化工学报 ›› 2025, Vol. 76 ›› Issue (12): 6121-6133.DOI: 10.11949/0438-1157.20250333

• 综述与专论 • 下一篇

张富民1,2( ), 王业飞1,2(

), 王业飞1,2( ), 王红波3, 丁名臣1,2, 陈五花1,2, 廖健1,2, 刘建斌4, 黄志学1,2

), 王红波3, 丁名臣1,2, 陈五花1,2, 廖健1,2, 刘建斌4, 黄志学1,2

收稿日期:2025-04-02

修回日期:2025-06-26

出版日期:2025-12-31

发布日期:2026-01-23

通讯作者:

王业飞

作者简介:张富民(1998—),男,博士研究生,zfm110239@163.com

基金资助:

Fumin ZHANG1,2( ), Yefei WANG1,2(

), Yefei WANG1,2( ), Hongbo WANG3, Mingchen DING1,2, Wuhua CHEN1,2, Jian LIAO1,2, Jianbin LIU4, Zhixue HUANG1,2

), Hongbo WANG3, Mingchen DING1,2, Wuhua CHEN1,2, Jian LIAO1,2, Jianbin LIU4, Zhixue HUANG1,2

Received:2025-04-02

Revised:2025-06-26

Online:2025-12-31

Published:2026-01-23

Contact:

Yefei WANG

摘要:

稠油的高黏度与低流动性是制约其开采的技术瓶颈。水溶性聚合物型降黏剂凭借其对油相降黏与水相增黏的独特双效协同机制,为解决此难题提供了极具前景的化学驱途径。综述了水溶性聚合物型稠油降黏剂的作用机理,探讨了聚合物型降黏剂的分子设计进展。从常规的长链烷基类单体、芳香族单体到响应型单体,研究了这些单体在水溶性聚合物型降黏剂中的应用,并分析了不同类型聚合物型降黏剂的降黏效果及机理。尽管现有的聚合物降黏剂在降低稠油黏度方面取得了显著成效,但仍面临多孔介质中规律不清晰、乳状液破乳难以及经济性等挑战。

中图分类号:

张富民, 王业飞, 王红波, 丁名臣, 陈五花, 廖健, 刘建斌, 黄志学. 水溶性聚合物型稠油降黏剂研究进展[J]. 化工学报, 2025, 76(12): 6121-6133.

Fumin ZHANG, Yefei WANG, Hongbo WANG, Mingchen DING, Wuhua CHEN, Jian LIAO, Jianbin LIU, Zhixue HUANG. Research progress of water-soluble polymer viscosity reducer[J]. CIESC Journal, 2025, 76(12): 6121-6133.

