化工学报 ›› 2025, Vol. 76 ›› Issue (7): 3153-3171.DOI: 10.11949/0438-1157.20241401

收稿日期:2024-12-04

修回日期:2025-01-06

出版日期:2025-07-25

发布日期:2025-08-13

通讯作者:

李文怀,周嵬

作者简介:王子恒(2002—),男,硕士研究生,zihengwang@njtech.edu.cn

基金资助:

Ziheng WANG1,2( ), Wenhuai LI1,2(

), Wenhuai LI1,2( ), Wei ZHOU1,2,3(

), Wei ZHOU1,2,3( )

)

Received:2024-12-04

Revised:2025-01-06

Online:2025-07-25

Published:2025-08-13

Contact:

Wenhuai LI, Wei ZHOU

摘要:

固体氧化物燃料电池(SOFC)以其高效、低排放特性成为可持续能源的关键,但电极反应机理的复杂性制约着其性能提升。图形电极作为一种新兴的电极结构,因其可精确调控电极的几何形状,显著提升了三相边界(TPB)的长度和反应表面积,极大促进了SOFC电化学反应速率,并为反应机理的深入研究提供了理想平台。综述了图形电极在SOFC反应机理研究中的应用及其制备技术。图形电极通过微纳加工实现了电极-电解质界面的精确结构控制,显著增加了TPB的长度和反应活性面积,从而提升了电池的电化学性能和长期稳定性。详细探讨了图形电极在SOFC反应机理研究中的独特优势,包括其在电化学反应动力学、物质传输机制以及电荷传输耦合研究中的应用。通过对TPB反应、气体扩散、电流分布等关键过程的精确控制,图形电极能够简化复杂的多孔电极结构,提供了深入分析电极反应过程的理想平台。最后展望了其未来发展方向及面临的挑战,特别是在规模化应用和新型材料探索方面的潜力。

中图分类号:

王子恒, 李文怀, 周嵬. 图形电极在固体氧化物燃料电池中的应用[J]. 化工学报, 2025, 76(7): 3153-3171.

Ziheng WANG, Wenhuai LI, Wei ZHOU. Application of patterned electrodes in solid oxide fuel cell[J]. CIESC Journal, 2025, 76(7): 3153-3171.

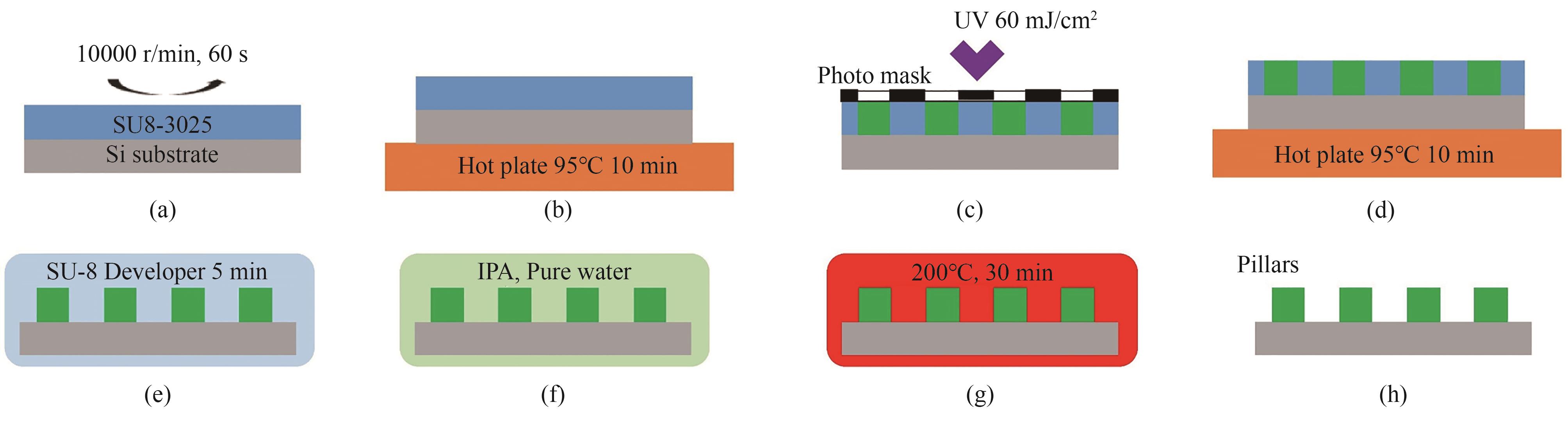

图3 主模加工工艺:(a) SU8旋转涂层;(b)预烘烤;(c)光掩膜紫外曝光;(d)烘烤;(e)在PGMEA中显影;(f)冲洗;(g)烘烤使SU8完全固化;(h)得到主柱图案[34]

Fig.3 Fabrication process of the master mold: (a) SU8 spin coating; (b) pre-baking; (c) UV exposure through the photomask; (d) baking; (e) developing in PGMEA; (f) rinsing; (g) baking to cure SU8 completely; (h) master pillar pattern was obtained[34]

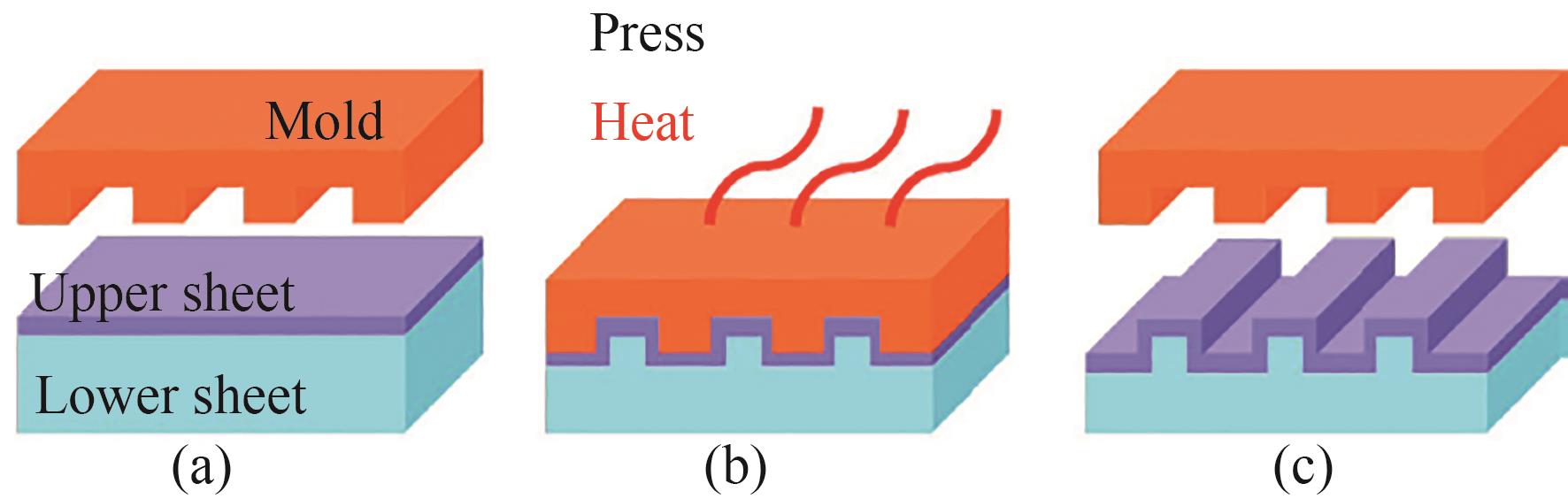

图5 (a)层状材料压印工艺示意图;(b)两张叠片在加热下压紧;(c)在板材表面和板材之间的界面上都有微图案[42]

Fig.5 (a) Schematic of the imprint process for layered material; (b) Two stacked sheets are pressed under heating; (c) Micro patterns are made on both surface and interface between sheets[42]

