化工学报 ›› 2025, Vol. 76 ›› Issue (4): 1809-1819.DOI: 10.11949/0438-1157.20240930

张忠州1( ), 李怡霏1(

), 李怡霏1( ), 陈双1,2, 强军锋2, 刘育红1(

), 陈双1,2, 强军锋2, 刘育红1( )

)

收稿日期:2024-08-15

修回日期:2024-11-15

出版日期:2025-04-25

发布日期:2025-05-12

通讯作者:

刘育红

作者简介:张忠州(1995—),男,博士研究生,707464656@qq.com

Zhongzhou ZHANG1( ), Yifei LI1(

), Yifei LI1( ), Shuang CHEN1,2, Junfeng QIANG2, Yuhong LIU1(

), Shuang CHEN1,2, Junfeng QIANG2, Yuhong LIU1( )

)

Received:2024-08-15

Revised:2024-11-15

Online:2025-04-25

Published:2025-05-12

Contact:

Yuhong LIU

摘要:

热塑性酚醛树脂(NR)的性能与其交联网络结构密切相关,多领域应用对NR的性能提出了更高的要求,然而NR的强度、玻璃化转变温度(Tg)与韧性的提升存在着矛盾,同时提高NR的强度、韧性和Tg仍然面临着挑战。通过环氧基低聚倍半硅氧烷(EPOSS)和联苯酚醛树脂(BN)反应制备了改性剂BEP,与树脂构建了具有不均一交联结构的BEP+NR共固化网络,实现了树脂强度和韧性的提升,在此基础上对BEP+NR体系的固化特性进行了动力学研究,通过调控BEP的均聚、BEP和NR的共固化以及NR的固化得到了致密的不均一交联网络。1BEP+NR固化物的Tg、弯曲强度、冲击强度分别达到146.3℃、4.1 kJ/m2、76.5 MPa,相比NR分别提高10.9℃、78.2%、50.9%。随着BEP均聚程度的增加,交联网络的不均一性进一步增加,BEP+NR的力学性能、热稳定性和Tg降低。

中图分类号:

张忠州, 李怡霏, 陈双, 强军锋, 刘育红. 环氧基倍半硅氧烷修饰的联苯酚醛改性热塑性酚醛树脂性能[J]. 化工学报, 2025, 76(4): 1809-1819.

Zhongzhou ZHANG, Yifei LI, Shuang CHEN, Junfeng QIANG, Yuhong LIU. Properties of epoxy polyhedral oligosiloxanes decorative biphenyl phenolics modified novolac resin[J]. CIESC Journal, 2025, 76(4): 1809-1819.

