化工学报 ›› 2025, Vol. 76 ›› Issue (11): 5842-5852.DOI: 10.11949/0438-1157.20250532

• 流体力学与传递现象 • 上一篇

陈永珍1,2( ), 宋文吉2(

), 宋文吉2( ), 陈二雄2, 秦坤2, 周雨杰3, 杜群2, 冯自平1,2

), 陈二雄2, 秦坤2, 周雨杰3, 杜群2, 冯自平1,2

收稿日期:2025-05-13

修回日期:2025-06-30

出版日期:2025-11-25

发布日期:2025-12-19

通讯作者:

宋文吉

作者简介:陈永珍(1985—),女,博士研究生,工程师,chenyz@ms.giec.ac.cn

基金资助:

Yongzhen CHEN1,2( ), Wenji SONG2(

), Wenji SONG2( ), Erxiong CHEN2, Kun QIN2, Yujie ZHOU3, Qun DU2, Ziping FENG1,2

), Erxiong CHEN2, Kun QIN2, Yujie ZHOU3, Qun DU2, Ziping FENG1,2

Received:2025-05-13

Revised:2025-06-30

Online:2025-11-25

Published:2025-12-19

Contact:

Wenji SONG

摘要:

为了对冰浆清管能力进行定量描述,以实验研究的方式分析过冷水冰浆管内流动及清管能力特性。首先,对体积含冰率范围为22.7%~33.5%的冰浆柱塞流动的管壁切应力进行研究,发现切应力大小主要受含冰率和推动水流速的影响。重点研究冰浆清管能力衰减特性,发现推动水流速越快,冰浆空隙率越高,渗透速率越快。柱塞长度为总管长度的10%,且温度分别为6、9和12℃时,冰浆柱塞前进21.5 m,压降保持率分别为87.02%、81.13%和74.21%,温度提高3℃,压降保持率分别下降了5.89%和6.92%。柱塞长度为20%,温度分别为15、18和21℃时,叠加了推动水流速提高了0.02 m/s对压降的影响,温度提高3℃,压降保持率分别下降了1.75%和3.09%,推动水温度增加引起的压降降低不容忽视。根据冲量定律定义冰浆柱塞清管能力保持率,柱塞长度分别为管长的10%、20%和30%时,冰浆柱塞前进21.5 m,6℃时清管能力保持率分别为67.18%、79.60%和86.67%。且温度每增加1℃,10%和20%冰浆柱塞长度时的清管能力衰减约为1.1%,30%冰浆柱塞长度时的清管能力衰减约为0.9%。

中图分类号:

陈永珍, 宋文吉, 陈二雄, 秦坤, 周雨杰, 杜群, 冯自平. 高浓度冰浆管内流动特性及清管能力衰减研究[J]. 化工学报, 2025, 76(11): 5842-5852.

Yongzhen CHEN, Wenji SONG, Erxiong CHEN, Kun QIN, Yujie ZHOU, Qun DU, Ziping FENG. Flow characteristics and pigging performance degradation of high-concentration ice slurry in pipelines[J]. CIESC Journal, 2025, 76(11): 5842-5852.

