化工学报 ›› 2025, Vol. 76 ›› Issue (11): 6008-6017.DOI: 10.11949/0438-1157.20250678

• 表面与界面工程 • 上一篇

收稿日期:2025-06-22

修回日期:2025-07-22

出版日期:2025-11-25

发布日期:2025-12-19

通讯作者:

任延杰

作者简介:赵斌(1968—), 男, 博士, 教授, zhaobin@csust.edu.cn

基金资助:

Bin ZHAO1( ), Jing LIAO1, Yanjie REN2(

), Jing LIAO1, Yanjie REN2( ), Junchen ZHOU1, Yan LI3

), Junchen ZHOU1, Yan LI3

Received:2025-06-22

Revised:2025-07-22

Online:2025-11-25

Published:2025-12-19

Contact:

Yanjie REN

摘要:

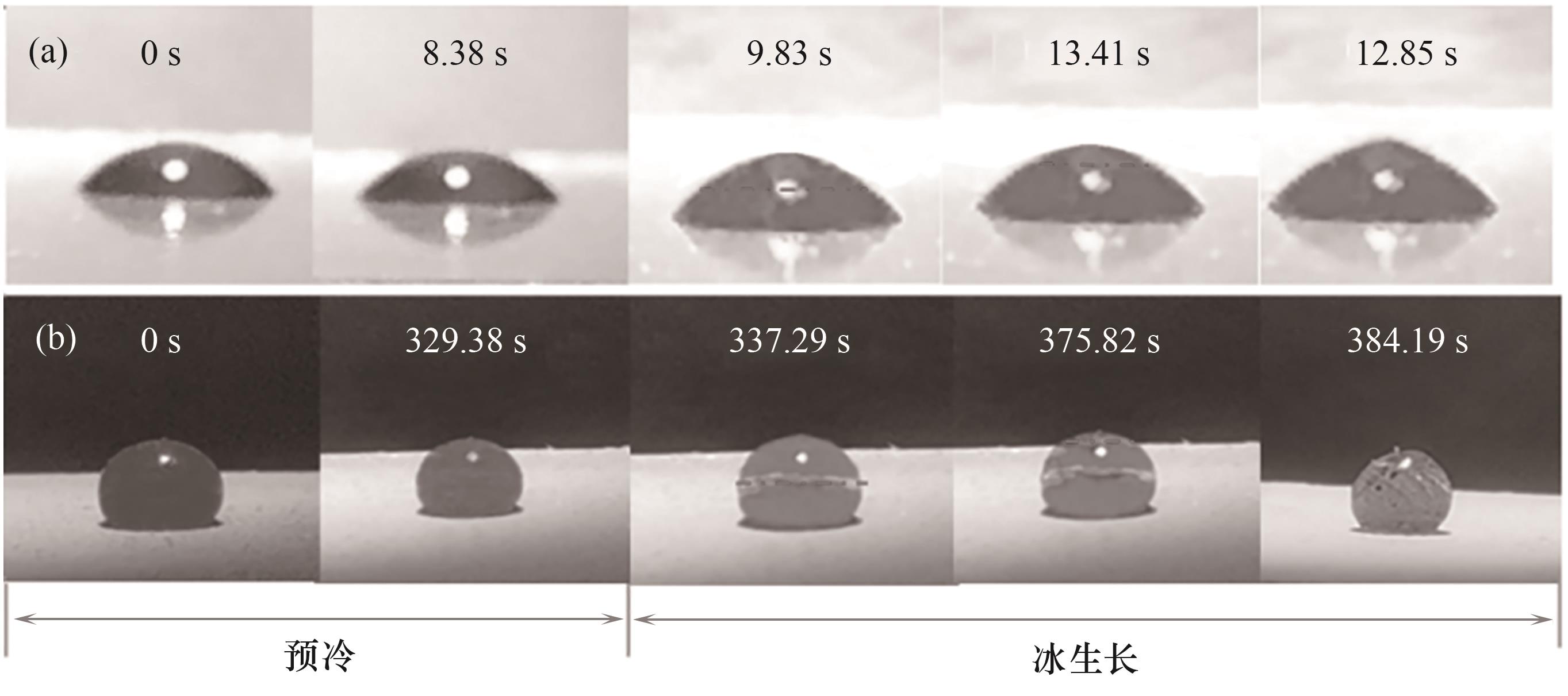

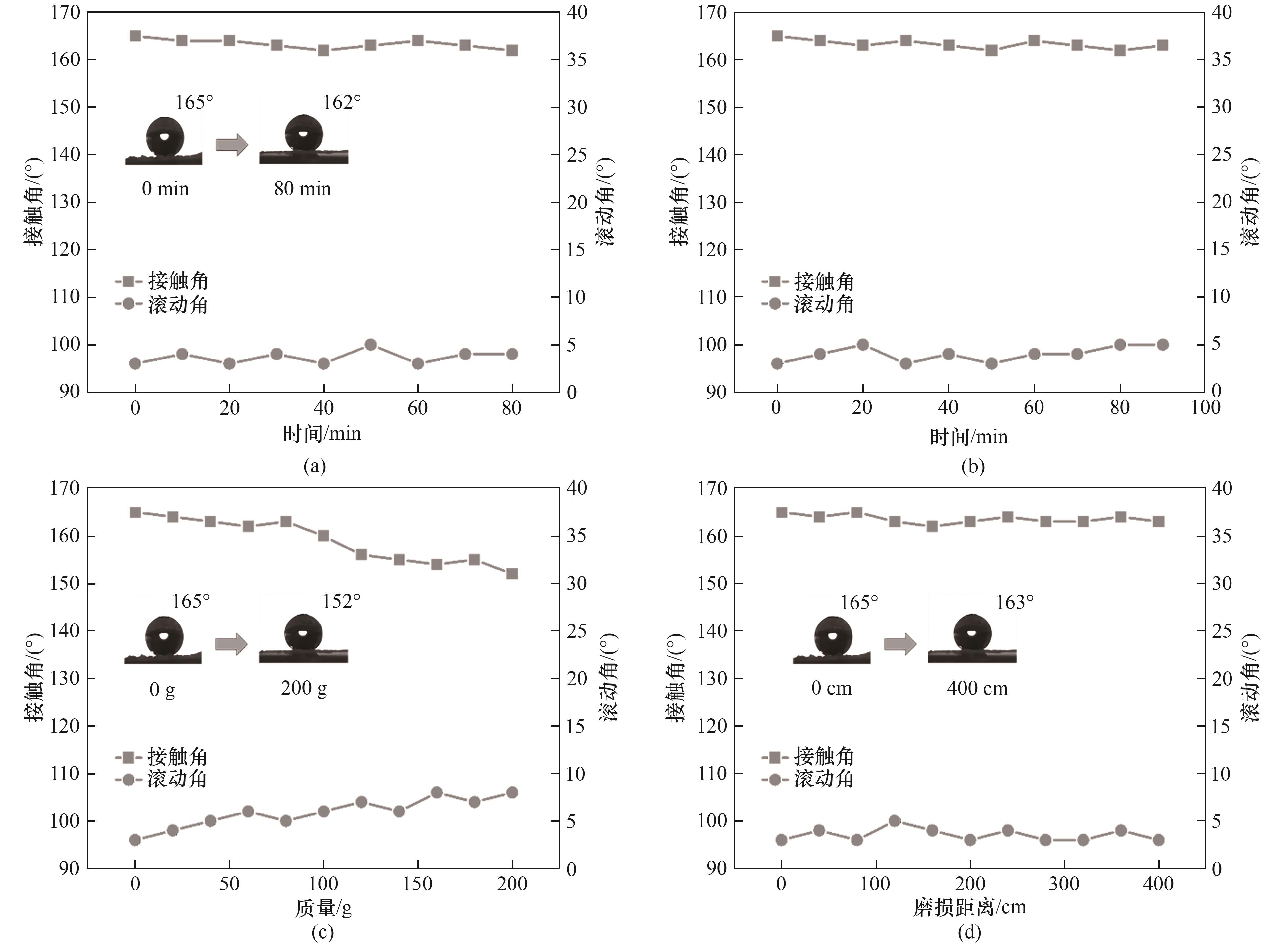

针对超疏水铝合金在苛刻环境应用的稳定性需求,提出一种化学-电化学协同刻蚀结合硬脂酸原位修饰的制备工艺。采用该工艺在6061铝合金上构建了微纳结构,实现接触角为165°、滚动角为3°的超疏水特性。该超疏水铝合金在空气和油中均具有优异的自清洁性能,在低温环境下超疏水铝合金的结冰时间为384.19 s(对照组12.85 s),表现出良好的环境稳定性及防覆冰特性;在超声(40 Hz)振动80 min、沸水中处理1.5 h、线性磨损(400 cm)后的接触角仍大于160°,落砂(200 g)冲击后接触角为152°,表明该超疏水铝合金具有优异的机械耐久性。

中图分类号:

赵斌, 廖静, 任延杰, 周俊臣, 李岩. 化学-电化学协同刻蚀制备超疏水铝合金及其性能研究[J]. 化工学报, 2025, 76(11): 6008-6017.

Bin ZHAO, Jing LIAO, Yanjie REN, Junchen ZHOU, Yan LI. Preparation and properties of superhydrophobic aluminum alloy via chemical-electrochemical synergistic etching[J]. CIESC Journal, 2025, 76(11): 6008-6017.

