化工学报 ›› 2025, Vol. 76 ›› Issue (7): 3197-3211.DOI: 10.11949/0438-1157.20241425

孙国庆1( ), 李海波2, 丁志阳3, 郭文辉3, 徐浩3, 赵艳侠1(

), 李海波2, 丁志阳3, 郭文辉3, 徐浩3, 赵艳侠1( )

)

收稿日期:2024-12-09

修回日期:2025-02-19

出版日期:2025-07-25

发布日期:2025-08-13

通讯作者:

赵艳侠

作者简介:孙国庆(1999—),男,硕士研究生,1325097091@qq.com

基金资助:

Guoqing SUN1( ), Haibo LI2, Zhiyang DING3, Wenhui GUO3, Hao XU3, Yanxia ZHAO1(

), Haibo LI2, Zhiyang DING3, Wenhui GUO3, Hao XU3, Yanxia ZHAO1( )

)

Received:2024-12-09

Revised:2025-02-19

Online:2025-07-25

Published:2025-08-13

Contact:

Yanxia ZHAO

摘要:

近年来,随着新能源汽车的高速发展,对电池的比容量、循环效率以及安全性提出了更高的要求。硅基负极材料因超高理论比容量(4200 mAh/g)和丰富储量成为突破锂离子电池能量密度瓶颈的核心方向,但其产业化进程受制于锂化过程中>300%的体积膨胀及SEI膜动态破裂引发的结构失效。综述了国内外在硅材料与其他物质的材料制备、复合工艺、元素掺杂、结构设计、纳米化硅材料以及SEI膜研究等方面的前沿研究成果,并阐述了硅负极产业化方向的未来发展,为硅基负极的发展提供了重要参考。

中图分类号:

孙国庆, 李海波, 丁志阳, 郭文辉, 徐浩, 赵艳侠. 硅基负极材料的研究进展[J]. 化工学报, 2025, 76(7): 3197-3211.

Guoqing SUN, Haibo LI, Zhiyang DING, Wenhui GUO, Hao XU, Yanxia ZHAO. Research progress of silicon based anode materials[J]. CIESC Journal, 2025, 76(7): 3197-3211.

| 负极材料类型 | 嵌锂相 | 理论质量比容量/(mAh/g) | 理论体积比容量/(mAh/cm3) |

|---|---|---|---|

| C | LiC6 | 372 | 837 |

| Li4Ti5O12 | Li7Ti5O12 | 175 | 613 |

| Si | Li4.4Si | 4200 | 9786 |

| Sb | Li4.4Sb | 660 | 4422 |

| Sn | Li3Sn | 994 | 7246 |

| Mg | Li3Mg | 3350 | 4355 |

| Al | LiAl | 993 | 2681 |

表1 各类负极材料的理论质量比容量和理论体积比容量[4,17-19]

Table 1 Theoretical specific capacity and volumetric specific capacity of various anode materials[4,17-19]

| 负极材料类型 | 嵌锂相 | 理论质量比容量/(mAh/g) | 理论体积比容量/(mAh/cm3) |

|---|---|---|---|

| C | LiC6 | 372 | 837 |

| Li4Ti5O12 | Li7Ti5O12 | 175 | 613 |

| Si | Li4.4Si | 4200 | 9786 |

| Sb | Li4.4Sb | 660 | 4422 |

| Sn | Li3Sn | 994 | 7246 |

| Mg | Li3Mg | 3350 | 4355 |

| Al | LiAl | 993 | 2681 |

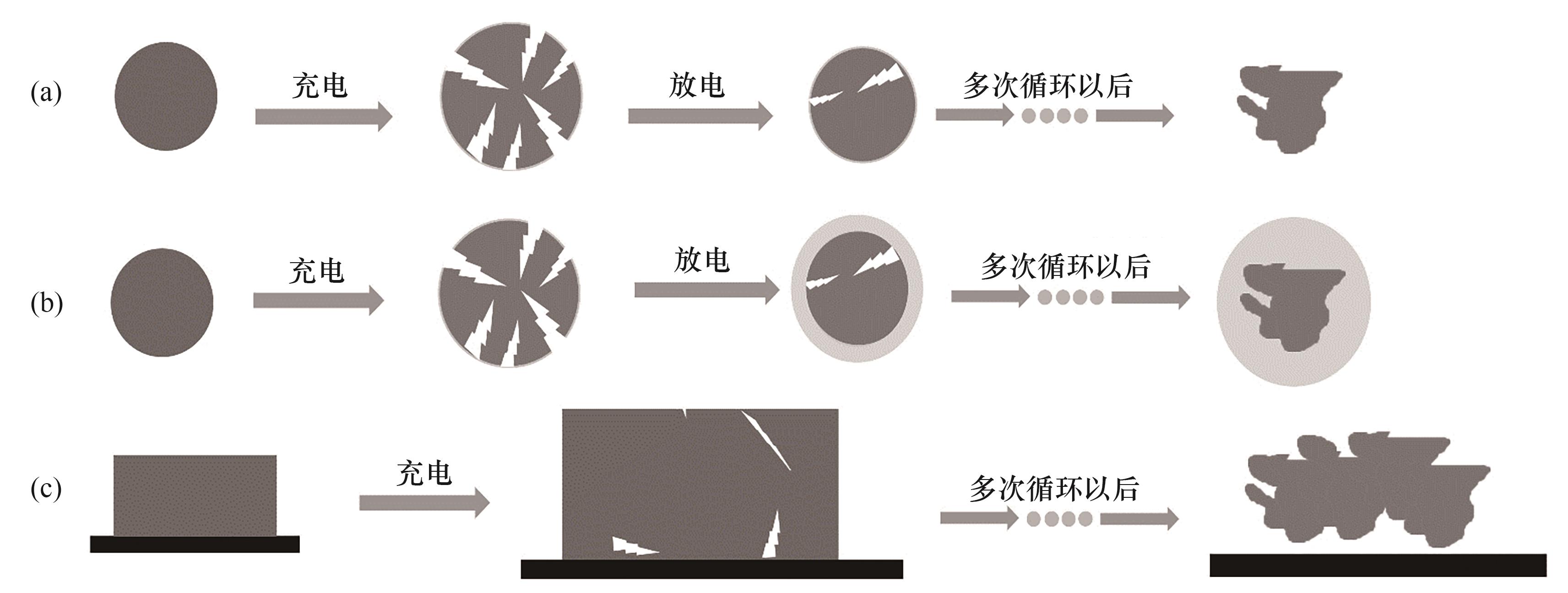

图1 (a)电极材料膨胀导致粉化;(b) SEI膜不断产生与破碎;(c)多次循环后材料与集流体丧失电接触[8]

Fig.1 (a) Expansion of the electrode material leading to pulverisation; (b) Continuous generation and fragmentation of the SEI film; (c) Loss of electrical contact between the material and the collector after multiple cycles[8]