| 序号 | Φv | Φm | Φ | 相对误差/% |

|---|---|---|---|---|

| 1 | 31.01 | 29.23 | 30.51 | 4.20 |

| 2 | 41.04 | 39.01 | 39.41 | 1.01 |

| 3 | 45.60 | 43.51 | 45.74 | 4.88 |

表1 冰浆含冰率系数相对误差

Table 1 Relative error of ice fraction

| 序号 | Φv | Φm | Φ | 相对误差/% |

|---|---|---|---|---|

| 1 | 31.01 | 29.23 | 30.51 | 4.20 |

| 2 | 41.04 | 39.01 | 39.41 | 1.01 |

| 3 | 45.60 | 43.51 | 45.74 | 4.88 |

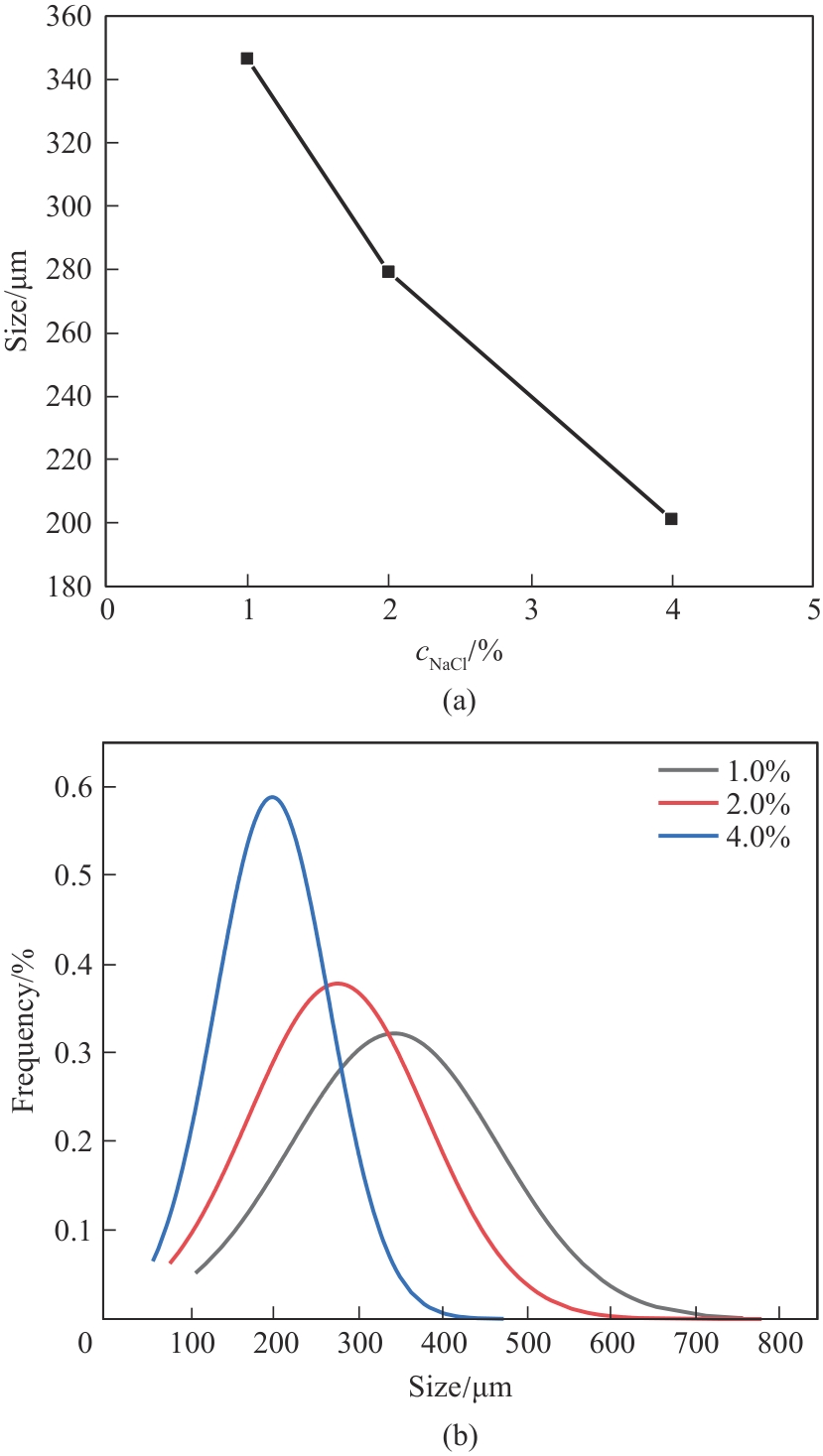

图3 不同初始盐浓度下的冰晶平均粒径(a)及正态分布曲线(b)

Fig.3 Particle size distribution (a) and Gaussian fitting curves (b) of ice slurry at different initial NaCl concentrations