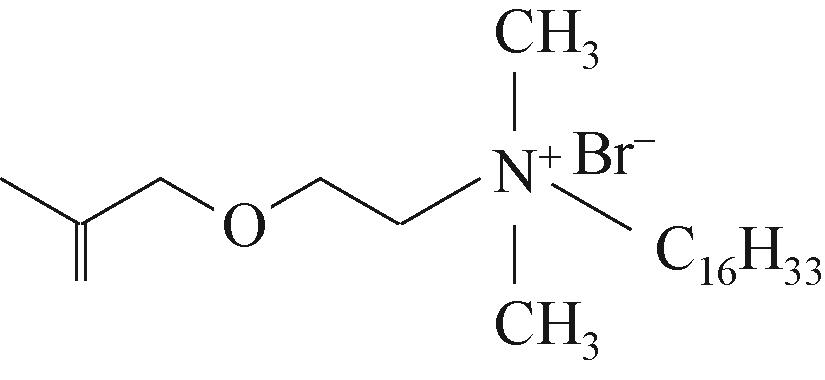

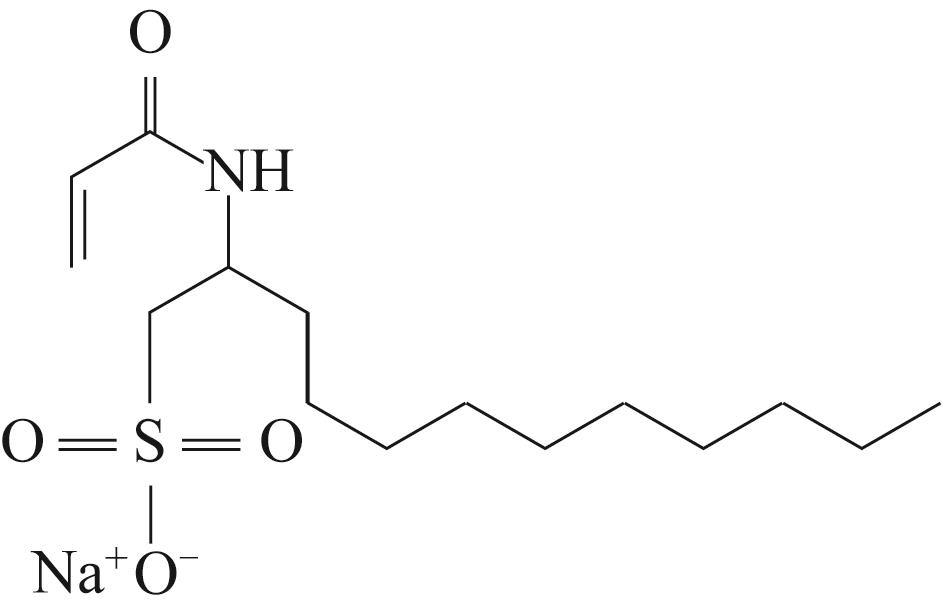

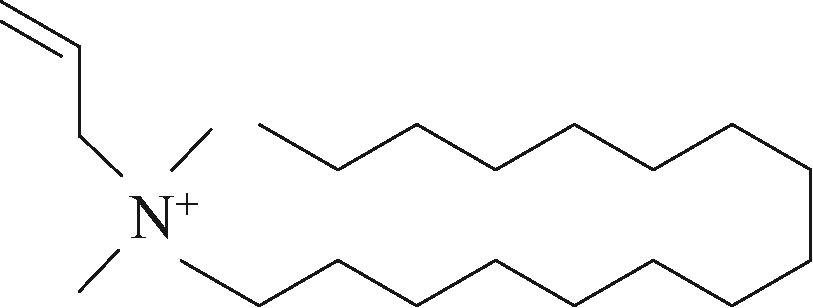

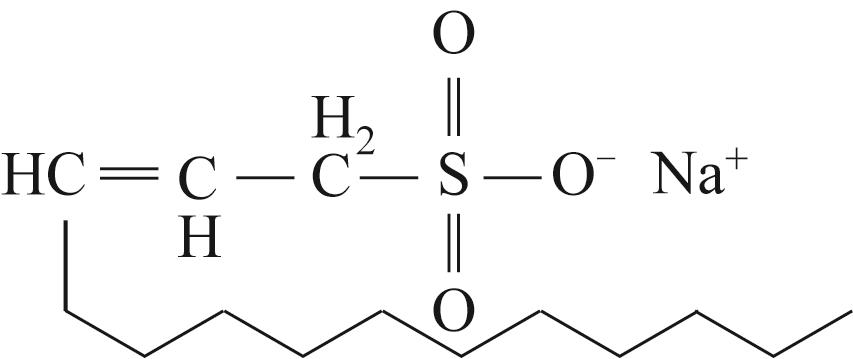

| 单体名称 | 结构式 | 优点 | 缺点 | 文献 |

|---|---|---|---|---|

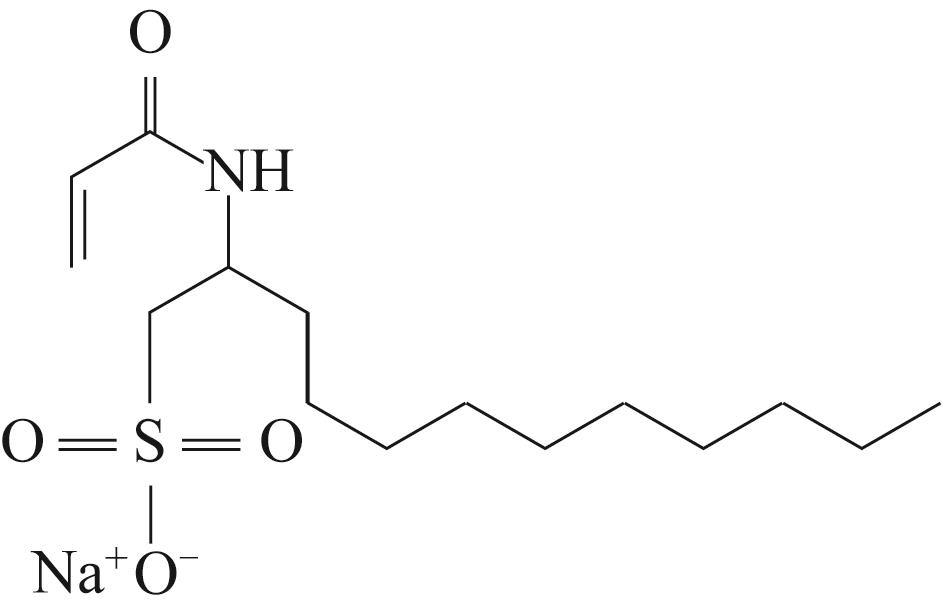

| 2-丙烯酰胺基十二烷基磺酸钠 |  | 注入0.2PV的1500 mg/L的两亲聚合物提高采收率27% | 界面张力较高 | [ |

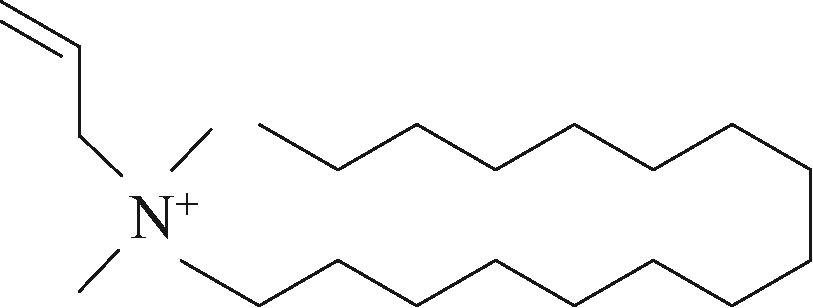

| 十六烷基二甲基烯丙基氯化铵 |  | 对稠油的降黏率超过95%,能使稠油采收率提高17.9% | 合成复杂,成本昂贵 | [ |

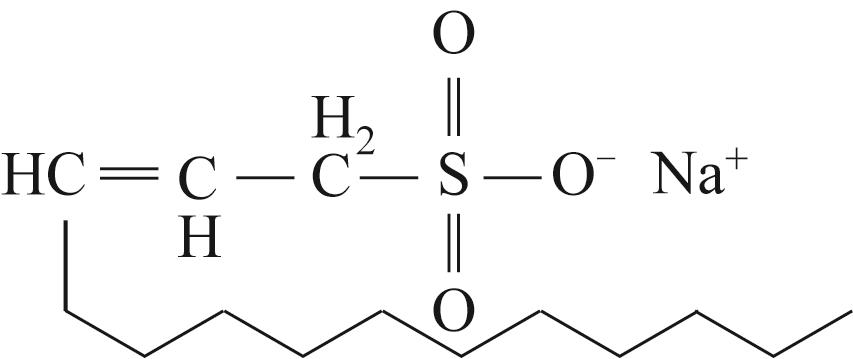

| 十二烷基烯烃磺酸钠 |  | 对超稠油(>15000 mPa·s)的降黏率达90%以上 | 破乳困难 | [ |

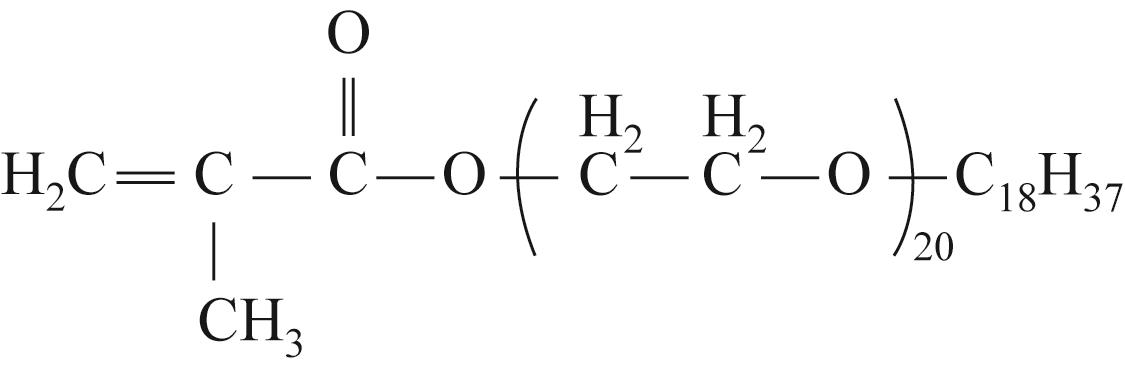

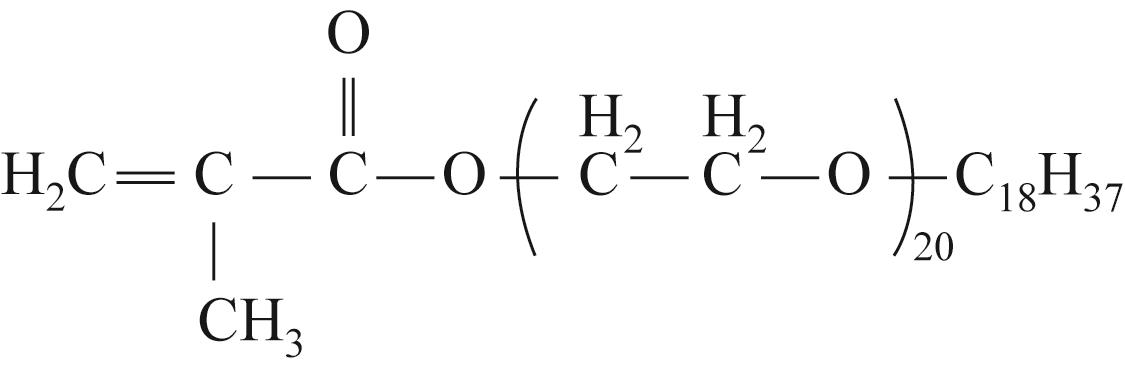

| 长链烷基聚醚类(POM) |  | 对黏度为1000 mPa·s稠油降黏率为87.0%~90.6% | 对高黏稠油适用性差 | [ |

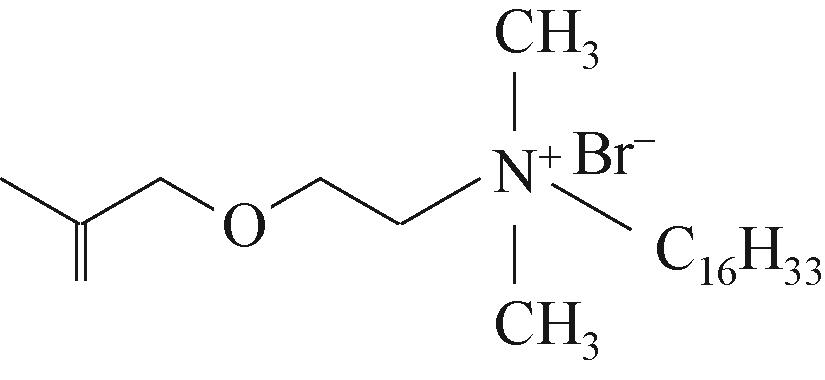

| L季铵盐单体 |  | 对普通稠油的降黏率为99.07%,耐温抗盐性能好 | 合成复杂,且聚合物分子量大,破乳困难 | [ |

表1 聚合物型降黏剂常用的长链烷基类单体

Table 1 Commonly used long-chain alkyl monomers for polymer viscosity reducers

| 单体名称 | 结构式 | 优点 | 缺点 | 文献 |

|---|---|---|---|---|

| 2-丙烯酰胺基十二烷基磺酸钠 |  | 注入0.2PV的1500 mg/L的两亲聚合物提高采收率27% | 界面张力较高 | [ |

| 十六烷基二甲基烯丙基氯化铵 |  | 对稠油的降黏率超过95%,能使稠油采收率提高17.9% | 合成复杂,成本昂贵 | [ |

| 十二烷基烯烃磺酸钠 |  | 对超稠油(>15000 mPa·s)的降黏率达90%以上 | 破乳困难 | [ |

| 长链烷基聚醚类(POM) |  | 对黏度为1000 mPa·s稠油降黏率为87.0%~90.6% | 对高黏稠油适用性差 | [ |

| L季铵盐单体 |  | 对普通稠油的降黏率为99.07%,耐温抗盐性能好 | 合成复杂,且聚合物分子量大,破乳困难 | [ |

| [1] | Xue L, Liu P C, Zhang Y. Development and research status of heavy oil enhanced oil recovery[J]. Geofluids, 2022, 2022(1): 5015045. |

| [2] | Ahmadi M, Chen Z X. Challenges and future of chemical assisted heavy oil recovery processes[J]. Advances in Colloid and Interface Science, 2020, 275: 102081. |