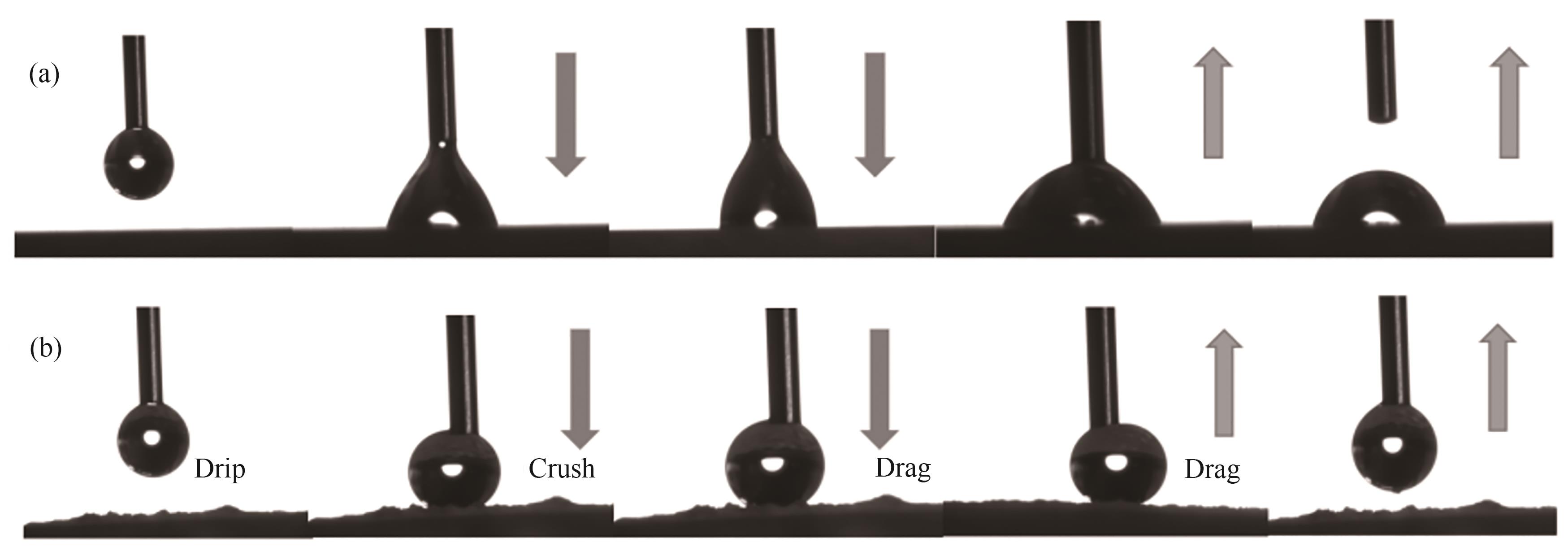

图5 水滴在表面的黏附行为: (a)未经处理的铝合金;(b)超疏水处理的铝合金

Fig. 5 Adhesion behavior of water droplets on the surface: (a) untreated aluminum alloy; (b) superhydrophobically treated aluminum alloy