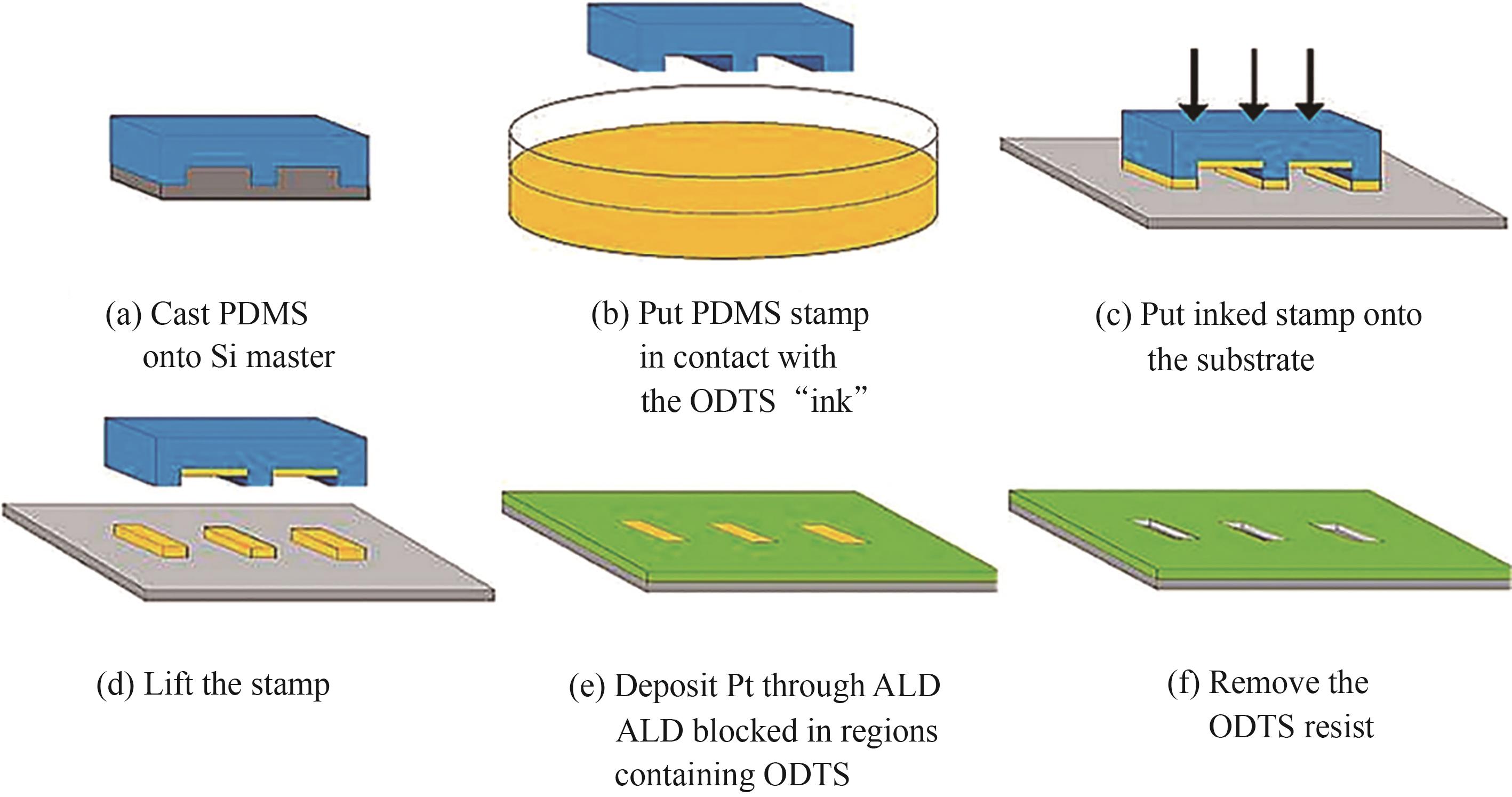

图6 使用µCP和选择性ALD制备图像化铂薄膜的过程示意图[45]

Fig.6 Schematic outline of the procedure to fabricate patterned Pt thin films using microcontact printing and selective atomic layer deposition[45]

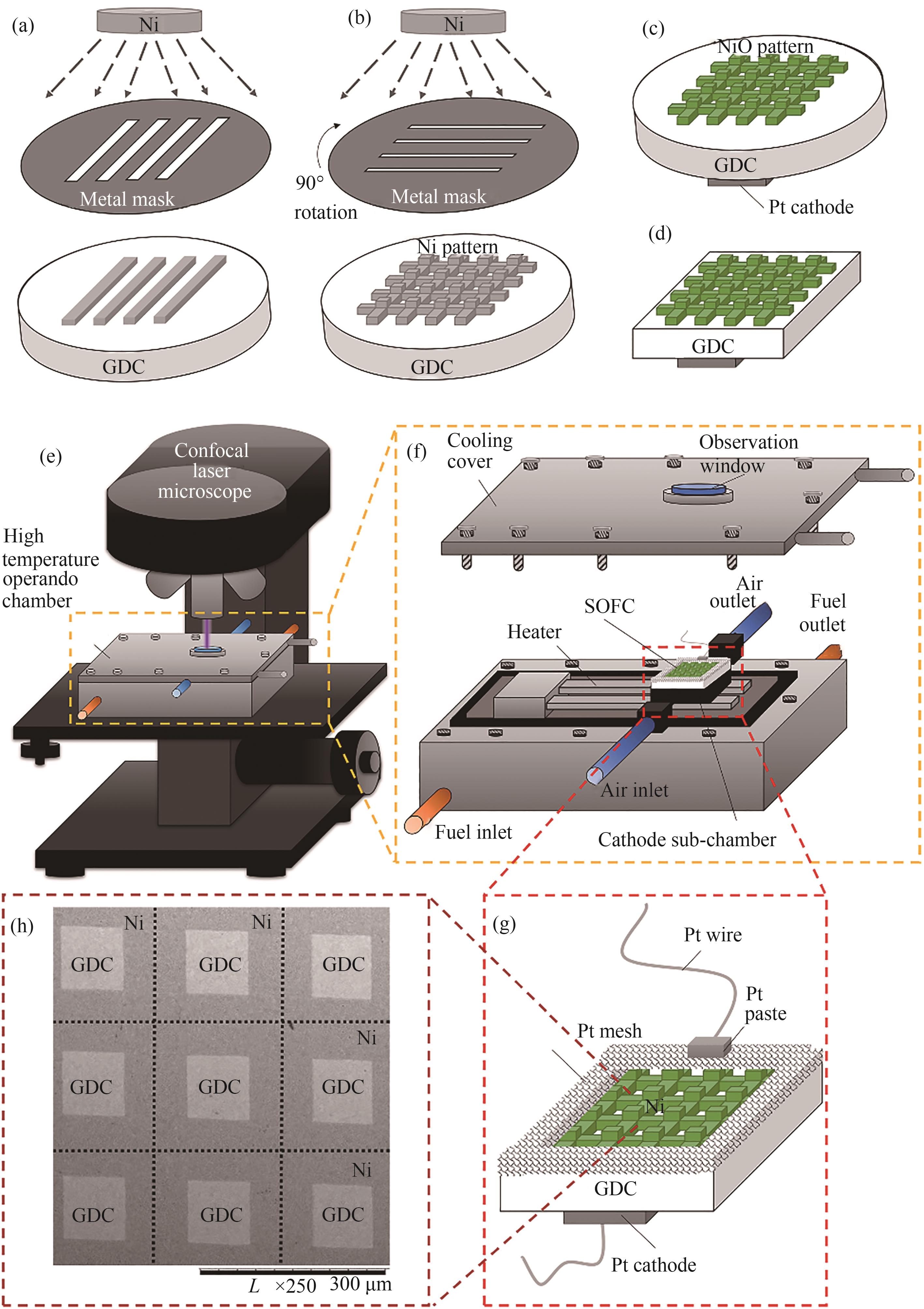

图7 电池制造过程和实验装置的示意图:(a)第一次溅射;(b)第二次溅射;(c) Pt阴极制作;(d)电池尺寸调整;(e)共聚焦激光显微镜实验设置;(f)高温室;(g)图像化电池结构;(h)图像化阳极的SEM图像[49]

Fig.7 Schematic representations of the cell fabrication process and the experimental setup: (a) first sputtering; (b) second sputtering; (c) Pt cathode fabrication; (d) size adjustment of the cell; (e) experimental set-up with a confocal laser microscope; (f) high temperature chamber; (g) patterned cell configuration; (h) SEM image of the patterned anode[49]

| 温度/℃ | 极化电阻/(Ω·cm2) | ||||

|---|---|---|---|---|---|

空白 无压力 | 空白 P=4.9 kPa | 点阵28 µm 无压力 | 点阵28 µm P=2.45 kPa | 点阵28 µm P=4.90 kPa | |

| 700 | 2.47 | 2.61 | 5.05 | 2.09 | 1.70 |

| 750 | 1.17 | 1.27 | 2.92 | 1.00 | 0.91 |

| 800 | 0.54 | 0.55 | 1.87 | 0.43 | 0.41 |

| 850 | 0.28 | 0.25 | 1.31 | 0.19 | 0.18 |

| 900 | 0.14 | 0.13 | 1.03 | 0.10 | 0.10 |

| 平均变化 | — | -0.36% | +301% | -22.2% | -28.4% |

表1 在不同压力下烧结的对称电池在不同温度下的极化电阻测量[31]

Table 1 Polarisation resistance measured at different temperatures on symmetrical cells sintered with different pressures[31]

| 温度/℃ | 极化电阻/(Ω·cm2) | ||||

|---|---|---|---|---|---|

空白 无压力 | 空白 P=4.9 kPa | 点阵28 µm 无压力 | 点阵28 µm P=2.45 kPa | 点阵28 µm P=4.90 kPa | |