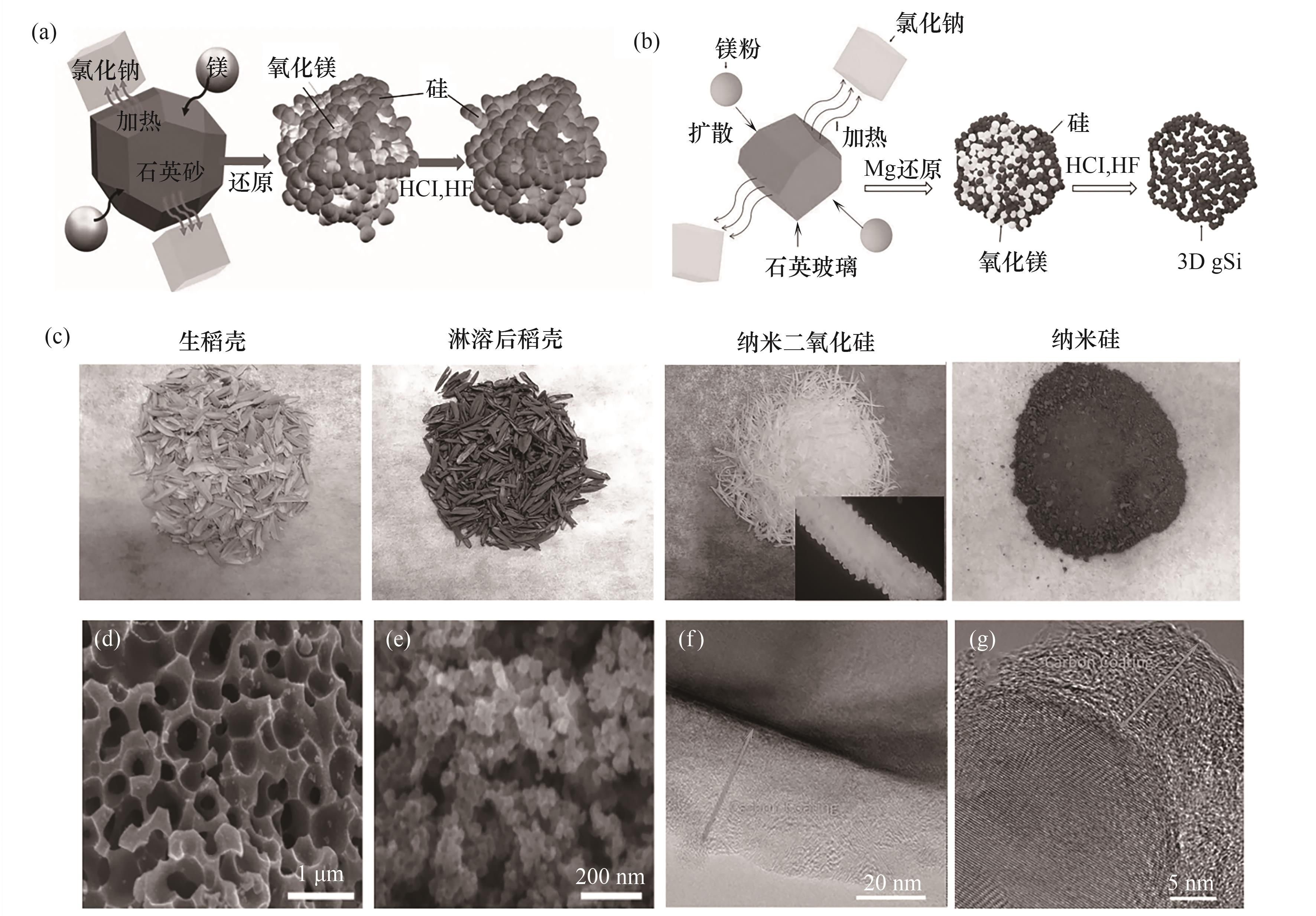

图2 (a)海滩沙石制纳米硅流程图;(b)废旧玻璃制硅材料流程图;(c)稻壳材料处理后的宏观形貌;(d)、(e)稻壳材料处理后的微观形貌;(f)、(g)海滩沙石处理后碳包覆[35,38-39]

Fig.2 (a) Flow chart of beach sand and gravel to make nanosilica; (b) Flow chart of waste glass to make silicon material; (c) Macroscopic morphology after treatment of rice husk material; (d),(e) Microscopic morphology after treatment of rice husk material; (f),(g) Carbon encapsulation after treatment of beach sand and gravel[35,38-39]