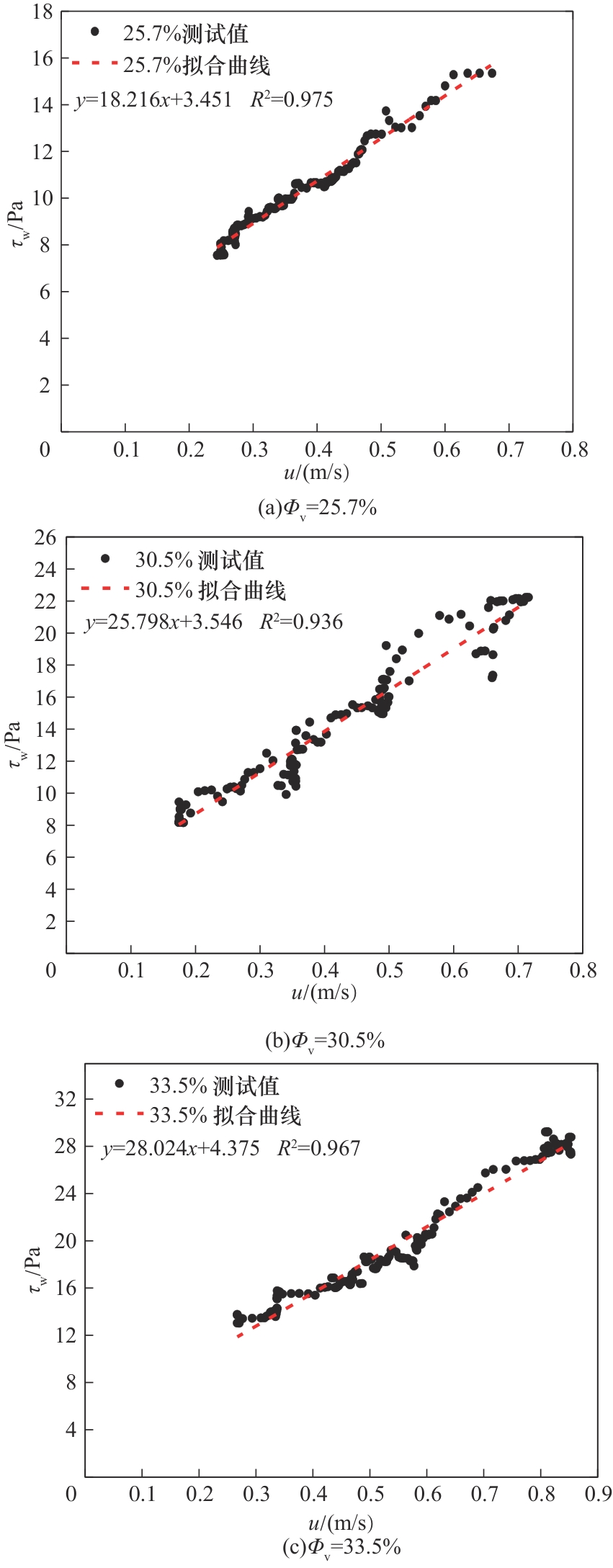

图4 1.5%含盐率下制备的冰浆不同含冰率下的流速和切应力关系

Fig.4 Relationship between liquid flow velocity and shear stress of ice slurry prepared with 1.5% NaCl solutions under different ice fractions