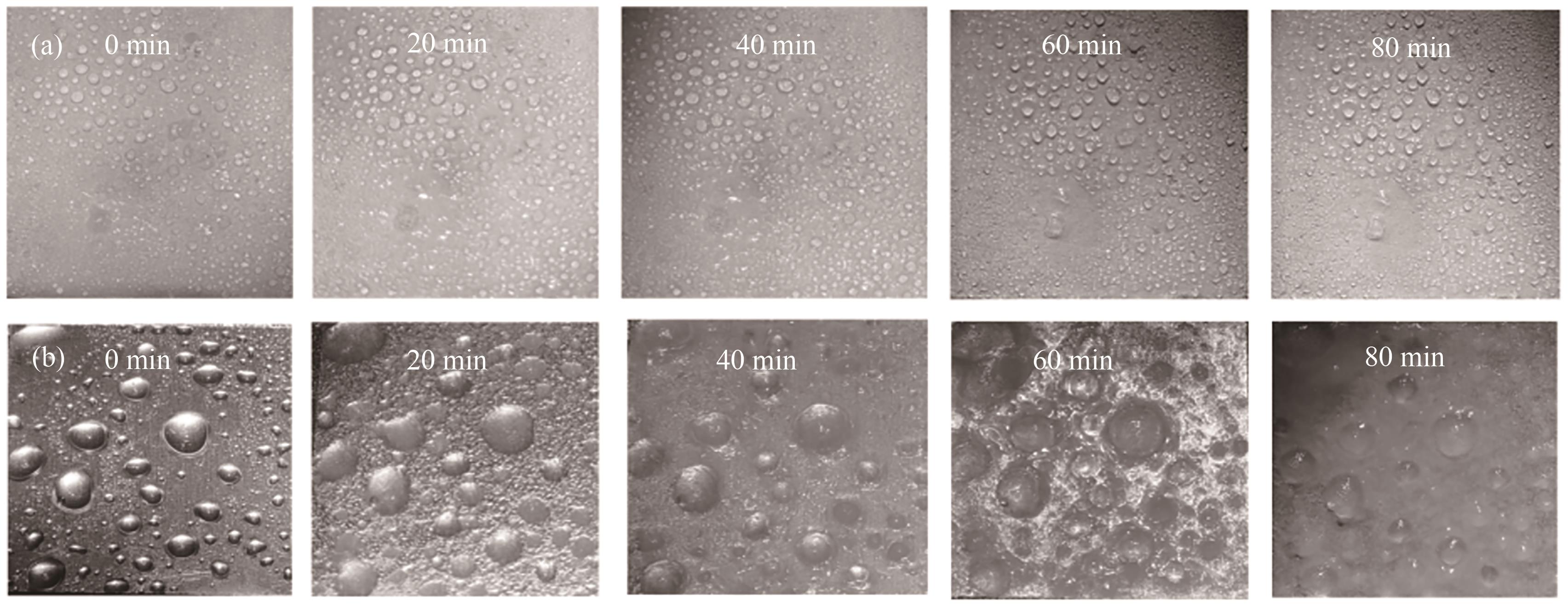

图6 超疏水处理前后的铝合金的覆冰行为:(a)未处理的铝合金;(b)超疏水铝合金

Fig. 6 Icing behavior of aluminum alloys before and after treatments: (a) untreated aluminum alloy; (b) superhydrophobic aluminum alloy

图7 水滴在未处理铝合金(a)和超疏水铝合金(b)表面发生冻结的光学图像

Fig.7 Optical images of water droplet freezing on untreated aluminum alloy (a) and superhydrophobic aluminum alloy (b) surfaces

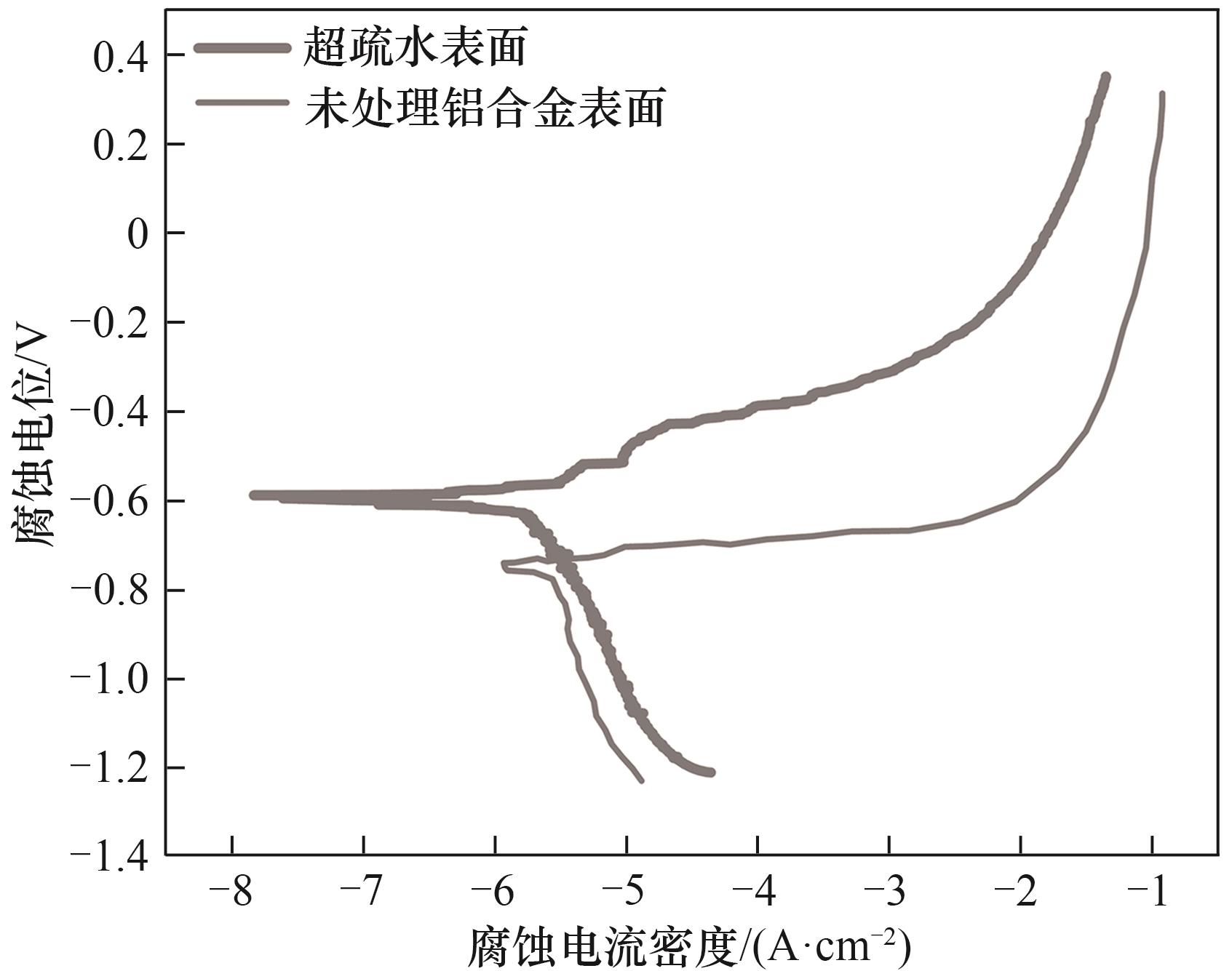

图8 未处理铝合金和超疏水铝合金在3.5%(质量)NaCl水溶液中的极化曲线

Fig.8 Potentiodynamic polarization curves of the as-received aluminum alloy substrate and the superhydrophobic aluminium alloy surface in 3.5%(mass) NaCl aqueous solution