| [3] | 刘慧卿, 东晓虎. 稠油热复合开发提高采收率技术现状与趋势[J]. 石油科学通报, 2022, 7(2): 174-184. |

| Liu H Q, Dong X H. Current status and future trends of hybrid thermal EOR processes in heavy oil reservoirs[J]. Petroleum Science Bulletin, 2022, 7(2): 174-184. | |

| [4] | 孔鑫鑫, 唐晓东, 李晶晶, 等. 稠油冷采技术现状及展望[J]. 石油化工, 2025, 54(4): 597-605. |

| Kong X X, Tang X D, Li J J, et al. Current status and prospect of cold recovery technology for heavy oil[J]. Petrochemical Technology, 2025, 54(4): 597-605. | |

| [5] | 关文龙, 蒋有伟, 郭二鹏, 等. “双碳”目标背景下的稠油开发对策[J]. 石油学报, 2023, 44(5): 826-840. |

| Guan W L, Jiang Y W, Guo E P, et al. Heavy oil development strategy under the “Carbon Peaking and Carbon Neutrality” target[J]. Acta Petrolei Sinica, 2023, 44(5): 826-840. | |

| [6] | Liu J B, Zhong L G, Ren L, et al. Laboratory evaluation of fluidity of heavy oil emulsions in formation pores medium[J]. ACS Omega, 2021, 6(1): 623-632. |

| [7] | Cheraghian G, Kiani S, Nassar N N, et al. Silica nanoparticle enhancement in the efficiency of surfactant flooding of heavy oil in a glass micromodel[J]. Industrial & Engineering Chemistry Research, 2017, 56(30): 8528-8534. |

| [8] | Zhang F F, Liu Y G, Wang Q X, et al. Fabricating a heavy oil viscosity reducer with weak interaction effect: synthesis and viscosity reduction mechanism[J]. Colloid and Interface Science Communications, 2021, 42: 100426. |

| [9] | Aliabadian E, Sadeghi S, Rezvani Moghaddam A, et al. Application of graphene oxide nanosheets and HPAM aqueous dispersion for improving heavy oil recovery: effect of localized functionalization[J]. Fuel, 2020, 265: 116918. |

