化工学报 ›› 2025, Vol. 76 ›› Issue (12): 6328-6338.DOI: 10.11949/0438-1157.20250653

收稿日期:2025-06-17

修回日期:2025-08-02

出版日期:2025-12-31

发布日期:2026-01-23

通讯作者:

于源

作者简介:李兴帅(1999—),男,硕士研究生,1121149767@qq.com

基金资助:Received:2025-06-17

Revised:2025-08-02

Online:2025-12-31

Published:2026-01-23

Contact:

Yuan YU

摘要:

超细粉体因其物化特性应用广泛,制备粒度分布窄而细的超细粉体是提升产品性能的关键。在不增加能耗和设备复杂度的前提下,设计了双层转笼结构,通过数值模拟与分级实验,分析了其对气力分级机流场及细粉产品分布的影响。模拟结果表明,双层转笼引流锥由于重力分级作用使环形区气流在近转笼外缘向下运动且径向速度减小,改善了环形区粉体分散性并减小了细粉粒径。物料分级实验结果验证,双层转笼显著减小细粉粒径,且随引流锥长度增加,细粉粒径更小、粒度分布更窄,二次分级效果更为显著。

中图分类号:

李兴帅, 于源. 用于超细粉体分级的双层转笼设计与研究[J]. 化工学报, 2025, 76(12): 6328-6338.

Xingshuai LI, Yuan YU. Design and study on dual-layer rotor cage for ultrafine powder classification[J]. CIESC Journal, 2025, 76(12): 6328-6338.

