化工学报 ›› 2025, Vol. 76 ›› Issue (12): 6644-6657.DOI: 10.11949/0438-1157.20250655

甄箫斐1,2( ), 黄雷雨1,2, 孙一铭1,2, 刘佳1,2, 曹文炅1,2, 韩燕3, 董缇1,2(

), 黄雷雨1,2, 孙一铭1,2, 刘佳1,2, 曹文炅1,2, 韩燕3, 董缇1,2( )

)

收稿日期:2025-06-18

修回日期:2025-08-13

出版日期:2025-12-31

发布日期:2026-01-23

通讯作者:

董缇

作者简介:甄箫斐(1987—),男,博士,教授,zxf283386515@163.com

基金资助:

Xiaofei ZHEN1,2( ), Leiyu HUANG1,2, Yiming SUN1,2, Jia LIU1,2, Wenjiong CAO1,2, Yan HAN3, Ti DONG1,2(

), Leiyu HUANG1,2, Yiming SUN1,2, Jia LIU1,2, Wenjiong CAO1,2, Yan HAN3, Ti DONG1,2( )

)

Received:2025-06-18

Revised:2025-08-13

Online:2025-12-31

Published:2026-01-23

Contact:

Ti DONG

摘要:

锂离子电池的深度应用和大容量高能量的研发趋势促使电池在差异性换热条件下的性能演变备受关注。本研究以20 Ah的软包磷酸铁锂电池为对象,建立了考虑48层并联电芯的单体电池三维电化学-热耦合模型,探讨了单体电池在差异性的换热面积、对流传热系数和温度梯度条件下电池内外部的热行为、电行为以及电化学特征。研究发现,不同换热面积时,在4C放电时,不同换热条件下的温度梯度差异较大,其中某些条件下温差可达8.54℃,10C放电时的温差可达30℃,但三种换热条件之间温差相差不大,受换热面积影响较小。在不同传热系数时,单侧强制对流虽能有效控制整体温升,却加剧了厚度方向的温度不均匀性,10C放电时横截面温差可达5.05℃,为单侧自然对流的1.64倍。不同温度梯度时,10C放电时负极固相锂浓度是1C时的6.1倍,负极过电势峰值增加91%。研究工作揭示了差异性换热条件下电池内部行为的演化规律,为高倍率、大容量电池的热管理与安全设计提供了参考。

中图分类号:

甄箫斐, 黄雷雨, 孙一铭, 刘佳, 曹文炅, 韩燕, 董缇. 差异换热条件下锂离子动力电池内外部关键参数演化研究[J]. 化工学报, 2025, 76(12): 6644-6657.

Xiaofei ZHEN, Leiyu HUANG, Yiming SUN, Jia LIU, Wenjiong CAO, Yan HAN, Ti DONG. Study on evolution of key internal and external parameters of lithium-ion power battery under different heat transfer conditions[J]. CIESC Journal, 2025, 76(12): 6644-6657.

