化工学报 ›› 2020, Vol. 71 ›› Issue (9): 4189-4199.DOI: 10.11949/0438-1157.20200850

收稿日期:2020-06-28

修回日期:2020-07-29

出版日期:2020-09-05

发布日期:2020-09-05

通讯作者:

丁晓斌,邢卫红

作者简介:左成业(1996—),男,硕士,基金资助:

Chengye ZUO1( ),Rui TU2,Xiaobin DING1,2(

),Rui TU2,Xiaobin DING1,2( ),Weihong XING1(

),Weihong XING1( )

)

Received:2020-06-28

Revised:2020-07-29

Online:2020-09-05

Published:2020-09-05

Contact:

Xiaobin DING,Weihong XING

摘要:

乙酸与异丁醇酯化反应生产乙酸异丁酯,产生大量含异丁醇的废水,常规生化处理负荷重,浪费资源。采用PDMS复合膜分离回收酯化废水中的异丁醇,考察了异丁醇浓度对PDMS复合膜溶胀度及分离性能的影响,优化渗透汽化过程操作参数,研究了乙酸异丁酯对PDMS复合膜回收异丁醇效果的影响。结果表明,随着异丁醇浓度从1%增大到3%(质量),PDMS复合膜溶胀度先增大后趋于平稳,异丁醇的渗透通量呈增大趋势,分离因子保持在15左右;操作温度从30℃升至60℃时,渗透通量增大,异丁醇的分离因子下降,总表观活化能为33.87 kJ/mol;流速增加,Reynolds数增大,异丁醇渗透通量变化不大,但分离因子略有增大;微量乙酸异丁酯的存在可促进渗透汽化膜回收异丁醇。采用PDMS复合膜分离酯化废水中的异丁醇,回收率大于94.0%,渗余液中异丁醇浓度可降至0.1%(质量)左右。研究结果可为PDMS复合膜处理低浓度有机溶剂废水提供依据。

中图分类号:

左成业, 涂睿, 丁晓斌, 邢卫红. PDMS复合膜回收酯化反应废水中的异丁醇[J]. 化工学报, 2020, 71(9): 4189-4199.

Chengye ZUO, Rui TU, Xiaobin DING, Weihong XING. Recovery of isobutanol from esterified wastewater by PDMS composite membrane[J]. CIESC Journal, 2020, 71(9): 4189-4199.

| 试剂 | 摩尔质量/(g·mol-1) | 摩尔体积/(cm3·mol-1) | 沸点/℃ | 蒸气压(20℃)/Pa | 溶解度参数/ (cal·cm-3)1/2 |

|---|---|---|---|---|---|

| 异丁醇 | 74.12 | 91.5 | 107.9 | 1170 | 10.8 |

| 乙酸异丁酯 | 116.16 | 131.55 | 116.6 | 1789 | 8.3 |

| 水 | 18.02 | 18.0 | 100 | 2340 | 23.4 |

| PDMS | 58000 | — | — | — | 7.3 |

表1 异丁醇、乙酸异丁酯和水的物化性质[23-24]

Table 1 Physicochemical properties of isobutanol, isobutyl acetate and water[23-24]

| 试剂 | 摩尔质量/(g·mol-1) | 摩尔体积/(cm3·mol-1) | 沸点/℃ | 蒸气压(20℃)/Pa | 溶解度参数/ (cal·cm-3)1/2 |