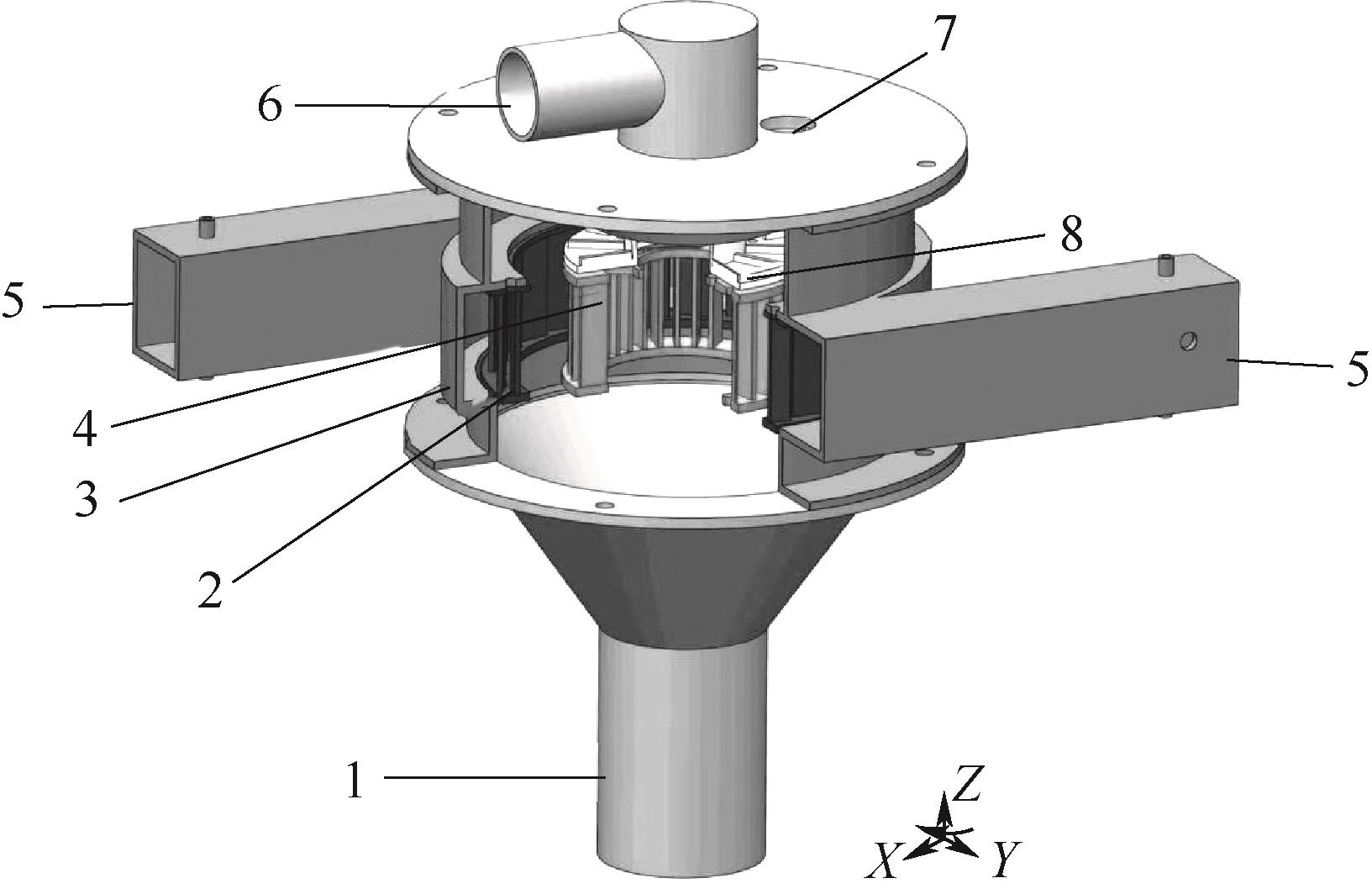

图1 涡流空气分级机三维模型1—粗粉收集区;2—导风叶片;3—蜗壳;4—转笼;5—进风口;6—细粉出口;7—喂料口;8—撒料盘

Fig.1 3D model of the turbo air classifier1—coarse powder collection chamber; 2—guide vane; 3—volut;e 4—rotor cage; 5—air inlet; 6—fine powder outlet; 7—feeding inlet; 8—spreading plate