| 700 | 2.47 | 2.61 | 5.05 | 2.09 | 1.70 |

| 750 | 1.17 | 1.27 | 2.92 | 1.00 | 0.91 |

| 800 | 0.54 | 0.55 | 1.87 | 0.43 | 0.41 |

| 850 | 0.28 | 0.25 | 1.31 | 0.19 | 0.18 |

| 900 | 0.14 | 0.13 | 1.03 | 0.10 | 0.10 |

| 平均变化 | — | -0.36% | +301% | -22.2% | -28.4% |

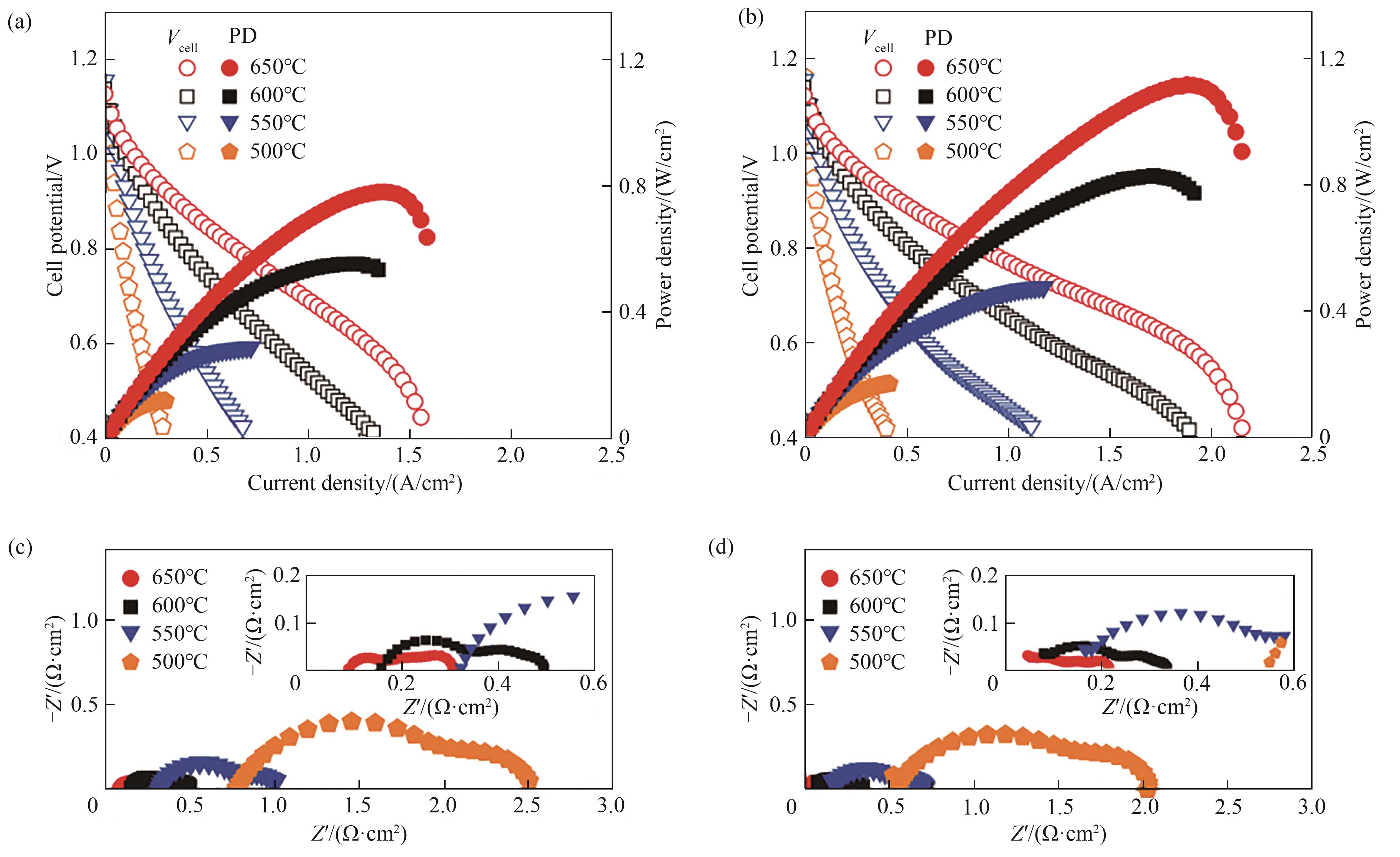

图8 平面电池和3D电池的电化学性能:平面电池(a)和3D电池(b)在不同工作温度下的电流密度-电压-功率密度曲线;平面电池(c)和3D电池(d)在0.75 V电压及不同工作温度下的Nyquist图(插图为低电阻区域的放大图)[52]

Fig.8 Electrochemical performance of planar- and 3D-cells: Current density-voltage-power density curves for the planar-cell (a) and 3D-cell (b) at different operating temperatures; The Nyquist plots for the planar-cell (c) and 3D-cell (d) under the voltage of 0.75 V and different operating temperatures (The insets are magnified views of the low-resistance region)[52]

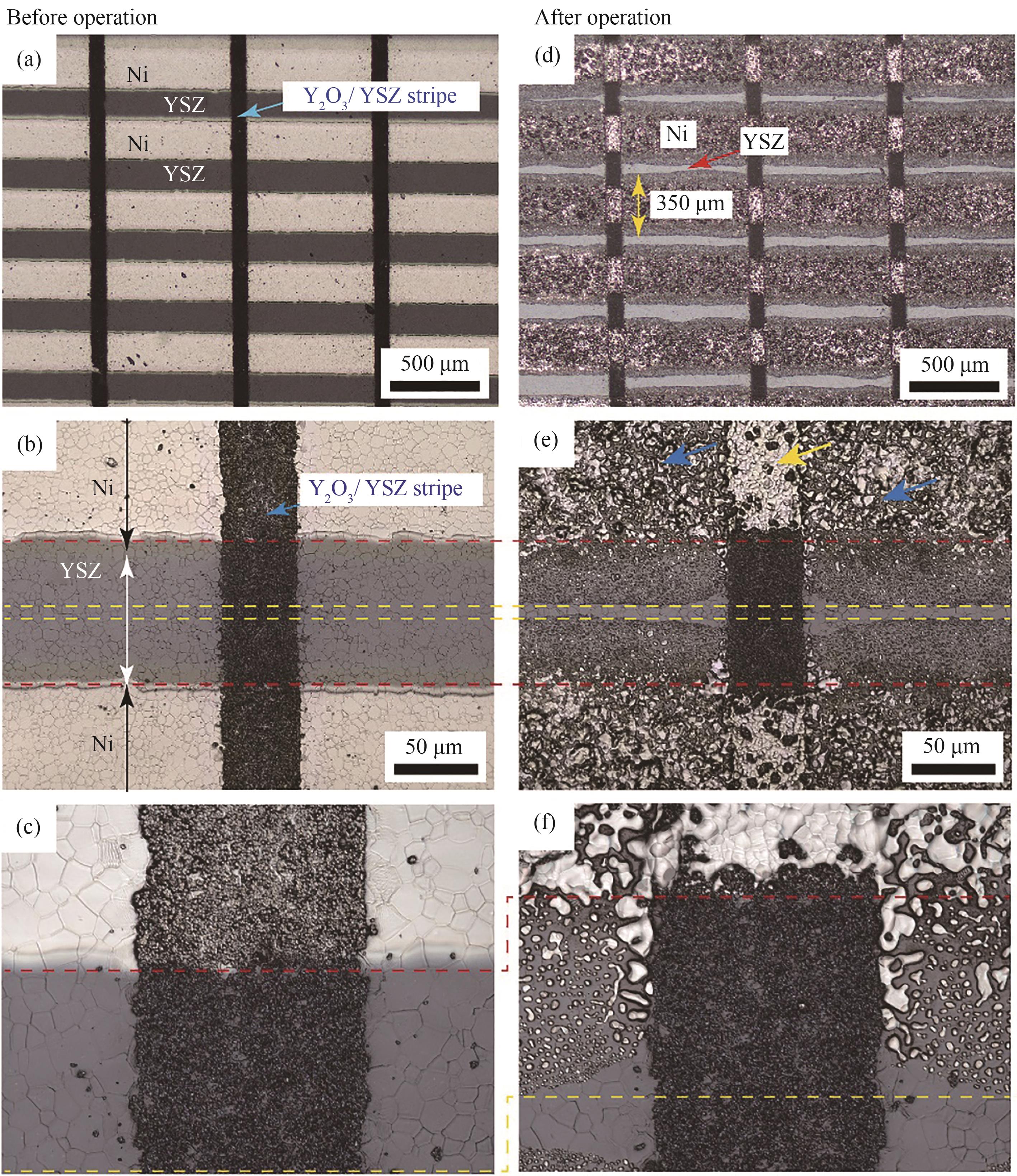

图9 Y2O3多孔条纹电池在运行前后镍形貌的光学显微镜图像(Ni的初始边缘由红色虚线标示,迁移后的Ni前沿由黄色虚线标示)[60]

Fig.9 Optical microscopy images of Ni morphology on the Y2O3 porous stripe cells (The initial edge of Ni is indicated by the red dashed line, and the migrated Ni front is indicated by the yellow dashed line)[60]