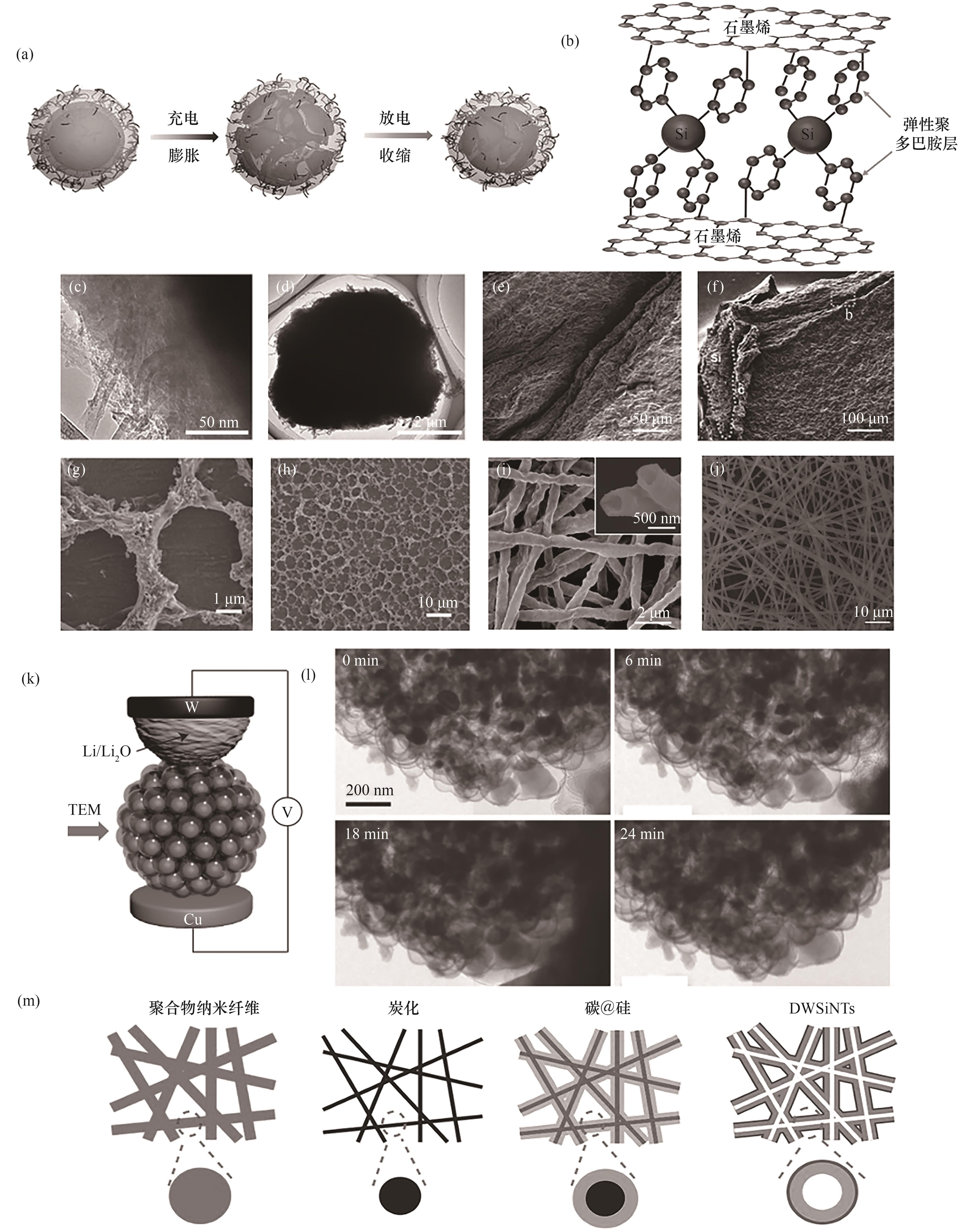

图3 (a)弹性包覆示意图;(b)“三明治”结构示意图;(c)、(d)不同精度下弹性包覆SEM图;(e)、(f)三明治结构SEM图;(g)、(h)“呼吸图”法为硅搭建“房子”;(i)循环2000次后DWSiNTs表面均匀覆盖SEI膜;(j)DWSiNTs SEM图;(k)、(l)原位TEM装置示意图以及拍摄TEM图像;(m)DWSiNTs合成示意图[46-48,52-55]

Fig.3 (a) Elastic coating diagram; (b) Schematic diagram of the “sandwich” structure; (c),(d) SEM images of elastic coating with different accuracy; (e),(f) SEM images of sandwich structure; (g),(h) “Breathing map” method was used to build a “house” for silicon; (i) DWSiNTs surface was uniformly covered with SEI film after 2000 cycles; (j)DWSiNTs SEM images; (k),(l) Schematic diagram of the in-situ TEM device and TEM images; (m) Schematic diagram of DWSiNTs synthesis[46-48,52-55]

| 结构设计 | 活性物质 | 活性物质含量/% | 充放电条件 | 循环圈数/次 | 初始比容量/(mAh/g) | 剩余可逆容量/(mAh/g) | 容量保持率/% |

|---|---|---|---|---|---|---|---|

| 未设计 | Si | 100 | 300 mA/g | 60 | 3250 | 0 | 0 |

| 核壳结构 | Si | 77 | 1.86 A/g | 1000 | 1196(第二圈) | 1160 | 97 |

| 弹性包覆 | SiO2 | 22 | 750 mA/g | 500 | 1500 | 836 | 55 |

| “三明治”结构 | Si | 60 | 300 mA/g | 400 | 1000 | 930 | 93 |

| “呼吸图”蜂窝结构 | Si | 50 | 50 mA/g | 50 | 1686 | 1183 | 70 |

| DWSiNTs | Si、SiO2 | 60 | 24 A/g | 6000 | 681.9(第二圈) | 600 | 83 |

表2 各类硅负极结构设计与纯硅负极性能对比[46-48,52-55]

Table 2 Structural design of various types of silicon negative electrode and performance comparison of pure silicon negative electrode[46-48,52-55]

| 结构设计 | 活性物质 | 活性物质含量/% | 充放电条件 | 循环圈数/次 | 初始比容量/(mAh/g) | 剩余可逆容量/(mAh/g) | 容量保持率/% |

|---|---|---|---|---|---|---|---|

| 未设计 | Si | 100 | 300 mA/g | 60 | 3250 | 0 | 0 |

| 核壳结构 | Si | 77 | 1.86 A/g | 1000 | 1196(第二圈) | 1160 | 97 |

| 弹性包覆 | SiO2 | 22 | 750 mA/g | 500 | 1500 | 836 | 55 |

| “三明治”结构 | Si | 60 | 300 mA/g | 400 | 1000 | 930 | 93 |

| “呼吸图”蜂窝结构 | Si | 50 | 50 mA/g | 50 | 1686 | 1183 | 70 |

| DWSiNTs | Si、SiO2 | 60 | 24 A/g | 6000 | 681.9(第二圈) | 600 | 83 |

| 对比维度 | 预置空隙 | 牺牲缓冲层 | 自支撑框架 | 原位限制 |

|---|---|---|---|---|

| 设计原理 | 人为预留膨胀空间(孔洞/间隙) | 刻蚀牺牲层形成空腔 | 刚性骨架限制膨胀方向 | 循环中动态约束膨胀方向 |

| 结构特点 | 夹层空隙、层间间隙 | 核壳结构(如Si@刻蚀SiO2@C) | 蜂窝状/管状骨架 | 刚性外壳(如SiO2)包裹硅内核 |

| 功能侧重 | 被动容纳膨胀 | 主动预留可控缓冲空间 | 机械约束膨胀方向 | 实时抑制膨胀路径 |

| 优势 | 结构简单,应力分散均匀 | 空间尺寸精准可控 | 膨胀抑制效果显著 | 循环中持续稳定约束 |

| 局限 | 空隙利用率低,能量密度损失 | 刻蚀工艺复杂,可能损伤硅材料 | 骨架刚性易导致局部应力集中 | 外壳破裂风险(长期循环) |

表3 缺陷构筑类改性机制的差异[46-48,52-55]

Table 3 The difference of modification mechanism of defect construction type[46-48,52-55]