| [10] | Pothula G K, Vij R K, Bera A. An overview of chemical enhanced oil recovery and its status in India[J]. Petroleum Science, 2023, 20(4): 2305-2323. |

| [11] | Tackie-Otoo B N, Ayoub Mohammed M A, Yekeen N, et al. Alternative chemical agents for alkalis, surfactants and polymers for enhanced oil recovery: Research trend and prospects[J]. Journal of Petroleum Science and Engineering, 2020, 187: 106828. |

| [12] | Lee J, Babadagli T. Mitigating greenhouse gas intensity through new generation techniques during heavy oil recovery[J]. Journal of Cleaner Production, 2021, 286: 124980. |

| [13] | Wang Z W, Shi J N, Liu R Q, et al. A water-soluble polymeric surfactant with thickening water and emulsifying oil simultaneously for heavy oil recovery[J]. Journal of Molecular Liquids, 2022, 366: 120293. |

| [14] | Wang F J, Xu H, Liu Y K, et al. Experimental study on the enhanced oil recovery mechanism of an ordinary heavy oil field by polymer flooding[J]. ACS Omega, 2023, 8(15): 14089-14096. |

| [15] | Fei D T, Guo J X, Xiong R Y, et al. Preparation and performance evaluation of amphiphilic polymers for enhanced heavy oil recovery[J]. Polymers, 2023, 15(23): 4606. |

| [16] | Ji Y F, Wang D P, Cao X L, et al. Both-branch amphiphilic polymer oil displacing system: molecular weight, surfactant interactions and enhanced oil recovery performance[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2016, 509: 440-448. |