| 方程名称 | 控制方程 | 边界条件 |

|---|---|---|

| 固相电荷守恒 | ||

| 液相电荷守恒 | ||

| 固相质量守恒 | ||

| 液相质量守恒 | ||

| 电极动力学 |

表1 电化学控制方程和能量方程

Table 1 Electrochemical control equations and energy equations

| 方程名称 | 控制方程 | 边界条件 |

|---|---|---|

| 固相电荷守恒 | ||

| 液相电荷守恒 | ||

| 固相质量守恒 | ||

| 液相质量守恒 | ||

| 电极动力学 |

| 方程名称 | 控制方程 | 初始条件与边界条件 |

|---|---|---|

| 能量守衡方程 | ||

| 反应热 | ||

| 极化热 | ||

| 欧姆热 |

表2 热模型控制方程

Table 2 Control equations of thermal model

| 方程名称 | 控制方程 | 初始条件与边界条件 |

|---|---|---|

| 能量守衡方程 | ||

| 反应热 | ||

| 极化热 | ||

| 欧姆热 |

| 参数 | 负集流体 | 负极 | 隔膜 | 正极 | 正集流体 |

|---|---|---|---|---|---|

| 厚度δ/μm | 10③ | 46③ | 20③ | 59③ | 19③ |

| 密度ρ/(kg·m-3) | 900① | 1437.4① | 1978① | 1260.2① | 385① |

| 颗粒半径r/μm | — | 7.5① | — | 0.6① | — |

| 固相体积分数εs | — | 0.45④ | — | 0.47④ | — |

| 孔隙率εl | — | 0.525④ | 0.54④ | 0.354④ | — |

| 最大锂离子浓度cs,max/(mol·m-3) | — | 31370① | — | 22806① | — |

| 初始SOC | — | 0.8④ | — | 0.13④ | — |

| 初始电解质浓度cl,0/(mol·m-3) | — | — | 1200① | — | — |

| 固相电导率σs/(S·m-1) | — | 100① | — | 0.5① | — |

| Bruggeman因子p | — | 1.5① | 1.5① | 1.5① | — |

| 负/正极转移系数αa, αc | — | 0.5① | — | 0.5① | — |

| 比热容cp /(J·kg-1·K-1) | 385① | 1437.4① | 1978① | 1260.2① | 900① |

| 热导率λ/(W·m-1·K-1) | 400① | 1.04① | 0.334① | 1.48① | 238① |

| 自然对流传热系数h/(W·m-2·K-1) | — | — | 5② | — | — |

| 参考温度Tref /K | 298.15① | 298.15① | 298.15① | 298.15① | 298.15① |

表3 仿真静态参数

Table 3 Static parameters for simulation

| 参数 | 负集流体 | 负极 | 隔膜 | 正极 | 正集流体 |

|---|---|---|---|---|---|

| 厚度δ/μm | 10③ | 46③ | 20③ | 59③ | 19③ |

| 密度ρ/(kg·m-3) | 900① | 1437.4① | 1978① | 1260.2① | 385① |

| 颗粒半径r/μm | — | 7.5① | — | 0.6① | — |

| 固相体积分数εs | — | 0.45④ | — | 0.47④ | — |

