. Low-surface-energy monomer for ultrathin silicone membrane fabrication: towards enhanced ethanol/water pervaporation performance[J]. Separation and Purification Technology, 2019, 222: 361-368. |

| 52 | Fan H W, Wang N X, Ji S L, et al. Nanodisperse ZIF-8/PDMS hybrid membranes for biobutanol permselective pervaporation[J]. Journal of Materials Chemistry A, 2014, 2(48): 20947-20957. |

| 53 | Fan H W, Shan L L, Meng H, et al. High-throughput production of nanodisperse hybrid membranes on various substrates[J]. Journal of Membrane Science, 2018, 552: 177-188. |

| 54 | Si Z H, Cai D, Li S F, et al. Carbonized ZIF-8 incorporated mixed matrix membrane for stable ABE recovery from fermentation broth[J]. Journal of Membrane Science, 2019, 579: 309-317. |

| 55 | Wu G R, Li Y L, Geng Y Z, et al. In situ preparation of COF-LZU1 in poly(ether-block-amide) membranes for efficient pervaporation of n-butanol/water mixture[J]. Journal of Membrane Science, 2019, 581: 1-8. |

| 56 | Gao L, Alberto M, Gorgojo P, et al. High-flux PIM-1/PVDF thin film composite membranes for 1-butanol/water pervaporation[J]. Journal of Membrane Science, 2017, 529: 207-214. |

| 57 | Zhang X, Tong Z W, Liu C, et al. Functionalized MOF-derived nanoporous carbon as compatible nanofiller to fabricate defect-free PDMS-based mixed matrix pervaporation membranes[J]. ACS Omega, 2022, 7(18): 15786-15794. |

| 58 | Zhang X, Liu F Z, Xu L S, et al. Heterostructured ZIF-8/lamellar talc composites incorporated polydimethylsiloxane membrane with enhanced separation performance for butanol recovery[J]. Journal of Membrane Science, 2022, 650: 120433. |

| 59 | Zhang A S, Li S H, Ahmad A, et al. Coordinate covalent grafted ILs-modified MIL-101/PEBA membrane for pervaporation: adsorption simulation and separation characteristics[J]. Journal of Membrane Science, 2021, 619: 118807. |

| 60 | Gu J, Zhang X R, Bai Y X, et al. ZSM-5 filled polyether block amide membranes for separating EA from aqueous solution by pervaporation[J]. International Journal of Polymer Science, 2013, 2013(1): 760156. |

| 61 | Wu H H, Shen F, Su Y, et al. Modification of polyacrylonitrile membranes via plasma treatment followed by polydimethylsiloxane coating for recovery of ethyl acetate from aqueous solution through vacuum membrane distillation[J]. Separation and Purification Technology, 2018, 197: 178-188. |

| 62 | Kachhadiya D D, Murthy Z V P. Microfluidic synthesized ZIF-67 decorated PVDF mixed matrix membranes for the pervaporation of toluene/water mixtures[J]. Journal of Membrane Science, 2023, 676: 121607. |

| 63 | Naik P V, Wee L H, Meledina M, et al. PDMS membranes containing ZIF-coated mesoporous silica spheres for efficient ethanol recovery via pervaporation[J]. Journal of Materials Chemistry A, 2016, 4(33): 12790-12798. |

| 64 | Zhang G L, Cheng H F, Su P C, et al. PIM-1/PDMS hybrid pervaporation membrane for high-efficiency separation of n-butanol-water mixture under low concentration[J]. Separation and Purification Technology, 2019, 216: 83-91. |

| 65 | Zhu H P, Li R H, Liu G Z, et al. Efficient separation of methanol/dimethyl carbonate mixtures by UiO-66 MOF incorporated chitosan mixed-matrix membrane[J]. Journal of Membrane Science, 2022, 652: 120473. |

| 66 | Matavos-Aramyan S, Bagheri G, Jazebizadeh M H. Pervaporation separation of toluene from aqueous solutions using nano-based PEBA/NaX mixed matrix membrane[J]. Silicon, 2019, 11(4): 1725-1730. |

| 67 | Sun Y, Zhao H H, Mao H, et al. Silica hollow spheres-based superhydrophobic PDMS composite membrane for enhanced acetone permselective pervaporation[J]. Separation and Purification Technology, 2023, 304: 122041. |

| 68 | Kim H J, Brunelli N A, Brown A J, et al. Silylated mesoporous silica membranes on polymeric hollow fiber supports: synthesis and permeation properties[J]. ACS Applied Materials & Interfaces, 2014, 6(20): 17877-17886. |

| 69 | Chen X L, Zhou Q L, Zhang Y F, et al. Incorporating mixed-ligand zeolitic imidazolate framework into polydimethyldiethoxysilane (PDMDES) membrane for enhancing alcohol pervaporation recovery[J]. ACS Applied Materials & Interfaces, 2024, 16(48): 66594-66610. |