| [17] | Gbadamosi A, Patil S, Kamal M S, et al. Application of polymers for chemical enhanced oil recovery: a review[J]. Polymers, 2022, 14(7): 1433. |

| [18] | Maaref S, Kantzas A, Bryant S L. The effect of water alternating solvent based nanofluid flooding on heavy oil recovery in oil-wet porous media[J]. Fuel, 2020, 282: 118808. |

| [19] | Wang Q X, Zhang W, Wang C, et al. Microstructure of heavy oil components and mechanism of influence on viscosity of heavy oil[J]. ACS Omega, 2023, 8(12): 10980-10990. |

| [20] | Villegas O, Vallverdu G S, Bouyssiere B, et al. Cancellation of dipole moment of models of asphaltene aggregates as a mean for their dispersion in toluene and THF calculated using molecular dynamics[J]. Fuel, 2023, 334: 126472. |

| [21] | da Costa L M, Stoyanov S R, Gusarov S, et al. Density functional theory investigation of the contributions of π-π stacking and hydrogen-bonding interactions to the aggregation of model asphaltene compounds[J]. Energy & Fuels, 2012, 26(5): 2727-2735. |

| [22] | Afra S, Nasr-El-Din H A, Socci D, et al. Green phenolic amphiphile as a viscosity modifier and asphaltenes dispersant for heavy and extra-heavy oil[J]. Fuel, 2018, 220: 481-489. |

| [23] | Sautaux J, Marx F, Gunkel I, et al. Mechanically robust supramolecular polymer co-assemblies[J]. Nature Communications, 2022, 13: 356. |

| [24] | Chen M G, Deng H, Geng X F, et al. Synthesis and evaluation of a low molecular weight amphiphilic polymer for enhanced oil recovery[J]. Journal of Surfactants and Detergents, 2021, 24(6): 991-1002. |

| [25] | Liu Z Y, Mendiratta S, Chen X, et al. Amphiphilic-polymer-assisted hot water flooding toward viscous oil mobilization[J]. Industrial & Engineering Chemistry Research, 2019, 58(36): 16552-16564. |

| [26] | Wang X, Zhang H, Liang X W, et al. New amphiphilic macromolecule as viscosity reducer with both asphaltene dispersion and emulsifying capacity for offshore heavy oil[J]. Energy & Fuels, 2021, 35(2): 1143-1151. |

| [27] | Mao J C, Liu J W, Wang H B, et al. Novel terpolymers as viscosity reducing agent for Tahe super heavy oil[J]. RSC Advances, 2017, 7(31): 19257-19261. |

| [28] | Mao J C, Liu J W, Peng Y K, et al. Quadripolymers as viscosity reducers for heavy oil[J]. Energy & Fuels, 2018, 32(1): 119-124. |

| [29] | Li N, Ma H, Wang T Y, et al. Effect of molecular weight on the properties of water-soluble terpolymers for heavy oil viscosity reduction[J]. Journal of the Taiwan Institute of Chemical Engineers, 2023, 144: 104738. |

| [30] | Yang H B, Lv Z Q, Zhang M, et al. A novel active amphiphilic polymer for enhancing heavy oil recovery: synthesis, characterization and mechanism[J]. Journal of Molecular Liquids, 2023, 391: 123210. |

| [31] | Zhang X J, Guo J X, Fei D T, et al. Polymer surfactants as viscosity reducers for ultra-heavy oil: synthesis and viscosity reduction mechanism[J]. Fuel, 2024, 357: 129871. |

| [32] | Ge S, Shi L T, Ye Z B, et al. Synthesis and mechanistic investigation of an amphiphilic polymer in enhancing extra-heavy oil recovery via viscosity reduction[J]. Langmuir, 2024, 40(34): 18049-18062. |

| [33] | Li P C, Zhang F S, Gong Y J, et al. Synthesis and properties of functional polymer for heavy oil viscosity reduction[J]. Journal of Molecular Liquids, 2021, 330: 115635. |

| [34] | Inada C, Kobayashi Y, Yamakawa M, et al. Interfacial assembly and properties of amphiphilic polymer-grafted nanoparticles: effect of chemical design and density of grafted polymers[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2024, 692: 133921. |

| [35] | 刘诚, 李杨, 张春庆, 等. 接枝共聚物分子设计及合成方法研究进展[J]. 高分子通报, 2009(5): 36-41. |

| Liu C, Li Y, Zhang C Q, et al. Research progress in molecule design and synthetic technique of graft copolymer[J]. Polymer Bulletin, 2009(5): 36-41. | |

| [36] | Sakamoto Y, Nishimura T. Recent advances in the self-assembly of sparsely grafted amphiphilic copolymers in aqueous solution[J]. Polymer Chemistry, 2022, 13(46): 6343-6360. |

| [37] | Shi L T, Liu C L, Chen M, et al. Synthesis and evaluation of a hyperbranched copolymer as viscosity reducer for offshore heavy oil[J]. Journal of Petroleum Science and Engineering, 2021, 196: 108011. |

| [38] | Li J, Wang Q X, Liu Y G, et al. Long branched-chain amphiphilic copolymers: synthesis, properties, and application in heavy oil recovery[J]. Energy & Fuels, 2018, 32(6): 7002-7010. |