| 孔隙率εl | — | 0.525④ | 0.54④ | 0.354④ | — |

| 最大锂离子浓度cs,max/(mol·m-3) | — | 31370① | — | 22806① | — |

| 初始SOC | — | 0.8④ | — | 0.13④ | — |

| 初始电解质浓度cl,0/(mol·m-3) | — | — | 1200① | — | — |

| 固相电导率σs/(S·m-1) | — | 100① | — | 0.5① | — |

| Bruggeman因子p | — | 1.5① | 1.5① | 1.5① | — |

| 负/正极转移系数αa, αc | — | 0.5① | — | 0.5① | — |

| 比热容cp /(J·kg-1·K-1) | 385① | 1437.4① | 1978① | 1260.2① | 900① |

| 热导率λ/(W·m-1·K-1) | 400① | 1.04① | 0.334① | 1.48① | 238① |

| 自然对流传热系数h/(W·m-2·K-1) | — | — | 5② | — | — |

| 参考温度Tref /K | 298.15① | 298.15① | 298.15① | 298.15① | 298.15① |

| 描述 | 参数 | 正极表达式 | 负极表达式 |

|---|---|---|---|

| 固相扩散系数 | Ds | ||

| 反应速率常数 | ki | ||

| 平衡电势 | Uref | ||

| 熵热系数 | |||

| 集流体电导率 | σcc | ||

| 液相电导率 | κ(cl,T) | ||

| 液相扩散系数 | Dl (cl,T) | ||

传递 系数 | |||

表4 材料动态参数

Table 4 Material dynamic parameters

| 描述 | 参数 | 正极表达式 | 负极表达式 |

|---|---|---|---|

| 固相扩散系数 | Ds | ||

| 反应速率常数 | ki | ||

| 平衡电势 | Uref | ||

| 熵热系数 | |||

| 集流体电导率 | σcc | ||

| 液相电导率 | κ(cl,T) | ||

| 液相扩散系数 | Dl (cl,T) | ||

传递 系数 | |||

| 参数 | 数值 |

|---|---|

| 标称容量/Ah | 20 |

| 标称电压/V | 3.3 |

| 充电截止电压/V | 3.6 |

| 放电截止电压/V | 2.0 |

| 外形尺寸/(mm×mm×mm) | 227×160×7.5 |

| 质量/g | 496 |

表5 磷酸铁锂电池的基本参数

Table 5 Basic parameters of LiFePO4 battery

| 参数 | 数值 |

|---|---|

| 标称容量/Ah | 20 |

| 标称电压/V | 3.3 |

| 充电截止电压/V | 3.6 |

| 放电截止电压/V | 2.0 |

| 外形尺寸/(mm×mm×mm) | 227×160×7.5 |

| 质量/g | 496 |

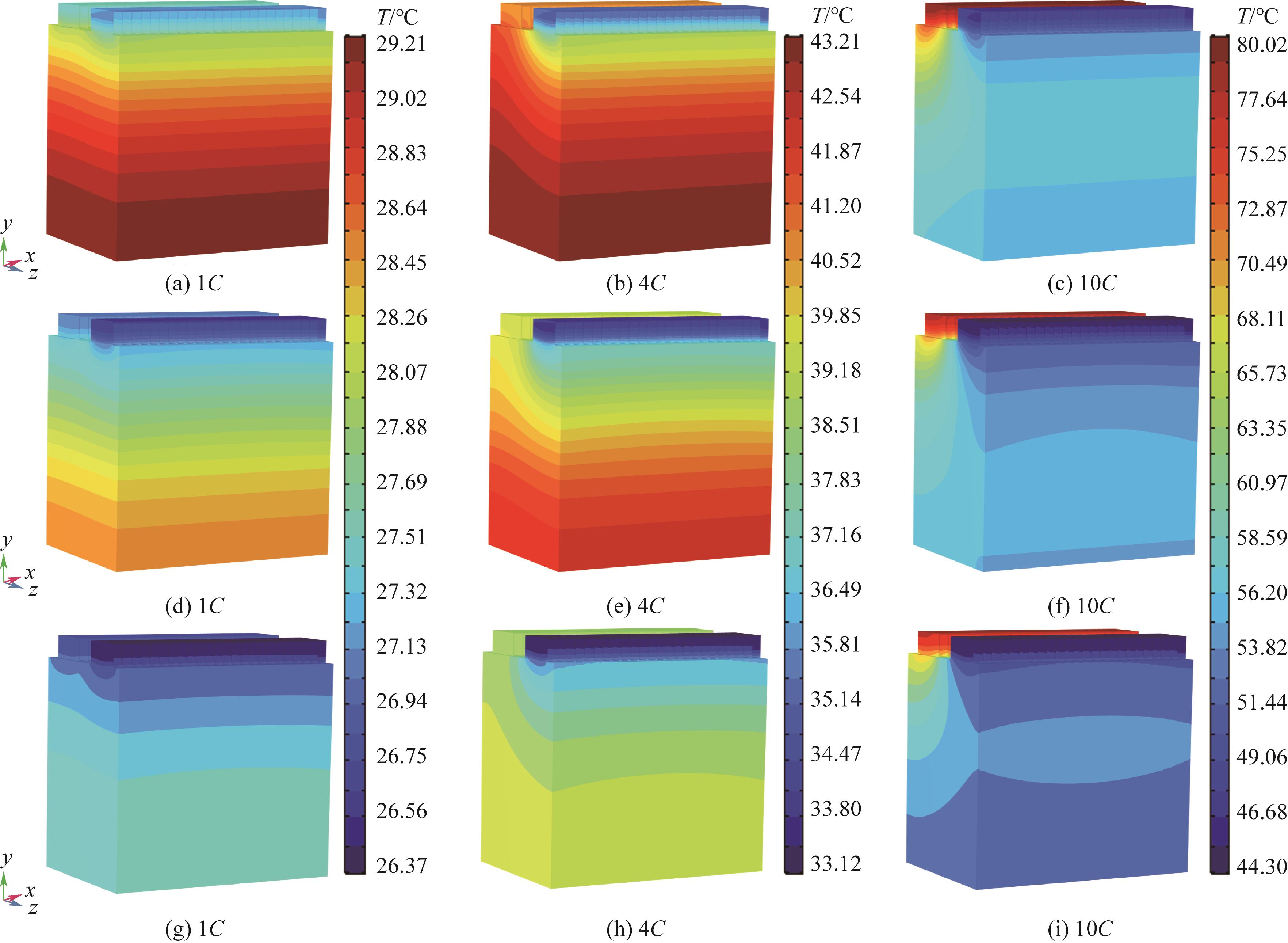

图6 三维体温度分布:(a)~(c) Case1工况; (d)~(f) Case2工况; (g)~(i) Case3工况

Fig.6 Three-dimensional temperature distribution: (a)—(c) Case1 condition; (d)—(f) Case2 condition; (g)—(i) Case3 condition

