化工学报 ›› 2021, Vol. 72 ›› Issue (10): 5362-5371.DOI: 10.11949/0438-1157.20210400

张正义1( ),张千1(

),张千1( ),楼紫阳2,3,刘伟3,朱宇楠1,袁春波1,于潇1,赵天涛1

),楼紫阳2,3,刘伟3,朱宇楠1,袁春波1,于潇1,赵天涛1

收稿日期:2021-03-22

修回日期:2021-05-07

出版日期:2021-10-05

发布日期:2021-10-05

通讯作者:

张千

作者简介:张正义(1998—),男,硕士研究生,基金资助:

Zhengyi ZHANG1( ),Qian ZHANG1(

),Qian ZHANG1( ),Ziyang LOU2,3,Wei LIU3,Yunan ZHU1,Chunbo YUAN1,Xiao YU1,Tiantao ZHAO1

),Ziyang LOU2,3,Wei LIU3,Yunan ZHU1,Chunbo YUAN1,Xiao YU1,Tiantao ZHAO1

Received:2021-03-22

Revised:2021-05-07

Online:2021-10-05

Published:2021-10-05

Contact:

Qian ZHANG

摘要:

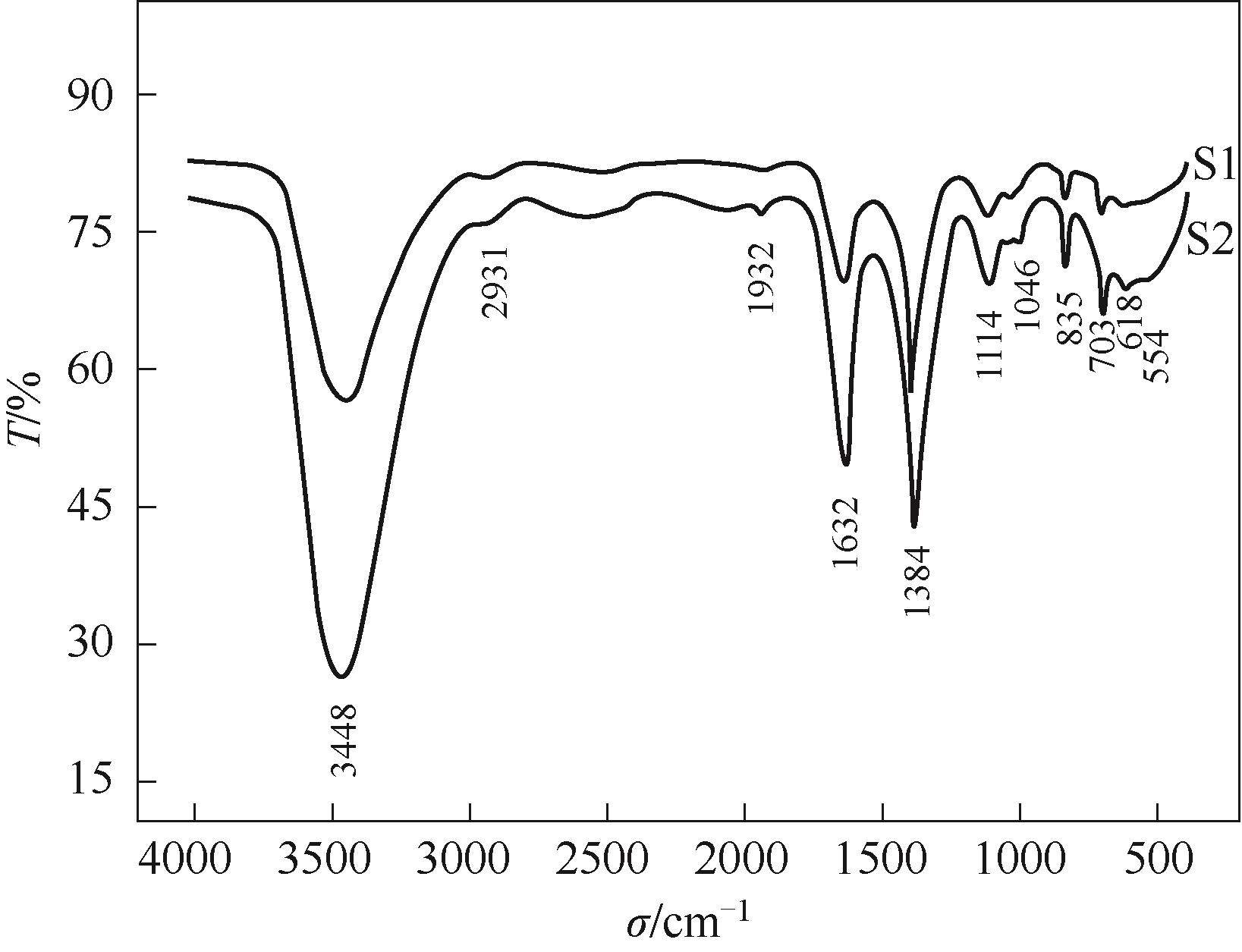