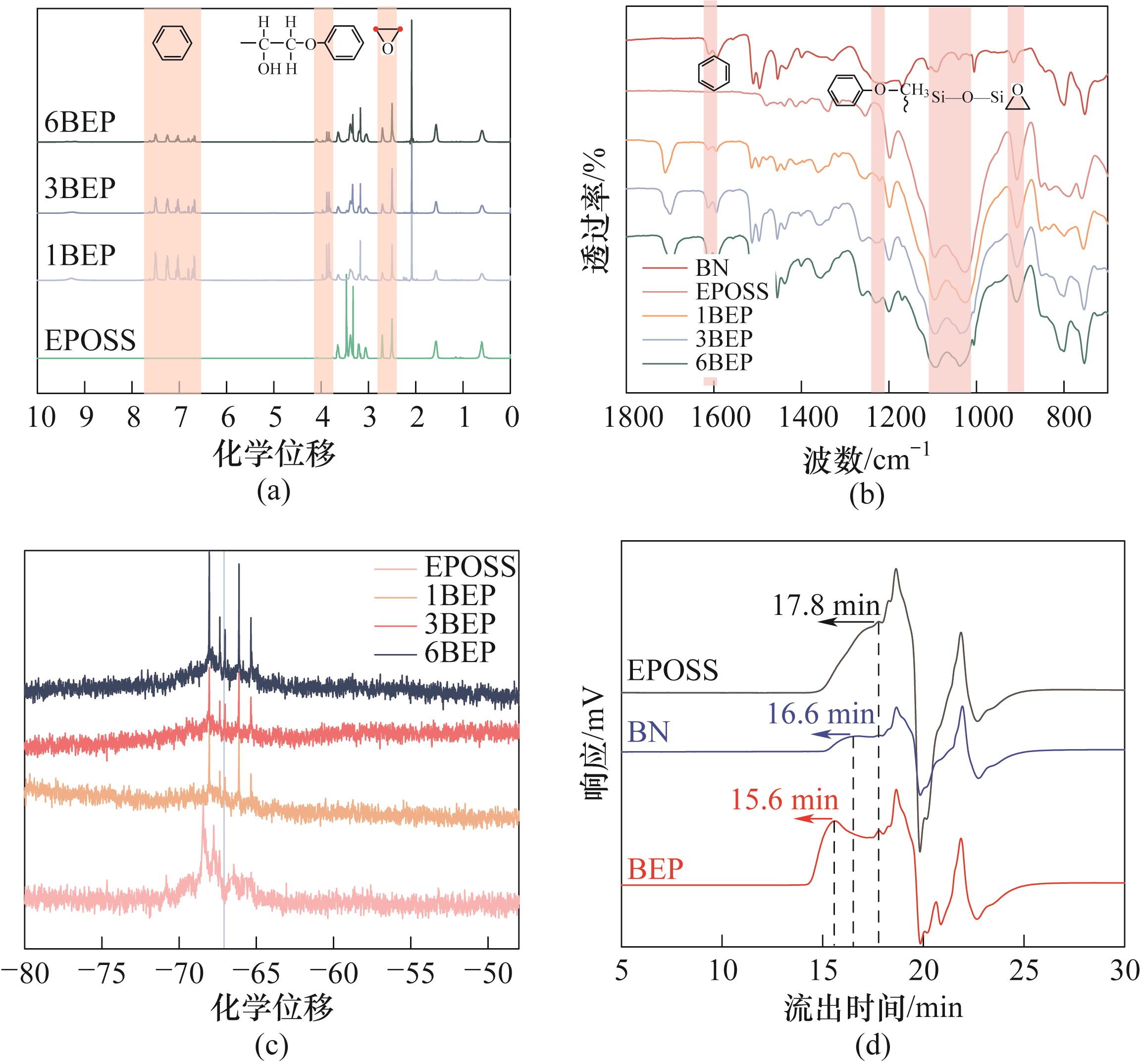

图2 (a)EPOSS和BEP的1H NMR曲线;(b)BN、BEP和EPOSS的FT-IR曲线;(c)EPOSS和BEP的29Si NMR曲线;(d)EPOSS、BN和BEP的GPC曲线

Fig.2 (a) 1H NMR curves of EPOSS and BEP; (b) FT-IR curves of BN, BEP and EPOSS; (c) 29Si NMR curves of EPOSS and BEP; (d) GPC curves of EPOSS, BN and BEP