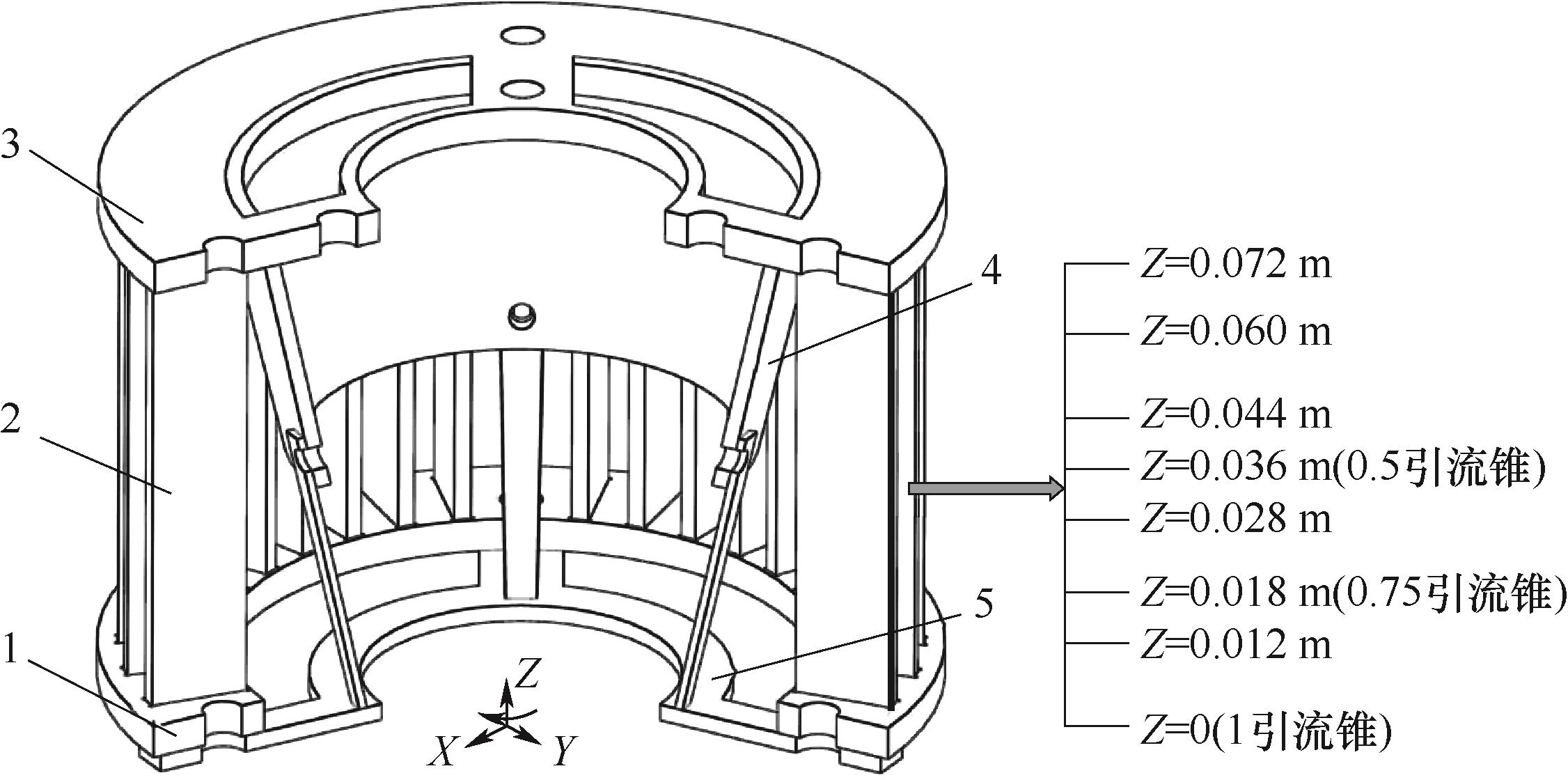

图4 双层转笼结构剖视图1—下轮架;2—转笼叶片;3—上轮架;4—引流锥;5—三角支架

Fig.4 Cross-sectional view of the dual-layer rotor cage structure1—lower wheel frame; 2—rotor cage blade; 3—upper wheel frame; 4—diversion cone; 5—triangle bracket

| 颗粒粒径/μm | 微分分数/% |

|---|---|

| <1 | 4.73 |

| <1~≤3 | 7.01 |

| <3~≤7 | 10.74 |

| <7~≤15 | 17.49 |

| <15~≤30 | 23.57 |

| <30~≤40 | 13.59 |

| <40~≤50 | 10.77 |

| <50~≤60 | 7.81 |

| <60~≤70 | 2.75 |

| >70 | 1.54 |

表1 碳酸钙原料粒度质量微分分布

Table 1 Particle size differential distribution of calcium carbonate raw material (mass-based)