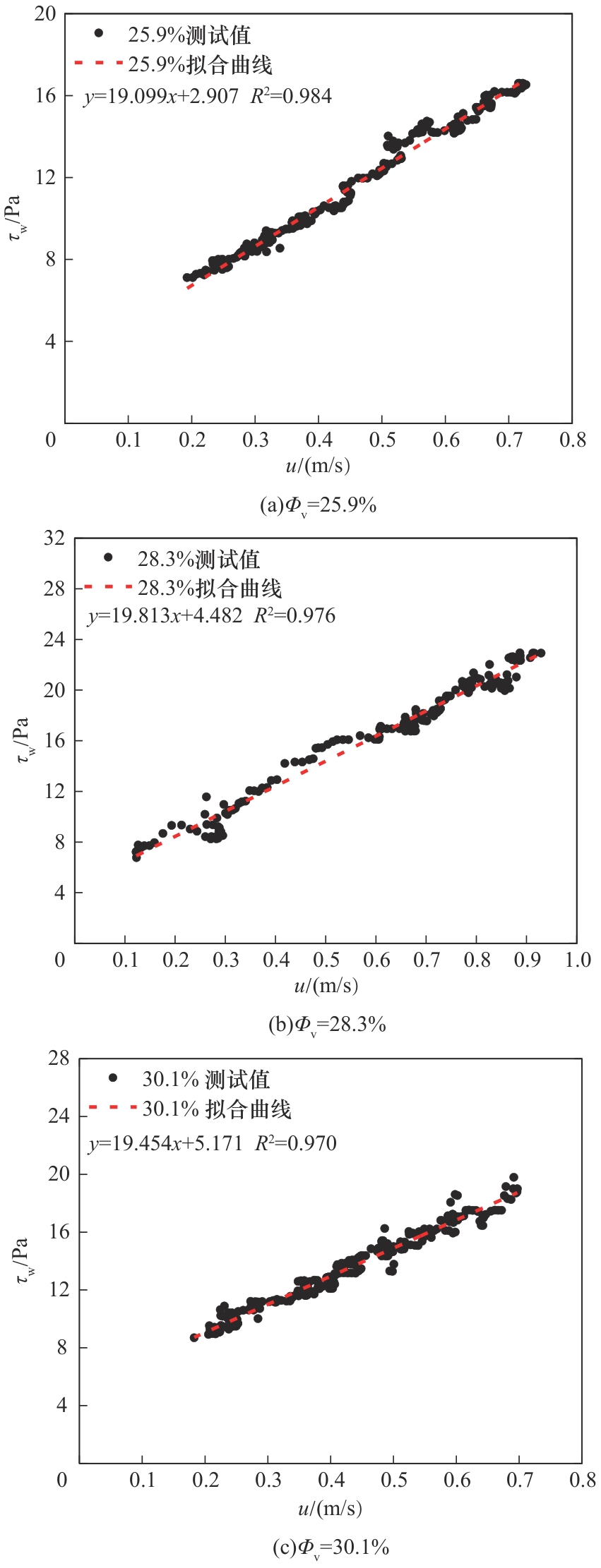

图5 2.2%含盐率下制备的冰浆不同含冰率下的流速和切应力关系

Fig.5 Relationship between liquid flow velocity and shear stress of ice slurry prepared with 2.2% NaCl solutions under different ice fractions