| 70 | Chen X L, Zhou Q L, Chen L Y, et al. Facile preparation of thin and nanodisperse ZIF-8/PDMDES hybrid membrane for efficient alcohol recovery via pervaporation[J]. Chemical Engineering Research and Design, 2024, 206: 27-42. |

| 71 | Ren C, Si Z H, Qu Y X, et al. CF3-MOF enhanced pervaporation selectivity of PDMS membranes for butanol separation[J]. Separation and Purification Technology, 2022, 284: 120255. |

| 72 | Han W T, Han Z W, Gao X C, et al. Inter-integration reactive distillation with vapor permeation for ethyl levulinate production: equipment development and experimental validating[J]. AIChE Journal, 2022, 68(2): e17441. |

| 73 | Le Hir M, Magne A, Clair T, et al. Solvent regeneration in complex mixture using pervaporation[J]. Organic Process Research & Development, 2021, 25(3): 469-485. |

| 74 | Nishiyama S, Kimura N, Hirai T, et al. Concentrating isopropanol using a pervaporation pilot-scale system and simulating membrane performance in a single-stage process[J]. Industrial & Engineering Chemistry Research, 2023, 62(36): 14611-14619. |

| 75 | Sun X F, Dang G F, Ding X B, et al. Production of alcohol-free wine and grape spirit by pervaporation membrane technology[J]. Food and Bioproducts Processing, 2020, 123: 262-273. |

| [1] | 郭彭涛, 王婷, 薛波, 应允攀, 刘大欢. 用于CH4/N2分离的多吸附位点超微孔MOF[J]. 化工学报, 2025, 76(5): 2304-2312. |

| [2] | 李紫鹃, 谭晓艳, 吴永盛, 杨陈怡, 陈红, 毕小刚, 刘捷, 喻发全. 分子模拟研究三维扭曲催化芳烃-降冰片烯环化聚合物膜的CO2/N2分离机理[J]. 化工学报, 2025, 76(5): 2348-2357. |

| [3] | 花敬贤, 罗宇荣, 顾亚伟, 吴婷婷, 潘宜昌, 邢卫红. 超薄取向ZIF-8膜的制备及乙烯/乙烷高效分离[J]. 化工学报, 2025, 76(5): 2209-2218. |

| [4] | 李艳, 雷美丽, 李鑫钢. 基于分离性能的顺序式模拟移动床结构调控策略[J]. 化工学报, 2025, 76(5): 2219-2229. |

| [5] | 刘鑫, 郑皓仁, 陈强, 丁静怡, 黄康, 徐至. 全钒液流电池用纤维素纳米晶掺杂混合基质膜[J]. 化工学报, 2025, 76(5): 2294-2303. |

| [6] | 巴雅琪, 吴涛, 邸安頔, 陆安慧. 多孔炭材料用于低碳烃分离的研究进展[J]. 化工学报, 2025, 76(5): 2136-2157. |

| [7] | 谈朋, 李雪梅, 刘晓勤, 孙林兵. 基于柔性MOFs的磁响应复合材料及其丙烯吸附性能研究[J]. 化工学报, 2025, 76(5): 2230-2240. |

| [8] | 向昕辰, 鲁丹, 赵影, 姚之侃, 寇瑞强, 郑丹军, 周志军, 张林. 聚酰胺纳滤膜表面季铵化提高荷正电性及其锂镁分离性能[J]. 化工学报, 2025, 76(5): 2377-2386. |

| [9] | 王金月, 谢恩泽, 马翰泽, 袁晟, 何光伟, 姜忠义. 单原子层分离膜:进展与展望[J]. 化工学报, 2025, 76(5): 1943-1959. |

| [10] | 陆艳秋, 狄扬, 石文博, 殷聪聪, 汪勇. 基于新型有机多孔聚合物的智能响应膜研究进展[J]. 化工学报, 2025, 76(5): 2101-2118. |

| [11] | 陶春珲, 李印辉, 傅钰, 段然, 赵泽一, 唐羽丰, 张罡, 马和平. 不同吸附剂对低浓度Kr气的选择性吸附与纯化[J]. 化工学报, 2025, 76(5): 2358-2366. |

| [12] | 刘雨, 蔡振波, 纪利俊, 马晓华. ZIF-67/PDMS复合膜分离废次烟草的中性香气组分[J]. 化工学报, 2025, 76(5): 2337-2347. |

| [13] | 赵浩帆, 任豪杰, 刘宗凯, 董冠英, 张亚涛. MOFs玻璃膜在气体分离领域的研究进展[J]. 化工学报, 2025, 76(5): 2042-2054. |

| [14] | 张越, 刘佳鑫, 马敬, 刘毅. 金属有机骨架膜应用于海水提铀研究进展[J]. 化工学报, 2025, 76(5): 2087-2100. |

| [15] | 李家顺, 李旺, 秦祖赠, 苏通明, 谢新玲, 纪红兵. 聚酰亚胺增强木质纤维素纳米纤丝气凝胶制备及其油水分离性能研究[J]. 化工学报, 2025, 76(5): 2169-2185. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号