| 颗粒粒径/μm | 微分分数/% |

|---|---|

| <1 | 4.73 |

| <1~≤3 | 7.01 |

| <3~≤7 | 10.74 |

| <7~≤15 | 17.49 |

| <15~≤30 | 23.57 |

| <30~≤40 | 13.59 |

| <40~≤50 | 10.77 |

| <50~≤60 | 7.81 |

| <60~≤70 | 2.75 |

| >70 | 1.54 |

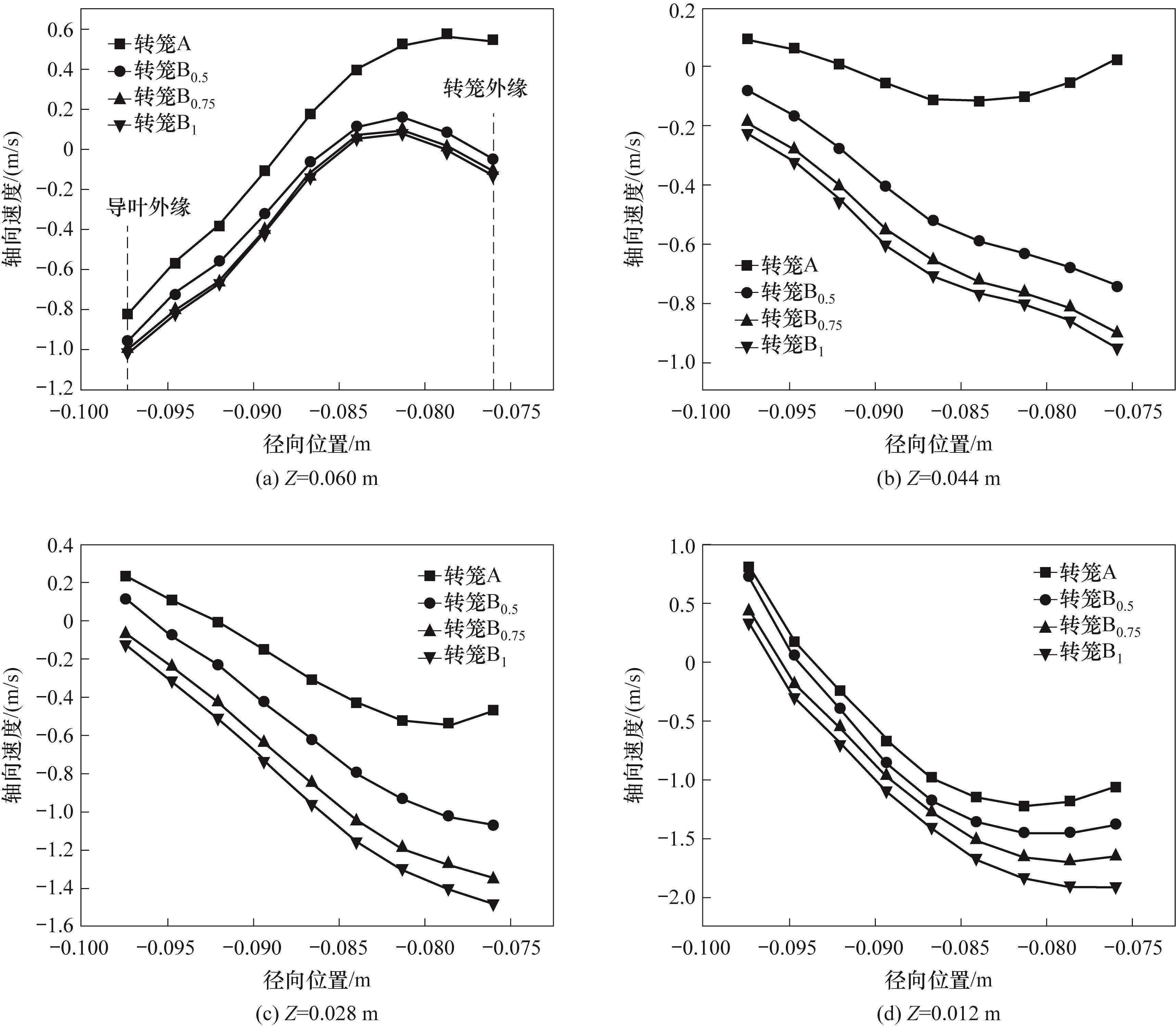

图7 4种转笼分级机环形区不同轴向高度轴向速度曲线图

Fig.7 Axial velocity curves in the annular region of the classifier with four different rotor cages at various axial heights