| [39] | 费东涛, 郭继香, 孙建芳, 等. 一种两亲聚合物稠油降黏剂的制备及性能评价[J]. 精细化工, 2022, 39(5): 1072-1080. |

| Fei D T, Guo J X, Sun J F, et al. Synthesis and performance evaluation of an amphiphilic polymer viscosity reducer for heavy oil[J]. Fine Chemicals, 2022, 39(5): 1072-1080. | |

| [40] | Li Q, Wang X D, Li Q Y, et al. New amphiphilic polymer with emulsifying capability for extra heavy crude oil[J]. Industrial & Engineering Chemistry Research, 2018, 57(49): 17013-17023. |

| [41] | 陈明贵, 陈登亚, 梁洁, 等. 水溶性两亲聚合物稠油乳化剂的制备及驱油效率[J]. 油田化学, 2019, 36(2): 306-313. |

| Chen M G, Chen D Y, Liang J, et al. New water soluble amphiphilic block copolymer for emulsion flooding of heavy oil[J]. Oilfield Chemistry, 2019, 36(2): 306-313. | |

| [42] | Röpert M C, Schußmann M G, Esfahani M K, et al. Effect of side chain length in polystyrene POM–POMs on melt rheology and solid mechanical fatigue[J]. Macromolecules, 2022, 55(13): 5485-5496. |

| [43] | Zhou P, Pan G X, Spaccini R, et al. Molecular changes in particulate organic matter (POM) in a typical Chinese paddy soil under different long-term fertilizer treatments[J]. European Journal of Soil Science, 2010, 61(2): 231-242. |

| [44] | Azad M S, Dalsania Y K, Trivedi J J. Capillary breakup extensional rheometry of associative and hydrolyzed polyacrylamide polymers for oil recovery applications[J]. Journal of Applied Polymer Science, 2018, 135(22): 46253. |

| [45] | 张文, 龙军, 任强, 等. 沥青质分子聚集行为研究进展[J]. 化工进展, 2019, 38(5): 2158-2163. |

| Zhang W, Long J, Ren Q, et al. Research progress on aggregation behavior of asphaltene[J]. Chemical Industry and Engineering Progress, 2019, 38(5): 2158-2163. | |

| [46] | 韦胜超, 姚志林, 卞贺, 等. 氢键作用对沥青质超分子聚集的影响[J]. 石油学报(石油加工), 2021, 37(3): 556-565. |

| Wei S C, Yao Z L, Bian H, et al. Effects of hydrogen bonding interactions on the asphaltene supramolecular aggregation[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2021, 37(3): 556-565. | |

| [47] | Chen M F, Chen W H, Wang Y F, et al. Hydrogen-bonded amphiphilic polymer viscosity reducer for enhancing heavy oil recovery: synthesis, characterization and mechanism[J]. European Polymer Journal, 2022, 180: 111589. |

| [48] | Yu J, Quan H P, Chang S H, et al. Research on a fluorine-containing asphaltene dispersant and its application in improving the fluidity of heavy oil[J]. Journal of Molecular Liquids, 2023, 375: 121318. |

| [49] | Wang X, Liu W F, Shi L T, et al. Application of a novel amphiphilic polymer for enhanced offshore heavy oil recovery: mechanistic study and core displacement test[J]. Journal of Petroleum Science and Engineering, 2022, 215: 110626. |

| [50] | Chen M F, Wang Y F, Chen W H, et al. Synthesis and evaluation of multi-aromatic ring copolymer as viscosity reducer for enhancing heavy oil recovery[J]. Chemical Engineering Journal, 2023, 470: 144220. |

| [51] | Chen S H, AlSofi A M, Wang J X, et al. A polycyclic-aromatic hydrocarbon-based water-soluble formulation for heavy oil viscosity reduction and oil displacement[J]. Energy & Fuels, 2023, 37(16): 11864-11880. |

| [52] | Chen X Y, Wang N, Xia S Q. Research progress and development trend of heavy oil emulsifying viscosity reducer: a review[J]. Petroleum Science and Technology, 2021, 39(15/16): 550-563. |

| [53] | 张阳, 蒋琪, 毛金成, 等. 一种双重刺激响应型聚合物稠油乳化降黏剂及制备方法: 115368885A[P]. 2022-11-22. |

| Zhang Y, Jiang Q, Mao J C, et al. Dual-stimulus-responsive polymer thick oil emulsifying viscosity reducer and preparation method thereof: 115368885A[P]. 2022-11-22. | |

| [54] | 张倩洁, 单子悦, 张冬梅, 等. 刺激响应型聚合物乳化剂的研究进展[J]. 日用化学工业, 2023, 53(11): 1305-1314. |

| Zhang Q J, Shan Z Y, Zhang D M, et al. Research progress of stimuli-responsive polymer emulsifiers[J]. China Surfactant Detergent & Cosmetics, 2023, 53(11): 1305-1314. | |

| [55] | Wu Y T, Zeng M, Cheng Q Y, et al. Recent progress toward physical stimuli-responsive emulsions[J]. Macromolecular Rapid Communications, 2022, 43(18): 2200193. |

| [56] | Hu M Q, Russell T P. Polymers with advanced architectures as emulsifiers for multi-functional emulsions[J]. Materials Chemistry Frontiers, 2021, 5(3): 1205-1220. |

| [57] | Arnal-Pastor M, Comín-Cebrián S, Martínez-Ramos C, et al. Hydrophilic surface modification of acrylate-based biomaterials[J]. Journal of Biomaterials Applications, 2016, 30(9): 1429-1441. |