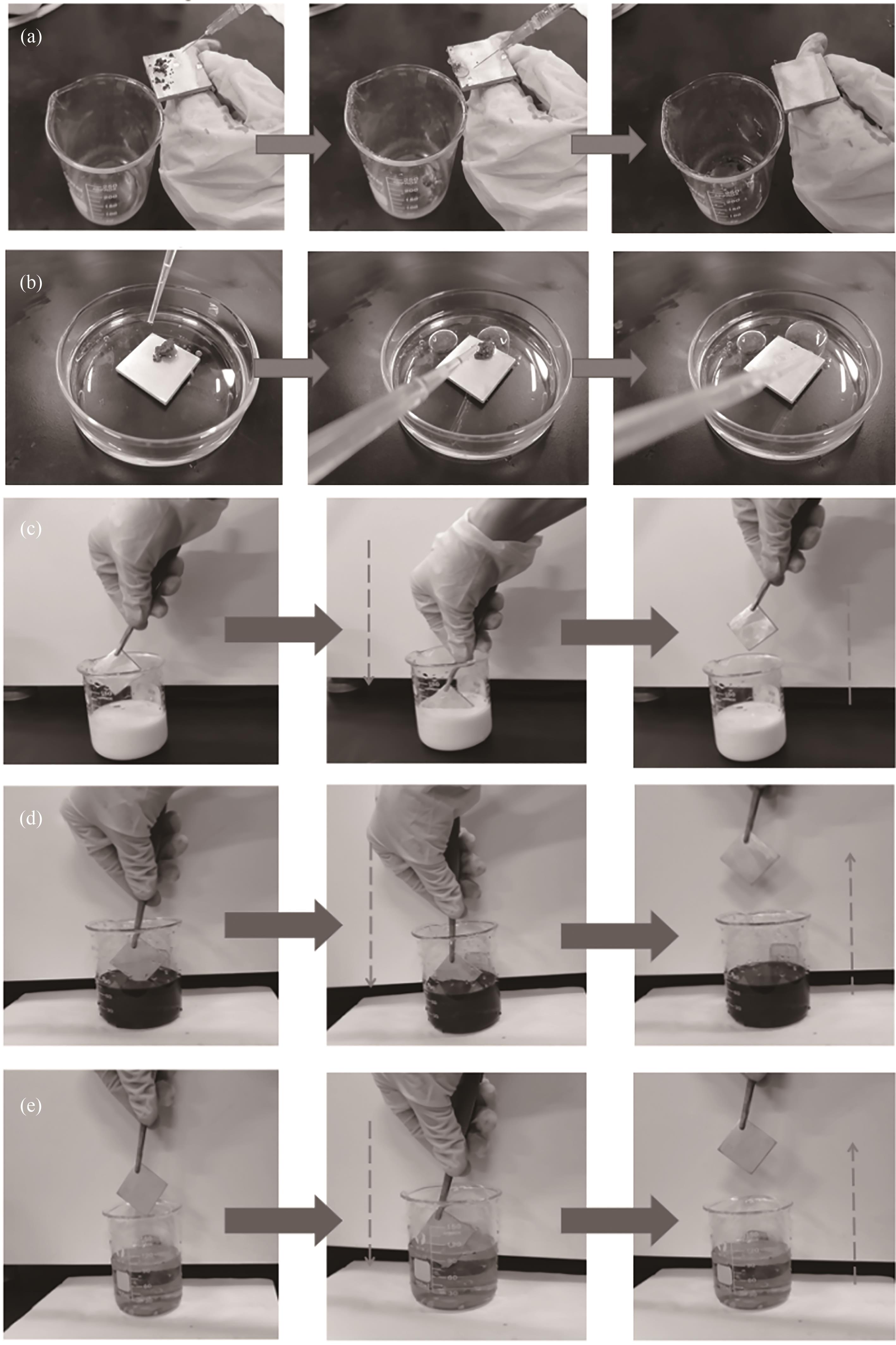

图9 超疏水铝合金在空气(a)、油(b)、牛奶(c)、甲基蓝溶液(d)、果汁(e)中的自清洁实验

Fig. 9 Self-cleaning experiments of superhydrophobic aluminum alloy in air (a), oil (b), milk (c), methyl blue solution (d) and fruit juice (e)