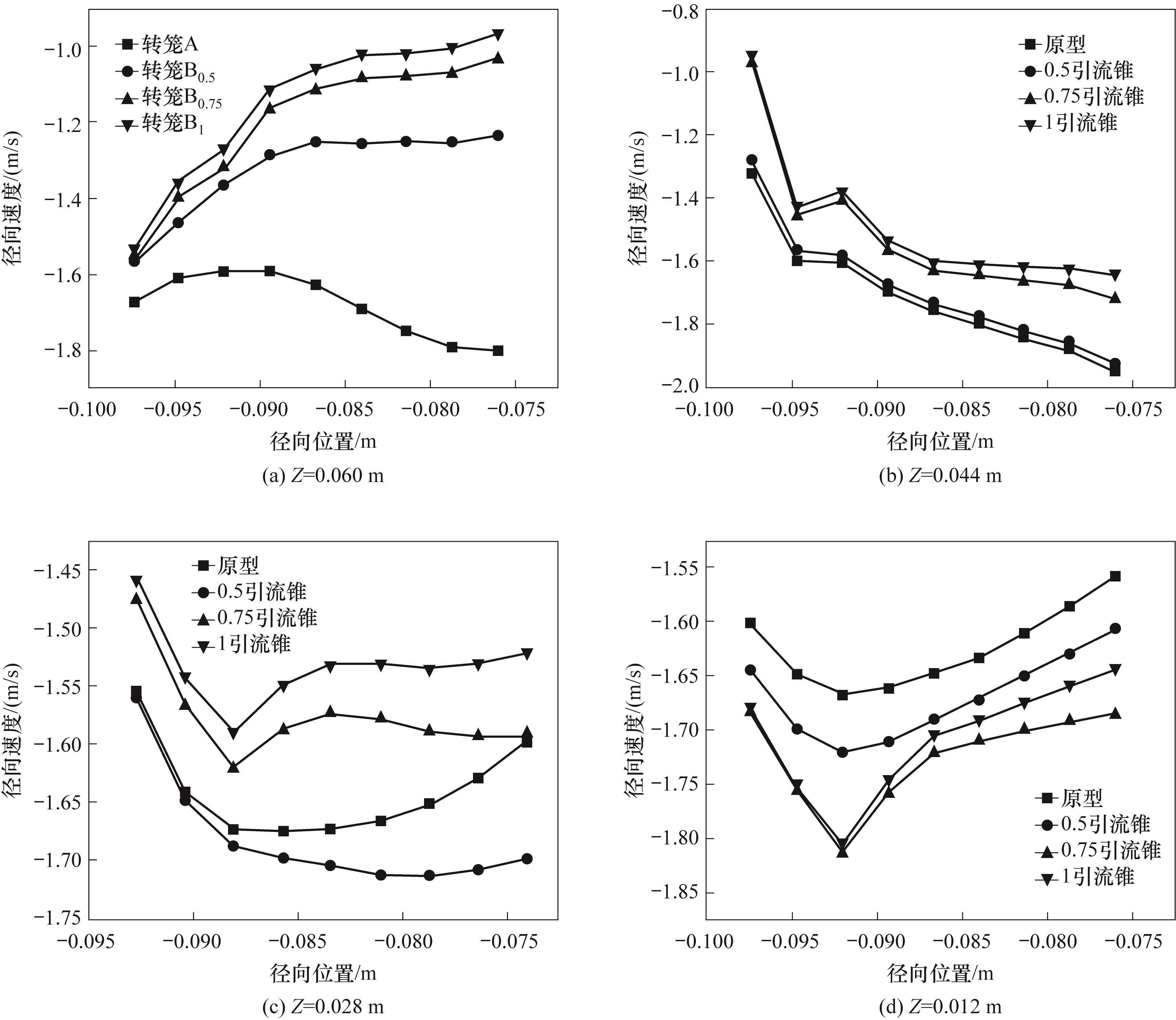

图8 4种分级机环形区不同轴向高度径向速度曲线图

Fig.8 Radial velocity curves in the annular region of the classifier with four different rotor cages at various axial heights

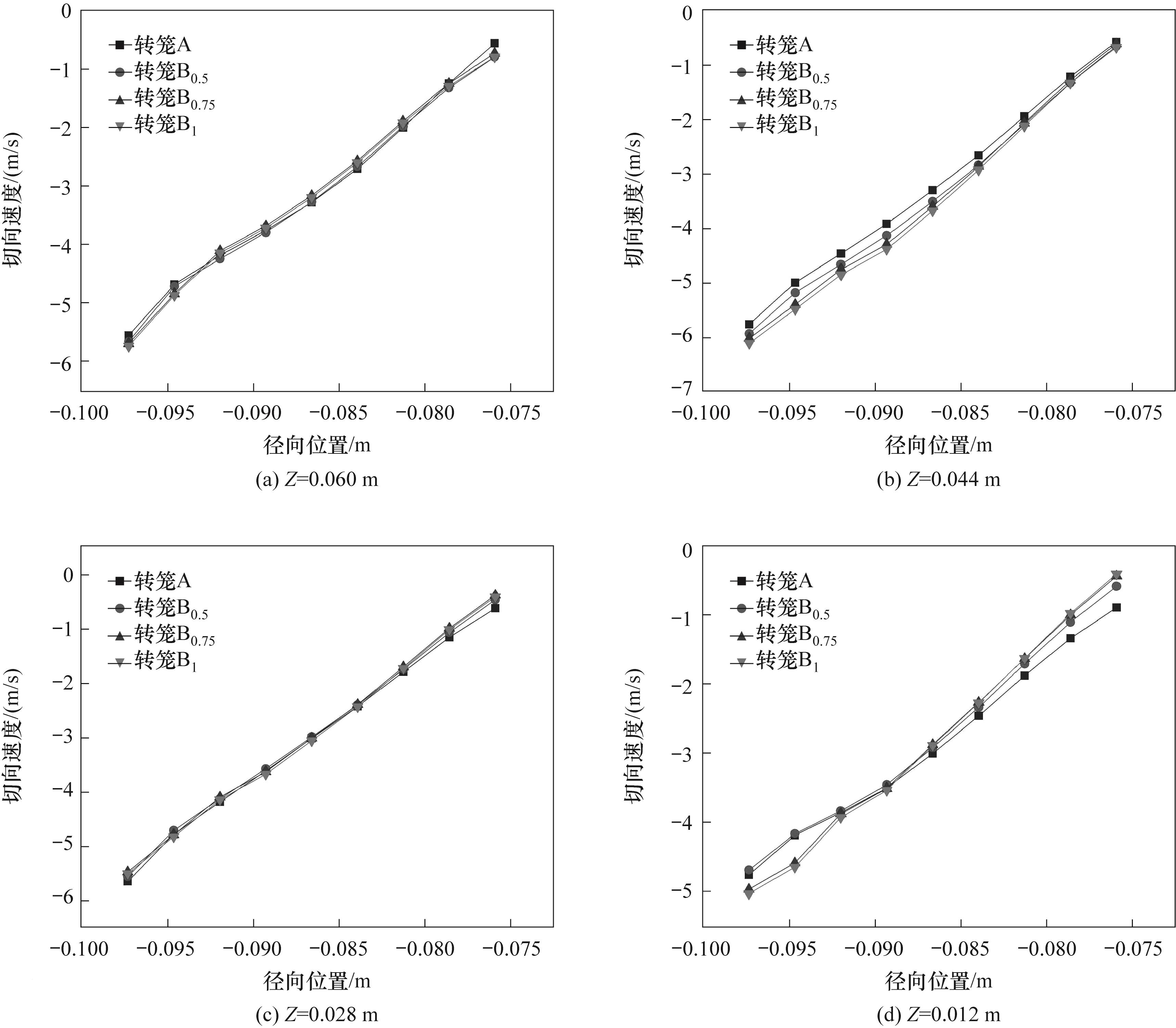

图9 4种分级机环形区不同轴向高度切向速度曲线图

Fig.10 Tangential velocity curves in the annular region of the classifier with four different rotor cages at various axial heights