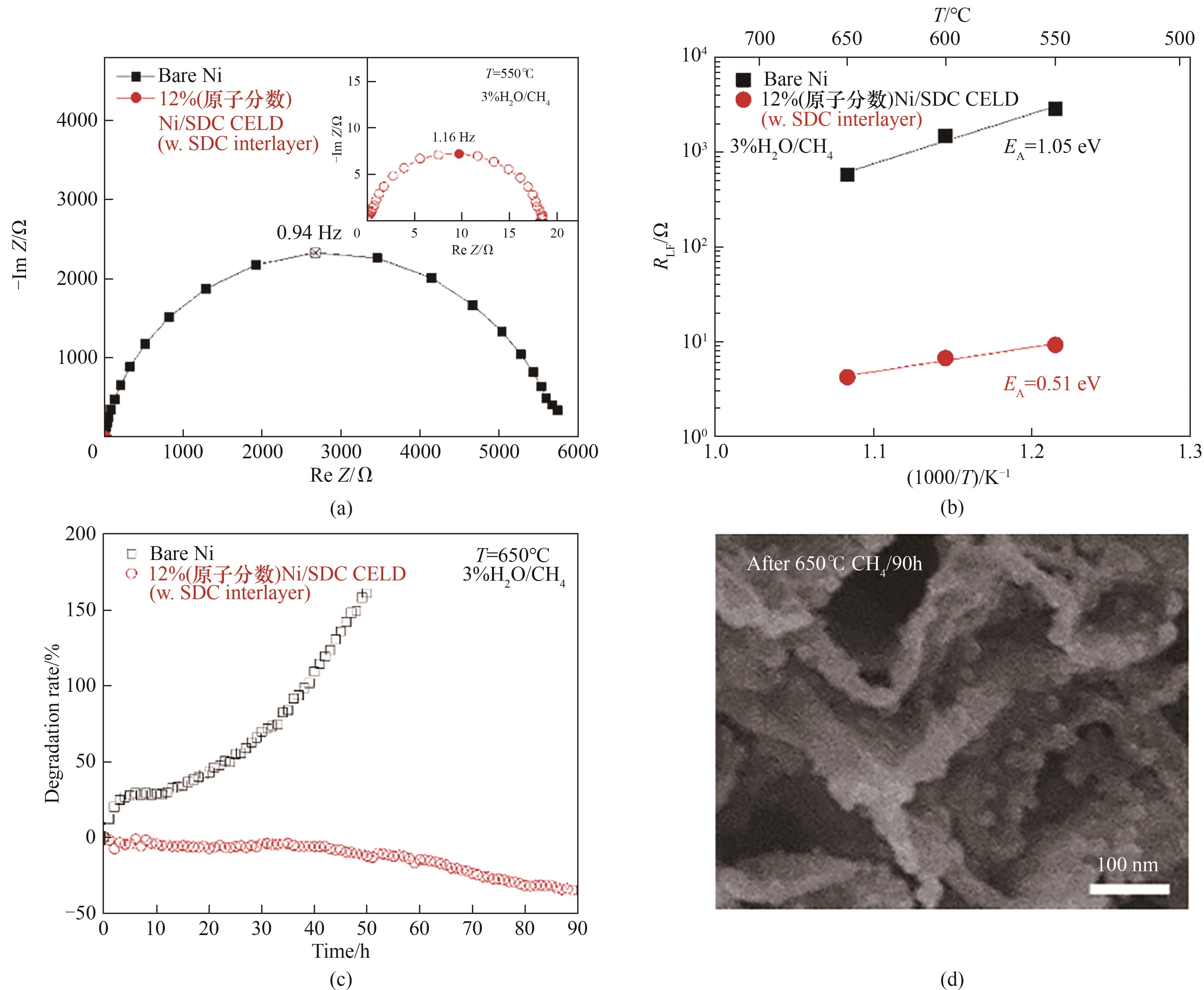

图10 在近乎干燥的CH4气氛下的性能与稳定性:(a)在550℃、3% H2O/CH4气氛下,未经电化学沉积(CELD)处理的对称模型Ni-YSZ(图案化Ni‖YSZ‖图案化Ni)和12%(原子分数) Ni NP-SDC阴极电解质层时的典型阻抗谱;(b)裸Ni和12%(原子分数)Ni NP-SDC在3% H2O/CH4气氛下的低频电阻(RLF)随温度的变化情况;(c)在650℃、3% H2O/CH4气氛下,裸Ni和12%(原子分数)Ni NP-SDC的RLF的降解速率;(d)在650℃、3% H2O/CH4气氛下进行90 h电化学阻抗谱测试后,12%(原子分数)Ni NP-SDC的扫描电子显微镜图像[68]

Fig.10 Performance and stability under a nearly dry CH4 atmosphere: (a) Typical impedance spectra of the symmetric model Ni-YSZ (patterned Ni‖YSZ‖patterned Ni) without CELD and with 12% (atom) Ni NP-SDC CELD obtained under a 3%H2O/CH4 atmosphere at 550℃; (b) Temperature dependence of the RLF of bare Ni and 12% (atom) Ni NP-SDC under a 3%H2O/CH4 atmosphere; (c) Degradation rate of the RLF of bare Ni and 12% (atom) Ni NP-SDC under a 3% H2O/CH4 atmosphere at 650℃; (d) SEM image of the 12% (atom) Ni NP-SDC after the EIS test under 3% H2O/CH4 at 650℃ for 90 h[68]

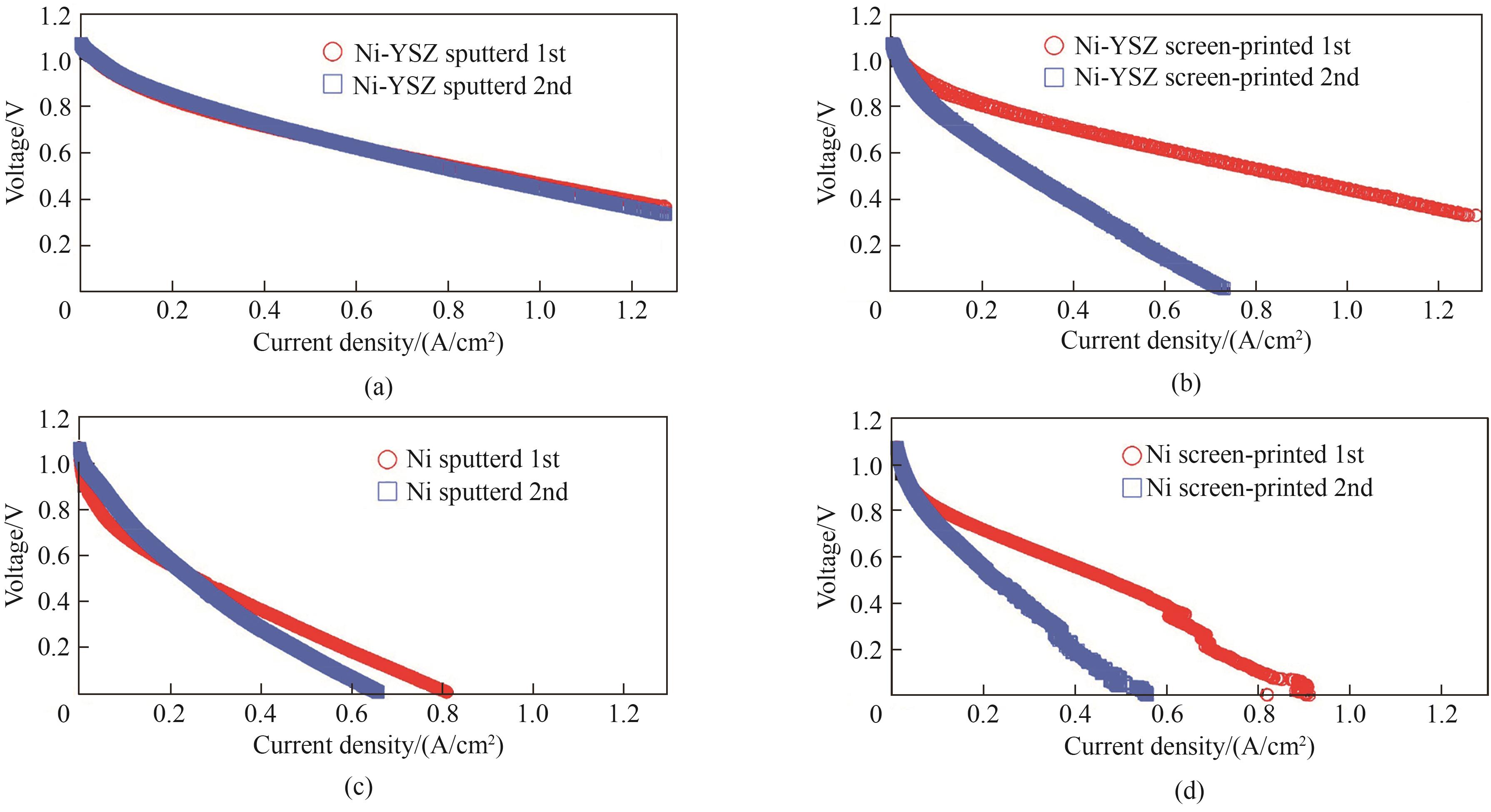

图11 在800℃、含5%水蒸气的氢气气氛下,阳极与参比电极之间的电流-电压特性:(a)溅射法制备的Ni-YSZ;(b)丝网印刷法制备的Ni-YSZ;(c)溅射法制备的Ni;(d)丝网印刷法制备的Ni[69]

Fig.11 Current-voltage characteristics between the anode and reference electrodes under a 5% humidified hydrogen atmosphere at 800℃: (a) Ni-YSZ by sputtering; (b) Ni-YSZ by screen printing; (c) Ni by sputtering; (d) Ni by screen printing[69]