图10 超疏水铝合金的机械稳定性:(a)超声振动;(b)沸水;(c)落砂冲击;(d)线性耐磨

Fig. 10 Mechanical stability of the superhydrophobic aluminum alloy under different conditions: (a) ultrasonic vibration; (b) boiling water; (c) sand impact; (d) linear abrasion

| 材料 | 载荷/kPa | 磨损距离/cm | 落砂质量/g | 测试前接触角/(°) | 测试后接触角/(°) |

|---|---|---|---|---|---|

| 超疏水6061铝合金[ | 1 | 60 | — | 161 | 155 |

| 超疏水5083铝合金[ | 4.9 | 480 | — | 165 | 146 |

| 超疏水2024铝合金[ | 4.9 | 100 | — | 160 | 147 |

| 超疏水锌镀层[ | 3 | 200 | — | 158 | 142 |

| 无氟超疏水涂层[ | — | — | 120 | 156 | 154 |

| 超疏水聚合物涂层 [ | — | — | 30 | 176 | 148 |

| 本文中的超疏水6061铝合金 | 4.9 | 400 | — | 165 | 162 |

| — | — | 200 | 165 | 152 |

表1 本文制备的超疏水铝合金线性耐磨和落砂磨损性能与文献对比

Table 1 Comparison of linear wear resistance and sand drop wear resistance of superhydrophobic aluminum alloys prepared in this paper with those in literatures

| 材料 | 载荷/kPa | 磨损距离/cm | 落砂质量/g | 测试前接触角/(°) | 测试后接触角/(°) |

|---|---|---|---|---|---|

| 超疏水6061铝合金[ | 1 | 60 | — | 161 | 155 |

| 超疏水5083铝合金[ | 4.9 | 480 | — | 165 | 146 |

| 超疏水2024铝合金[ | 4.9 | 100 | — | 160 | 147 |

| 超疏水锌镀层[ | 3 | 200 | — | 158 | 142 |

| 无氟超疏水涂层[ | — | — | 120 | 156 | 154 |

| 超疏水聚合物涂层 [ | — | — | 30 | 176 | 148 |

| 本文中的超疏水6061铝合金 | 4.9 | 400 | — | 165 | 162 |

| — | — | 200 | 165 | 152 |

| [1] | Sarbada S, Shin Y C. Superhydrophobic contoured surfaces created on metal and polymer using a femtosecond laser[J]. Applied Surface Science, 2017, 405: 465-475. |

| [2] | Feng L B, Yan Z N, Qiang X H, et al. Facile formation of superhydrophobic aluminum alloy surface and corrosion-resistant behavior[J]. Applied Physics A, 2016, 122(3): 165. |

| [3] | 张跃忠. 金属特殊润湿性表面制备及性能研究[M]. 北京:化学工业出版社, 2021. |

| Zhang Y Z. Study on Preparation and Application of Metal Surface with Special Wettability[M]. Beijing: Chemical Industry Press, 2021. | |

| [4] | Si Y F, Guo Z G. Superhydrophobic nanocoatings: from materials to fabrications and to applications[J]. Nanoscale, 2015, 7(14): 5922-5946. |

| [5] | Feng L, Li S H, Li Y S, et al. Super-hydrophobic surfaces: from natural to artificial[J]. Advanced Materials, 2002, 14(24): 1857-1860. |

| [6] | Xiang T F, Han Y, Guo Z Q, et al. Fabrication of inherent anticorrosion superhydrophobic surfaces on metals[J]. ACS Sustainable Chemistry & Engineering, 2018, 6(4): 5598-5606. |

| [7] | Cho E C, Chang-Jian C W, Chen H C, et al. Robust multifunctional superhydrophobic coatings with enhanced water/oil separation, self-cleaning, anti-corrosion, and anti-biological adhesion[J]. Chemical Engineering Journal, 2017, 314: 347-357. |

| [8] | Liu Y C, Huang W J, Wu S H, et al. Excellent superhydrophobic surface and anti-corrosion performance by nanostructure of discotic columnar liquid crystals[J]. Corrosion Science, 2018, 138: 1-7. |

| [9] | Wu D H, Guo Z G. Robust and muti-repaired superhydrophobic surfaces via one-step method on copper and aluminum alloys[J]. Materials Letters, 2018, 213: 290-293. |

| [10] | Dong B B, Wang F H, Abadikhah H, et al. Simple fabrication of concrete with remarkable self-cleaning ability, robust superhydrophobicity, tailored porosity, and highly thermal and sound insulation[J]. ACS Applied Materials & Interfaces, 2019, 11(45): 42801-42807. |

| [11] | Gose J W, Golovin K, Boban M, et al. Characterization of superhydrophobic surfaces for drag reduction in turbulent flow[J]. Journal of Fluid Mechanics, 2018, 845: 560-580. |

| [12] | Zhou X, Yu S R, Jiao S Z, et al. Fabrication of superhydrophobic TiO2 quadrangular nanorod film with self-cleaning, anti-icing properties[J]. Ceramics International, 2019, 45(9): 11508-11516. |

| [13] | Qiu C, Li M, Chen S X. Anti-icing characteristics of PTFE super hydrophobic coating on titanium alloy surface[J]. Journal of Alloys and Compounds, 2021, 860: 157907. |