| 转笼类型 | 分级粒径d50/μm |

|---|---|

| 转笼A | 32.5 |

| 转笼B0.5 | 24.6 |

| 转笼B0.75 | 16.2 |

| 转笼B1 | 12.2 |

表2 4种转笼分级机分级粒径

Table 2 Cut sizes with four classifiers

| 转笼类型 | 分级粒径d50/μm |

|---|---|

| 转笼A | 32.5 |

| 转笼B0.5 | 24.6 |

| 转笼B0.75 | 16.2 |

| 转笼B1 | 12.2 |

| 转笼类型 | 平均粒径D50/μm | 粒度分布指数n |

|---|---|---|

| 转笼A | 10.49 | 1.138 |

| 转笼B0.5 | 9.08 | 1.152 |

| 转笼B0.75 | 7.34 | 1.173 |

| 转笼B1 | 5.96 | 1.230 |

表3 4种转笼结构细粉产品平均粒径D50和粒度分布指数n

Table 3 Average particle size D50 and particle size distribution index n of the fine powder for the four different rotor cages

| 转笼类型 | 平均粒径D50/μm | 粒度分布指数n |

|---|---|---|

| 转笼A | 10.49 | 1.138 |

| 转笼B0.5 | 9.08 | 1.152 |

| 转笼B0.75 | 7.34 | 1.173 |

| 转笼B1 | 5.96 | 1.230 |

| [1] | 吴祖璇, 张邦胜, 王芳, 等. 超细粉体制备技术研究[J]. 中国资源综合利用, 2020, 38(12): 108-112. |

| Wu Z X, Zhang B S, Wang F, et al. Research on preparation technology of ultrafine powder[J]. China Resources Comprehensive Utilization, 2020, 38(12): 108-112. | |

| [2] | Chu F Z, Zhang K, Shen H P, et al. Influence of satellite and agglomeration of powder on the processability of AlSi10Mg powder in laser powder bed fusion[J]. Journal of Materials Research and Technology, 2021, 11: 2059-2073. |

| [3] | Zhu X P, Liu W, Zhang H P, et al. Narrowing particle size distributions to enhance powder coating performance by improved classifying[J]. Powder Technology, 2024, 435: 119443. |

| [4] | 陈路明, 刘英莉, 陆海峰, 等. 通气作用下超细粉体应力演变与料仓设计研究[J]. 化工学报, 2025, 76(8): 3853-3863. |

| Chen L M, Liu Y L, Lu H F, et al. Study on stress evolution and hopper design of ultrafine powder under aeration conditions[J]. CIESC Journal, 2025, 76(8): 3853-3863. | |

| [5] | 李柏林, 李彦臻, 李懿. 水泥工业选粉技术现状与发展趋势[J]. 新世纪水泥导报, 2022, 28(2): 42-46. |

| Li B L, Li Y Z, Li Y. Present situation and development trend of powder concentrating technology in cement industry[J]. Cement Guide for New Epoch, 2022, 28(2): 42-46. | |

| [6] | Ren W J, Liu J X, Yu Y. Design of a rotor cage with non-radial arc blades for turbo air classifiers[J]. Powder Technology, 2016, 292: 46-53. |

| [7] | Mou X L, Jia F C, Fang Y, et al. CFD-based structural optimization of rotor cage for high-efficiency rotor classifier[J]. Processes, 2021, 9(7): 1148. |

| [8] | 赵海朋, 任成, 张来龙, 等. 涡流空气分级机转笼底盘结构对分级性能的影响[J]. 北京化工大学学报(自然科学版), 2018, 45(6): 73-78. |

| Zhao H P, Ren C, Zhang L L, et al. Influence of the rotor cage underpan on the classification performance of a turbo air classifier[J]. Journal of Beijing University of Chemical Technology (Natural Science), 2018, 45(6): 73-78. | |