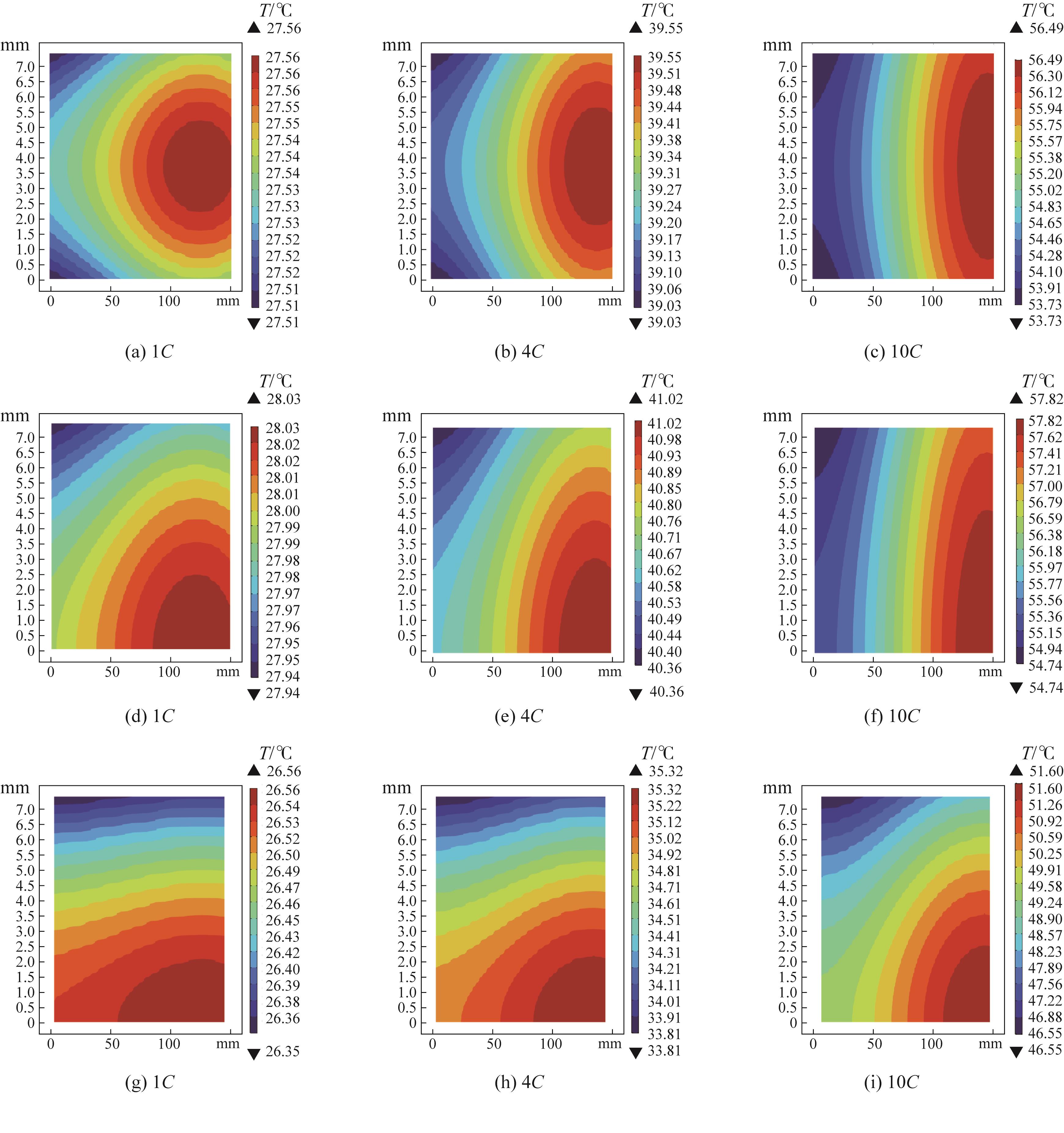

图8 放电结束时刻y方向中间截面二维温度分布:(a)~(c) Case3工况;(d)~(f) Case4工况;(g)~(i) Case5工况

Fig.8 Two-dimensional temperature distribution at the middle cross-section in the y-direction at the end of discharge: (a)—(c) Case3 condition; (d)—(f) Case4 condition; (g)—(i) Case5 condition