| [14] | 谢震廷, 王宏, 朱恂, 等. 光热超疏水材料的制备与防、除冰性能研究[J]. 化工学报, 2021, 72(11): 5840-5848. |

| Xie Z T, Wang H, Zhu X, et al. Preparation and anti-icing/deicing performance of photothermal superhydrophobic surfaces [J]. CIESC Journal, 2021, 72(11): 5840-5848. | |

| [15] | Wang G Y, Shen Y Z, Tao J, et al. Fabrication of a superhydrophobic surface with a hierarchical nanoflake-micropit structure and its anti-icing properties[J]. RSC Advances, 2017, 7(16): 9981-9988. |

| [16] | Bird J C, Dhiman R, Kwon H M, et al. Reducing the contact time of a bouncing drop[J]. Nature, 2013, 503(7476): 385-388. |

| [17] | 向静, 王宏, 朱恂, 等. 荷叶表面的复刻及微纳结构对疏水性能的影响[J]. 化工学报, 2019, 70(9): 3545-3552. |

| Xiang J, Wang H, Zhu X, et al. Fast replication method for lotus leaf and effect of micro-nanostructure on hydrophobic properties[J]. CIESC Journal, 2019, 70(9): 3545-3552. | |

| [18] | Dimitrakellis P, Gogolides E. Hydrophobic and superhydrophobic surfaces fabricated using atmospheric pressure cold plasma technology: a review[J]. Advances in Colloid and Interface Science, 2018, 254: 1-21. |

| [19] | Zhang B B, Zhu Q J, Li Y T, et al. Facile fluorine-free one step fabrication of superhydrophobic aluminum surface towards self-cleaning and marine anticorrosion[J]. Chemical Engineering Journal, 2018, 352: 625-633. |

| [20] | Zhang Y W, Bi J R, Wang S Q, et al. Functional food packaging for reducing residual liquid food: thermo-resistant edible super-hydrophobic coating from coffee and beeswax[J]. Journal of Colloid and Interface Science, 2019, 533: 742-749. |

| [21] | Barthwal S, Lee B, Lim S H. Fabrication of robust and durable slippery anti-icing coating on textured superhydrophobic aluminum surfaces with infused silicone oil[J]. Applied Surface Science, 2019, 496: 143677. |

| [22] | Tan J Y, Hao J J, An Z Q, et al. Superhydrophobic surfaces on brass substrates fabricated via micro-etching and a growth process[J]. RSC Advances, 2017, 7(42): 26145-26152. |

| [23] | Wu Y H, Zhao W J, Wang W R, et al. Fabricating binary anti-corrosion structures containing superhydrophobic surfaces and sturdy barrier layers for Al alloys[J]. RSC Advances, 2016, 6(6): 5100-5110. |

| [24] | 邢敏, 雷西萍, 关晓琳, 等. 铝合金超疏水表面的构建及其稳定性与自清洁性能研究[J]. 表面技术, 2021, 50(9):152-161. |

| Xing M, Lei X P, Guan X L, et al. Research on construction of superhydrophobic surface of aluminum alloy and its stability and self-cleaning performance [J]. Surface Technology, 2021, 50(9):152-161. | |

| [25] | Wenzel R N. Resistance of solid surfaces to wetting by water[J]. Industrial & Engineering Chemistry, 1936, 28(8): 988-994. |

| [26] | Yao X D, Hawkins S C, Falzon B G. An advanced anti-icing/de-icing system utilizing highly aligned carbon nanotube webs[J]. Carbon, 2018, 136: 130-138. |

| [27] | Maldonado C S, de la Rosa J R, Lucio-Ortiz C J, et al. Low concentration Fe-doped alumina catalysts using sol-gel and impregnation methods: the synthesis, characterization and catalytic performance during the combustion of trichloroethylene[J]. Materials, 2014, 7(3): 2062-2086. |

| [28] | Rittermeier A, Miao S J, Schröter M K, et al. The formation of colloidal copper nanoparticles stabilized by zinc stearate: one-pot single-step synthesis and characterization of the core-shell particles[J]. Physical Chemistry Chemical Physics, 2009, 11(37): 8358-8366. |

| [29] | Shen Y Z, Wang G Y, Tao J, et al. Anti-icing performance of superhydrophobic texture surfaces depending on reference environments[J]. Advanced Materials Interfaces, 2017, 4(22): 1700836. |

| [30] | Liu W, Xu Q J, Han J, et al. A novel combination approach for the preparation of superhydrophobic surface on copper and the consequent corrosion resistance[J]. Corrosion Science, 2016, 110: 105-113. |

| [31] | Barati Darband G, Aliofkhazraei M, Khorsand S, et al. Science and engineering of superhydrophobic surfaces: review of corrosion resistance, chemical and mechanical stability[J]. Arabian Journal of Chemistry, 2020, 13(1): 1763-1802. |

| [32] | Zhang X Y, Wang H Y, Zhang X G, et al. A multifunctional super-hydrophobic coating based on PDA modified MoS2 with anti-corrosion and wear resistance[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2019, 568: 239-247. |