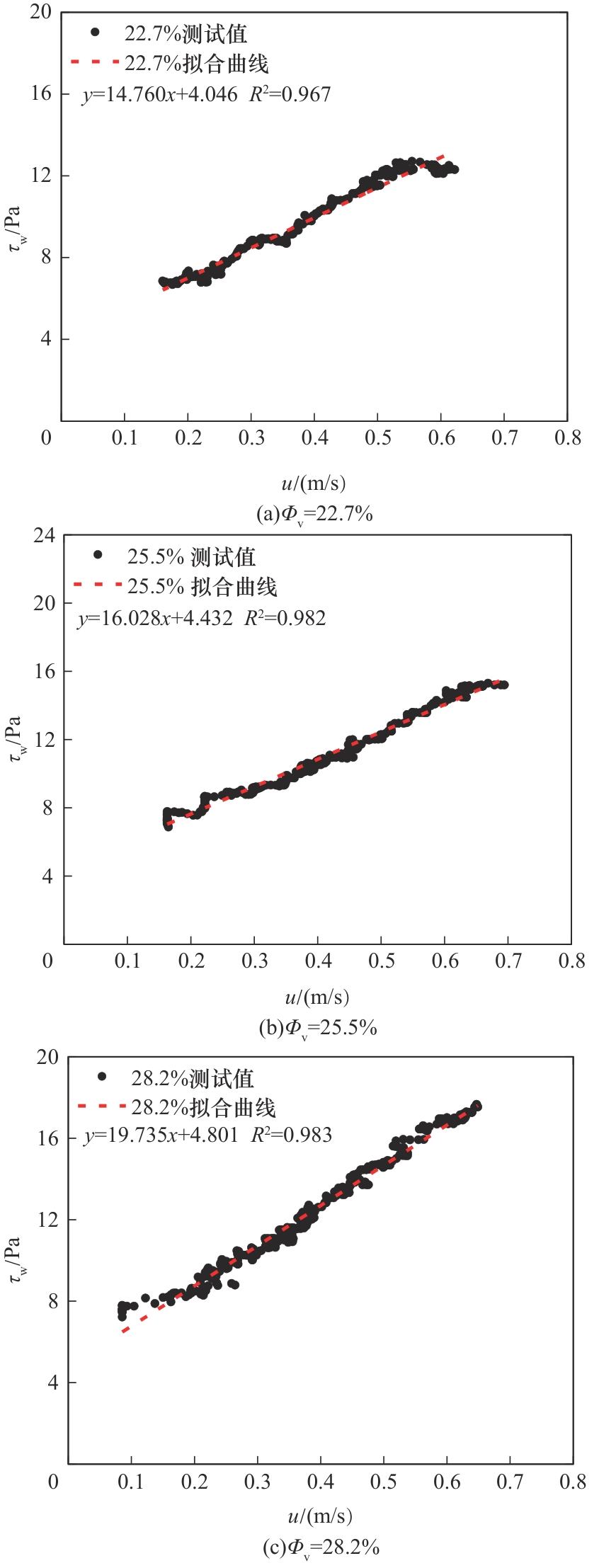

图6 2.9%含盐率下制备的冰浆不同含冰率下的流速和切应力关系

Fig.6 Relationship between liquid flow velocity and shear stress of ice slurry prepared with 2.9% NaCl solutions under different ice fractions