腐殖质的去除效率是催化臭氧氧化降解垃圾渗滤液RO浓液中有机物的关键,活性炭负载金属铈催化剂(Ce-AC)催化臭氧氧化可有效提高腐殖质的去除效率。本文通过XRD、SEM和EDS等手段对Ce-AC催化剂进行表征,对比不同催化剂催化臭氧氧化对RO浓液COD去除及可生化性的影响,通过降解产物光谱分析明晰腐殖质的降解机制。结果表明,铈氧化物是以CeO2萤石晶型的形式负载在AC上,负载后的AC比表面积和孔容积减少,平均孔径增加。催化剂Ce-AC对COD和UV254的去除效果最好,为44.7%和67.3%,出水可生化性显著提升,B/C比从0.06提升到0.47。紫外-可见光谱表明,体系代表腐殖质的芳香类化合物降解效率明显;三维荧光光谱表明体系中腐殖质类物质被极大程度地降解,荧光区域积分的结果表明腐殖质类物质的去除效率达到了66.7%;傅里叶红外光谱表明腐殖质类物质被氧化分解成了相对小分子的碳水化合物和有机胺、硫和醇等。

中图分类号:

张正义,张千,楼紫阳,刘伟,朱宇楠,袁春波,于潇,赵天涛. 催化臭氧氧化处理渗滤液RO浓液的氧化特性及光谱分析[J]. 化工学报, 2021, 72(10): 5362-5371.

Zhengyi ZHANG,Qian ZHANG,Ziyang LOU,Wei LIU,Yunan ZHU,Chunbo YUAN,Xiao YU,Tiantao ZHAO. Oxidation characteristics and spectral analysis of leachate reverse osmosis concentrate by catalytic ozonation[J]. CIESC Journal, 2021, 72(10): 5362-5371.