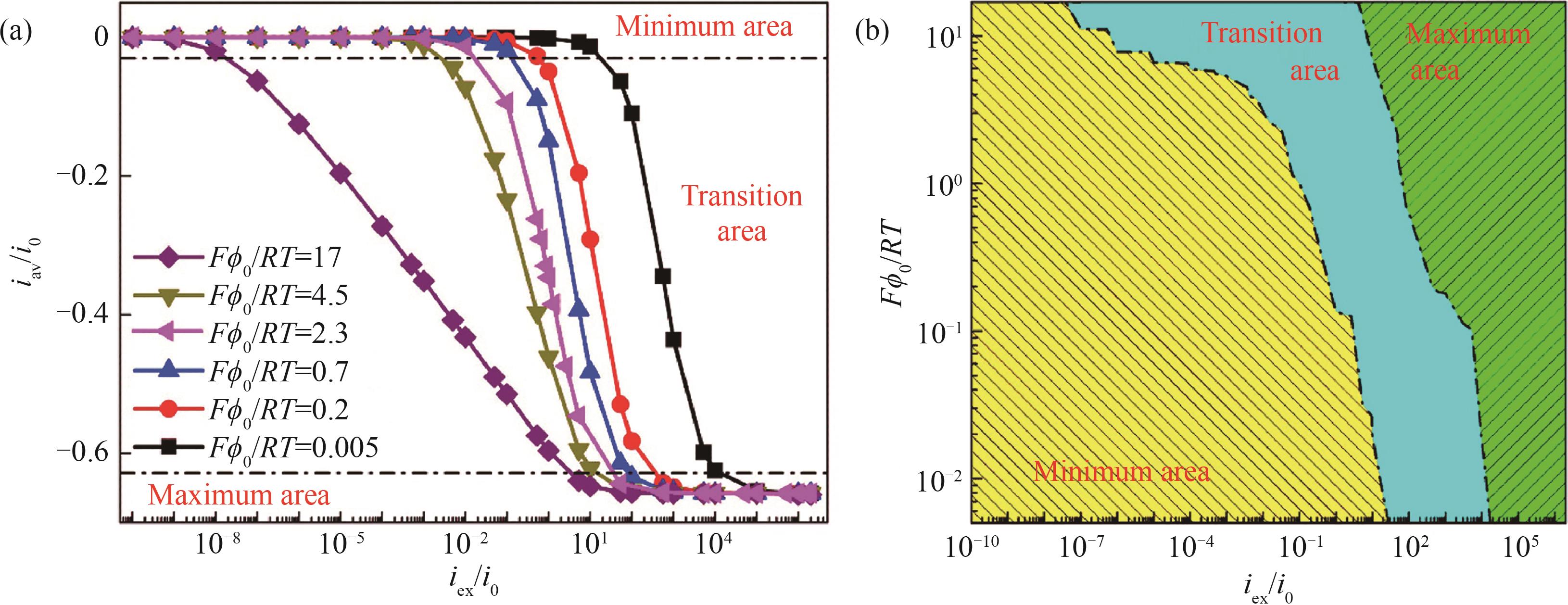

图12 (a)无量纲交换电流密度(iex/i0)和无量纲电位(Fϕ0/RT)对无量纲平均电流密度(iav/i0)的综合影响;(b)基于图(a)生成的相图(用于设计和操作嵌入离子导体中的半圆柱形电子导体条图案化阳极,其中最大面积、过渡面积和最小面积分别对应于图(a)中虚点线划分的底部、中部和上部区域)[76]

Fig.12 (a) Combined effect of dimensionless exchange current density (iex/i0) and dimensionless potential (Fϕ0/ RT) on dimensionless average current density (iav/i0); (b) Phase map generated based on Fig.(a) for rational design and operation of patterned anode with semi-cylinder electronic conductor strips embedded in ionic conductor, in which the maximum area, the transition area and the minimum area correspond to the bottom, middle and upper areas of Fig.(a) divided by dash dot line[76]

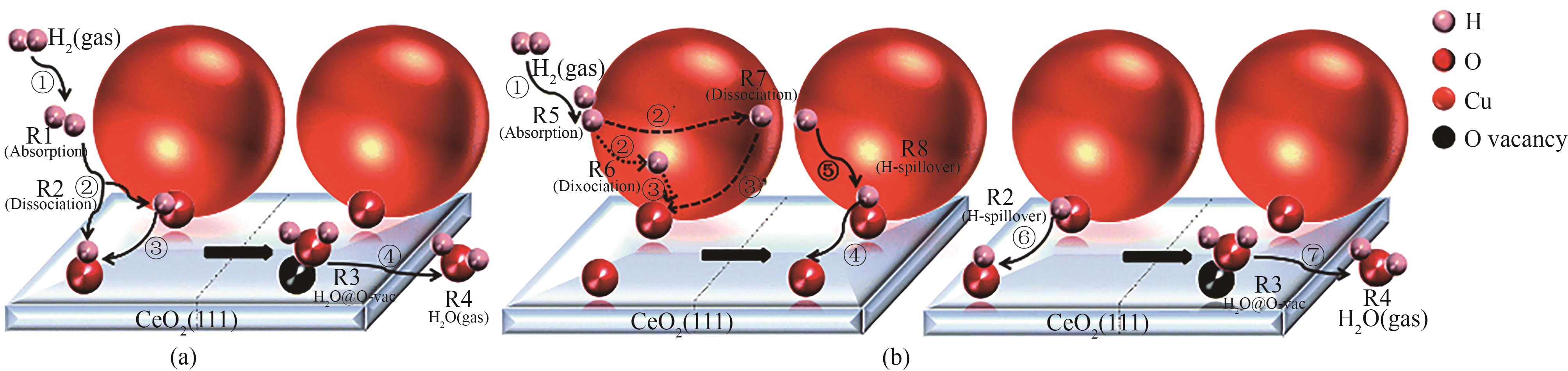

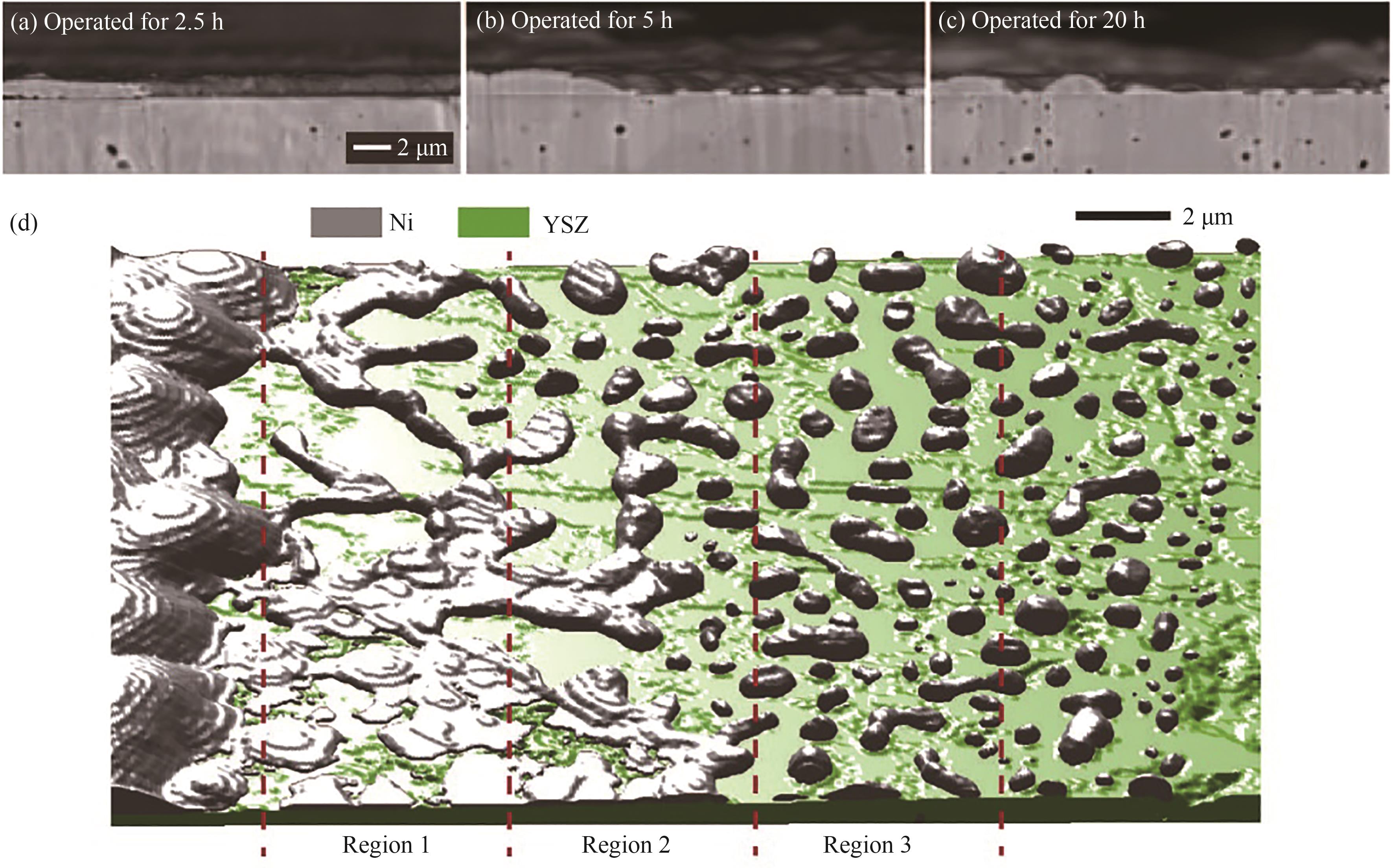

图13 Cu10/CeO2(111)表面H2氧化的TPB (a)和氢溢流(b)途径示意图[86]

Fig.13 Schematic of TPB (a) and H-spillover (b) pathways for H2 oxidation on the Cu10/CeO2(111) surface[86]

图14 H2氧化反应能量对比(黑线和紫线分别为H2在化学计量学CeO2(111)和Cu10/CeO2(111)的TPB途径上的氧化反应;ΔEx 表示相邻两个反应步骤间结构的能量差,即第x步的能量减去第x-1步的能量;ΔETS表示过渡态的能垒;Rx对应图13)[86]

Fig.14 Comparison of reaction energy profiles for H2 oxidation (The black line and the purple line refer to H2 oxidation on the stoichiometric CeO2(111) and the TPB pathway of the Cu10/CeO2(111), respectively; ΔEx represents the energy difference of structures between two neighboring reaction steps, which is the energy of the xth minus the energy of the (x-1) th; ΔETS represents the energy barrier of the transition state; Rx corresponds to Fig.13)[86]