| 对比维度 | 预置空隙 | 牺牲缓冲层 | 自支撑框架 | 原位限制 |

|---|---|---|---|---|

| 设计原理 | 人为预留膨胀空间(孔洞/间隙) | 刻蚀牺牲层形成空腔 | 刚性骨架限制膨胀方向 | 循环中动态约束膨胀方向 |

| 结构特点 | 夹层空隙、层间间隙 | 核壳结构(如Si@刻蚀SiO2@C) | 蜂窝状/管状骨架 | 刚性外壳(如SiO2)包裹硅内核 |

| 功能侧重 | 被动容纳膨胀 | 主动预留可控缓冲空间 | 机械约束膨胀方向 | 实时抑制膨胀路径 |

| 优势 | 结构简单,应力分散均匀 | 空间尺寸精准可控 | 膨胀抑制效果显著 | 循环中持续稳定约束 |

| 局限 | 空隙利用率低,能量密度损失 | 刻蚀工艺复杂,可能损伤硅材料 | 骨架刚性易导致局部应力集中 | 外壳破裂风险(长期循环) |

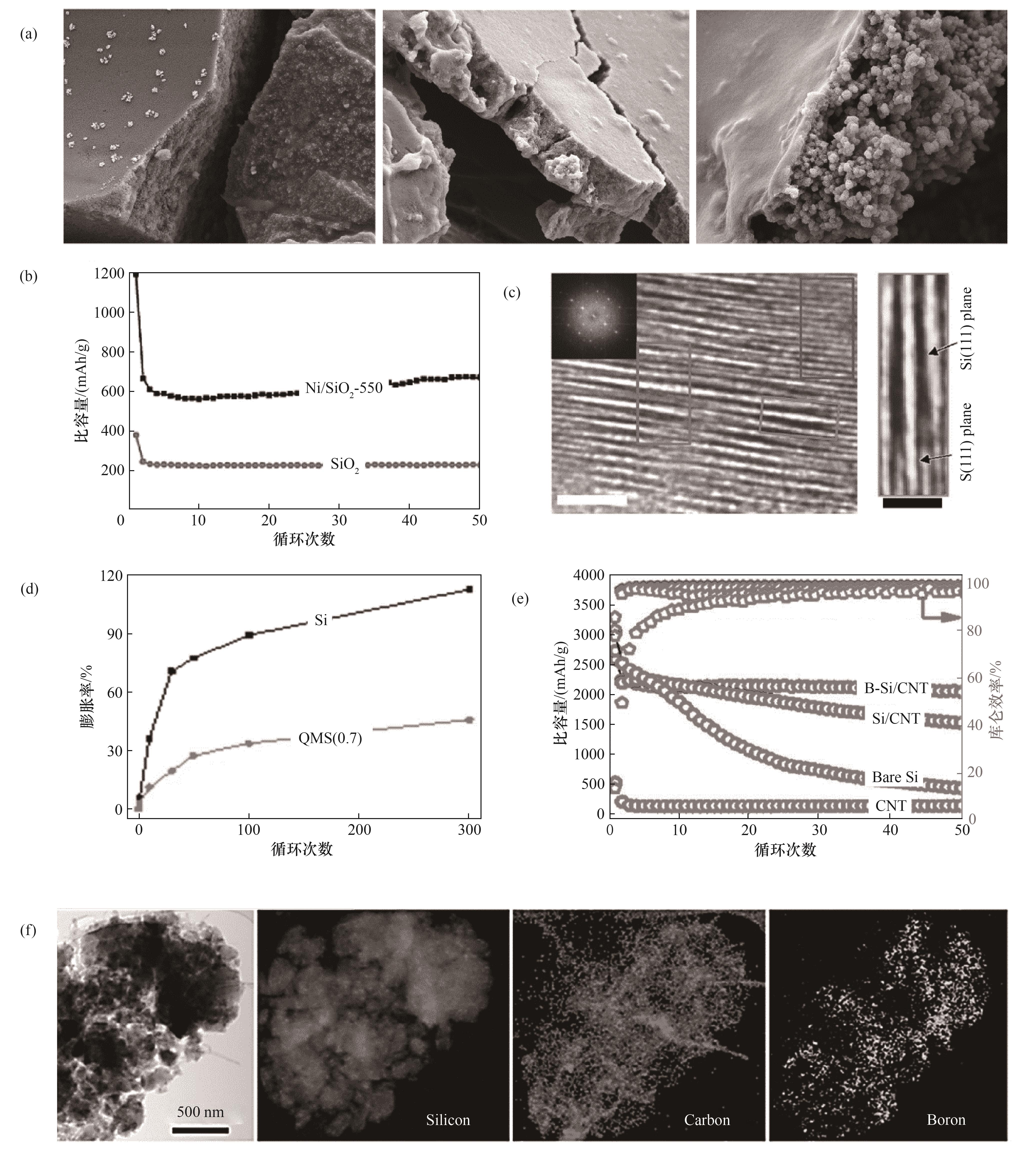

图4 (a)不同比例N掺杂循环后电极SEM图;(b)Ni元素掺杂与硅氧负极循环比较;(c)QMS的TEM图像以及放大后晶格条纹TEM图像;(d)QMS与Si电极300次循环后膨胀率对比;(e)不同材料负极长循环对比;(f)B元素均匀掺杂[59-66]

Fig.4 (a) SEM images of the electrodes after cycling with different ratios of N doping; (b) Comparison of Ni elemental doping with SiO2 anode cycling; (c) QMS TEM images as well as enlarged lattice fringing TEM images; (d) Comparison of the expansion rate of the QMS versus Si electrodes after 300 cycles; (e) Comparison of the various types of comparative anodes with long cycling; (f) Homogeneous doping with B elements[59-66]