| 指标 | 数值 |

|---|---|

| COD/(mg/L) | 2090 |

| BOD5/(mg/L) | 120.5 |

| 182 | |

| TN/(mg/L) | 510 |

| pH | 8.69 |

表1 RO浓液的水质特点

Table 1 Water quality characteristics of leachate reverse osmosis concentrate

| 指标 | 数值 |

|---|---|

| COD/(mg/L) | 2090 |

| BOD5/(mg/L) | 120.5 |

| 182 | |

| TN/(mg/L) | 510 |

| pH | 8.69 |

| 样品名称 | SBET/(m2/g) | 平均孔径/nm | 孔容积/(cm3/g) |

|---|---|---|---|

| AC | 1432 | 3.5578 | 1.0310 |

| Ce-AC | 1359 | 4.0484 | 0.9770 |

表2 AC和Ce-AC的孔结构参数

Table 2 Pore structure parameters of AC and Ce-AC

| 样品名称 | SBET/(m2/g) | 平均孔径/nm | 孔容积/(cm3/g) |

|---|---|---|---|

| AC | 1432 | 3.5578 | 1.0310 |

| Ce-AC | 1359 | 4.0484 | 0.9770 |

| 区域 | 原液Φi,n/ (au·nm2) | 原液Pi,n/ % | 处理后Φi,n/ (au·nm2) | 处理后Pi,n/ % |

|---|---|---|---|---|

| 区域Ⅰ | 28366154 | 22.1 | 20050717 | 31.2 |

| 区域Ⅱ | 34839219 | 27.1 | 13617790 | 21.2 |

| 区域Ⅲ | 16503733 | 12.9 | 14286136 | 22.3 |

| 区域Ⅳ | 48637041 | 37.9 | 16207813 | 25.3 |

表3 处理前后各区域FRI值对比

Table 3 Comparison of FRI values of each region before and after processing

| 区域 | 原液Φi,n/ (au·nm2) | 原液Pi,n/ % | 处理后Φi,n/ (au·nm2) | 处理后Pi,n/ % |

|---|---|---|---|---|

| 区域Ⅰ | 28366154 | 22.1 | 20050717 | 31.2 |

| 区域Ⅱ | 34839219 | 27.1 | 13617790 | 21.2 |

| 区域Ⅲ | 16503733 | 12.9 | 14286136 | 22.3 |

| 区域Ⅳ | 48637041 | 37.9 | 16207813 | 25.3 |

图12 Ce-AC/O3体系处理RO浓液前(S1)、后(S2)的傅里叶红外光谱

Fig.12 Fourier transform infrared spectroscopy of RO concentrate before ( S1 ) and after ( S2 ) treatment with Ce-AC/O3 system

| 1 | 薛晓冬. 膜组合工艺在垃圾渗滤液处理中的应用[J]. 环境与发展, 2019, 31(2): 102,105. |

| Xue X D. Application of membrane combination process in landfill leachate treatment[J]. Environment and Development, 2019, 31(2): 102,105. | |

| 2 | 艾恒雨, 孟棒棒, 李娜, 等. 我国垃圾渗滤液膜浓缩液处理现状与污染控制建议[J]. 环境工程技术学报, 2016, 6(6): 553-558. |

| Ai H Y, Meng B B, Li N, et al. Treatment status and pollution control suggestions for membrane concentrated leachate in China[J]. Journal of Environmental Engineering Technology, 2016, 6(6): 553-558. | |

| 3 | 徐蘇士. UV-Fenton工艺对垃圾渗滤液纳滤浓缩液的处理研究[D]. 北京: 清华大学, 2012. |

| Xu S S. Research on UV-Fenton treatment of concentrated water from nanofiltration of landfill leachate[D]. Beijing: Tsinghua University, 2012. | |

| 4 | 王洪庆, 乐晨. 混凝沉淀-Fenton氧化法处理垃圾渗滤液纳滤浓缩液的研究[J]. 广东化工, 2016, 43(6): 116-117. |

| Wang H Q, Le C. Study on the treatment of concentrated water from nanofiltration of bio-treated landfill leachate by coagulation-sedimentation and Fenton oxidation process [J]. Guangdong Chemical Industry, 2016, 43(6): 116-117. | |

| 5 | 黄力彦, 吕逵弟, 谭艳来, 等. 铁碳微电解法预处理垃圾渗滤液膜滤浓缩液[J]. 工业安全与环保, 2015, 41(7): 37-39. |

| Huang L Y, Lyu K D, Tan Y L, et al. Pretreatment of concentrated leachate from RO system by iron carbon micro- electrolysis[J]. Industrial Safety and Environmental Protection, 2015, 41(7): 37-39. | |

| 6 | Chen T, Gu W, Li G, et al. Significant enhancement in catalytic ozonation efficacy: from granular to super-fine powdered activated carbon[J]. Frontiers of Environmental Science and Engineering, 2018, 12(1): 6-11. |

| 7 | 骆沁沁. 催化氧化法提标减排印染废水COD的中试研究[D]. 杭州: 浙江大学, 2012. |

| Luo Q Q. Pilotscale experiment to reduce COD of dyeing and printing wastewater using catalyzed oxidation[D]. Hangzhou: Zhejiang University, 2012. | |