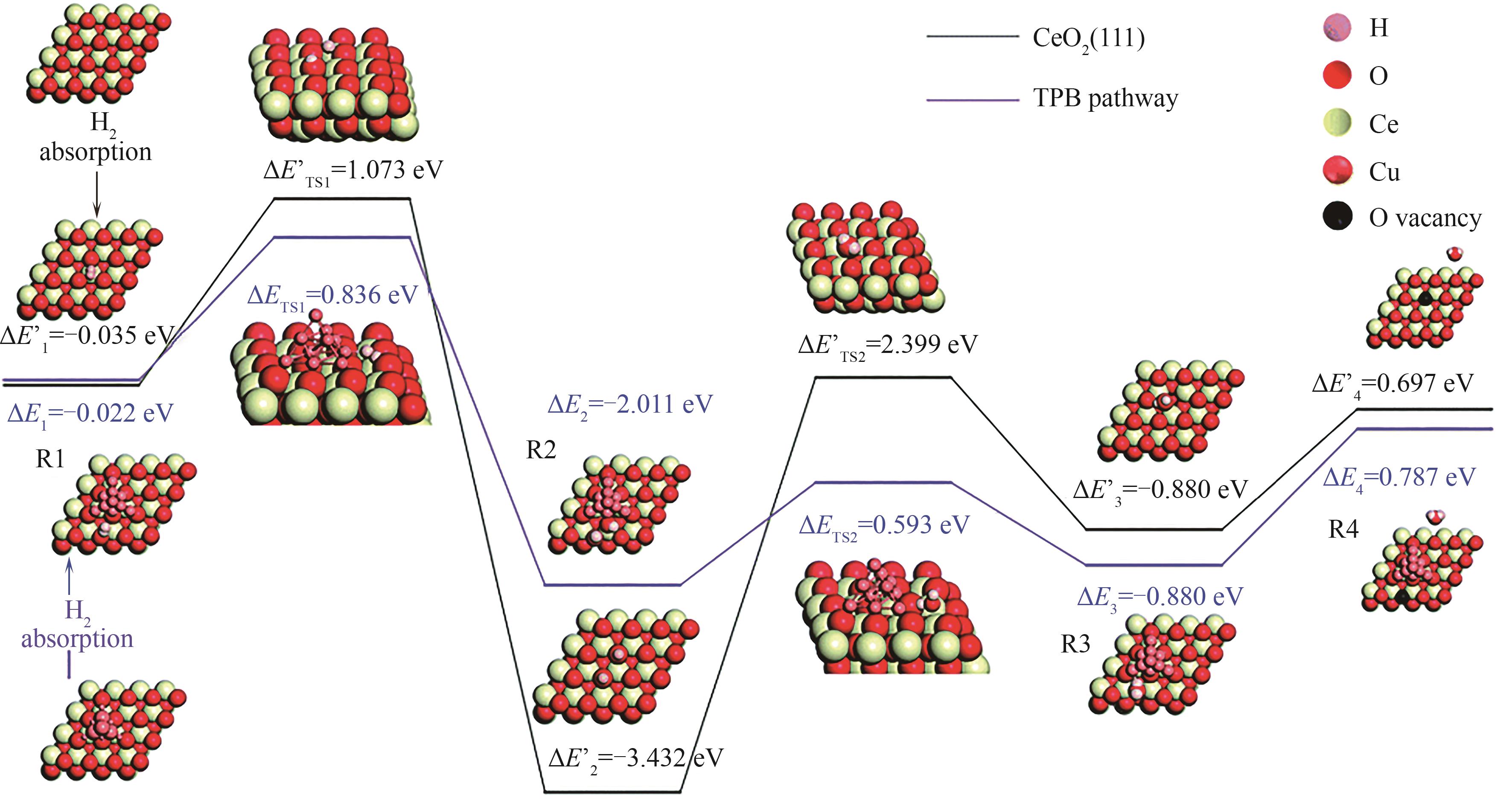

图16 在(a) 2.5 h、 (b) 5 h和(c) 20 h VW-R = 0.7 V下的Ni膜电极截面的SEM图像;(d)工作20 h后电极微观结构的FIB-SEM重建[89]

Fig.16 SEM images of Ni film electrode cross-sections after (a) 2.5 h, (b) 5 h and (c) 20 h operations at VW-R = 0.7 V; (d) The FIB-SEM reconstruction of the electrode microstructure corresponding to Fig.(c) after 20 h operation[89]

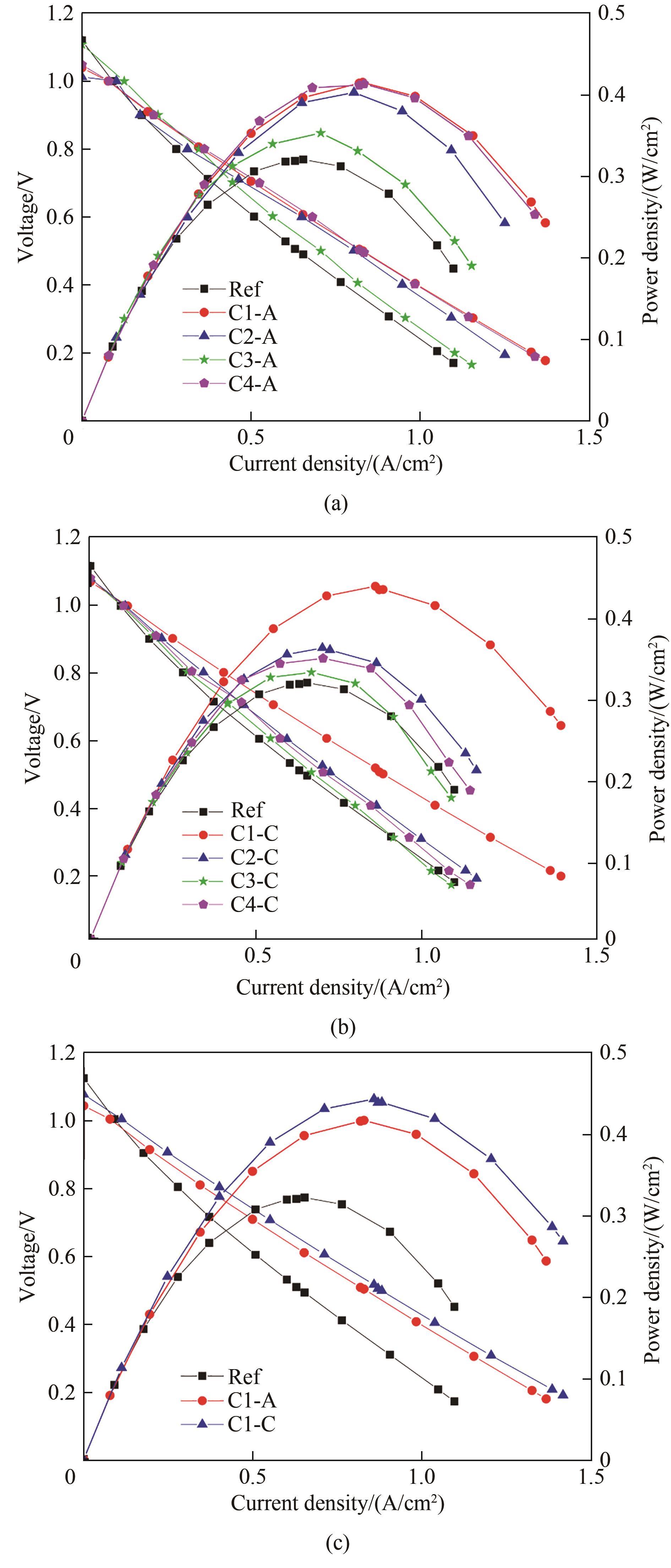

图17 在800℃工作温度下,电池(a) C1-A~C4-A以及(b)C1-C~C4-C的性能和(c)最佳情况[97]

Fig.17 Performances of (a) C1-A—C4-A and (b) C1-C—C4-C and (c) the best cases at 800℃ operating temperature[97]