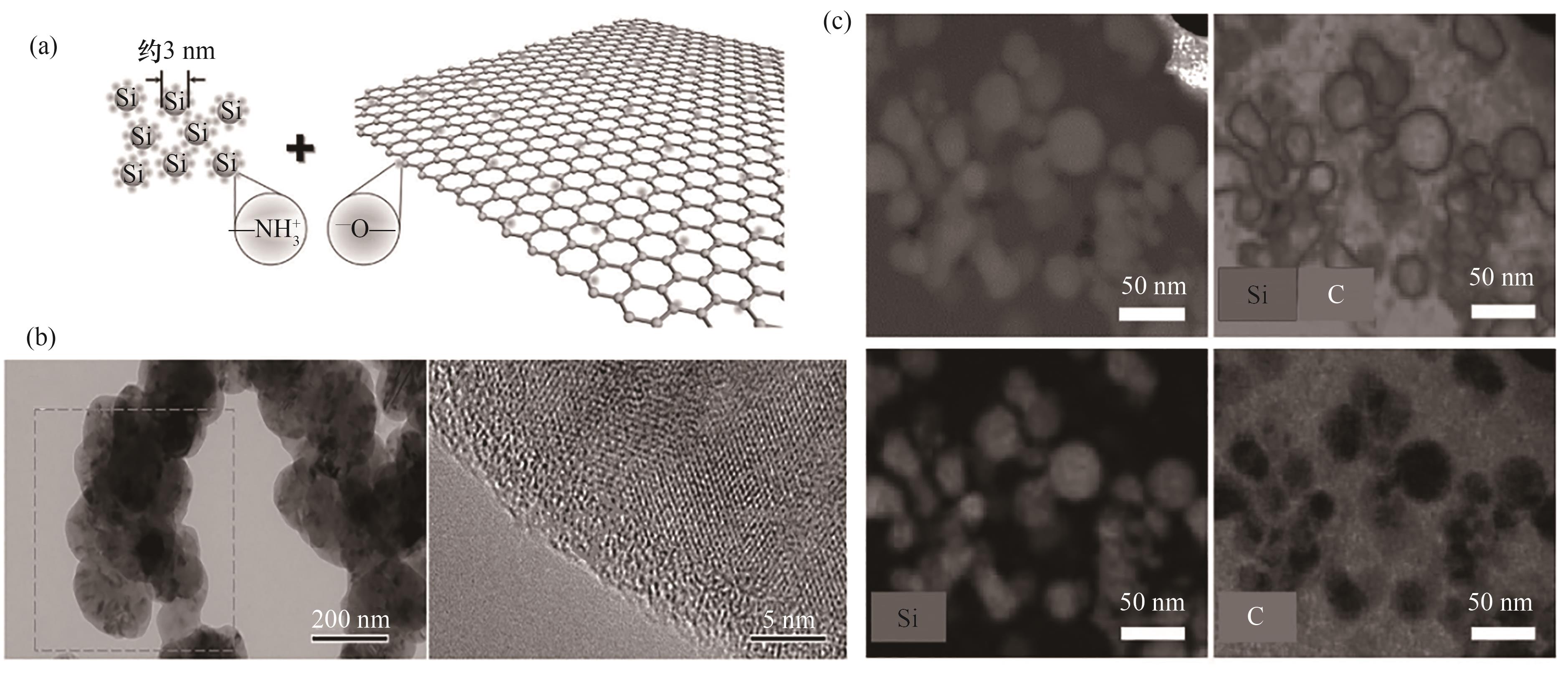

图5 (a)纳米Si QD沉积自组装在石墨烯网表面;(b)3.5 nm碳涂层包覆纳米硅的TEM图;(c)无定形碳包裹的纳米硅的TEM、EDS图[87-90]

Fig.5 (a) Nano-Si QD deposited self-assembled on the surface of graphene mesh; (b) 3.5 nm carbon coating encapsulating nano-Si; (c) TEM, EDS images of amorphous carbon encapsulated nano-Si[87-90]

| [1] | Anonymous. Battery revolution to evolution[J]. Nature Energy, 2019, 4: 893. |

| [2] | Sun Y K, Chen Z H, Noh H J, et al. Nanostructured high-energy cathode materials for advanced lithium batteries[J]. Nature Materials, 2012, 11(11): 942-947. |

| [3] | Khan A J, Gao L, Zhang Y, et al. Advancements and challenges in Si-based solid-state batteries: from anode design to manufacturing processes[J]. Next Materials, 2025, 7: 100371. |

| [4] | Peng J, Li W W, Wu Z Y, et al. Engineering Si-based anode materials with homogeneous distribution of SiO x and carbon for lithium-ion batteries[J]. Energy & Fuels, 2022, 36(10): 5465-5474. |

| [5] | 中商产业研究院. 2023年中国电化学储能行业市场前景及投资研究报告[J]. 电器工业, 2024(1): 8-13 |

| China Commerce Industry Research Institute. Market prospect and investment research report of electrochemical energy storage industry in China in 2023[J]. China Electrical Equipment Industry, 2024(1): 8-13. | |

| [6] | 中商产业研究院. 2024年中国储能电池行业市场前景预测[J]. 汽车与配件, 2023(23): 50-51. |

| China Commerce Industry Research Institute. Market prospect forecast of China energy storage battery industry in 2024[J]. Automobile & Parts, 2023(23): 50-51. | |

| [7] | Goodenough J B, Kim Y. Challenges for rechargeable batteries[J]. Journal of Power Sources, 2011, 196(16): 6688-6694. |

| [8] | Wu H, Cui Y. Designing nanostructured Si anodes for high energy lithium ion batteries[J]. Nano Today, 2012, 7(5): 414-429. |

| [9] | McBrayer J D, Rodrigues M F, Schulze M C, et al. Calendar aging of silicon-containing batteries[J]. Nature Energy, 2021, 6: 866-872. |

| [10] | Philippe B, Dedryvère R, Allouche J, et al. Nanosilicon electrodes for lithium-ion batteries: interfacial mechanisms studied by hard and soft X-ray photoelectron spectroscopy[J]. Chemistry of Materials, 2012, 24(6): 1107-1115. |

| [11] | Fu K, Lu Y, Dirican M, et al. Chamber-confined silicon-carbon nanofiber composites for prolonged cycling life of Li-ion batteries[J]. Nanoscale, 2014, 6(13): 7489-7495. |

| [12] | Huo H Y, Jiang M, Bai Y, et al. Chemo-mechanical failure mechanisms of the silicon anode in solid-state batteries[J]. Nature Materials, 2024, 23(4): 543-551. |

| [13] | Niu C J, Lee H, Chen S R, et al. High-energy lithium metal pouch cells with limited anode swelling and long stable cycles[J]. Nature Energy, 2019, 4: 551-559. |

| [14] | 常增花, 王建涛, 李文进, 等. 锂离子电池硅基负极界面反应的研究进展[J]. 材料工程, 2019, 47(2): 11-25. |

| Chang Z H, Wang J T, Li W J, et al. Research progress on interface reaction of silicon-based anode for lithium-ion battery[J]. Journal of Materials Engineering, 2019, 47(2): 11-25. | |

| [15] | Pharr M, Zhao K J, Wang X W, et al. Kinetics of initial lithiation of crystalline silicon electrodes of lithium-ion batteries[J]. Nano Letters, 2012, 12(9): 5039-5047. |

| [16] | Beaulieu L Y, Eberman K W, Turner R L, et al. Colossal reversible volume changes in lithium alloys[J]. Electrochemical and Solid-State Letters, 2001, 4(9): A137. |

| [17] | Dahlman C J, Heo S, Zhang Y T, et al. Dynamics of lithium insertion in electrochromic titanium dioxide nanocrystal ensembles[J]. Journal of the American Chemical Society, 2021, 143(22): 8278-8294. |

| [18] | Xu H, Li S, Chen X L, et al. Sn-alloy foil electrode with mechanical prelithiation: full-cell performance up to 200 cycles[J]. Advanced Energy Materials, 2019, 9(42): 1902150. |

| [19] | Yang C R, Pu Z C, Jiang Z F, et al. H2O-boosted Mg-proton collaborated energy storage for rechargeable Mg-metal batteries[J]. Advanced Energy Materials, 2022, 12(34): 2201718. |

| [20] | Eom K, Lee J T, Oschatz M, et al. A stable lithiated silicon-chalcogen battery via synergetic chemical coupling between silicon and selenium[J]. Nature Communications, 2017, 8: 13888. |

| [21] | Huang Q Q, Song J X, Gao Y, et al. Supremely elastic gel polymer electrolyte enables a reliable electrode structure for silicon-based anodes[J]. Nature Communications, 2019, 10: 5586. |

| [22] | Pomerantseva E, Bonaccorso F, Feng X L, et al. Energy storage: the future enabled by nanomaterials[J]. Science, 2019, 366(6468): eaan8285. |

| [23] | Shi Q T, Zhou J H, Ullah S, et al. A review of recent developments in Si/C composite materials for Li-ion batteries[J]. Energy Storage Materials, 2021, 34: 735-754. |

| [24] | Chan C K, Peng H L, Liu G, et al. High-performance lithium battery anodes using silicon nanowires[J]. Nature Nanotechnology, 2008, 3(1): 31-35. |

| [25] | Yang J P, Wang Y X, Li W, et al. Amorphous TiO2 shells: a vital elastic buffering layer on silicon nanoparticles for high-performance and safe lithium storage[J]. Advanced Materials, 2017, 29(48): 1700523. |