|---|---|---|---|---|---|

| 异丁醇 | 74.12 | 91.5 | 107.9 | 1170 | 10.8 |

| 乙酸异丁酯 | 116.16 | 131.55 | 116.6 | 1789 | 8.3 |

| 水 | 18.02 | 18.0 | 100 | 2340 | 23.4 |

| PDMS | 58000 | — | — | — | 7.3 |

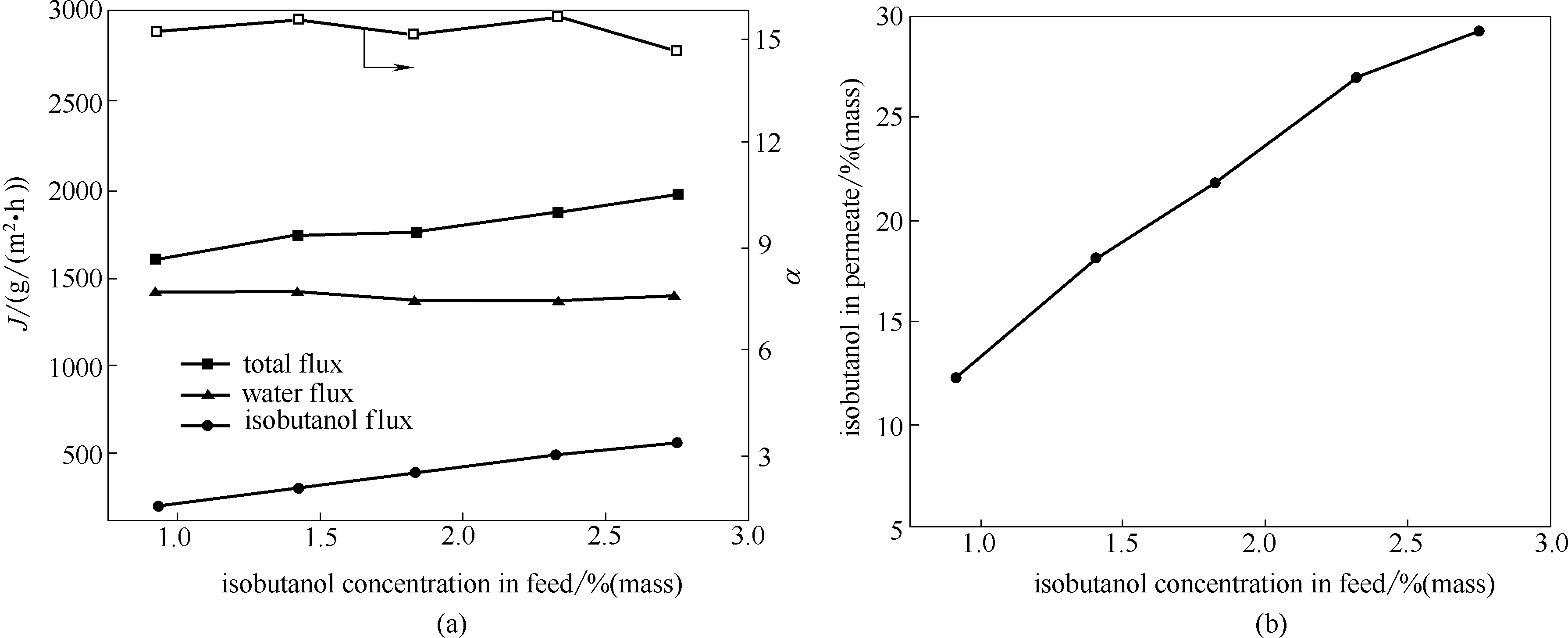

图4 进料液异丁醇浓度对通量、分离因子(a)和渗透液异丁醇浓度(b)的影响

Fig.4 Effect of isobutanol feed concentration on flux, separation factor(a) and isobutanol concentration(b) in permeate

图5 进料液温度对渗透液、渗余液的异丁醇浓度(a)和通量、分离因子(b)的影响

Fig.5 Effect of feed temperature on isobutanol concentration in permeate and retentate (a), flux and separation factor (b)

图9 进料液异丁醇浓度对渗余液异丁醇浓度、渗透液异丁醇质量(a)和平均通量、回收率(b)的影响

Fig.9 Effect of isobutanol feed concentrations on isobutanol concentration in retentate and isobutanol quality in permeate (a) and average flux and recovery rate (b)

| 酯化废水批次 | 异丁醇浓度/ %(质量) | 平均总通量/ (g/(m2·h)) | 异丁醇通量/ (g/(m2·h)) | 渗余侧浓度/ %(质量) | 渗余液质量/kg | 渗透液质量/kg | 异丁醇回收率/ % |

|---|---|---|---|---|---|---|---|

| 1 | 7.76 | 671.3 | 213.2 | 0.11 | 18.958 | 5.5214 | 98.9 |

| 2 | 7.27 | 752.2 | 199.5 | 0.12 | 18.23 | 5.5986 | 98.8 |

| 3 | 8.17 | 751.1 | 224.9 | 0.1 | 18.248 | 6.3824 | 99.1 |

| 4 | 7.78 | 769.7 | 212.9 | 0.16 | 18.072 | 6.1923 | 98.5 |

| 5 | 8.33 | 676.1 | 229.5 | 0.09 | 18.915 | 6.1297 | 99.2 |

| 6 | 8.2 | 801.1 | 225.9 | 0.09 | 17.785 | 6.1258 | 99.2 |

表2 渗透汽化过程处理含异丁醇的酯化工业废水

Table 2 Treatment of esterified industrial wastewater containing isobutanol by pervaporation