| [33] | Barthwal S, Lim S H. Robust and chemically stable superhydrophobic aluminum-alloy surface with enhanced corrosion-resistance properties[J]. International Journal of Precision Engineering and Manufacturing-Green Technology, 2020, 7(2): 481-492. |

| [34] | Zhang B B, Xu W C, Zhu Q J, et al. Mechanically robust superhydrophobic porous anodized AA5083 for marine corrosion protection[J]. Corrosion Science, 2019, 158: 108083. |

| [35] | Li L J, Huang T, Lei J L, et al. Robust biomimetic-structural superhydrophobic surface on aluminum alloy[J]. ACS Applied Materials & Interfaces, 2015, 7(3): 1449-1457. |

| [36] | Jain R, Pitchumani R. Fabrication and characterization of zinc-based superhydrophobic coatings[J]. Surface and Coatings Technology, 2018, 337: 223-231. |

| [37] | Wang F, Pi J, Song F, et al. A superhydrophobic coating to create multi-functional materials with mechanical/chemical/physical robustness[J]. Chemical Engineering Journal, 2020, 381: 122539. |

| [38] | Ipekci H H, Arkaz H H, Onses M S, et al. Superhydrophobic coatings with improved mechanical robustness based on polymer brushes[J]. Surface and Coatings Technology, 2016, 299: 162-168. |

| [1] | 王三一, 黄文来. 电化学合成氨流程建模与优化[J]. 化工学报, 2025, 76(9): 4474-4486. |

| [2] | 娄岚浩, 杨立鹏, 杨晓光. 锂离子电池电化学机理模型参数辨识研究综述[J]. 化工学报, 2025, 76(9): 4369-4382. |

| [3] | 刘建海, 王磊, 鲁朝金, 白志山, 张平雨. 耦合电化学与多相流模型的电解槽性能研究[J]. 化工学报, 2025, 76(8): 3885-3893. |

| [4] | 罗佳欣, 袁艳. 压电材料在固态金属二次电池中的研究进展[J]. 化工学报, 2025, 76(8): 3822-3833. |

| [5] | 刘世昌, 李一白, 王靖, 刘永忠. 氢气驱动电化学捕碳系统的模块化设计与优化[J]. 化工学报, 2025, 76(8): 4108-4118. |

| [6] | 杨宁, 李皓男, LIN Xiao, GEORGIADOU Stella, LIN Wen-Feng. 从塑料废弃物到能源催化剂:塑料衍生碳@CoMoO4复合材料在电解水析氢反应中的应用[J]. 化工学报, 2025, 76(8): 4081-4094. |

| [7] | 王御风, 罗小雪, 范鸿亮, 吴白婧, 李存璞, 魏子栋. 耦合电解水制氢的绿色有机电合成——电极界面调控策略综述[J]. 化工学报, 2025, 76(8): 3753-3771. |

| [8] | 吴鹂霄, 燕溪溪, 张素娜, 徐一鸣, 钱佳颖, 乔永民, 王利军. 磷掺杂微晶石墨的制备及其在锂离子电池负极材料中的电化学性能研究[J]. 化工学报, 2025, 76(7): 3615-3625. |

| [9] | 陈培强, 郑群, 姜玉廷, 熊春华, 陈今茂, 王旭东, 黄龙, 阮曼, 徐万里. 电液流量及电流密度对海水激活电池输出特性的影响[J]. 化工学报, 2025, 76(7): 3235-3245. |

| [10] | 王子恒, 李文怀, 周嵬. 图形电极在固体氧化物燃料电池中的应用[J]. 化工学报, 2025, 76(7): 3153-3171. |

| [11] | 丁宏鑫, 干文翔, 赵雍洋, 贾润泽, 康子祺, 赵玉隆, 向勇. X65钢焊接接头在超临界CO2相及富H2O相中的腐蚀机理研究[J]. 化工学报, 2025, 76(7): 3426-3435. |

| [12] | 李欣然, 常龙娇, 罗绍华, 李永兵, 杨瑞芬, 侯增磊, 邹杰. Ho掺杂诱导NCM622局域电子重构抑制阳离子混排的改性机制研究[J]. 化工学报, 2025, 76(7): 3733-3741. |

| [13] | 王珺仪, 夏章讯, 景粉宁, 王素力. 基于重整气的高温聚合物电解质膜燃料电池电化学阻抗谱弛豫时间分布研究[J]. 化工学报, 2025, 76(7): 3509-3520. |

| [14] | 陆昕晟, 郭晓镭, 王世丞, 陆海峰, 刘海峰. 秸秆类生物质的粉碎特性研究[J]. 化工学报, 2025, 76(7): 3539-3551. |

| [15] | 孙国庆, 李海波, 丁志阳, 郭文辉, 徐浩, 赵艳侠. 硅基负极材料的研究进展[J]. 化工学报, 2025, 76(7): 3197-3211. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号