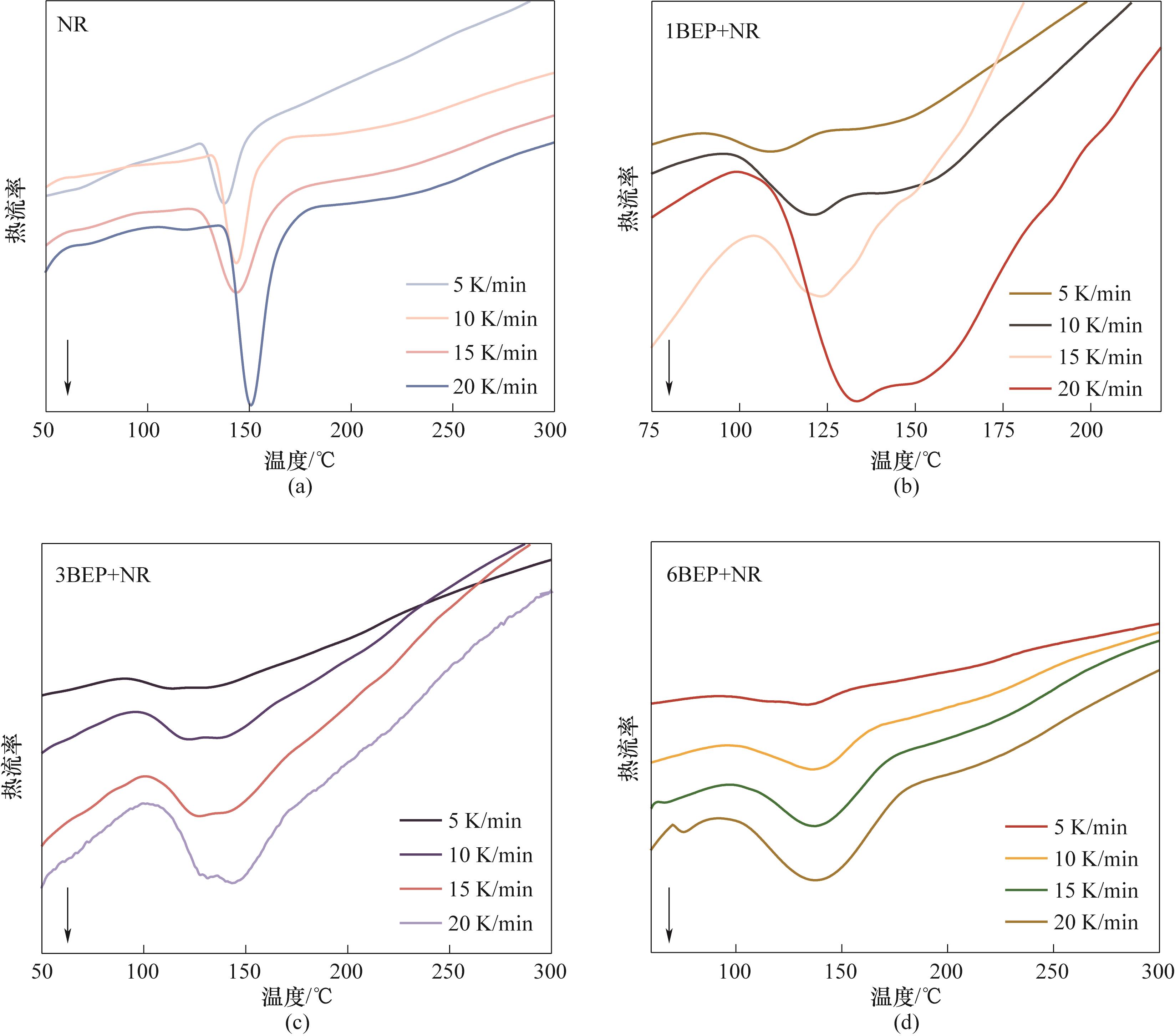

图3 NR(a)、1BEP+NR(b)、3BEP+NR(c)和6BEP+NR(d)在不同升温速率下的DSC曲线

Fig.3 DSC curves of NR (a), 1BEP+NR (b), 3BEP+NR (c) and 6BEP+NR (d) under different heating rates

| 样品 | β/(K/min) | Ti/℃ | Td/℃ | ΔT/℃ |

|---|---|---|---|---|

| NR | 5 | 123.7 | 153.7 | 30.0 |

| 10 | 130.2 | 168.8 | 38.6 | |

| 15 | 126.7 | 177.7 | 51.0 | |

| 20 | 131.6 | 185.2 | 53.6 | |

| 1BEP+NR | 5 | 93.1 | 180.9 | 87.8 |

| 10 | 99.6 | 188.6 | 89.0 | |

| 15 | 102.6 | 197.7 | 95.1 | |

| 20 | 103.6 | 211.6 | 108.0 | |

| 3BEP+NR | 5 | 91.3 | 173.5 | 82.2 |

| 10 | 97.2 | 176.8 | 79.6 | |

| 15 | 102.6 | 201.3 | 98.7 | |

| 20 | 104.8 | 203.2 | 98.4 | |

| 6BEP+NR | 5 | 87.6 | 170.2 | 82.6 |

| 10 | 94.1 | 184.4 | 90.3 | |

| 15 | 98.7 | 180.9 | 82.2 | |

| 20 | 100.5 | 194.1 | 93.6 |

表1 NR、1BEP+NR、3BEP+NR和6BEP+NR在不同升温速率下的DSC特征参数

Table 1 DSC parameters of NR, 1BEP+NR, 3BEP+NR and 6BEP+NR under different heating rates