| 8 | 何帅明, 莫立焕, 徐峻, 等. 活性炭负载铈催化臭氧处理桉木制浆废水[J]. 中国造纸, 2016, 35(3): 1-6. |

| He S M, Mo L H, Xu J, et al. Catalytic ozonation of eucalyptus pulping effluent by cerium loaded on activated carbon[J]. China Pulp and Paper, 2016, 35(3): 1-6. | |

| 9 | Jouanneau S, Recoules L, Durand M J, et al. Methods for assessing biochemical oxygen demand (BOD): a review[J]. Water Research, 2014, 49(1): 62-82. |

| 10 | 陈炜鸣, 张爱平, 李民, 等. O3/H2O2降解垃圾渗滤液浓缩液的氧化特性及光谱解析[J]. 中国环境科学, 2017, 37(6): 2160-2172. |

| Chen W M, Zhang A P, Li M, et al. Decomposition of organics in concentrated landfill leachate with ozone/hydrogen peroxide system: oxidation characteristics and spectroscopic analyses[J]. China Environmental Science, 2017, 37(6): 2160-2172. | |

| 11 | Stedmon C A, Bro R. Characterizing dissolved organic matter fluorescence with parallel factor analysis: a tutorial[J]. Limnology and Oceanography: Methods, 2008, 6(11): 572-579. |

| 12 | Chen W, Westerhoff P, Leenheer J A, et al. Fluorescence excitation-emission matrix regional integration to quantify spectra for dissolved organic matter[J]. Environmental Science and Technology, 2003, 37(24): 5701-5710. |

| 13 | 王佳琴, 李卫华, 申慧彦, 等. 污水厂进出水中DOM的三维荧光和FTIR光谱解析[J]. 环境科学与技术, 2018, 41(1): 71-76. |

| Wang J Q, Li W H, Shen H Y, et al. Analysis of dissolved organic matter of the sewage influent and effluents from wastewater treatment plant using EEM fluorescence and FTIR spectroscopy[J]. Environmental Science and Technology, 2018, 41(1): 71-76. | |

| 14 | 毛锡嵩, 夏雪雯, 兰苑培, 等. 不同气氛加热过程中CeO2晶体结构的原位研究[J]. 中国稀土学报, 2020, 38(4): 483-489. |

| Mao X S, Xia X W, Lan Y P, et al. In situ study of CeO2 crystal structure during heating in different atmospheres[J]. Journal of the Chinese Society of Rare Earths, 2020, 38(4): 483-489. | |

| 15 | 高晓慧, 杨儒. 萤石型层状介孔CeO2的合成[C]//中国化工学会年会暨全国化工新材料学术技术报告会. 中国化工学会, 北京化工大学, 北京工业大学, 2006. |

| Gao X H, Yang R. Synthesis of fluorite layered mesoporous CeO2[C]//Annual Conference of Chinese Chemical Society and National Academic and Technical Report on New Chemical Materials. The Chemical Industry and Engineering Society of China, Beijing University of Chemical Technology, Beijing University of Technology, 2006. | |

| 16 | 张涛, 马军, 陈忠林, 等. 有机酸在金属氧化物上的吸附对催化臭氧氧化的影响[J]. 环境科学, 2005, 26(5): 85-88. |

| Zhang T, Ma J, Chen Z L, et al. Effect of organic acids adsorption on catalytic ozonation with metal oxides[J]. Environmental Science, 2005, 26(5): 85-88. | |

| 17 | 王群, 杨一, 刘娟昉, 等. 二氧化铈催化分解水中臭氧的性能研究[J]. 中国给水排水, 2010, 26(11): 130-132. |

| Wang Q, Yang Y, Liu J F, et al. Study on ozone decomposition catalyzed by cerium dioxide[J]. China Water and Wastewater, 2010, 26(11): 130-132. | |

| 18 | Di T M, Zhu B C, Cheng B, et al. A direct Z-scheme g-C3N4/SnS2 photocatalyst with superior visible-light CO2 reduction performance[J]. Journal of Catalysis, 2017, 352: 532-541. |