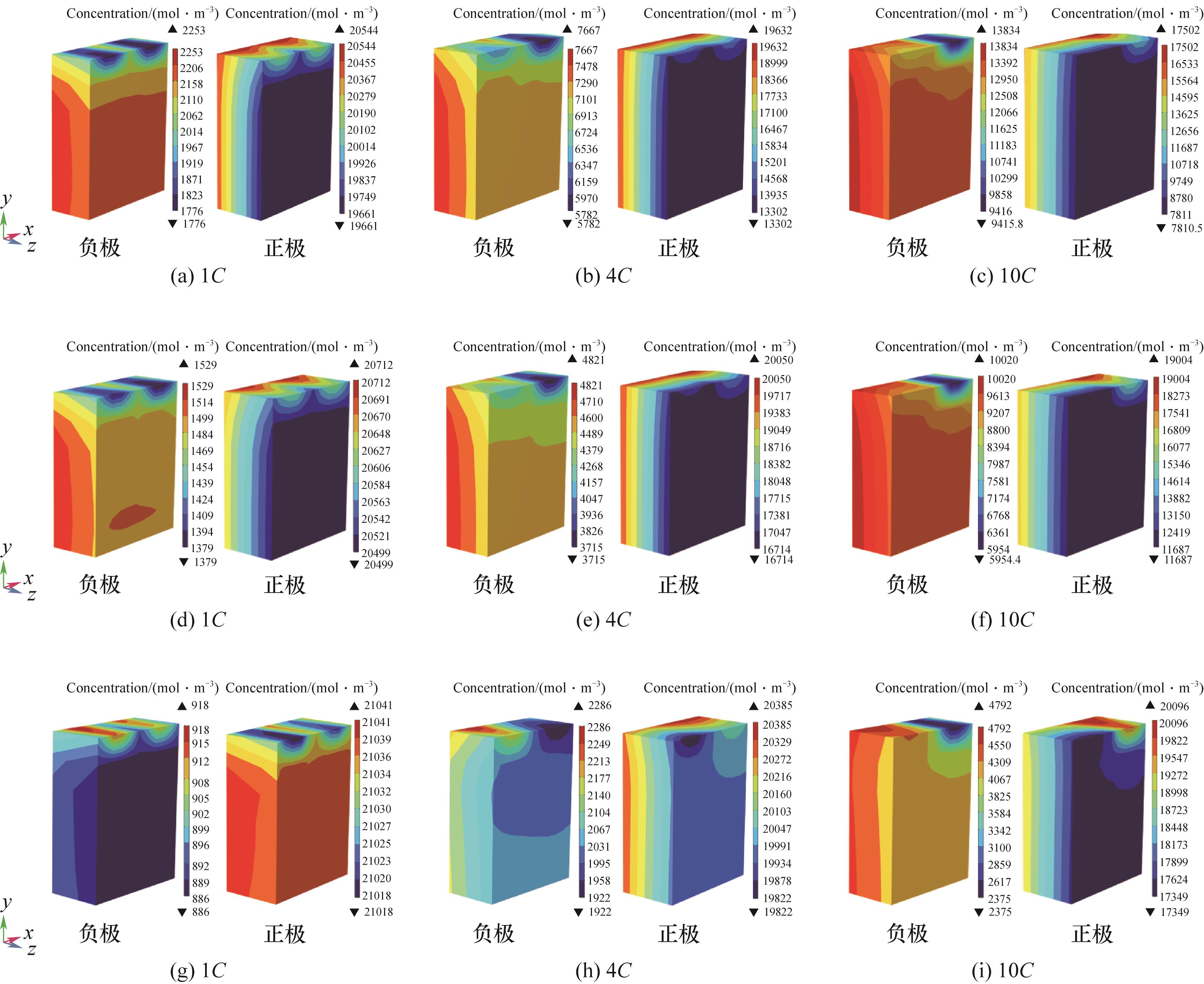

图9 放电结束时刻固相锂浓度分布:(a)~(c) Case6工况;(d)~(f) Case7工况;(g)~(i) Case8工况(正负极初始值分别为:2971.8、25096 mol·m-³)

Fig.9 Solid-phase lithium concentration distribution at the end of discharge: (a)—(c) Case 6 condition; (d)—(f) Case 7 condition; (g)—(i) Case 8 condition (initial values for anode and cathode: 2971.8 and 25096 mol·m-³, respectively)