| [26] | Tang C J, Liu Y N, Xu C, et al. Ultrafine nickel-nanoparticle-enabled SiO2 hierarchical hollow spheres for high-performance lithium storage[J]. Advanced Functional Materials, 2018, 28(3): 1704561. |

| [27] | Zhang W J. Lithium insertion/extraction mechanism in alloy anodes for lithium-ion batteries[J]. Journal of Power Sources, 2011, 196(3): 877-885. |

| [28] | Limthongkul P, Jang Y I, Dudney N J, et al. Electrochemically-driven solid-state amorphization in lithium-silicon alloys and implications for lithium storage[J]. Acta Materialia, 2003, 51(4): 1103-1113. |

| [29] | Amezawa K, Yamamoto N, Tomii Y, et al. Single-electrode Peltier heats of Li-Si alloy electrodes in LiCl-KCl eutectic melt[J]. Journal of the Electrochemical Society, 1998, 145(6): 1986-1993. |

| [30] | 易婷. 锂离子电池硅负极的失效和调控方法的研究进展[J]. 中国金属通报, 2020(6): 230-231. |

| Yi T. Research progress on failure and control methods of silicon anode for lithium ion battery[J]. China Metal Bulletin, 2020(6): 230-231. | |

| [31] | Frith J T, Lacey M J, Ulissi U. A non-academic perspective on the future of lithium-based batteries[J]. Nature Communications, 2023, 14(1): 420. |

| [32] | Liu Y Y, Zhou G M, Liu K, et al. Design of complex nanomaterials for energy storage: past success and future opportunity[J]. Accounts of Chemical Research, 2017, 50(12): 2895-2905. |

| [33] | Fu K, Yildiz O, Bhanushali H, et al. Aligned carbon nanotube-silicon sheets: a novel nano-architecture for flexible lithium ion battery electrodes[J]. Advanced Materials, 2013, 25(36): 5109-5114. |

| [34] | Zhang Y Y, Li K, Ji P Y, et al. Silicon-multi-walled carbon nanotubes-carbon microspherical composite as high-performance anode for lithium-ion batteries[J]. Journal of Materials Science, 2017, 52(7): 3630-3641. |

| [35] | Favors Z, Wang W, Bay H H, et al. Scalable synthesis of nano-silicon from beach sand for long cycle life Li-ion batteries[J]. Scientific Reports, 2014, 4: 5623. |

| [36] | Dunn B, Kamath H, Tarascon J M. Electrical energy storage for the grid: a battery of choices[J]. Science, 2011, 334(6058): 928-935. |

| [37] | Zhang R Y, Du Y J, Li D, et al. Highly reversible and large lithium storage in mesoporous Si/C nanocomposite anodes with silicon nanoparticles embedded in a carbon framework[J]. Advanced Materials, 2014, 26(39): 6749-6755. |

| [38] | Liu N, Huo K F, McDowell M T, et al. Rice husks as a sustainable source of nanostructured silicon for high performance Li-ion battery anodes[J]. Scientific Reports, 2013, 3: 1919. |

| [39] | Li C L, Liu C, Wang W, et al. Silicon derived from glass bottles as anode materials for lithium ion full cell batteries[J]. Scientific Reports, 2017, 7: 917. |

| [40] | Liu D J, Kopold P, Van Aken P P A, et al. Energy storage materials from nature through nanotechnology: a sustainable route from reed plants to a silicon anode for lithium-ion batteries[J]. Angewandte Chemie International Edition, 2015, 54(33): 9632-9636. |

| [41] | Lin N, Han Y, Wang L B, et al. Preparation of nanocrystalline silicon from SiCl4 at 200℃ in molten salt for high-performance anodes for lithium ion batteries[J]. Angewandte Chemie International Edition, 2015, 54(12): 3822-3825. |

| [42] | 王学求, 谢学锦, 张本仁, 等. 地壳全元素探测: 构建“化学地球”[J]. 地质学报, 2010, 84(6): 854-864. |

| Wang X Q, Xie X J, Zhang B R, et al. China geochemical probe: making “geochemical earth”[J]. Acta Geologica Sinica, 2010, 84(6): 854-864. | |

| [43] | Eiby G A. New zealand crustal structure[J]. Nature, 1955, 176(4470): 32. |

| [44] | Wu H, Du N, Shi X X, et al. Rational design of three-dimensional macroporous silicon as high performance Li-ion battery anodes with long cycle life[J]. Journal of Power Sources, 2016, 331: 76-81. |

| [45] | Cong R Y, Choi J Y, Song J B, et al. Characteristics and electrochemical performances of silicon/carbon nanofiber/graphene composite films as anode materials for binder-free lithium-ion batteries[J]. Scientific Reports, 2021, 11(1): 1283. |

| [46] | Pan H, Wang L, Shi Y, et al. A solid-state lithium-ion battery with micron-sized silicon anode operating free from external pressure[J]. Nature Communications, 2024, 15(1): 2263. |

| [47] | Li G, Huang L B, Yan M Y, et al. An integral interface with dynamically stable evolution on micron-sized SiO x particle anode[J]. Nano Energy, 2020, 74: 104890. |

| [48] | Agyeman D A, Song K, Lee G H, et al. Carbon-coated Si nanoparticles anchored between reduced graphene oxides as an extremely reversible anode material for high energy-density Li-ion battery[J]. Advanced Energy Materials, 2016, 6(20): 1600904. |

| [49] | Tang H, Tu J P, Liu X Y, et al. Self-assembly of Si/honeycomb reduced graphene oxide composite film as a binder-free and flexible anode for Li-ion batteries[J]. Journal of Materials Chemistry A, 2014, 2(16): 5834-5840. |

| [50] | Yin S Y, Zhang Y Y, Kong J H, et al. Assembly of graphene sheets into hierarchical structures for high-performance energy storage[J]. ACS Nano, 2011, 5(5): 3831-3838. |

| [51] | Wang G K, Sun X, Lu F Y, et al. Flexible pillared graphene-paper electrodes for high-performance electrochemical supercapacitors[J]. Small, 2012, 8(3): 452-459. |

| [52] | Zhu L W, Wan L S, Jin J, et al. Honeycomb porous films prepared from porphyrin-cored star polymers: submicrometer pores induced by transition of monolayer into multilayer structures[J]. The Journal of Physical Chemistry C, 2013, 117(12): 6185-6194. |

| [53] | Srinivasarao M, Collings D, Philips A, et al. Three-dimensionally ordered array of air bubbles in a polymer film[J]. Science, 2001, 292(5514): 79-83. |

| [54] | Liu N, Lu Z D, Zhao J, et al. A pomegranate-inspired nanoscale design for large-volume-change lithium battery anodes[J]. Nature Nanotechnology, 2014, 9(3): 187-192. |

| [55] | Sung J, Kim N, Ma J, et al. Subnano-sized silicon anode via crystal growth inhibition mechanism and its application in a prototype battery pack[J]. Nature Energy, 2021, 6: 1164-1175. |