| 19 | Imai A, Onuma K, Inamori Y, et al. Effects of pre-ozonation in refractory leachate treatment by the biological activated carbon fluidized bed process[J]. Environmental Technology (United Kingdom), 1998, 19(2): 213-221. |

| 20 | Cortez S, Teixeira P, Oliveira R, et al. Evaluation of Fenton and ozone-based advanced oxidation processes as mature landfill leachate pre-treatments[J]. Journal of Environmental Management, 2011, 92(3): 749-755. |

| 21 | 邱松凯, 范举红, 黄开坚, 等. 臭氧-曝气生物滤池深度处理垃圾焚烧渗滤液可行性研究[J]. 中国环境科学, 2014, 34(10): 2513-2521. |

| Qiu S K, Fan J H, Huang K J, et al. A study on municipal waste leachate treatment with ozonation-biological aerated filter[J]. China Environmental Science, 2014, 34(10): 2513-2521. | |

| 22 | Tizaoui C, Bouselmi L, Mansouri L, et al. Landfill leachate treatment with ozone and ozone/hydrogen peroxide systems[J]. Journal of Hazardous Materials, 2007, 140(1/2): 316-324. |

| 23 | Beltrán F J, Rivas J, Álvarez P, et al. Kinetics of heterogeneous catalytic ozone decomposition in water on an activated carbon[J]. Ozone: Science and Engineering, 2002, 24(4): 227-237. |

| 24 | Deng R Y, He Q, Yang D X, et al. Enhanced synergistic performance of nano-Fe0-CeO2 composites for the degradation of diclofenac in DBD plasma[J]. Chemical Engineering Journal, 2021, 406: 126884. |

| 25 | Anumol T, Sgroi M, Park M, et al. Predicting trace organic compound breakthrough in granular activated carbon using fluorescence and UV absorbance as surrogates[J]. Water Research, 2015, 76(1): 76-87. |

| 26 | 姚磊, 马涛, 张列宇, 等. 厌氧共代谢处理晚期垃圾渗滤液中难降解有机物的研究[J]. 水处理技术, 2019, 45(8): 30-34. |

| Yao L, Ma T, Zhang L Y, et al. Study on anaerobic co-metabolism for treatment of refractory organic matter in late landfill leachate[J]. Technology of Water Treatment, 2019, 45(8): 30-34. | |

| 27 | 程亮, 张保林, 徐丽, 等. 腐殖酸热分解动力学[J]. 化工学报, 2014, 65(9): 3470-3478. |

| Cheng L, Zhang B L, Xu L, et al. Thermal decomposition kinetics of humic acid[J]. CIESC Journal, 2014, 65(9): 3470-3478. | |

| 28 | 隆佳君, 彭澍晗, 褚华强, 等. 铈类催化剂催化臭氧化的研究进展[J]. 环境污染与防治, 2019, 41(5): 596-601, 607. |

| Long J J, Peng S H, Chu H Q, et al. Research progress of cerium catalysts for catalytic ozonation[J]. Environmental Pollution and Control, 2019, 41(5): 596-601, 607. | |

| 29 | 张丽丽, 庄媛, 胡春, 等. 多相催化技术的固液微界面调控原理及应用进展[J]. 环境科学学报, 2020, 40(12): 4225-4233. |

| Zhang L L, Zhuang Y, Hu C, et al. Control mechanism of solid-liquid micro-interface and application progress for heterogeneous catalysis technology[J]. Acta Scientiae Circumstantiae, 2020, 40(12): 4225-4233. | |

| 30 | 王家德, 袁通斌, 周丹飞, 等. 基于原位红外光谱的水相苯酚电氧化机理研究[J]. 化工学报, 2019, 70(12): 4821-4827. |

| Wang J D, Yuan T B, Zhou D F, et al. Mechanism of phenol electro-oxidation in aqueous solution based on in situ infrared spectroscopy[J]. CIESC Journal, 2019, 70(12): 4821-4827. | |

| 31 | Tian Y, Chen L, Jiang T L. Characterization and modeling of the soluble microbial products in membrane bioreactor[J]. Separation and Purification Technology, 2011, 76(3): 316-324. |