| [58] | Sun Z Y, Zhao Q C, Haag R, et al. Responsive emulsions for sequential multienzyme cascades[J]. Angewandte Chemie International Edition, 2021, 60(15): 8410-8414. |

| [59] | Zhang T H, Fan J J, Qiu W X, et al. Oppositely sensitive pH-responsive surfactants derived from polymer-grafted carbon dots[J]. Carbon, 2025, 238: 120126. |

| [60] | Sun Y H, Qing M M, Qi J, et al. Insights into the efficient release of the polyacrylamide drag reducer via a pH-responsive inverse polymer emulsion[J]. Langmuir, 2024, 40(12): 6394-6401. |

| [61] | He X R, Chen B, He S, et al. Reversible emulsification based on pH-responsive surfactant with dynamic imine bond[J]. Journal of Molecular Liquids, 2024, 394: 123792. |

| [62] | Wu R N, Yan Y H, Li X X, et al. Preparation and controllable heavy oil viscosity reduction performance of pH-responsive star block copolymers[J]. Journal of Molecular Liquids, 2023, 389: 122925. |

| [63] | Qi L, Luo Z G, Lu X X. Facile synthesis of starch-based nanoparticle stabilized Pickering emulsion: its pH-responsive behavior and application for recyclable catalysis[J]. Green Chemistry, 2018, 20(7): 1538-1550. |

| [64] | Zhu T Y, Kang W L, Yang H B, et al. Fabrication of a pH-responsive emulsifier for heavy oil recovery based on dynamic imine bond[J]. Journal of Molecular Liquids, 2021, 332: 115916. |

| [65] | Weaver J V M, Armes S P, Bütün V. Synthesis and aqueous solution properties of a well-defined thermo-responsive schizophrenic diblock copolymer[J]. Chemical Communications, 2002(18): 2122-2123. |

| [66] | Jiang Y N, Yan R Y, Pang B, et al. A novel temperature-dependent hydrogel emulsion with sol/gel reversible phase transition behavior based on polystyrene-co-poly(N-isopropylacrylamide)/poly(N-isopropylacrylamide) core-shell nanoparticle[J]. Macromolecular Rapid Communications, 2021, 42(2): 2000507. |

| [67] | Zhang X W, Qin J Q, Yin Z H, et al. Temperature-responsive polymeric surfactant-based emulsion for dual oil-solid and oil-water separation from oily sludges[J]. Separation and Purification Technology, 2025, 373: 133519. |

| [68] | Li Q, Liu L F, Sun D J, et al. Recent advances in switchable surfactants for heavy oil production: a review[J]. Energy Geoscience, 2024, 5(4): 100342. |

| [69] | Hu J W, Gao H T, Xie W Q, et al. Preparation and investigation of temperature-responsive SiO2–PSBMA Janus nanosheet with salt-tolerant properties for enhanced recovery of heavy oil[J]. ACS Applied Materials & Interfaces, 2024, 16(51): 70851-70862. |

| [70] | Wang T Y, Wang C H, Ma H, et al. Preparation of temperature-sensitive SiO2–PSBMA for reducing the viscosity of heavy oil[J]. Energy & Fuels, 2023, 37(3): 1896-1906. |

| [71] | Li H, Liu P, Yuan J, et al. Thermo-responsive brush copolymers by “grafting through” strategy implemented on the surface of the macromonomer micelles and their high emulsifying performance[J]. Macromolecular Chemistry and Physics, 2017, 218(15): 1700131. |

| [72] | Ranka M, Katepalli H, Blankschtein D, et al. Schizophrenic diblock-copolymer-functionalized nanoparticles as temperature-responsive Pickering emulsifiers[J]. Langmuir, 2017, 33(46): 13326-13331. |

| [73] | Li L, Guo A R, Sun H X, et al. Research and application of thermosensitive Pickering emulsion with X-ray and ultrasound dual-modal imaging functions for intra-arterial embolization treatment[J]. Journal of Pharmaceutical Analysis, 2024, 15(4): 101133. |

| [74] | Glasing J, Bouchard J, Jessop P G, et al. Grafting well-defined CO2-responsive polymers to cellulose nanocrystals via nitroxide-mediated polymerisation: effect of graft density and molecular weight on dispersion behaviour[J]. Polymer Chemistry, 2017, 8(38): 6000-6012. |

| [75] | Shieh Y T, Tai P Y, Cheng C C. Polymer nanoparticles with a sensitive CO2-responsive hydrophilic/hydrophobic surface[J]. Journal of Polymer Science Part A: Polymer Chemistry, 2019, 57(21): 2149-2156. |

| [76] | Guan X Q, Liu D F, Lu H S, et al. CO2 responsive emulsions: generation and potential applications[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2019, 582: 123919. |

| [77] | 孙彩霞, 马浩, 于福策, 等. CO2响应型β-环糊精材料用于稠油降黏[J]. 精细化工, 2024, 41(4): 895-901, 919. |

| Sun C X, Ma H, Yu F C, et al. CO2-responsive beta-cyclodextrin materials for heavy oil viscosity reduction[J]. Fine Chemicals, 2024, 41(4): 895-901, 919. | |