| 样品 | β/(K/min) | Ti/℃ | Td/℃ | ΔT/℃ |

|---|---|---|---|---|

| NR | 5 | 123.7 | 153.7 | 30.0 |

| 10 | 130.2 | 168.8 | 38.6 | |

| 15 | 126.7 | 177.7 | 51.0 | |

| 20 | 131.6 | 185.2 | 53.6 | |

| 1BEP+NR | 5 | 93.1 | 180.9 | 87.8 |

| 10 | 99.6 | 188.6 | 89.0 | |

| 15 | 102.6 | 197.7 | 95.1 | |

| 20 | 103.6 | 211.6 | 108.0 | |

| 3BEP+NR | 5 | 91.3 | 173.5 | 82.2 |

| 10 | 97.2 | 176.8 | 79.6 | |

| 15 | 102.6 | 201.3 | 98.7 | |

| 20 | 104.8 | 203.2 | 98.4 | |

| 6BEP+NR | 5 | 87.6 | 170.2 | 82.6 |

| 10 | 94.1 | 184.4 | 90.3 | |

| 15 | 98.7 | 180.9 | 82.2 | |

| 20 | 100.5 | 194.1 | 93.6 |

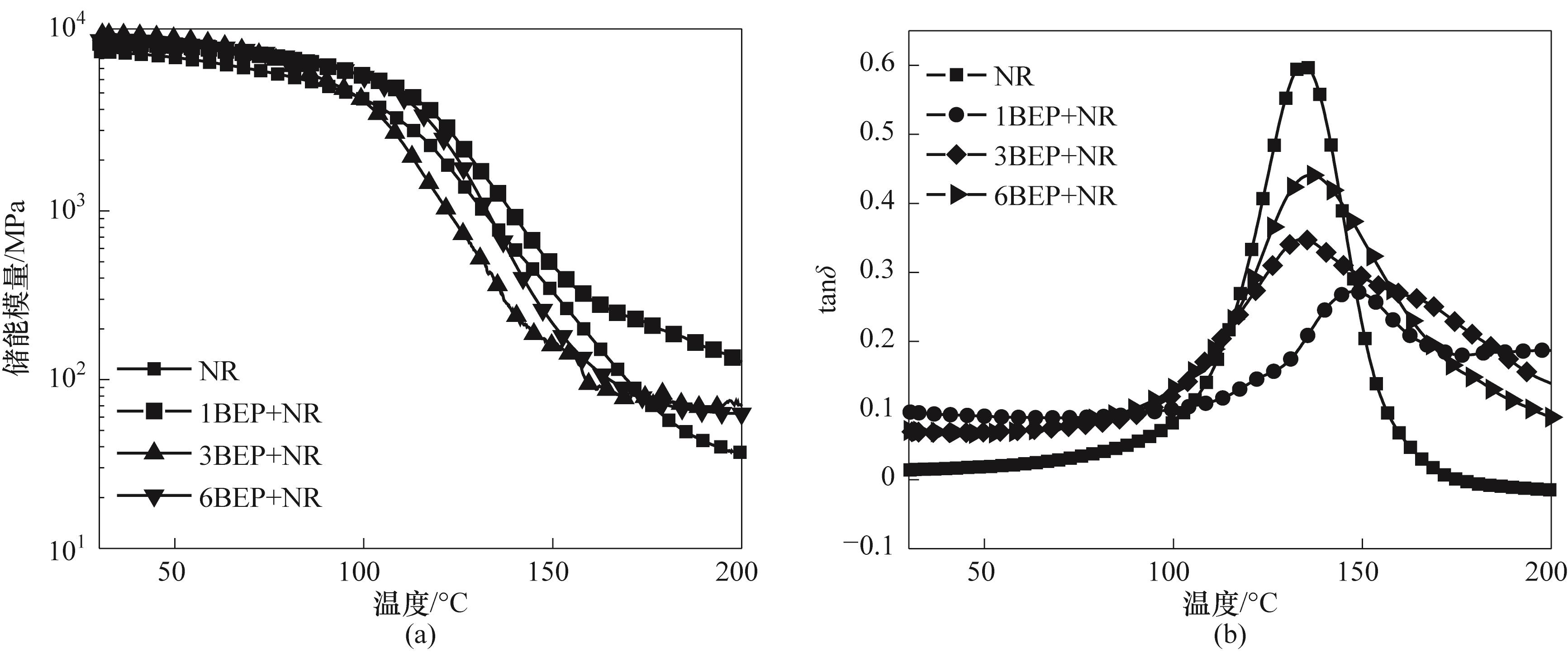

图7 NR和BPR+NR体系固化物的储能模量(a)和损耗因子(b)随温度的变化曲线

Fig.7 Variation curves of energy storage modulus (a) and loss factor (b) with temperature for NR and BPR+NR system cures