| [9] | 黄强. 涡流空气分级机转笼及导风叶片结构改进的研究[D]. 北京: 北京化工大学, 2011. |

| Huang Q. Study on the structure of rotor cage and guide blade in a turbo air classifier[D]. Beijing: Beijing University of Chemical Technology, 2011. | |

| [10] | 刘春雨, 孙占朋, 杨光. 三转笼涡流空气分级机流场特性与分级性能分析[J]. 计算机仿真, 2023, 40(4): 300-304. |

| Liu C Y, Sun Z P, Yang G. Analysis of flow field characteristics and classification performance of turbo air classifier with three rotor cages[J]. Computer Simulation, 2023, 40(4): 300-304. | |

| [11] | 陈伟燚. 基于多物理场耦合的离心分级机效能优化[D]. 桂林: 桂林电子科技大学, 2024. |

| Chen W Y. Centrifugal classifier performance optimization based on multiphysics coupling[D]. Guilin: Guilin University of Electronic Technology, 2024. | |

| [12] | 蔡仁良. 流体密封技术原理与工程应用[M]. 北京: 化学工业出版社, 2013. |

| Cai R L. Fluid Sealing Technology[M]. Beijing: Chemical Industry Press, 2013. | |

| [13] | 张扬, 刘峰斌, 李德才, 等. 高速磁性液体旋转密封结构优化设计与试验研究[J]. 润滑与密封, 2025, 50(7): 30-38. |

| Zhang Y, Liu F B, Li D C, et al. Optimal design and experimental study of high speed magnetic liquid rotary seal structure[J]. Lubrication Engineering, 2025, 50(7): 30-38. | |

| [14] | 赵华楠, 吕晓仁, 吕宝华, 等. 基于流固热多场耦合的高速旋转唇形密封性能研究[J]. 润滑与密封, 2024, 49(2): 43-49. |

| Zhao H N, Lv X R, Lv B H, et al. Study on the performance of high-speed rotating lip seal based on fluid-solid-heat multi-field coupling[J]. Lubrication Engineering, 2024, 49(2): 43-49. | |

| [15] | 曹迎妮. 颗粒物性对涡流气力分级效果的影响研究[D]. 北京: 北京化工大学, 2024. |

| Cao Y N. Study on the effect of particle physical prameters on turbo pneumatic classification[D]. Beijing: Beijing University of Chemical Technology, 2024. | |

| [16] | 刘家祥. 涡流空气分级机分级特性及性能改进的研究[D]. 沈阳: 东北大学, 1997. |

| Liu J X. Study on classification characteristics and performance improvement of vortex air classifier[D]. Shenyang: Northeastern University, 1997. | |

| [17] | 陈薇薇. 涡流空气分级机几何相似模型的分析和研究[D]. 北京: 北京化工大学, 2023. |

| Chen W W. Analysis and study for geometrically similar turbo air classifier model[D]. Beijing: Beijing University of Chemical Technology, 2023. | |

| [18] | Yu Y, Wang L, Liu J. Analysis of numerical simulation models for the turbo air classifier[J]. Materialwissenschaft und Werkstofftechnik, 2022, 53(5): 644-657. |

| [19] | 柏威, 鄂学全. 基于非结构化同位网格的SIMPLE算法[J]. 计算力学学报, 2003, 20(6): 702-710. |

| Bai W, E X Q. Implement of SIMPLE algorithm based on unstructured colocated meshes[J]. Chinese Journal of Computational Mechanics, 2003, 20(6): 702-710. | |

| [20] | Ataş S, Tekir U, Paksoy M A, et al. Numerical and experimental analysis of pulverized coal mill classifier performance in the Soma B Power Plant[J]. Fuel Processing Technology, 2014, 126: 441-452. |

| [21] | 冯乐乐, 王景玉, 吴玉新, 等. 颗粒特性对撞击分离器性能影响的实验与数值研究[J]. 化工学报, 2018, 69(8): 3348-3355. |

| Feng L L, Wang J Y, Wu Y X, et al. Experimental and numerical investigation on effect of particle characteristics on performance of plate-type impact separator[J]. CIESC Journal, 2018, 69(8): 3348-3355. | |

| [22] | González-Tello P, Camacho F, Vicaria J M, et al. A modified Nukiyama-Tanasawa distribution function and a Rosin-Rammler model for the particle-size-distribution analysis[J]. Powder Technology, 2008, 186(3): 278-281. |

| [23] | Zhang G H, Fan Y B, Yang R S, et al. Application of the Rosin-Rammler function to describe quartz sandstone particle size distribution produced by high-pressure gas rapid unloading at different infiltration pressure[J]. Powder Technology, 2022, 412: 117982. |