| 酯化废水批次 | 异丁醇浓度/ %(质量) | 平均总通量/ (g/(m2·h)) | 异丁醇通量/ (g/(m2·h)) | 渗余侧浓度/ %(质量) | 渗余液质量/kg | 渗透液质量/kg | 异丁醇回收率/ % |

|---|---|---|---|---|---|---|---|

| 1 | 7.76 | 671.3 | 213.2 | 0.11 | 18.958 | 5.5214 | 98.9 |

| 2 | 7.27 | 752.2 | 199.5 | 0.12 | 18.23 | 5.5986 | 98.8 |

| 3 | 8.17 | 751.1 | 224.9 | 0.1 | 18.248 | 6.3824 | 99.1 |

| 4 | 7.78 | 769.7 | 212.9 | 0.16 | 18.072 | 6.1923 | 98.5 |

| 5 | 8.33 | 676.1 | 229.5 | 0.09 | 18.915 | 6.1297 | 99.2 |

| 6 | 8.2 | 801.1 | 225.9 | 0.09 | 17.785 | 6.1258 | 99.2 |

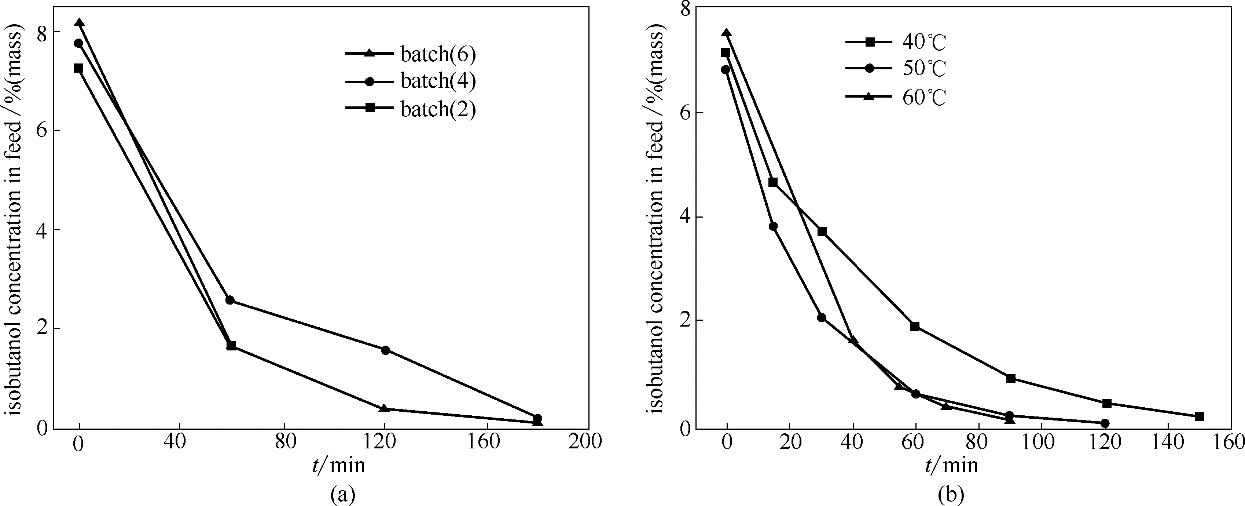

图10 不同批次(a)和不同温度进料液(b)的渗余液中异丁醇浓度随时间变化

Fig.10 Change of isobutanol concentration in the retentate with time different batches (a) and different feed temperatures (b)

| 1 | Jayamani I, Cupples A M. Effect of isobutanol on toluene biodegradation in nitrate amended, sulfate amended and methanogenic enrichment microcosms[J]. Biodegradation, 2013, 24(5): 657-663. |

| 2 | Schaefer C E, Yang X, Pelz O, et al. Anaerobic biodegradation of iso-butanol and ethanol and their relative effects on BTEX biodegradation in aquifer materials[J]. Chemosphere, 2010, 81(9): 1111-1117. |

| 3 | Gai H, Lin K, Feng Y, et al. Conceptual design of an extractive distillation process for the separation of azeotropic mixture of n-butanol-isobutanol-water[J]. Chinese Journal of Chemical Engineering, 2018, 26(10): 44-51. |