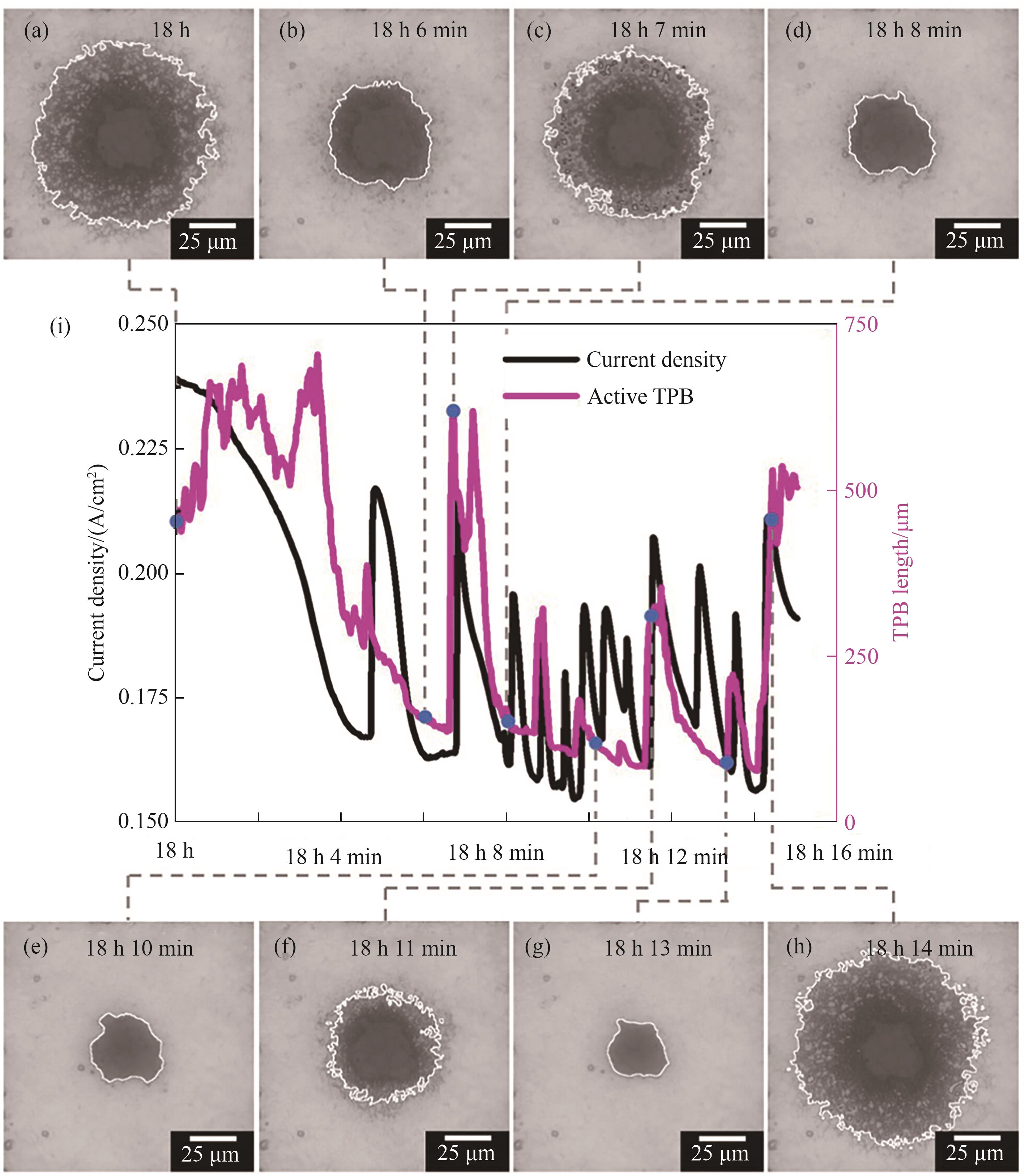

图18 RSOC在阳极极化条件下的原位观测结果(a)~(h)(其中白色线条表示活性TPB);(i)电流密度和活性TPB长度随时间的变化情况[图(a)~(h)是图(i)中蓝色点处的俯视图][103]

Fig.18 Operando observation of RSOC cell under anodic polarization (a)—(h) (white line indicates active TPB); (i) Developments of current density and active TPB length over time [Figs.(a)—(h) are the top views at the blue points in Fig.(i)][103]

| [42] | Tsumori F, Xu Y, Tanaka Y, et al. Micrometer-scale imprinting process for ceramic sheet from powder compound material[J]. Procedia Engineering, 2014, 81: 1433-1438. |

| [43] | Park J, Lee Y, Chang I, et al. Atomic layer deposition of yttria-stabilized zirconia thin films for enhanced reactivity and stability of solid oxide fuel cells[J]. Energy, 2016, 116: 170-176. |

| [44] | Kwon C W, Son J W, Lee J H, et al. High-performance micro-solid oxide fuel cells fabricated on nanoporous anodic aluminum oxide templates[J]. Advanced Functional Materials, 2011, 21(6): 1154-1159. |

| [45] | Jiang X R, Huang H, Prinz F B, et al. Application of atomic layer deposition of platinum to solid oxide fuel cells[J]. Chemistry of Materials, 2008, 20(12): 3897-3905. |

| [46] | Pederson L R, Singh P, Zhou X D. Application of vacuum deposition methods to solid oxide fuel cells[J]. Vacuum, 2006, 80(10): 1066-1083. |

| [47] | Lu C, Sang J K, Yang J, et al. The effects of H2O and CO2 on Ni migration in the anodes of solid oxide fuel cells[J]. International Journal of Hydrogen Energy, 2024, 60: 1442-1448. |

| [48] | Jiao Z J, Shikazono N. Study on the effects of polarization on local morphological change of nickel at active three-phase-boundary using patterned nickel-film electrode in solid oxide fuel cell anode[J]. Acta Materialia, 2017, 135: 124-131. |

| [49] | Komatsu Y, Sciazko A, Suzuki Y, et al. Operando observation of patterned nickel-gadolinium doped ceria solid oxide fuel cell anode[J]. Journal of Power Sources, 2021, 516: 230670. |

| [50] | Chesnaud A, Delloro F, Geagea M, et al. Corrugated electrode/electrolyte interfaces in SOFC: theoretical and experimental development[J]. ECS Transactions, 2017, 78(1): 1851-1863. |

| [51] | Iwai H, Kuroyanagi A, Saito M, et al. Power generation enhancement of solid oxide fuel cell by cathode-electrolyte interface modification in mesoscale assisted by level set-based optimization calculation[J]. Journal of Power Sources, 2011, 196(7): 3485-3495. |

| [52] | Goh Y G, Kim J H, Kim H, et al. Unraveling the effects of asymmetric interfaces in three-dimensional solid oxide fuel cells[J]. Journal of Materials Chemistry A, 2024, 12(34): 22504-22509. |

| [53] | Shin S S, Kim J H, Bae K T, et al. Multiscale structured low-temperature solid oxide fuel cells with 13 W power at 500℃[J]. Energy & Environmental Science, 2020, 13(10): 3459-3468. |

| [54] | Gohar O, Khan M Z, Saleem M, et al. Navigating the future of solid oxide fuel cell: comprehensive insights into fuel electrode related degradation mechanisms and mitigation strategies[J]. Advances in Colloid and Interface Science, 2024, 331: 103241. |

| [55] | 郑尧, 周嵬, 冉然, 等. 钙钛矿型固体氧化物燃料电池阳极材料[J]. 化学进展, 2008, 20(S1): 413-421. |

| Zheng Y, Zhou W, Ran R, et al. Perovskite as anode materials for solid oxide fuel cells[J]. Progress in Chemistry, 2008, 20(S1): 413-421. | |

| [56] | Lv X Q, Chen H L, Zhou W, et al. Direct-methane solid oxide fuel cells with an in situ formed Ni-Fe alloy composite catalyst layer over Ni-YSZ anodes[J]. Renewable Energy, 2020, 150: 334-341. |

| [57] | Elmutasim O, Dhawale D S, Giddey S, et al. Unravelling the reaction mechanism on Ni-YSZ anode supported direct ammonia solid fuel cell: experimental and theoretical studies[J]. Applied Surface Science, 2025, 686: 162175. |

| [58] | Trini M, Hauch A, De Angelis S, et al. Comparison of microstructural evolution of fuel electrodes in solid oxide fuel cells and electrolysis cells[J]. Journal of Power Sources, 2020, 450: 227599. |

| [59] | Ouyang Z F, Sciazko A, Komatsu Y, et al. Effects of transition metal elements on Ni migration in solid oxide cell fuel electrodes[J]. ECS Transactions, 2023, 111(6): 171-179. |

| [60] | Yao G, Okabe T, Shikazono N. Ni migration on porous yttria-stabilized zirconia and yttria-micropatterned fuel electrodes in solid oxide fuel cells[J]. Journal of Power Sources, 2024, 609: 234720. |

| [61] | Xiang Y, Da Y L, Shikazono N, et al. Quantitative study on solid oxide fuel cell anode microstructure stability based on 3D microstructure reconstructions[J]. Journal of Power Sources, 2020, 477: 228653. |

| [62] | 熊洁, 焦成冉, 韩敏芳. 不同燃料SOFC的理论电池电动势及其性能[J]. 化工学报, 2013, 64(7): 2664-2671. |

| Xiong J, Jiao C R, Han M F. Theoretical electromotive force and performance of SOFC fed with different fuel gases[J]. CIESC Journal, 2013, 64(7): 2664-2671. | |

| [63] | 由宏新, 丁信伟, 阿布里提·阿布都拉. SOFC中不同浓度干甲烷在Ni-YSZ阳极上的反应[J]. 化工学报, 2006, 57(3): 620-625. |

| You H X, Ding X W, Abudula Abuliti. Reactions of low and middle concentration dry methane on Ni-YSZ anode of SOFC[J]. Journal of Chemical Industry and Engineering (China), 2006, 57(3): 620-625. | |

| [64] | Wang W, Su C, Wu Y Z, et al. Progress in solid oxide fuel cells with nickel-based anodes operating on methane and related fuels[J]. Chemical Reviews, 2013, 113(10): 8104-8151. |

| [65] | 谢静, 徐明益, 班帅, 等. 天然气内重整和外重整下SOFC多场耦合三维模拟分析[J]. 化工学报, 2019, 70(1): 214-226. |

| Xie J, Xu M Y, Ban S, et al. Simulation analysis of multi-physics coupling SOFC fueled nature gas in the way of internal reforming and external reforming[J]. CIESC Journal, 2019, 70(1): 214-226. | |

| [66] | 郭祥, 乔金硕, 王振华, 等. 碳燃料固体氧化物燃料电池结构研究进展[J]. 化工学报, 2023, 74(1): 290-302. |

| Guo X, Qiao J S, Wang Z H, et al. Progress of structure for carbon-fueled solid oxide fuel cells[J]. CIESC Journal, 2023, 74(1): 290-302. | |

| [67] | Choi Y, Brown E C, Haile S M, et al. Electrochemically modified, robust solid oxide fuel cell anode for direct-hydrocarbon utilization[J]. Nano Energy, 2016, 23: 161-171. |

| [68] | Kim J, Choi Y, Lim D K, et al. Electrochemically plated nickel-decorated ceria nanostructures for direct hydrocarbon solid oxide fuel cell electrodes[J]. Journal of Materials Chemistry A, 2022, 10(39): 20886-20895. |