| [56] | Wu H, Chan G, Choi J W, et al. Stable cycling of double-walled silicon nanotube battery anodes through solid-electrolyte interphase control[J]. Nature Nanotechnology, 2012, 7(5): 310-315. |

| [57] | Dong Y J, Liu C, Li F, et al. Highly conductive ultrafine N-doped silicon powders prepared by high-frequency thermal plasma and their application as anodes for lithium-ion batteries[J]. ACS Applied Electronic Materials, 2024, 6(2): 816-827. |

| [58] | Bie X, Dong Y W, Xiong M, et al. Nitrogen-doped carbon matrix to optimize cycling stability of lithium ion battery anode from SiO x materials[J]. Inorganics, 2024, 12(1): 9. |

| [59] | Zuo H, Irran E, Klare H F T, et al. Electrophilic activation of S-Si reagents by silylium ions for their regio-and diastereoselective addition across C—C multiple bonds[J]. Angewandte Chemie International Edition, 2024, 63: e202401599. |

| [60] | 付洁, 王朔, 殷营营, 等. 一种氮掺杂多孔硅碳负极材料及其制备方法和应用: 202411533624.X[P]. 2025-01-24. |

| Fu J, Wang S, Yin Y Y, et al. A nitrogen doped porous silicon carbon negative electrode material and its preparation method and application: 202411533624.X[P]. 2025-01-24. | |

| [61] | 樊培贤, 梅一丹, 张静, 等. 应对硅负极材料体积变化的策略[J]. 云南化工, 2020, 47(11): 135-137. |

| Fan P X, Mei Y D, Zhang J, et al. Strategies for volume change of silicon anode materials[J]. Yunnan Chemical Technology, 2020, 47(11): 135-137. | |

| [62] | 温广武, 唐校福. 氮掺杂石墨烯/硅三维锂离子负极复合材料及其制备方法: 201810215307.1[P]. 2018-10-02. |

| Wen G W, Tang X F. Nitrogen doped graphene/silicon three-dimensional lithium-ion negative electrode composite material and its preparation method: 201810215307.1[P]. 2018-10-02. | |

| [63] | 黄明竹, 胡伟敏. 硅中硫族杂质中性多原子集团的电子结构[J]. 中国科学技术大学学报, 1988, 18(1): 23-32. |

| Huang M Z, Hu W M. Electronic structures of chalcogen impurities as neutral multi-atom clusters in Si[J]. Journal of University of Science and Technology of China, 1988, 18(1): 23-32. | |

| [64] | Luque A, Martí A. Increasing the efficiency of ideal solar cells by photon induced transitions at intermediate levels[J]. Physical Review Letters, 1997, 78(26): 5014-5017. |

| [65] | Ryu J, Seo J H, Song G, et al. Infinitesimal sulfur fusion yields quasi-metallic bulk silicon for stable and fast energy storage[J]. Nature Communications, 2019, 10(1): 2351. |

| [66] | Li P, Hwang J Y, Sun Y K. Nano/microstructured silicon-graphite composite anode for high-energy-density Li-ion battery[J]. ACS Nano, 2019, 13(2): 2624-2633. |

| [67] | 吴士超, 赵子云, 兰丹妮, 等. 硅负极材料及其制备方法和应用: 202211010892.4[P]. 2024-03-08. |

| Wu S C, Zhao Z Y, Lan D N, et al. Silicon negative electrode material and its preparation method and application: 202211010892.4[P]. 2024-03-08. | |

| [68] | 谢英朋, 赵瑞瑞, 冀亚娟. 一种硅负极材料、负极片、电池: 119050293A[P]. 2024-11-29. |

| Xie Y P, Zhao R R, Ji Y J. A silicon negative electrode material, negative electrode sheet, and battery: 119050293A[P]. 2024-11-29. | |

| [69] | 李龙. 界面优化对锂离子电池硅负极性能影响的研究[D]. 武汉: 中国地质大学, 2021. |

| Li L. Study on the influence of interface optimization on the performance of silicon anode for lithium ion batteries[D]. Wuhan: China University of Geosciences, 2021. | |

| [70] | Lu J J, Sun Y W, Pang S, et al. The crucial role of impurity of photovoltaic silicon waste in dictating the performance of lithium-ion battery anodes[J]. Journal of Cleaner Production, 2024, 434: 140209. |

| [71] | 陈晓东. 金属有机骨架基复合材料的制备及其催化应用研究[D]. 广州: 华南理工大学, 2019. |

| Chen X D. Study on preparation and catalytic application of metal-organic matrix composites[D]. Guangzhou: South China University of Technology, 2019. | |

| [72] | Song R F, Yang L L, Luan J Y, et al. MgSiO3 doped, carbon-coated SiO x anode with enhanced initial coulombic efficiency for lithium-ion battery[J]. Journal of Energy Storage, 2025, 105: 114687. |

| [73] | Zhao J, Jing J J, Li W Q, et al. Noncovalent crosslinked liquid metal-incorporated polymer binder based on multiple dynamic bonds for silicon microparticle anode[J]. Energy Storage Materials, 2023, 63: 102991. |

| [74] | 陈懋松, 陈苇伦, 赖鸿政, 等. 元素掺杂的硅碳复合负极材料及其制备方法: 117096292A[P]. 2023-11-21. |

| Chen M S, Chen W L, Lai H Z, et al. Element doped silicon carbon composite negative electrode material and its preparation method: 117096292A[P]. 2023-11-21. | |

| [75] | 周军华, 罗飞, 褚赓, 等. 锂离子电池纳米硅碳负极材料研究进展[J]. 储能科学与技术, 2020, 9(2): 569-582. |

| Zhou J H, Luo F, Chu G, et al. Research progress on nano silicon-carbon anode materials for lithium ion battery[J]. Energy Storage Science and Technology, 2020, 9(2): 569-582. | |

| [76] | Zhang X H, Wang D H, Qiu X Y, et al. Stable high-capacity and high-rate silicon-based lithium battery anodes upon two-dimensional covalent encapsulation[J]. Nature Communications, 2020, 11(1): 3826. |

| [77] | Gasparov V A. High-frequency size effect study of the Fermi surface of metals[J]. Physics-Uspekhi, 2018, 61(3): 289-302. |

| [78] | Kelley K, Preacher K J. On effect size[J]. Psychological Methods, 2012, 17(2): 137-152. |

| [79] | Sun Y M, Liu N, Cui Y. Promises and challenges of nanomaterials for lithium-based rechargeable batteries[J]. Nature Energy, 2016, 1(7): 16071. |

| [80] | Yang Y, Li S, Li S S, et al. High-performance hybrid supercapacitor enabled by advantageous heterojunction boosted starfish-like ZnCo-S electrode[J]. Journal of Alloys and Compounds, 2022, 928: 166997. |

| [81] | Yoo J K, Kim J, Jung Y S, et al. Scalable fabrication of silicon nanotubes and their application to energy storage[J]. Advanced Materials, 2012, 24(40): 5452-5456. |