| 4 | 邢卫红, 顾学红. 高性能膜材料与膜技术[M]. 北京: 化学工业出版社, 2017: 369. |

| Xing W H, Gu X H. High-Performance Membrane Materials and Membrane Technology[M]. Beijing: Chemical Industry Press, 2017: 369. | |

| 5 | 史宝利, 贾丽娜, 张芯. 聚二甲基硅氧烷与渗透汽化分离膜[M]. 北京: 科学出版社, 2017: 228. |

| Shi B L, Jia L N, Zhang X. Polydimethylsiloxane and Pervaporation Separation Membrane[M]. Beijing: Science Press, 2017: 228. | |

| 6 | Shao P, Huang R. Polymeric membrane pervaporation[J]. Journal of Membrane Science, 2007, 287(2): 162-179. |

| 7 | Liu H, Wang N, Zhao C, et al. Membrane materials in the pervaporation separation of aromatic/aliphatic hydrocarbon mixtures—a review[J]. Chinese Journal of Chemical Engineering, 2018, 26(1): 1-16. |

| 8 | 宗传欣, 丁晓斌, 南江普, 等. 膜法VOCs气体分离技术研究进展[J]. 膜科学与技术, 2020, 40(1): 284-293. |

| Zong C X, Ding X B, Nan J P, et al. Research progress of membrane VOCs gas separation technology[J]. Membrane Science and Technology, 2020, 40(1): 284-293. | |

| 9 | Yang W, Zhou H, Zong C, et al. Study on membrane performance in vapor permeation of VOC/N2 mixtures via modified constant volume/variable pressure method[J]. Separation and Purification Technology, 2019, 223(1): 24-30. |

| 10 | Castro-Muñoz R, Galiano F, Fíla V, et al. Mixed matrix membranes (MMMs) for ethanol purification through pervaporation: current state of the art[J]. Reviews in Chemical Engineering, 2019, 35(5): 565-590. |

| 11 | 侯影飞, 许杨, 李海平, 等. 渗透汽化膜改性技术研究进展[J]. 膜科学与技术, 2018, 38(1): 136-142. |

| Hou Y F, Xu Y, Li H P, et al. Research progress of pervaporation membrane modification technology[J]. Membrane Science and Technology, 2018, 38(1): 136-142. | |

| 12 | Yong W, Xiang M, Tengfei M, et al. Green recovery of hazardous acetonitrile from high-salt chemical wastewater by pervaporation[J]. Journal of Cleaner Production, 2018, 197(1): 742-749. |

| 13 | Han X L, Zhang X M, Ma X X, et al. Modified ZSM-5/polydimethylsiloxane mixed matrix membranes for ethanol/water separation via pervaporation[J]. Polymer Composites, 2016, 37(4): 1282-1291. |

| 14 | 牟春霞, 张时雨, 邹昀, 等. 疏水SiO2填充PDMS膜分离水中乙酸正丁酯的性能[J]. 化工学报, 2017, 68(6): 2407-2414. |

| Mou C X, Zhang S Y, Zou J, et al. Separation of n-butyl acetate in water with PDMS membrane filled with hydrophobic SiO2[J]. CIESC Journal, 2017, 68(6): 2407-2414. | |

| 15 | Wang X, Chen J, Fang M, et al. ZIF-7/PDMS mixed matrix membranes for pervaporation recovery of butanol from aqueous solution[J]. Separation and Purification Technology, 2016, 163(4): 39-47. |

| 16 | Xue C, Du G Q, Chen L J, et al. A carbon nanotube filled polydimethylsiloxane hybrid membrane for enhanced butanol recovery[J]. Scientific Reports, 2014, 4(1): 5925-5932 |

| 17 | Li S, Chen Z, Yang Y, et al. Improving the pervaporation performance of PDMS membranes for n-butanol by incorporating silane-modified ZIF-8 particles[J]. Separation and Purification Technology, 2019, 215(4): 163-172. |

| 18 | Hu M J, Wu Z Y, Sun L, et al. Improving pervaporation performance of PDMS membranes by interpenetrating polymer network for recovery of bio-butanol[J]. Separation and Purification Technology, 2019, 228(1): 160-178. |

| 19 | Jee K Y, Lee Y T. Preparation and characterization of siloxane composite membranes for n-butanol concentration from ABE solution by pervaporation[J]. Journal of Membrane Science, 2014, 456(4): 1-10. |