| 样品 | E′(40℃)/MP | Tg/℃ | Er/MPa | Ve/(kmol/m3) |

|---|---|---|---|---|

| NR | 7004 | 135.4 | 37.1 | 3.64 |

| 1BEP+NR | 8409 | 146.3 | 129.0 | 12.33 |

| 3BEP+NR | 10947 | 134.6 | 73.2 | 7.20 |

| 6BEP+NR | 9803 | 137.2 | 63.1 | 6.17 |

表2 NR和BPR+NR体系的DMA数据

Table 2 DMA data for NR and BPR+NR system

| 样品 | E′(40℃)/MP | Tg/℃ | Er/MPa | Ve/(kmol/m3) |

|---|---|---|---|---|

| NR | 7004 | 135.4 | 37.1 | 3.64 |

| 1BEP+NR | 8409 | 146.3 | 129.0 | 12.33 |

| 3BEP+NR | 10947 | 134.6 | 73.2 | 7.20 |

| 6BEP+NR | 9803 | 137.2 | 63.1 | 6.17 |

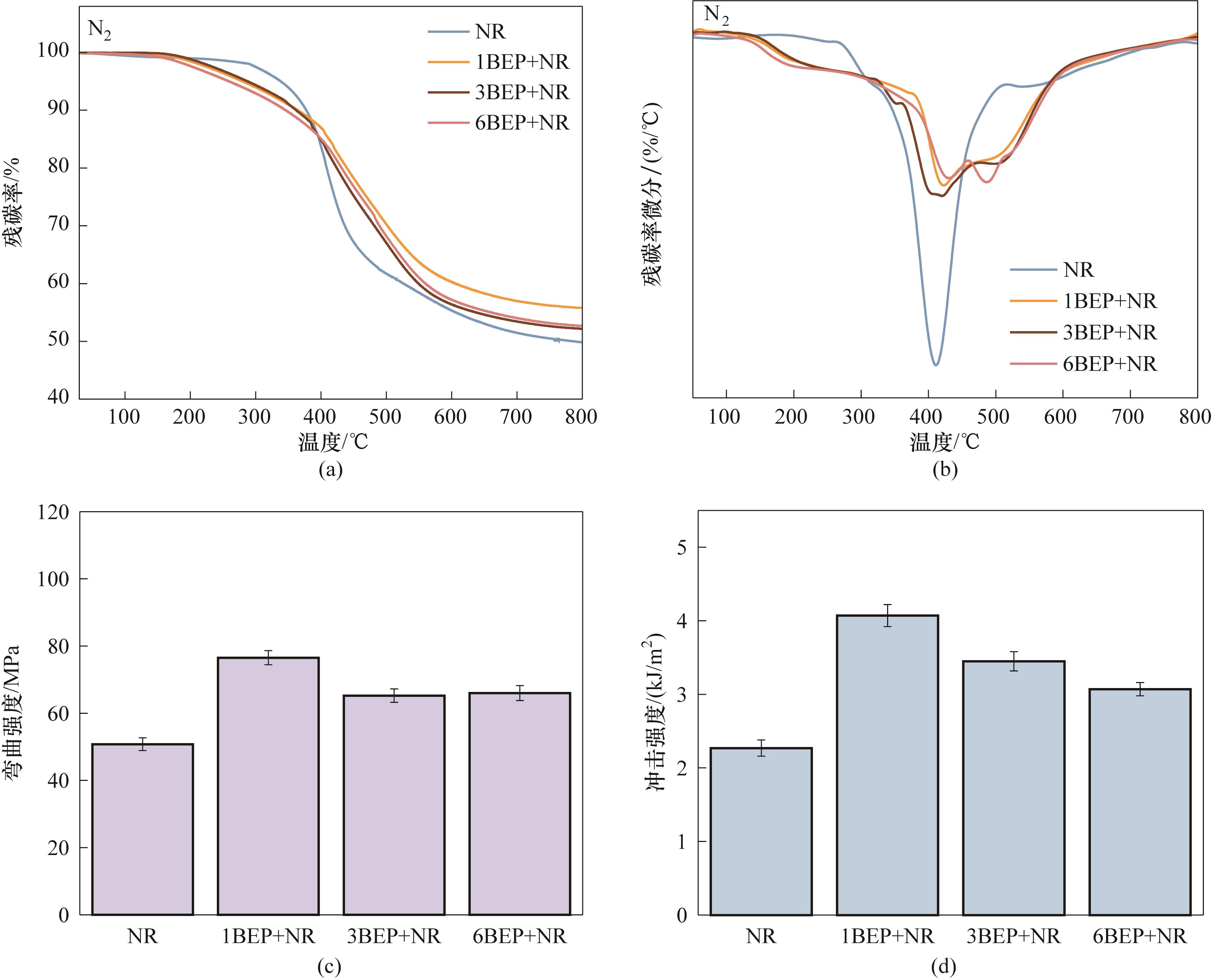

图8 NR和BEP+NR体系的TGA(a)和DTG(b)曲线以及弯曲强度(c)和冲击强度(d)

Fig.8 (a) TGA and (b) DTG curves, (c) flexural strength and (d) impact strength of NR and BEP+NR systems

| 样品 | T5%/℃ | 800℃残炭率/%(N2) |

|---|---|---|

| NR | 338.3 | 49.8 |

| 1BEP+NR | 280.1 | 55.8 |

| 3BEP+NR | 287.3 | 52.1 |

| 6BEP+NR | 258.2 | 52.6 |

表3 NR和BEP+NR体系的热重数据

Table 3 TGA data of NR and BEP+NR systems

| 样品 | T5%/℃ | 800℃残炭率/%(N2) |

|---|---|---|

| NR | 338.3 | 49.8 |

| 1BEP+NR | 280.1 | 55.8 |

| 3BEP+NR | 287.3 | 52.1 |

| 6BEP+NR | 258.2 | 52.6 |

| 1 | Li J J, Zhu Y, Bian R H, et al. Construction of a boron nitride nanosheet hybrid for tough, strong, and flame-retardant phenolic resins[J]. Chemical Engineering Journal, 2023, 471: 144463. |