| [24] | Kumar R, Gopireddy S R, Jana A K, et al. Study of the discharge behavior of Rosin-Rammler particle-size distributions from hopper by discrete element method: a systematic analysis of mass flow rate, segregation and velocity profiles[J]. Powder Technology, 2020, 360: 818-834. |

| [25] | Liu R R, Liu J X, Yu Y. Effects of axial inclined guide vanes on a turbo air classifier[J]. Powder Technology, 2015, 280: 1-9. |

| [26] | 刘克润, 于源. 涡流空气分级流场中团聚体破碎规律研究[J]. 化工学报, 2024, 75(10): 3477-3487. |

| Liu K R, Yu Y. Study of aggregate fragmentation laws in turbo air classification flow field[J]. CIESC Journal, 2024, 75(10): 3477-3487. |

| [1] | 段浩磊, 陈浩远, 梁坤峰, 王林, 陈彬, 曹勇, 张晨光, 李硕鹏, 朱登宇, 何亚茹, 杨大鹏. 纯电动车热管理系统低GWP工质替代方案性能分析与综合评价[J]. 化工学报, 2025, 76(S1): 54-61. |

| [2] | 王俊鹏, 冯佳琪, 张恩搏, 白博峰. 曲折式与阵列式迷宫阀芯结构内流动与空化特性研究[J]. 化工学报, 2025, 76(S1): 93-105. |

| [3] | 赵子祥, 段钟弟, 孙浩然, 薛鸿祥. 大温差两相流动诱导水锤冲击的数值模型[J]. 化工学报, 2025, 76(S1): 170-180. |

| [4] | 黄灏, 王文, 贺隆坤. LNG船薄膜型液货舱预冷过程模拟与分析[J]. 化工学报, 2025, 76(S1): 187-194. |

| [5] | 汪思远, 刘国强, 熊通, 晏刚. 窗式空调器轴流风机的风速非均匀分布特性及其对冷凝器流路优化设计的影响规律[J]. 化工学报, 2025, 76(S1): 205-216. |

| [6] | 曹庆泰, 郭松源, 李建强, 蒋赞, 汪彬, 耑锐, 吴静怡, 杨光. 负过载下多孔隔板对液氧贮箱蓄液性能的影响研究[J]. 化工学报, 2025, 76(S1): 217-229. |

| [7] | 孙九春, 桑运龙, 王海涛, 贾浩, 朱艳. 泥水盾构仓体内射流对泥浆输送特性影响研究[J]. 化工学报, 2025, 76(S1): 246-257. |

| [8] | 何婷, 黄舒阳, 黄坤, 陈利琼. 基于余热利用的天然气化学吸收脱碳-高温热泵耦合流程研究[J]. 化工学报, 2025, 76(S1): 297-308. |

| [9] | 杨开源, 陈锡忠. 颗粒破碎的离散元及有限离散元模拟方法比较[J]. 化工学报, 2025, 76(9): 4398-4411. |

| [10] | 王一飞, 李玉星, 欧阳欣, 赵雪峰, 孟岚, 胡其会, 殷布泽, 郭雅琦. 基于裂尖减压特性的CO2管道断裂扩展数值计算[J]. 化工学报, 2025, 76(9): 4683-4693. |

| [11] | 陈昇, 李子争, 苗超, 白学刚, 李飞, 刘家璇, 李天天, 杨爽, 吕蓉蓉, 王江云. 大尺度密集场景高危氯气非均匀湍流扩散特性三维CFD模拟[J]. 化工学报, 2025, 76(9): 4630-4643. |

| [12] | 贾志勇, 沈宪琨, 蓝晓程, 王铁峰. 气体密度对高压流态化影响的CFD-DEM模拟[J]. 化工学报, 2025, 76(9): 4383-4397. |

| [13] | 刘奕扬, 邢志祥, 刘烨铖, 彭明, 李玉洋, 李云浩, 沈宁舟. 加氢站液氢泄漏扩散特性与安全监测数值模拟研究[J]. 化工学报, 2025, 76(9): 4694-4708. |

| [14] | 黄正宗, 刘科成, 李泽方, 曾平生, 刘永富, 闫红杰, 刘柳. 锌精馏炉砖砌式换热室数值模拟与场协同优化[J]. 化工学报, 2025, 76(9): 4425-4439. |

| [15] | 段炼, 周星睿, 袁文君, 陈飞. 连续相速度脉动对微通道内聚合物液滴生成和形貌的影响规律[J]. 化工学报, 2025, 76(9): 4578-4585. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号