| 20 | Chovau S, Gaykawad S, Straathof A J J, et al. Influence of fermentation by-products on the purification of ethanol from water using pervaporation[J]. Bioresource Technology, 2011, 102(2): 1669-1674. |

| 21 | Liu G, Gan L, Liu S, et al. PDMS/ceramic composite membrane for pervaporation separation of acetone-butanol-ethanol (ABE) aqueous solutions and its application in intensification of ABE fermentation process[J]. Chemical Engineering and Processing: Process Intensification, 2014, 86(4): 162-172. |

| 22 | Grimaldi J, Imbrogno J, Kilduff J, et al. New class of synthetic membranes: organophilic pervaporation brushes for organics recovery[J]. Chemistry of Materials, 2015, 27(11): 4142-4148. |

| 23 | 刘光启, 马连湘, 项曙光. 化学化工物性数据手册: 有机卷[M]. 北京: 化学工业出版社, 2013: 1103. |

| Liu Q G, Ma L X, Xiang S G. Chemical and Chemical Physical Property Data Manual: Organic Volume[M]. Beijing: Chemical Industry Press, 2013: 1103. | |

| 24 | Hansen C M. Hansen Solubility Parameters: A User􀆳s Handbook[M]// Boca Raton: CRC Press Inc., 2007: 546. |

| 25 | 刘燕青, 胡听听, 鲁落义, 等. PDMS/ZSM-5膜的制备及渗透汽化分离水中乙酸正丁酯和乙酸乙酯[J]. 化工学报, 2020, 71(2): 843-853. |

| Liu Y Q, Hu T T, Lu L Y, et al. Preparation of PDMS/ZSM-5 membrane and separation of n-butyl acetate and ethyl acetate in water by pervaporation[J]. CIESC Journal, 2020, 71(2): 843-853. | |

| 26 | Wijmans J G, Baker R W. The solution-diffusion model: a review[J]. Journal of Membrane Science, 1995, 107(1): 1-21. |

| 27 | Pan Y, Hang Y T, Zhao X H, , et al. Optimizing separation performance and interfacial adhesion of PDMS/PVDF composite membranes for butanol recovery from aqueous solution[J]. Journal of Membrane Science, 2019, 579(4): 210-218. |

| 28 | 张时雨, 邹昀, 韦藤幼, 等. β-环糊精/聚醚共聚乙酰胺填充膜的制备及渗透汽化分离水中微量苯酚[J]. 化工学报, 2016, 67(11): 4662-4670. |

| Zhang S Y, Zou J, Wei T Y, et al. Preparation of β-cyclodextrin/polyether copolyacetamide filling membrane and pervaporation separation of trace phenol in water[J]. CIESC Journal, 2016, 67(11): 4662-4670. | |

| 29 | Li S Y, Srivastava R, Parnas R S. Separation of 1-butanol by pervaporation using a novel tri-layer PDMS composite membrane[J]. Journal of Membrane Science, 2010, 363(1/2): 287-294. |

| 30 | 陈钟秀, 顾飞燕. 化工热力学[M]. 3版. 北京: 化学工业出版社, 2001: 335. |

| Chen Z X, Gu F Y. Chemical Thermodynamics[M]. 3nd ed. Beijing: Chemical Industry Press, 2001: 335. | |

| 31 | Wang X, Chen J, Fang M, et al. ZIF-7/PDMS mixed matrix membranes for pervaporation recovery of butanol from aqueous solution[J]. Separation and Purification Technology, 2016, 163(4): 39-47. |

| 32 | Segarceanu O, Leca M. Improved method to calculate Hansen solubility parameters of a polymer[J]. Progress in Organic Coatings, 1997, 31(4): 307-310. |

| 33 | Bonnet L, Rayez J C. Dynamical derivation of eyring equation and the second-order kinetic law[J]. International Journal of Quantum Chemistry, 2010, 110(13): 2355-2359. |

| 34 | Fariba S K, Toraj M, Fast Fereshteh N., facile and scalable fabrication of novel microporous silicalite-1/PDMS mixed matrix membranes for efficient ethanol separation by pervaporation[J]. Separation and Purification Technology,2019, 229(10): 55-59. |

| 35 | Bakhshi A, Mohammadi T, Aroujalian A. Pervaporation separation of binary and ternary mixtures with polydimethylsiloxane membranes[J]. Journal of Applied Polymer Science, 2008, 107(3): 1777-1782. |