| 2 | Jiang H C, Du Y T, Wang J H, et al. Enhanced bamboo interfacial bonding performance on the basis of toughening phenol formaldehyde resin by flour[J]. Polymer Composites, 2023, 44(1): 524-535. |

| 3 | 王建, 雷子萱, 姚家钰, 等. 对苯二甲醛酚醛树脂的制备及其固化动力学研究[J]. 化工学报, 2022, 73(3): 1403-1415. |

| Wang J, Lei Z X, Yao J Y, et al. Synthesis and curing kinetics of terephthalaldehyde phenolic resin[J]. CIESC Journal, 2022, 73(3): 1403-1415. | |

| 4 | Hirano K, Asami M. Phenolic resins—100 years of progress and their future[J]. Reactive and Functional Polymers, 2013, 73(2): 256-269. |

| 5 | Liu H Z, Chen F, Liu B, et al. Super toughened poly(lactic acid) ternary blends by simultaneous dynamic vulcanization and interfacial compatibilization[J]. Macromolecules, 2010, 43(14): 6058-6066. |

| 6 | Yee A F, Pearson R A. Toughening mechanisms in elastomer-modified epoxies[J]. Journal of Materials Science, 1986, 21(7): 2462-2474. |

| 7 | Shibatsuka T, Kawauchi T. Improvement of thermal properties of polybenzoxazines synthesized from an oligonuclear phenolic compound without sacrificing toughness by introducing crosslinkable groups separated by rigid biphenyl linkers[J]. Polymer, 2023, 265: 125613. |

| 8 | Saiev S, Bonnaud L, Dumas L, et al. Do carbon nanotubes improve the thermomechanical properties of benzoxazine thermosets?[J]. ACS Applied Materials & Interfaces, 2018, 10(31): 26669-26677. |

| 9 | Agag T, Takeichi T. Synthesis and characterization of benzoxazine resin-SiO2 hybrids by sol-gel process: the role of benzoxazine-functional silane coupling agent[J]. Polymer, 2011, 52(13): 2757-2763. |

| 10 | 朱其仁, 李锦春, 王丽娟, 等. 苯酚-亚联苯型酚醛树脂的合成与表征[J]. 化工学报, 2009, 60(4): 1052-1056. |

| Zhu Q R, Li J C, Wang L J, et al. Synthesis and characterization of phenol-biphenylene resin[J]. CIESC Journal, 2009, 60(4): 1052-1056. | |

| 11 | 徐力, 吴谦秋, 雷子萱, 等. 硅氧烷预聚体改性热塑性酚醛树脂的交联结构及其力学性能[J]. 化工学报, 2022, 73(10): 4734-4744. |

| Xu L, Wu Q Q, Lei Z X, et al. Crosslinking structure and mechanical properties of thermoplastic phenolic resin modified with siloxane prepolymer[J]. CIESC Journal, 2022, 73(10): 4734-4744. | |

| 12 | Di Lorenzo F, Seiffert S. Nanostructural heterogeneity in polymer networks and gels[J]. Polymer Chemistry, 2015, 6(31): 5515-5528. |

| 13 | Pistor V, Soares B G, Mauler R S. Influence of different concentrations of N-phenylaminopropyl–POSS on the thermodynamic fragility of the cured epoxy resin[J]. Polymer, 2013, 54(9): 2292-2298. |

| 14 | Izumi A, Shudo Y, Nakao T, et al. Cross-link inhomogeneity in phenolic resins at the initial stage of curing studied by 1H-pulse NMR spectroscopy and complementary SAXS/WAXS and SANS/WANS with a solvent-swelling technique[J]. Polymer, 2016, 103: 152-162. |

| 15 | Ponson L, Pindra N. Crack propagation through disordered materials as a depinning transition: a critical test of the theory[J]. Physical Review. E, 2017, 95(5): 053004. |

| 16 | Chi H, Zhang G C, Wang N, et al. Enhancing the mechanical strength and toughness of epoxy resins with linear POSS nano-modifiers[J]. Nanoscale Advances, 2022, 4(4): 1151-1157. |

| 17 | Çakmakçi E. POSS: thermosetting polymer nanocomposites[M]//Polyhedral Oligomeric Silsesquioxane (POSS) Polymer Nanocomposites. Amsterdam: Elsevier, 2021: 127-175. |

| 18 | Zhang Z Z, Liu S Y, Li Y F, et al. Structural and thermal behavior of a novel phenolic resin and its composite with excellent ablative performance[J]. Chemical Engineering Journal, 2024, 489: 151448. |