| 序号 | 实验条件 | 实验结果 | |||

|---|---|---|---|---|---|

| Φv,caf | ε | 推动水流速/(m/s) | 渗透速率/(mm/s) | 修正σ | |

| 1 | 0.72 | 0.59 | 0.47 | 6.09 | 303.10 |

| 2 | 0.70 | 0.60 | 0.21 | 4.16 | 791.88 |

| 3 | 0.70 | 0.60 | 0.22 | 4.49 | 783.90 |

| 4 | 0.68 | 0.61 | 0.21 | 4.31 | 763.28 |

| 5 | 0.68 | 0.61 | 0.40 | 6.73 | 367.22 |

| 6 | 0.66 | 0.62 | 0.23 | 5.09 | 691.76 |

| 7 | 0.66 | 0.62 | 0.27 | 5.30 | 542.90 |

| 8 | 0.66 | 0.62 | 0.34 | 6.17 | 411.94 |

| 9 | 0.66 | 0.62 | 0.54 | 7.69 | 234.69 |

| 10 | 0.65 | 0.63 | 0.24 | 5.26 | 612.69 |

| 11 | 0.65 | 0.63 | 0.53 | 7.95 | 244.97 |

| 12 | 0.65 | 0.63 | 0.56 | 8.21 | 217.74 |

| 13 | 0.64 | 0.64 | 0.21 | 4.89 | 709.87 |

| 14 | 0.64 | 0.64 | 0.22 | 5.00 | 668.29 |

| 15 | 0.63 | 0.64 | 0.49 | 7.46 | 234.24 |

| 16 | 0.62 | 0.64 | 0.52 | 7.90 | 215.92 |

| 17 | 0.61 | 0.65 | 0.54 | 8.97 | 222.85 |

| 18 | 0.61 | 0.65 | 0.56 | 9.30 | 218.25 |

表2 σ值计算结果

Table 2 Calculation results of σ values

| 序号 | 实验条件 | 实验结果 | |||

|---|---|---|---|---|---|

| Φv,caf | ε | 推动水流速/(m/s) | 渗透速率/(mm/s) | 修正σ | |

| 1 | 0.72 | 0.59 | 0.47 | 6.09 | 303.10 |

| 2 | 0.70 | 0.60 | 0.21 | 4.16 | 791.88 |

| 3 | 0.70 | 0.60 | 0.22 | 4.49 | 783.90 |

| 4 | 0.68 | 0.61 | 0.21 | 4.31 | 763.28 |

| 5 | 0.68 | 0.61 | 0.40 | 6.73 | 367.22 |

| 6 | 0.66 | 0.62 | 0.23 | 5.09 | 691.76 |

| 7 | 0.66 | 0.62 | 0.27 | 5.30 | 542.90 |

| 8 | 0.66 | 0.62 | 0.34 | 6.17 | 411.94 |

| 9 | 0.66 | 0.62 | 0.54 | 7.69 | 234.69 |

| 10 | 0.65 | 0.63 | 0.24 | 5.26 | 612.69 |

| 11 | 0.65 | 0.63 | 0.53 | 7.95 | 244.97 |

| 12 | 0.65 | 0.63 | 0.56 | 8.21 | 217.74 |

| 13 | 0.64 | 0.64 | 0.21 | 4.89 | 709.87 |

| 14 | 0.64 | 0.64 | 0.22 | 5.00 | 668.29 |

| 15 | 0.63 | 0.64 | 0.49 | 7.46 | 234.24 |

| 16 | 0.62 | 0.64 | 0.52 | 7.90 | 215.92 |

| 17 | 0.61 | 0.65 | 0.54 | 8.97 | 222.85 |

| 18 | 0.61 | 0.65 | 0.56 | 9.30 | 218.25 |

| 温度/℃ | 柱塞长度10% | 柱塞长度20% | 柱塞长度30% | |||

|---|---|---|---|---|---|---|

| ΔPr/% | Δu/(m/s) | ΔPr/% | Δu/(m/s) | ΔPr/% | Δu/(m/s) | |

| 6 | 87.02 | -0.0058 | 90.22 | 0.0273 | 101.12 | 0.0212 |

| 9 | 81.13 | 0.0062 | 87.28 | 0.0286 | 101.49 | 0.0217 |

| 12 | 74.21 | 0.0054 | 86.83 | 0.0301 | 88.08 | 0.0266 |

| 15 | 77.76 | 0.0202 | 83.29 | 0.0180 | 88.93 | 0.0327 |

| 18 | 72.01 | 0.0402 | 81.54 | 0.0196 | 85.39 | 0.0271 |

| 21 | 71.00 | 0.0395 | 78.45 | 0.0189 | 89.07 | 0.0458 |

| 24 | — | — | 68.47 | 0.0140 | 78.51 | 0.0251 |

表3 不同柱塞长度及温度下的平均压降保持率

Table 3 Average pressure drop retention rates under different ice-pigging lengths and temperatures

| 温度/℃ | 柱塞长度10% | 柱塞长度20% | 柱塞长度30% | |||

|---|---|---|---|---|---|---|

| ΔPr/% | Δu/(m/s) | ΔPr/% | Δu/(m/s) | ΔPr/% | Δu/(m/s) | |

| 6 | 87.02 | -0.0058 | 90.22 | 0.0273 | 101.12 | 0.0212 |

| 9 | 81.13 | 0.0062 | 87.28 | 0.0286 | 101.49 | 0.0217 |

| 12 | 74.21 | 0.0054 | 86.83 | 0.0301 | 88.08 | 0.0266 |

| 15 | 77.76 | 0.0202 | 83.29 | 0.0180 | 88.93 | 0.0327 |

| 18 | 72.01 | 0.0402 | 81.54 | 0.0196 | 85.39 | 0.0271 |

| 21 | 71.00 | 0.0395 | 78.45 | 0.0189 | 89.07 | 0.0458 |

| 24 | — | — | 68.47 | 0.0140 | 78.51 | 0.0251 |

| [1] | Quarini G, Ainslie E, Herbert M, et al. Investigation and development of an innovative pigging technique for the water-supply industry[J]. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, 2010, 224(2): 79-89. |

| [2] | Huang Y J, Chen Z W, He G L, et al. Application of ice pigging in a drinking water distribution system: impacts on pipes and bulk water quality[J]. Engineering, 2024, 40: 122-130. |

| [3] | Quarini G, Aislie E, Ash D, et al. Transient thermal performance of ice slurries pumped through pipes[J]. Applied Thermal Engineering, 2013, 50(1): 743-748. |

| [4] | Kauffeld M, Gund S. Ice slurry—history, current technologies and future developments[J]. International Journal of Refrigeration, 2019, 99: 264-271. |

| [5] | Zhou Z J, Zhang G H, Lu W, et al. Review on high ice packing factor (IPF) ice slurry: fabrication, characterization, flow characteristics and applications[J]. Journal of Energy Storage, 2024, 81: 110378. |

| [6] | Huang Y J, Liu C, Shao Y, et al. Enhanced ice slurry with low oxidant consumption for ultrafast in-situ removal of micropollutants sheltered in sediments of water supply pipelines[J]. Water Research, 2025, 276: 123256. |

| [7] | 宋文吉, 冯自平, 肖睿. 冰浆技术及其应用进展[J]. 新能源进展, 2019, 7(2): 129-141. |

| Song W J, Feng Z P, Xiao R. Progress of ice slurry technology and its prosperity applications[J]. Advances in New and Renewable Energy, 2019, 7(2): 129-141. | |

| [8] | Chen M B, Song W J, Lin W Y, et al. Ice nucleation in supercooled water under shear[J]. Chemical Engineering Science, 2024, 300: 120674. |

| [9] | Du Q, Chen M B, Song W J, et al. Investigation on the evolution of ice particles and ice slurry flow characteristics during subcooling release[J]. International Journal of Heat and Mass Transfer, 2023, 209: 124008. |