| [82] | Li X L, Gu M, Hu S Y, et al. Mesoporous silicon sponge as an anti-pulverization structure for high-performance lithium-ion battery anodes[J]. Nature Communications, 2014, 5: 4105. |

| [83] | Graetz J, Ahn C C, Yazami R, et al. Highly reversible lithium storage in nanostructured silicon[J]. Electrochemical and Solid-State Letters, 2003, 6(9): A194. |

| [84] | McDowell M T, Ryu I, Lee S W, et al. Studying the kinetics of crystalline silicon nanoparticle lithiation with in situ transmission electron microscopy[J]. Advanced Materials, 2012, 24(45): 6034-6041. |

| [85] | Ryu I, Choi J W, Cui Y, et al. Size-dependent fracture of Si nanowire battery anodes[J]. Journal of the Mechanics and Physics of Solids, 2011, 59(9): 1717-1730. |

| [86] | Shimizu M, Usui H, Suzumura T, et al. Analysis of the deterioration mechanism of Si electrode as a Li-ion battery anode using Raman microspectroscopy[J]. The Journal of Physical Chemistry C, 2015, 119(6): 2975-2982. |

| [87] | Wang B, Li X L, Luo B, et al. Approaching the downsizing limit of silicon for surface-controlled lithium storage[J]. Advanced Materials, 2015, 27(9): 1526-1532. |

| [88] | Ma X L, Sun D, Zhang M L, et al. Nano-silicon encased in a S, N co-doped carbon shells anode delivers high lithium-ion storage performance[J]. ACS Sustainable Chemistry & Engineering, 2024, 12(33): 12542-12552. |

| [89] | Kwon H J, Hwang J Y, Shin H J, et al. Nano/microstructured silicon-carbon hybrid composite particles fabricated with corn starch biowaste as anode materials for Li-ion batteries[J]. Nano Letters, 2020, 20(1): 625-635. |

| [90] | Zhong Y L, Peng F, Bao F, et al. Large-scale aqueous synthesis of fluorescent and biocompatible silicon nanoparticles and their use as highly photostable biological probes[J]. Journal of the American Chemical Society, 2013, 135(22): 8350-8356. |

| [91] | Weintz D, Kühn S P, Winter M, et al. Tailoring the preformed solid electrolyte interphase in lithium metal batteries: impact of fluoroethylene carbonate[J]. ACS Applied Materials & Interfaces, 2023, 15(46): 53526-53532. |

| [92] | Chen S M, Deng Z K, Li J X, et al. Tuning reaction kinetics of fluorinated molecules to construct robust solid electrolyte interphases on SiO x anode[J]. Angewandte Chemie International Edition, 2025, 64(1): e202413927. |

| [93] | Wang J, Yang Z, Mao B G, et al. Transgenic engineering on silicon surfaces enables robust interface chemistry[J]. ACS Energy Letters, 2022, 7(8): 2781-2791. |

| [94] | Sun Z F, Yin Q Z, Chen H Y, et al. Building better solid-state batteries with silicon-based anodes[J]. Interdisciplinary Materials, 2023, 2(4): 635-663. |

| [95] | Wang J C, Chen L Q, Li H, et al. Anode interfacial issues in solid-state Li batteries: mechanistic understanding and mitigating strategies[J]. Energy & Environmental Materials, 2023, 6(4): e12613. |

| [1] | 高凤凤, 程慧峰, 杨博, 郝晓刚. 电驱动NiFeMn LDH/CNTs/PVDF膜电极选择性提取钨酸根离子[J]. 化工学报, 2025, 76(7): 3350-3360. |

| [2] | 陈培强, 郑群, 姜玉廷, 熊春华, 陈今茂, 王旭东, 黄龙, 阮曼, 徐万里. 电液流量及电流密度对海水激活电池输出特性的影响[J]. 化工学报, 2025, 76(7): 3235-3245. |

| [3] | 王子恒, 李文怀, 周嵬. 图形电极在固体氧化物燃料电池中的应用[J]. 化工学报, 2025, 76(7): 3153-3171. |

| [4] | 李欣然, 常龙娇, 罗绍华, 李永兵, 杨瑞芬, 侯增磊, 邹杰. Ho掺杂诱导NCM622局域电子重构抑制阳离子混排的改性机制研究[J]. 化工学报, 2025, 76(7): 3733-3741. |

| [5] | 吴鹂霄, 燕溪溪, 张素娜, 徐一鸣, 钱佳颖, 乔永民, 王利军. 磷掺杂微晶石墨的制备及其在锂离子电池负极材料中的电化学性能研究[J]. 化工学报, 2025, 76(7): 3615-3625. |

| [6] | 王珺仪, 夏章讯, 景粉宁, 王素力. 基于重整气的高温聚合物电解质膜燃料电池电化学阻抗谱弛豫时间分布研究[J]. 化工学报, 2025, 76(7): 3509-3520. |

| [7] | 康佳, 刘欢, 李海燕, 罗茂亮, 姚洪. 宽温区HCl/NaOH热介质中碳钢腐蚀行为及涂层性能研究[J]. 化工学报, 2025, 76(6): 2872-2885. |

| [8] | 张畅, 解强, 沙雨桐, 王炳杰, 梁鼎成, 刘金昌. 低灰低硅竹炭的制备及衍生硬炭的电化学性能[J]. 化工学报, 2025, 76(6): 3073-3083. |

| [9] | 郭明钢, 杨晓航, 代岩, 米盼盼, 马世鑫, 贺高红, 肖武, 崔福军. 贫氦管输天然气提氦多元化产品耦合工艺优化设计[J]. 化工学报, 2025, 76(5): 2251-2261. |

| [10] | 李坤, 黄锐, 丛君, 马海涛, 常龙娇, 罗绍华. NCM622正极材料结构形态和储锂特性的同步演变[J]. 化工学报, 2025, 76(4): 1831-1840. |

| [11] | 林纬, 杜建, 姚晨, 朱家豪, 汪威, 郑小涛, 徐建民, 喻九阳. 电化学水软化过程中离子输运与成核机理研究[J]. 化工学报, 2025, 76(4): 1788-1799. |

| [12] | 吴迪, 刘世朋, 王文伟, 姜久春, 杨晓光. 机械压力对锂金属电池性能影响的研究进展[J]. 化工学报, 2025, 76(4): 1422-1431. |

| [13] | 马钟琛, 魏子杰, 朱明涛, 叶恒棣, 郭学益, 谭磊. 一步氧化法制备锰酸锂正极材料用电池级四氧化三锰[J]. 化工学报, 2025, 76(3): 1363-1374. |

| [14] | 肖志华, 房浩楠, 郑方植, 孙冬, 陶丽达, 李永峰, 徐春明, 马新龙. NaCl辅助构筑高性能沥青基硬炭负极材料[J]. 化工学报, 2025, 76(2): 846-857. |

| [15] | 徐子易, 席阳, 宋泽文, 周海骏. 碳纳米材料在锌离子电池中的应用研究进展[J]. 化工学报, 2025, 76(1): 40-52. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号