| 19 | Lei Z X, Wang J, Zhang C, et al. Fabrication of a mechanically tough and strong SiO2@EPOSS modified novolac phenolic network by simultaneously improving its crosslinking inhomogeneity and crosslinking density[J]. Composites Science and Technology, 2021, 210: 108810. |

| 20 | Wang D G, Ding J, Wang B, et al. Synthesis and thermal degradation study of polyhedral oligomeric silsesquioxane (POSS) modified phenolic resin[J]. Polymers, 2021, 13(8): 1182. |

| 21 | Zhang C X, Wu G S, Jiang H. Tuning interfacial strength of silicone resin composites by varying the grafting density of octamaleamic acid-POSS modified onto carbon fiber[J]. Composites Part A: Applied Science and Manufacturing, 2018, 109: 555-563. |

| 22 | Chruściel J J, Leśniak E. Modification of epoxy resins with functional silanes, polysiloxanes, silsesquioxanes, silica and silicates[J]. Progress in Polymer Science, 2015, 41: 67-121. |

| 23 | Lei Z X, Ji J R, Wu Q Q, et al. Curing behavior and microstructure of epoxy-POSS modified novolac phenolic resin with different substitution degree[J]. Polymer, 2019, 178: 121587. |

| 24 | Kaya İ, Temizkan K, Aydın A. Synthesis and characterization of aromatic and aliphatic ether bridged polymers containing carbazole moieties[J]. Materials Science and Engineering B, 2013, 178(13): 863-874. |

| 25 | 岑浩. 碳纤维/环氧树脂复合材料的制备及界面性能的研究[D]. 杭州: 浙江理工大学, 2012. |

| Cen H. Preparation and interfacial properties of carbon fiber/epoxy resin composites[D]. Hangzhou: Zhejiang Sci-Tech University, 2012. | |

| 26 | Yao J Y, Wang J, Zhang Z Z, et al. Ferrocenecarboxaldehyde modified terephthalaldehyde-phenolic resin: a comprehensive study on the synthesis, curing behavior, and pyrolysis process[J]. Polymer, 2023, 278: 125993. |

| 27 | Ran Q C, Tian Q, Li C, et al. Investigation of processing, thermal, and mechanical properties of a new composite matrix-benzoxazine containing aldehyde group[J]. Polymers for Advanced Technologies, 2010, 21(3): 170-176. |

| 28 | Liu Y L, Chang G P. Novel approach to preparing epoxy/polyhedral oligometric silsesquioxane hybrid materials possessing high mass fractions of polyhedral oligometric silsesquioxane and good homogeneity[J]. Journal of Polymer Science Part A: Polymer Chemistry, 2006, 44(6): 1869-1876. |

| 29 | Wang X, Hu Y, Song L, et al. Thermal degradation behaviors of epoxy resin/POSS hybrids and phosphorus-silicon synergism of flame retardancy[J]. Journal of Polymer Science Part B: Polymer Physics, 2010, 48(6): 693-705. |

| 30 | 温淼琴. 笼型聚倍半硅氧烷的合成、表征及其对棉织物阻燃性能的影响研究[D]. 上海: 上海工程技术大学, 2016. |

| Wen M Q. Synthesis and characterization of cage polysilsesquioxane and its effect on flame retardancy of cotton fabric[D]. Shanghai: Shanghai University of Engineering Science, 2016. | |

| 31 | Ye M F, Wu Y W, Zhang W C, et al. Synthesis of incompletely caged silsesquioxane (T 7-POSS) compounds via a versatile three-step approach[J]. Research on Chemical Intermediates, 2018, 44(7): 4277-4294. |

| 32 | 徐文杰, 贾献峰, 王际童, 等. 有机硅/酚醛杂化气凝胶的制备和性能研究[J]. 化工学报, 2023, 74(8):3572-3583. |

| Xu W J, Jia X F, Wang J T, et al. Preparation and properties of silicone/phenolic hybrid aerogels[J]. CIESC Journal, 2023, 74(8):3572-3583. | |

| 33 | Xiao F, Sun Y Y, Xiu Y H, et al. Preparation, thermal and mechanical properties of POSS epoxy hybrid composites[J]. Journal of Applied Polymer Science, 2007, 104(4): 2113-2121. |

| 34 | Levchik G F, Si K, Levchik S V, et al. The correlation between cross-linking and thermal stability: cross-linked polystyrenes and polymethacrylates[J]. Polymer Degradation and Stability, 1999, 65(3): 395-403. |