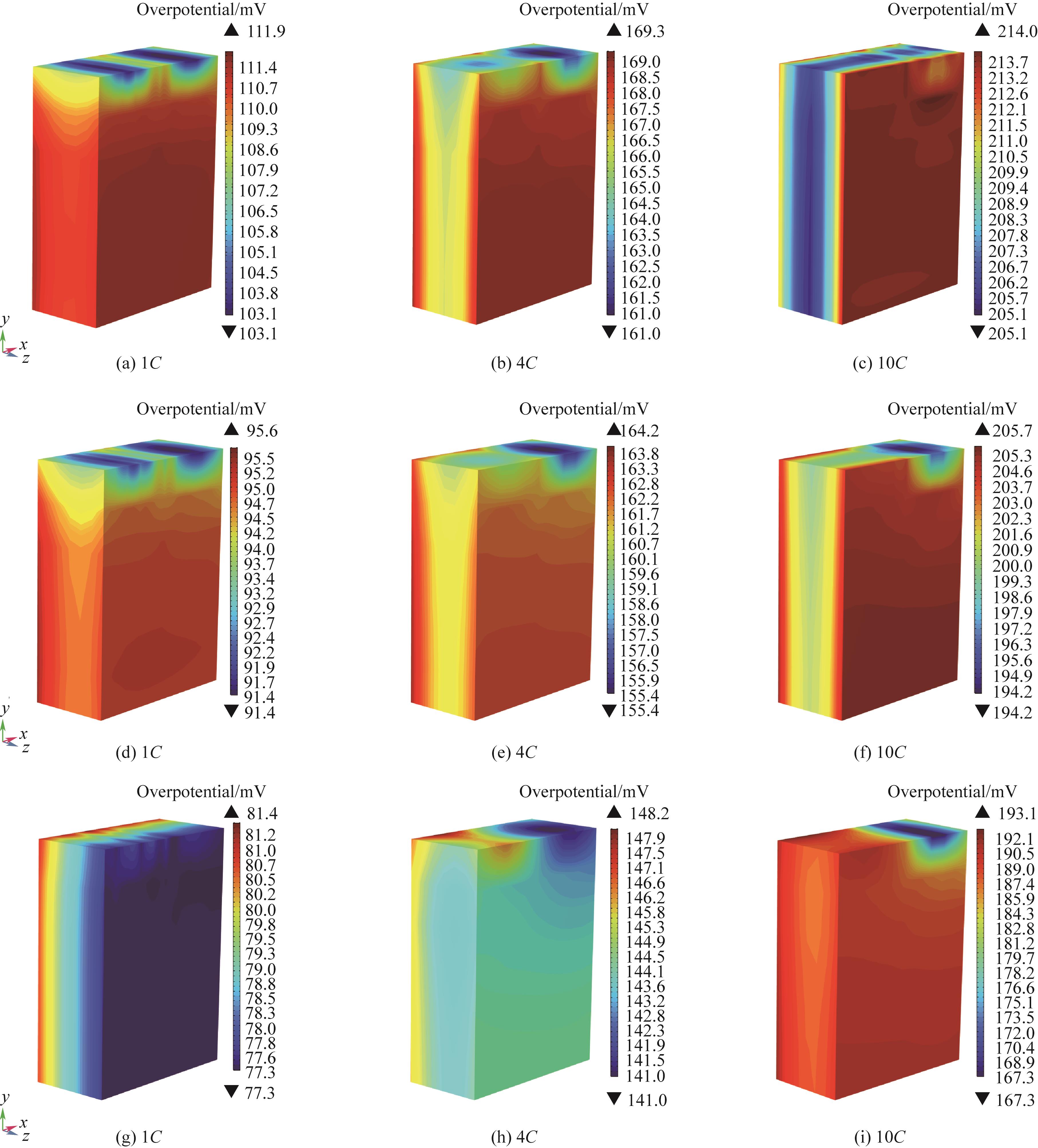

图10 放电结束时刻负极过电势分布:(a)~(c) Case6工况;(d)~(f) Case7工况;(g)~(i) Case8工况

Fig.10 Anode overpotential distribution at the end of discharge: (a)—(c) Case6 condition; (d)—(f) Case7 condition; (g)—(i) Case8 condition

| [1] | 陈国贺, 吕培召, 李孟涵, 等. 锂离子电池热失控传播特性及其抑制策略研究进展[J]. 储能科学与技术, 2024, 13(7): 2470-2482. |

| Chen G H, Lyu P Z, Li M H, et al. Research progress on thermal runaway propagation characteristics and suppression strategies of lithium-ion batteries[J]. Energy Storage Science and Technology, 2024, 13(7): 2470-2482. | |

| [2] | 李晋, 王青松, 孔得朋, 等. 锂离子电池储能安全评价研究进展[J]. 储能科学与技术, 2023, 12(7): 2282-2301. |

| Li J, Wang Q S, Kong D P, et al. Research progress on safety evaluation of lithium-ion battery energy storage[J]. Energy Storage Science and Technology, 2023, 12(7): 2282-2301. | |

| [3] | Ren D S, Liu X, Feng X N, et al. Model-based thermal runaway prediction of lithium-ion batteries from kinetics analysis of cell components[J]. Applied Energy, 2018, 228: 633-644. |

| [4] | Liao Z W, Lv D Z, Hu Q Y, et al. Review on aging risk assessment and life prediction technology of lithium energy storage batteries[J]. Energies, 2024, 17(15): 3668. |

| [5] | Dong T, Huang L Y, Liu J, et al. Advances and challenges in obtaining internal temperature for lithium-ion batteries[J]. Journal of Power Sources, 2025, 651: 237571. |

| [6] | Hollinger A S, McAnallen D R, Brockett M T, et al. Cylindrical lithium-ion structural batteries for drones[J]. International Journal of Energy Research, 2020, 44(1): 560-566. |

| [7] | Chen Z F, Jia L, Yin L F, et al. A review on thermal management of Li-ion battery: from small-scale battery module to large-scale electrochemical energy storage power station[J]. Journal of Thermal Science, 2025, 34(1): 1-23. |

| [8] | Wu X G, Du J Y, Guo H Q, et al. Boundary conditions for onboard thermal-management system of a battery pack under ultrafast charging[J]. Energy, 2022, 243: 123075. |

| [9] | Wang J L, Zhang Y M. Research on cooling characteristics of power battery fast-charging of refrigerant-based direct cooling system[J]. IOP Conference Series: Earth and Environmental Science, 2021, 696(1): 012007. |

| [10] | Zhang Y, Mei W X, Qin P, et al. Numerical modeling on thermal runaway triggered by local overheating for lithium iron phosphate battery[J]. Applied Thermal Engineering, 2021, 192: 116928. |

| [11] | Zhou Z Z, Li M Y, Zhou X D, et al. Investigating thermal runaway triggering mechanism of the prismatic lithium iron phosphate battery under thermal abuse[J]. Renewable Energy, 2024, 220: 119674. |