| 36 | 周浩力, 苏仪, 伊守亮, 等. 丙酮、乙醇对丁醇渗透汽化性能的影响[J]. 化工学报, 2010, 61(5): 77-83. |

| Zhou H L, Su Y, Yi S L, et al. Effects of acetone and ethanol on pervaporation of butanol[J]. CIESC Journal, 2010, 61(5): 77-83. | |

| 37 | Zhou H, Lv L, Liu G, et al. PDMS/PVDF composite pervaporation membrane for the separation of dimethyl carbonate from a methanol solution[J]. Journal of Membrane Sicence, 2014, 471(11): 47-55. |

| [1] | 张佳怡, 何佳莉, 谢江鹏, 王健, 赵鹬, 张栋强. 渗透汽化技术用于锂电池生产中N-甲基吡咯烷酮回收的研究进展[J]. 化工学报, 2023, 74(8): 3203-3215. |

| [2] | 刘鑫, 潘阳, 刘公平, 方静, 李春利, 李浩. 渗透汽化-隔壁塔精馏耦合初步分离费托合成水的过程研究[J]. 化工学报, 2022, 73(5): 2020-2030. |

| [3] | 毛恒, 王月, 王森, 刘伟民, 吕静, 陈甫雪, 赵之平. APTES改性ZIF-L/PEBA混合基质膜强化渗透汽化分离苯酚研究[J]. 化工学报, 2022, 73(3): 1389-1402. |

| [4] | 丁婉月, 马晓华. 合成次数及硅铝比调控SAPO-34分子筛膜的乙醇脱水性能[J]. 化工学报, 2021, 72(8): 4410-4417. |

| [5] | 方丽君, 王景梅, 林巧靖, 陈建华, 杨谦. 二苯并-18-冠醚-6/聚醚嵌段酰胺膜富集水中苯酚性能研究[J]. 化工学报, 2021, 72(7): 3716-3727. |

| [6] | 马珊宏, 叶枫, 王燕鸿, 郎雪梅, 樊栓狮, 李刚. ZSM-5沸石膜用于生物油的脱水分离及其再生过程研究[J]. 化工学报, 2020, 71(7): 3345-3353. |

| [7] | 金浩, 陆佳伟, 汤吉海, 张竹修, 费兆阳, 刘清, 陈献, 崔咪芬, 乔旭. 带侧线反应精馏-渗透汽化生产乙酸乙酯集成过程模拟与分析[J]. 化工学报, 2018, 69(8): 3469-3478. |

| [8] | 岳东敏, 张欠之, 孙德, 李冰冰, 毛钦烨, 彭从康. PVA/SO42--AAO催化-渗透汽化双功能复合膜合成乙酸乙酯[J]. 化工学报, 2018, 69(6): 2775-2781. |

| [9] | 张杏梅, 胡文玲, 孙鹤翔, 韩小龙, 王玉琪. 活性炭填充PEG/PVDF杂化膜的脱硫性能[J]. 化工学报, 2018, 69(2): 866-872. |

| [10] | 王洋, 庄黎伟, 马晓华, 许振良, 王志. 中空纤维膜渗透汽化过程中Dean涡强化传质的CFD模拟[J]. 化工学报, 2018, 69(11): 4655-4662. |

| [11] | 王倩, 张新儒, 王永洪, 侯蒙杰, 张桃, 李龙, 刘成岑. 渗透汽化-结晶耦合分离稀溶液中的香兰素[J]. 化工学报, 2017, 68(8): 3126-3132. |

| [12] | 那沙沙, 李卫星, 邢卫红. 无机杂化海藻酸钠渗透汽化膜的制备与分离性能对比[J]. 化工学报, 2016, 67(9): 3730-3737. |

| [13] | 杜广庆, 陈丽杰, 薛闯, 白凤武. 聚偏氟乙烯/聚二甲基硅氧烷渗透气化膜在丁醇分离中的应用[J]. 化工学报, 2014, 65(9): 3499-3504. |

| [14] | 杜广庆, 陈丽杰, 薛闯, 白凤武. 聚偏氟乙烯/聚二甲基硅氧烷渗透气化膜在丁醇分离中的应用[J]. 化工学报, 2014, 65(9): 0-0. |

| [15] | 李杰,王乃鑫,纪树兰. 有机/无机杂化渗透汽化优先透醇膜研究进展[J]. 化工进展, 2014, 33(11): 2982-2990. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号