| 35 | 刘晓洪, 王玲, 胡银霞. 钼酚醛树脂/TiO2纳米复合材料的研究[J]. 工程塑料应用, 2003, 31(2): 5-7. |

| Liu X H, Wang L, Hu Y X. Study on molybdenum-modifying phenolic resin/TiO2 nano-composite[J]. Engineering Plastics Application, 2003, 31(2): 5-7. | |

| 36 | Zhou J T, Yao Z J, Chen Y X, et al. Mechanical and thermal properties of graphene oxide/phenolic resin composite[J]. Polymer Composites, 2013, 34(8): 1245-1249. |

| 37 | Izumi A, Nakao T, Iwase H, et al. Structural analysis of cured phenolic resins using complementary small-angle neutron and X-ray scattering and scanning electron microscopy[J]. Soft Matter, 2012, 8(32): 8438-8445. |

| 38 | Brus J, Špírková M, Hlavatá D, et al. Self-organization, structure, dynamic properties, and surface morphology of silica/epoxy films as seen by solid-state NMR, SAXS, and AFM[J]. Macromolecules, 2004, 37(4): 1346-1357. |

| [1] | 朱峰, 赵跃, 马凤翔, 刘伟. 改性UIO-66对SF6/N2混合气体及其分解产物的吸附特性[J]. 化工学报, 2025, 76(4): 1604-1616. |

| [2] | 马韶阳, 徐涵卓, 张亮亮, 孙宝昌, 邹海魁, 罗勇, 初广文. 液-液非均相反应与传递过程强化方法研究进展[J]. 化工学报, 2025, 76(4): 1391-1403. |

| [3] | 徐芳, 张锐, 崔达, 王擎. ReaxFF-MD揭示木质素热解反应机制的分子动力学研究[J]. 化工学报, 2025, 76(3): 1253-1263. |

| [4] | 杨猛, 丁晓倩, 余涛, 刘畅, 汤成龙, 黄佐华. 甲烷/氧化亚氮绿色推进剂自着火特性实验及动力学[J]. 化工学报, 2025, 76(3): 1221-1229. |

| [5] | 李远华, 凌思棋, 封科军, 冯颖, 郭于菁, 谢世桓. 基于cMOFs的固定化脂肪酶微反应器的构筑及其扁桃酸催化应用[J]. 化工学报, 2025, 76(3): 1170-1179. |

| [6] | 严珅, 席悦, 张盛宇, 陈晓东, 吴铎. 基于IGC-ZLC法测定有机蒸气在ZSM-5中的晶内扩散系数[J]. 化工学报, 2025, 76(3): 1076-1083. |

| [7] | 张奇, 张睿, 郑涛, 曹欣, 刘植昌, 刘海燕, 徐春明, 张荣, 孟祥海. 基于分子模拟的新型双阳离子质子型离子液体捕集CO2研究[J]. 化工学报, 2025, 76(2): 797-811. |

| [8] | 党法璐, 孙志国, 高照, 王刚, 陈政宇, 张霖宙, 连竞存, 刘美佳, 张忠东, 刘超伟. 原油一步法催化裂解制低碳烯烃:实验和反应路径研究[J]. 化工学报, 2025, 76(2): 667-685. |

| [9] | 何传超, 周静红, 曹约强, 施尧, 周兴贵. Ag/SiO2催化草酸酯加氢制乙醇酸甲酯的床层-颗粒双尺度耦合模拟研究[J]. 化工学报, 2025, 76(2): 654-666. |

| [10] | 彭子林, 周蕾, 邓庆航, 叶光华, 周兴贵. 包含偏硅酸影响的3D NAND磷酸湿法刻蚀动力学[J]. 化工学报, 2025, 76(2): 645-653. |

| [11] | 吴雨轩, 常诚, 顾雪萍, 冯连芳, 张才亮. 面向立体异构的丁二烯乳液聚合过程模型化[J]. 化工学报, 2025, 76(2): 879-887. |

| [12] | 贾艳萍, 马艳菊, 管文昕, 杨彬, 张健, 张兰河. 响应面法优化Fe0/H2O2体系降解染料废水的工艺条件及机理[J]. 化工学报, 2025, 76(1): 348-362. |

| [13] | 郭珊, 田雨, 徐永滨, 王朋, 刘治明. 废旧电池再资源化制备高性能中熵合金催化剂及其性能研究[J]. 化工学报, 2025, 76(1): 231-240. |

| [14] | 赵焕娟, 包颖昕, 于康, 刘婧, 钱新明. 多元组分爆轰不稳定性定量实验研究[J]. 化工学报, 2024, 75(S1): 339-348. |

| [15] | 徐宏标, 杨亮, 李子栋, 刘道平. 盐水微滴/泡沫铜复合体系中甲烷水合物生成动力学研究[J]. 化工学报, 2024, 75(9): 3287-3296. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号