| [12] | Hu X S, Zheng Y S, Howey D A, et al. Battery warm-up methodologies at subzero temperatures for automotive applications: recent advances and perspectives[J]. Progress in Energy and Combustion Science, 2020, 77: 100806. |

| [13] | He C X, Yue Q L, Wan S B, et al. Experimental and numerical investigations of liquid cooling plates for pouch lithium-ion batteries considering non-uniform heat generation[J]. Applied Thermal Engineering, 2025, 258: 124777. |

| [14] | Wu W X, Wu W, Qiu X H, et al. Low-temperature reversible capacity loss and aging mechanism in lithium-ion batteries for different discharge profiles[J]. International Journal of Energy Research, 2019, 43(1): 243-253. |

| [15] | 黄瑞, 汪铭磊, 吴启超, 等. 不同换热环境对电池性能影响的试验研究[J]. 实验室研究与探索, 2022, 41(11): 45-48, 52. |

| Huang R, Wang M L, Wu Q C, et al. Experimental study on the influence of different heat transfer environments on battery performance[J]. Research and Exploration in Laboratory, 2022, 41(11): 45-48, 52. | |

| [16] | 宋缙华, 丰震河, 郭向飞, 等. 基于多尺度的空间锂离子蓄电池单体电-热耦合模型[J]. 上海航天, 2021, 38(5): 17-24. |

| Song J H, Feng Z H, Guo X F, et al. Multi-scale electro-thermal coupled model of space lithium-ion battery cell[J]. Shanghai Aerospace, 2021, 38(5): 17-24. | |

| [17] | Mei W X, Duan Q L, Zhao C P, et al. Three-dimensional layered electrochemical-thermal model for a lithium-ion pouch cell(part Ⅱ): The effect of units number on the performance under adiabatic condition during the discharge[J]. International Journal of Heat and Mass Transfer, 2020, 148: 119082. |

| [18] | 张赛, 汪振毅, 胡世旺. 基于电化学-热-力耦合模型的锂离子电池热失控研究[J]. 安全与环境学报, 2024, 24(2): 551-559. |

| Zhang S, Wang Z Y, Hu S W. Study on thermal runaway of lithium-ion batteries based on electrochemical-thermal-mechanical coupled model[J]. Journal of Safety and Environment, 2024, 24(2): 551-559. | |

| [19] | Jiang G W, Zhuang L, Hu Q H, et al. An investigation of heat transfer and capacity fade in a prismatic Li-ion battery based on an electrochemical-thermal coupling model[J]. Applied Thermal Engineering, 2020, 171: 115080. |

| [20] | 孙祺明. 基于电化学-热耦合模型的大容量磷酸铁锂电池热特性分析[D]. 武汉: 武汉理工大学, 2021. |

| Sun Q M. Thermal characteristic analysis of large-capacity lithium iron phosphate batteries based on an electrochemical-thermal coupled model[D]. Wuhan: Wuhan University of Technology, 2021. | |

| [21] | Wu X K, Song K F, Zhang X Y, et al. Safety issues in lithium ion batteries: materials and cell design[J]. Frontiers in Energy Research, 2019, 7: 65. |

| [22] | Sung C, Kim H, Kim C S, et al. Improvement of thermal stability of lithium ion pouch type cell[J]. ECS Meeting Abstracts, 2018, MA2018-01(3): 366. |

| [23] | Fuller T F, Doyle M, Newman J. Simulation and optimization of the dual lithium ion insertion cell[J]. Journal of the Electrochemical Society, 1994, 141(1): 1-10. |

| [24] | Doyle M, Newman J. Modeling the performance of rechargeable lithium-based cells: design correlations for limiting cases[J]. Journal of Power Sources, 1995, 54(1): 46-51. |

| [25] | Doyle M, Fuller T F, Newman J. Modeling of galvanostatic charge and discharge of the lithium/polymer/insertion cell[J]. Journal of the Electrochemical Society, 1993, 140(6): 1526-1533. |

| [26] | Azuaje-Berbecí B J, Ertan H B. A model for the prediction of thermal runaway in lithium-ion batteries[J]. Journal of Energy Storage, 2024, 90: 111831. |

| [27] | 陈昊鹏. 锂电池热电耦合特性分析与热行为仿真研究[D]. 长春: 吉林大学, 2023. |

| Chen H P. Analysis of thermoelectric coupling characteristics and thermal behavior simulation of lithium batteries[D]. Changchun: Jilin University, 2023. | |

| [28] | Mi J P, Liu X L, Zhu D M, et al. The exploration of the internal homogeneities for a LiFePO4 pouch lithium-ion battery with a 3D electrochemical-thermal coupled model[J]. Next Energy, 2024, 4: 100127. |