| [10] | Yang D, Hong W P. Particle dynamics study on influencing factors of ice slurry flow characteristics in district cooling systems[J]. Processes, 2024, 12(10): 2117. |

| [11] | 胡佳敏, 信昆仑, 王嘉莹, 等. 冰浆清洗供水管道影响因素分析及效果评估[J]. 给水排水, 2023, 59(12): 93-99. |

| Hu J M, Xin K L, Wang J Y, et al. Impact factors analysis and effectiveness evaluation of water distribution pipelines cleaning using ice slurry pigging technology[J]. Water & Wastewater Engineering, 2023, 59(12): 93-99. | |

| [12] | Hu J M, Fernandes del Pozo D, Nopens I, et al. Ice slurry pigging technology in drinking water distribution system: from flow mechanisms to pipelines cleaning application[J]. Process Safety and Environmental Protection, 2024, 191: 75-84. |

| [13] | Hu J M, Tao T. Numerical investigation of ice pigging isothermal flow in water-supply pipelines cleaning[J]. Chemical Engineering Research and Design, 2022, 182: 428-437. |

| [14] | Asaoka T, Tajima A, Kumano H. Experimental investigation on inhomogeneity of ice packing factor in ice slurry flow[J]. International Journal of Refrigeration, 2016, 70: 33-41. |

| [15] | Rayhan F A, Yanuar. Rheological behavior and drag reduction characteristics of ice slurry flow in spiral pipes[J]. Thermal Science and Engineering Progress, 2020, 20: 100734. |

| [16] | Huang Y J, Dong F L, He G L, et al. Review of ice slurry pigging techniques for the water supply industry: engineering design and application[J]. ACS ES&T Engineering, 2022, 2(7): 1144-1159. |

| [17] | 王继红, 王树刚, 张腾飞, 等. 水平管道内冰浆流动阻力特性实验研究[J]. 哈尔滨工程大学学报, 2014, 35(2): 161-165. |

| Wang J H, Wang S G, Zhang T F, et al. Experimental investigation into the properties of flowing resistance of ice slurry inside a horizontal pipeline[J]. Journal of Harbin Engineering University, 2014, 35(2): 161-165. | |

| [18] | Bordet A, Poncet S, Poirier M, et al. Flow visualizations and pressure drop measurements of isothermal ice slurry pipe flows[J]. Experimental Thermal and Fluid Science, 2018, 99: 595-604. |

| [19] | Yang B, Tang D K, Yuan W X, et al. Experimental study on pressure drop and ice blockage characteristics of ice slurry flow in big-diameter pipes[J]. International Journal of Refrigeration, 2025, 169: 214-225. |

| [20] | Ergun S, Orning A A. Fluid flow through randomly packed columns and fluidized beds[J]. Industrial & Engineering Chemistry, 1949, 41(6): 1179-1184. |

| [21] | Ergun S. Fluid flow through packed columns[J]. Chemical Engineering Progress, 1952, 48(2): 89-94. |

| [22] | 张晟, 张晓虎, 赵亮, 等. 基于Ergun方程的菱镁球团填充床层阻力特性实验[J]. 东北大学学报(自然科学版), 2021, 42(3): 347-352. |

| Zhang S, Zhang X H, Zhao L, et al. Experiment of resistance characteristics for magnesite pellets packed bed based on Ergun equation[J]. Journal of Northeastern University (Natural Science), 2021, 42(3): 347-352. | |

| [23] | 李景海, 翟国亮, 刘清霞, 等. 基于Ergun方程的微灌砂颗粒形状系数测定方法研究[J]. 节水灌溉, 2020(12): 1-5. |

| Li J H, Zhai G L, Liu Q X, et al. A study on the method of determination of the shape coefficient of sand particle in micro-irrigation based on Ergun equation[J]. Water Saving Irrigation, 2020(12): 1-5. | |

| [24] | McBryde D J. Ice pigging in the nuclear decommissioning industry[D]. Bristol: University of Bristol, 2015: 197-202. |

| [25] | 杨树人, 崔海清. 石油工程非牛顿流体力学[M]. 北京: 石油工业出版社, 2013: 70-71. |

| Yang S R, Cui H Q. Non-Newtonian Fluid Mechanics in Petroleum Engineering[M]. Beijing: Petroleum Industry Press, 2013: 70-71. | |