| [78] | Liu P W, Lu W Q, Wang W J, et al. Highly CO2/N2-switchable zwitterionic surfactant for Pickering emulsions at ambient temperature[J]. Langmuir, 2014, 30(34): 10248-10255. |

| [79] | Liang C, Harjani J R, Robert T, et al. Use of CO2-triggered switchable surfactants for the stabilization of oil-in-water emulsions[J]. Energy & Fuels, 2012, 26(1): 488-494. |

| [80] | Lu H S, Zhou Z, Jiang J F, et al. Carbon dioxide switchable polymer surfactant copolymerized with 2-(dimethylamino)ethyl methacrylate and butyl methacrylate as a heavy-oil emulsifier[J]. Journal of Applied Polymer Science, 2015, 132(3): 41307. |

| [81] | Liu J W, Li L, Xu Z Z, et al. CO2-responsive zwitterionic copolymer for effective emulsification and facile demulsification of crude heavy oil[J]. Journal of Molecular Liquids, 2021, 325: 115166. |

| [82] | 石昀, 安丽媛, 谢富强, 等. 一种水溶性双基稠油降黏剂的制备及应用[J]. 油田化学, 2023, 40(1): 102-109. |

| Shi Y, An L Y, Xie F Q, et al. Preparation and application of water-soluble double-based heavy oil viscosity-reducing agent[J]. Oilfield Chemistry, 2023, 40(1): 102-109. | |

| [83] | 伍晓妮. 两亲性降黏剂合成及性能评价[J]. 石油地质与工程, 2022, 36(1): 122-126. |

| Wu X N. Synthesis and performance evaluation of amphiphilic viscosity reducer[J]. Petroleum Geology and Engineering, 2022, 36(1): 122-126. |

| [1] | 段炼, 周星睿, 袁文君, 陈飞. 连续相速度脉动对微通道内聚合物液滴生成和形貌的影响规律[J]. 化工学报, 2025, 76(9): 4578-4585. |

| [2] | 张晓晨, 鲁中山, 郭腾, 桂恒, 宋红兵, 肖盟. 一株端羟基聚丁二烯降解菌的筛选及降解机理研究[J]. 化工学报, 2025, 76(8): 4205-4216. |

| [3] | 叶鑫煌, 薛嘉豪, 赵玉来. 可聚型Gemini表面活性剂的制备、表征及其稳定高内相乳液的研究[J]. 化工学报, 2025, 76(8): 4331-4340. |

| [4] | 林嘉豪, 付芳忠, 叶昊辉, 胡金, 姚明灿, 范鹤林, 王旭, 王瑞祥, 徐志峰. NdF3含量对NdF3-LiF熔盐局域结构和输运性质的影响[J]. 化工学报, 2025, 76(8): 3834-3841. |

| [5] | 乔亮, 李尚, 刘新亮, 王明, 张沛, 侯影飞. 三元共聚物稠油降黏剂的合成及分子模拟研究[J]. 化工学报, 2025, 76(7): 3686-3695. |

| [6] | 赵美, 甘雨欣, 赵绍磊, 杨令, 王亭杰. 硅橡胶用纳米二氧化硅表面有机修饰及补强机理研究进展[J]. 化工学报, 2025, 76(7): 3125-3136. |

| [7] | 王珺仪, 夏章讯, 景粉宁, 王素力. 基于重整气的高温聚合物电解质膜燃料电池电化学阻抗谱弛豫时间分布研究[J]. 化工学报, 2025, 76(7): 3509-3520. |

| [8] | 郭乃胜, 朱小波, 王双, 陈平, 褚召阳, 王志臣. 聚氨酯改性沥青高低温性能及影响因素的研究进展[J]. 化工学报, 2025, 76(6): 2505-2523. |

| [9] | 高冰冰, 许诺, 白云翔, 张春芳, 杨永强, 董亮亮. 氦气分离聚合物膜[J]. 化工学报, 2025, 76(5): 2119-2135. |

| [10] | 李紫鹃, 谭晓艳, 吴永盛, 杨陈怡, 陈红, 毕小刚, 刘捷, 喻发全. 分子模拟研究三维扭曲催化芳烃-降冰片烯环化聚合物膜的CO2/N2分离机理[J]. 化工学报, 2025, 76(5): 2348-2357. |

| [11] | 陆艳秋, 狄扬, 石文博, 殷聪聪, 汪勇. 基于新型有机多孔聚合物的智能响应膜研究进展[J]. 化工学报, 2025, 76(5): 2101-2118. |

| [12] | 范佳媛, 曾文慧, 任志超, 张文涛, 吕霜. 多熔点相变乳液的制备及性能强化研究[J]. 化工学报, 2025, 76(4): 1863-1874. |

| [13] | 宫政, 高秀鲁, 赵玲, 胡冬冬. 超临界CO2发泡PBAT/PLA复合材料及其形状记忆性能[J]. 化工学报, 2025, 76(2): 888-896. |

| [14] | 吴雨轩, 常诚, 顾雪萍, 冯连芳, 张才亮. 面向立体异构的丁二烯乳液聚合过程模型化[J]. 化工学报, 2025, 76(2): 879-887. |

| [15] | 翟紫航, 蒋杰, 李锦锦, 赵玲, 奚桢浩. 基于2,5-呋喃二甲酸的三元无规共聚酯PBSF的制备与性能[J]. 化工学报, 2025, 76(2): 868-878. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号