| 32 | 贾陈忠, 刘松, 张彩香, 等. 光催化氧化降解垃圾渗滤液中溶解性有机物[J]. 环境工程学报, 2013, 7(2): 451-456. |

| Jia C Z, Liu S, Zhang C X, et al. Degradation of dissolved organic matter in landfill leachate during photocatalytic treatment process[J]. Chinese Journal of Environmental Engineering, 2013, 7(2): 451-456. |

| [1] | 吕龙义, 及文博, 韩沐达, 李伟光, 高文芳, 刘晓阳, 孙丽, 王鹏飞, 任芝军, 张光明. 铁基导电材料强化厌氧去除卤代有机污染物:研究进展及未来展望[J]. 化工学报, 2023, 74(8): 3193-3202. |

| [2] | 屈园浩, 邓文义, 谢晓丹, 苏亚欣. 活性炭/石墨辅助污泥电渗脱水研究[J]. 化工学报, 2023, 74(7): 3038-3050. |

| [3] | 王刚, 车小平, 汪仕勇, 邱介山. 水溶性带电聚合物黏结剂修饰炭电极用于增强电容去离子性能[J]. 化工学报, 2022, 73(4): 1763-1771. |

| [4] | 张逸伟, 唐海荣, 何勇, 朱燕群, 王智化. 臭氧低温氧化烟气脱硝过程中的氮平衡试验研究[J]. 化工学报, 2022, 73(4): 1732-1742. |

| [5] | 刘立, 蒋鹏, 王伟, 张同桓, 穆立文, 陆小华, 朱家华. 基于过程模拟和随机森林模型的生物质制氢过程因素分析与预测[J]. 化工学报, 2022, 73(11): 5230-5239. |

| [6] | 张超, 陈健, 殷文华, 沈圆辉, 钮朝阳, 余秀鑫, 张东辉, 唐忠利. 变压吸附氢气纯化过程瞬态分析[J]. 化工学报, 2022, 73(1): 308-321. |

| [7] | 演康, 杨颂, 刘守军, 杨超, 樊惠玲, 上官炬. 低阶煤原位制备ZnO基活性炭脱硫剂[J]. 化工学报, 2021, 72(9): 4921-4930. |

| [8] | 黄莉婷, 韩昫身, 金艳, 马强, 于建国. 煤化工反渗透浓水的高效降解菌株筛选、鉴定及应用研究[J]. 化工学报, 2021, 72(9): 4881-4891. |

| [9] | 王晶, 韩巧宁, 雷以廷, 唐曼, 陈丽红, 车俊达, 刘祖广. 一步法制备富氧木质素活性炭及其亚甲基蓝吸附性能[J]. 化工学报, 2021, 72(5): 2826-2836. |

| [10] | 焦帅, 杨磊, 武婷婷, 李宏强, 吕辉鸿, 何孝军. 混合盐模板法制备超级电容器用氮掺杂分级多孔碳纳米片[J]. 化工学报, 2021, 72(5): 2869-2877. |

| [11] | 蒋雯雯, 聂鹏飞, 胡彬, 李菁菁, 刘建允. Al2O3/AC正极选择性电容吸附水中氟离子[J]. 化工学报, 2021, 72(5): 2817-2825. |

| [12] | 汪恺, 杜文莉, 隆建. 在线自适应波长选择方法及其在汽油调和过程中的应用[J]. 化工学报, 2021, 72(2): 1059-1066. |

| [13] | 周毅,王永洪,张新儒,李晋平. PEBA/氮硫共掺杂多孔碳球混合基质膜的制备及CO2分离性能研究[J]. 化工学报, 2021, 72(10): 5237-5246. |

| [14] | 苏银海,张书平,刘凌沁,熊源泉. 活性炭催化热解纤维素协同制备酚类和合成气[J]. 化工学报, 2021, 72(10): 5206-5217. |

| [15] | 李庆斯, 张雷. 血液灌流吸附剂材料的研究进展[J]. 化工学报, 2020, 71(S2): 12-23. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号