| [26] | 肖睿. TBAB包络化合物浆的管内流动和传热特性研究[D]. 广州: 中国科学院广州能源研究所, 2008. |

| Xiao R. Study on flow and heat transfer characteristics of TBAB clathrate hydrate slurry in pipes [D]. Guangzhou: Guangzhou Institute of Energy Conversion, Chinese Academy of Sciences, 2008. | |

| [27] | Mellari S. Experimental investigation and modeling of the pressure drop of ice slurry flow in horizontal pipe[J]. International Journal of Refrigeration, 2023, 147: 134-142. |

| [28] | 唐道轲, 付林, 杨波, 等. 大管径管道冰浆流动阻力特性实验研究[J]. 暖通空调, 2023, 53(10): 115-119. |

| Tang D K, Fu L, Yang B, et al. Experimental study on flow resistance characteristics of ice slurry in pipelines with large diameter[J]. Heating Ventilating & Air Conditioning, 2023, 53(10): 115-119. |

| [1] | 王俊鹏, 冯佳琪, 张恩搏, 白博峰. 曲折式与阵列式迷宫阀芯结构内流动与空化特性研究[J]. 化工学报, 2025, 76(S1): 93-105. |

| [2] | 袁琳慧, 王瑜. 单服务器浸没射流式液冷系统散热性能[J]. 化工学报, 2025, 76(S1): 160-169. |

| [3] | 孙云龙, 徐肖肖, 黄永方, 郭纪超, 陈卫卫. 水平光滑管内CO2流动沸腾的非绝热可视化研究[J]. 化工学报, 2025, 76(S1): 230-236. |

| [4] | 于宏鑫, 王宁波, 郭焱华, 邵双全. 动态蓄冰系统的板式换热器流动换热模拟研究[J]. 化工学报, 2025, 76(S1): 106-113. |

| [5] | 吴馨, 龚建英, 李祥宇, 王宇涛, 杨小龙, 蒋震. 超声波激励疏水表面液滴运动的实验研究[J]. 化工学报, 2025, 76(S1): 133-139. |

| [6] | 燕子腾, 詹飞龙, 丁国良. 空调用套管式分流器结构设计及分流效果验证[J]. 化工学报, 2025, 76(S1): 152-159. |

| [7] | 曹潇风, 张华海, 王江云, 王利民. 锥形气体层流元件结构设计及流动特性研究[J]. 化工学报, 2025, 76(9): 4440-4448. |

| [8] | 徐成龙, 李果, 王玉, 谢林生, 张国辉, 梁鹏飞. 等弧厚复杂药型螺压成型模具的模拟仿真研究[J]. 化工学报, 2025, 76(8): 3954-3963. |

| [9] | 王孝宇, 戴贵龙, 邓树坤, 龚凌诸. Laguerre-Voronoi开孔泡沫流动-传热综合性能孔隙尺度模拟[J]. 化工学报, 2025, 76(7): 3259-3273. |

| [10] | 周臣儒, 刘陈伟, 王志远, 綦民辉, 董三宝, 王翔宇, 李明忠. 甲醇和乙二醇对甲烷水合物黏附强度的影响[J]. 化工学报, 2025, 76(7): 3596-3604. |

| [11] | 朱先宇, 孙钱行, 周守军, 田永生, 孙钦鹏. 复合相变材料耦合微槽平板热管的电池热管理实验研究[J]. 化工学报, 2025, 76(6): 2652-2666. |

| [12] | 包兴, 郭雪岩. 圆柱颗粒结构修饰对填充床内流动和换热特性的影响[J]. 化工学报, 2025, 76(6): 2603-2615. |

| [13] | 杨浩杰, 刘春雨, 李雪娇, 于亮, 吕兴才. 低旋流配置下氨-甲烷-空气预混旋流火焰稳定性和排放特性[J]. 化工学报, 2025, 76(6): 3029-3040. |

| [14] | 刘雨, 蔡振波, 纪利俊, 马晓华. ZIF-67/PDMS复合膜分离废次烟草的中性香气组分[J]. 化工学报, 2025, 76(5): 2337-2347. |

| [15] | 张耀辉, 班宇杰, 杨维慎. 以蒸气加工法制备和修饰金属-有机框架膜[J]. 化工学报, 2025, 76(5): 2070-2086. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号