| [29] | 韦雪晴. 动力锂离子电池模组的热特性建模与支撑结构优化设计[D]. 长沙: 中南大学, 2023. |

| Wei X Q. Thermal characteristic modeling and support structure optimization design of power lithium-ion battery modules[D]. Changsha: Central South University, 2023. | |

| [30] | Panchal S, Dincer I, Agelin-Chaab M, et al. Transient electrochemical heat transfer modeling and experimental validation of a large sized LiFePO4/graphite battery[J]. International Journal of Heat and Mass Transfer, 2017, 109: 1239-1251. |

| [31] | Qian G N, Zan G B, Li J Z, et al. In-device battery failure analysis[J]. Advanced Materials, 2025, 37(10): 2416915. |

| [32] | 孟德超, 马紫峰, 李林森. 锂离子电池介尺度电化学反应非均匀性[J]. 化工进展, 2021, 40(9): 4869-4881. |

| Meng D C, Ma Z F, Li L S. Non-uniformity of mesoscale electrochemical reactions in lithium-ion batteries[J]. Chemical Industry and Engineering Progress, 2021, 40(9): 4869-4881. |

| [1] | 赵婧, 董书辰, 李高洋, 黄友科, 石浩森, 缪舒文, 谭辰妍, 朱唐琦, 李永帅, 潘慧, 凌昊. 基于电化学模型的电池性能模拟与优化[J]. 化工学报, 2025, 76(9): 4922-4932. |

| [2] | 娄岚浩, 杨立鹏, 杨晓光. 锂离子电池电化学机理模型参数辨识研究综述[J]. 化工学报, 2025, 76(9): 4369-4382. |

| [3] | 李欣然, 常龙娇, 罗绍华, 李永兵, 杨瑞芬, 侯增磊, 邹杰. Ho掺杂诱导NCM622局域电子重构抑制阳离子混排的改性机制研究[J]. 化工学报, 2025, 76(7): 3733-3741. |

| [4] | 吴鹂霄, 燕溪溪, 张素娜, 徐一鸣, 钱佳颖, 乔永民, 王利军. 磷掺杂微晶石墨的制备及其在锂离子电池负极材料中的电化学性能研究[J]. 化工学报, 2025, 76(7): 3615-3625. |

| [5] | 孙传付, 胡桂林, 曹俊杰, 左启斌, 陈媚, 夏玉珍. 梯度孔分布ZnO-GA锂离子电池负极材料研究[J]. 化工学报, 2025, 76(7): 3710-3718. |

| [6] | 孙文浩, 田君, 张锟, 刘娜, 曹宝森, 梁晓嫱. 锂离子电池用高热稳定性新型隔膜的研究新进展[J]. 化工学报, 2025, 76(6): 2524-2543. |

| [7] | 李坤, 黄锐, 丛君, 马海涛, 常龙娇, 罗绍华. NCM622正极材料结构形态和储锂特性的同步演变[J]. 化工学报, 2025, 76(4): 1831-1840. |

| [8] | 徐世彪, 韦正兵, 鲍梦凡, 程怡, 贾洋刚, 林娜, 冒爱琴. Cu阳离子空位提升钙钛矿型高熵氧化物储锂性能[J]. 化工学报, 2025, 76(12): 6718-6728. |

| [9] | 袁新烨, 邢显博, 刘登华, 丁伟涛, 范博瑞, 钟华, 韩凯. 气相沉积硅碳中硅结晶度对电化学性能的影响[J]. 化工学报, 2025, 76(12): 6708-6717. |

| [10] | 吴德威, 汪郑鹏, 周玥, 李晓宁, 陈招, 李卓, 刘成伟, 李学刚, 肖文德. 固定床法制备锂离子电池硅碳负极材料及其储锂性能研究[J]. 化工学报, 2024, 75(S1): 300-308. |

| [11] | 彭丹, 卢俊杰, 倪文静, 杨媛, 汪靖伦. 高电压钴酸锂电池电解液研究进展[J]. 化工学报, 2024, 75(9): 3028-3040. |

| [12] | 郭邦军, 贾理男, 张希. 全固态硫化物锂电池中NCM正极及其界面研究[J]. 化工学报, 2024, 75(3): 743-759. |

| [13] | 刘邦金, 汪林威, 吴月月, 刘永超, 钟国彬, 项宏发. 锂离子电池热管理研究进展[J]. 化工学报, 2024, 75(12): 4413-4431. |

| [14] | 胡成志, 王国贤, 唐伟建, 李阿飞, 陈章贤, 杨则恒, 张卫新. 高比能锂离子电池高镍正极材料的表面包覆改性研究进展[J]. 化工学报, 2024, 75(11): 4020-4036. |

| [15] | 闻文, 王慧艳, 周静红, 曹约强, 周兴贵. 石墨负极颗粒对锂离子电池容量衰减及SEI膜生长影响的模拟研究[J]. 化工学报, 2024, 75(1): 366-376. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号