| [69] | Shimura T, Nagato K, Shikazono N. Evaluation of electrochemical performance of solid-oxide fuel cell anode with pillar-based electrolyte structures[J]. International Journal of Hydrogen Energy, 2019, 44(23): 12043-12056. |

| [70] | Chen Y, DeGlee B, Tang Y, et al. A robust fuel cell operated on nearly dry methane at 500℃ enabled by synergistic thermal catalysis and electrocatalysis[J]. Nature Energy, 2018, 3(12): 1042-1050. |

| [71] | Chen Y B, Zhou W, Ding D, et al. Advances in cathode materials for solid oxide fuel cells: complex oxides without alkaline earth metal elements[J]. Advanced Energy Materials, 2015, 5(18): 1500537. |

| [72] | 杨晓幸, 苗鹤, 袁金良. 可逆固体氧化物燃料电池氧电极材料的研究进展[J]. 化工进展, 2021, 40(9): 4904-4917. |

| Yang X X, Miao H, Yuan J L. Research progress on oxygen electrode materials for reversible solid oxide fuel cells[J]. Chemical Industry and Engineering Progress, 2021, 40(9): 4904-4917. | |

| [73] | Luo Y, Li W Y, Shi Y X, et al. Reversible H2/H2O electrochemical conversion mechanisms on the patterned nickel electrodes[J]. International Journal of Hydrogen Energy, 2017, 42(40): 25130-25142. |

| [74] | Luo Y, Li W Y, Shi Y X, et al. Mechanism for reversible CO/CO2 electrochemical conversion on a patterned nickel electrode[J]. Journal of Power Sources, 2017, 366: 93-104. |

| [75] | Chen Y, Choi Y, Yoo S, et al. A highly efficient multi-phase catalyst dramatically enhances the rate of oxygen reduction[J]. Joule, 2018, 2(5): 938-949. |

| [76] | Xu H, Chen Y, Kim J H, et al. Lattice Boltzmann modelling of the coupling between charge transport and electrochemical reactions in a solid oxide fuel cell with a patterned anode[J]. International Journal of Hydrogen Energy, 2019, 44(57): 30293-30305. |

| [77] | Li W Y, Shi Y X, Luo Y, et al. Carbon monoxide/carbon dioxide electrochemical conversion on patterned nickel electrodes operating in fuel cell and electrolysis cell modes[J]. International Journal of Hydrogen Energy, 2016, 41(6): 3762-3773. |

| [78] | Amezawa K, Nishidate K, Diao Z, et al. (Invited) mechanism of cathodic reaction in proton-conducting ceramic fuel cells investigated by patterned model electrodes[J]. ECS Meeting Abstracts, 2022(47): 1737. |

| [79] | Bieberle A, Meier L P, Gauckler L J. The electrochemistry of Ni pattern anodes used as solid oxide fuel cell model electrodes[J]. Journal of the Electrochemical Society, 2001, 148(6): A646. |

| [80] | Bieberle A, Gauckler L J. Reaction mechanism of Ni pattern anodes for solid oxide fuel cells[J]. Solid State Ionics, 2000, 135(1/2/3/4): 337-345. |

| [81] | Adler S B. Factors governing oxygen reduction in solid oxide fuel cell cathodes[J]. Chemical Reviews, 2004, 104(10): 4791-4844. |

| [82] | Kim Y B, Hsu C M, Connor S T, et al. Nanopore patterned Pt array electrodes for triple phase boundary study in low temperature SOFC[J]. Journal of the Electrochemical Society, 2010, 157(9): B1269. |

| [83] | Utz A, Leonide A, Weber A, et al. Studying the CO-CO2 characteristics of SOFC anodes by means of patterned Ni anodes[J]. Journal of Power Sources, 2011, 196(17): 7217-7224. |

| [84] | Zheng M H, Wang S, Li M, et al. H2 and CO oxidation process at the three-phase boundary of Cu-ceria cermet anode for solid oxide fuel cell[J]. Journal of Power Sources, 2017, 345: 165-175. |

| [85] | Zheng M H, Gao J H, Xia C R. H2 oxidation pathways on Ni-ceria surface by electrical conductivity relaxation method[J]. Solid State Ionics, 2018, 319: 92-97. |

| [86] | Wang S, Zheng M H, Li M, et al. Synergistic effects towards H2 oxidation on the Cu-CeO2 electrode: a combination study with DFT calculations and experiments[J]. Journal of Materials Chemistry A, 2016, 4(15): 5745-5754. |

| [87] | Jiao Z J, Shikazono N. Study on nickel morphological change at active three-phase-boundary in solid oxide fuel cell anode using patterned nickel-film electrode[J]. ECS Meeting Abstracts, 2017(1): 77. |

| [88] | Li W Y, Shi Y X, Luo Y, et al. Carbon deposition on patterned nickel/yttria stabilized zirconia electrodes for solid oxide fuel cell/solid oxide electrolysis cell modes[J]. Journal of Power Sources, 2015, 276: 26-31. |

| [89] | Jiao Z J, Busso E P, Shikazono N. Influence of polarization on the morphological changes of nickel in fuel electrodes of solid oxide cells[J]. Journal of the Electrochemical Society, 2020, 167(2): 024516. |

| [90] | He W D, Zou J, Wang B, et al. Gas transport in porous electrodes of solid oxide fuel cells: a review on diffusion and diffusivity measurement[J]. Journal of Power Sources, 2013, 237: 64-73. |

| [91] | Zhang Y, Knibbe R, Sunarso J, et al. Recent progress on advanced materials for solid-oxide fuel cells operating below 500℃[J]. Advanced Materials, 2017, 29(48): 1700132. |

| [92] | 刘顺利. 质子导体直接氨燃料电池设计及机理分析[D]. 福州: 福州大学, 2022. |

| Liu S L. Design and mechanism analysis of proton conductor direct ammonia fuel cell[D]. Fuzhou: Fuzhou University, 2022. | |

| [93] | Patel H, Biradar N, Venkataraman V, et al. Pattern electrodes for studying SOFC electrochemistry[J]. ECS Transactions, 2013, 57(1): 1613-1618. |

| [94] | Luo Y, Shi Y X, Li W Y, et al. Elementary reaction modeling of reversible CO/CO2 electrochemical conversion on patterned nickel electrodes[J]. Journal of Power Sources, 2018, 379: 298-308. |

| [95] | Habibzadeh B, Sukeshini A M, Becker B, et al. CO electrochemical oxidation on Ni patterned anodes for assessing solid oxide fuel cell kinetics[J]. ECS Transactions, 2008, 11(33): 53-61. |

| [96] | Timurkutluk C, Altan T, Onbilgin S, et al. Mesh patterned electrolyte supports for high-performance solid oxide fuel cells[J]. International Journal of Energy Research, 2022, 46(8): 10689-10703. |

| [97] | Timurkutluk C, Altan T, Yildirim F, et al. Improving the electrochemical performance of solid oxide fuel cells by surface patterning of the electrolyte[J]. Journal of Power Sources, 2021, 512: 230489. |

| [98] | He A, Onishi J, Shikazono N. Optimization of electrode-electrolyte interface structure for solid oxide fuel cell cathode[J]. Journal of Power Sources, 2020, 449: 227565. |

| [99] | Fan J, Wang Y, Shi J, et al. Influences of hydrogen-natural gas mixtures on the performance of an internal reforming solid oxide fuel cell unit: a simulation study[J]. Journal of the Electrochemical Society, 2022, 169(4): 044511. |

| [100] | Wen Y, Abe H, Hirata A, et al. Correlation between the charge-transport properties and the 3D-phase connectivities in patterned Pt/CeO2 nanostructured composites: implications for solid-oxide fuel cells[J]. ACS Applied Nano Materials, 2021, 4(12): 13602-13611. |

| [101] | Tabish A N, Fan L Y, Farhat I, et al. Computational fluid dynamics modeling of anode-supported solid oxide fuel cells using triple-phase boundary-based kinetics[J]. Journal of Power Sources, 2021, 513: 230564. |

| [102] | Koep E, Compson C, Liu M L, et al. A photolithographic process for investigation of electrode reaction sites in solid oxide fuel cells[J]. Solid State Ionics, 2005, 176(1/2): 1-8. |

| [103] | Ouyang Z F, Komatsu Y, Sciazko A, et al. operando observations of active three phase boundary of patterned nickel-yttria stabilized zirconia electrode in solid oxide cell[J]. Journal of Power Sources, 2022, 529: 231228. |

| [104] | Sunarso J, Hashim S S, Zhu N, et al. Perovskite oxides applications in high temperature oxygen separation, solid oxide fuel cell and membrane reactor: a review[J]. Progress in Energy and Combustion Science, 2017, 61: 57-77. |

| [105] | Zhu Y L, Zhou W, Shao Z P. Perovskite/carbon composites: applications in oxygen electrocatalysis[J]. Small, 2017, 13(12): 1603793. |

| [106] | Zhou W, Ran R, Shao Z P. Progress in understanding and development of Ba0.5Sr0.5Co0.8Fe0.2O3- δ -based cathodes for intermediate-temperature solid-oxide fuel cells: a review[J]. Journal of Power Sources, 2009, 192(2): 231-246. |

| [107] | Song Y F, Chen Y B, Wang W, et al. Self-assembled triple-conducting nanocomposite as a superior protonic ceramic fuel cell cathode[J]. Joule, 2019, 3(11): 2842-2853. |

| [108] | Yi Y N, Ran R, Wang W, et al. Perovskite-based nanocomposites as high-performance air electrodes for protonic ceramic cells[J]. Current Opinion in Green and Sustainable Chemistry, 2022, 38: 100711. |

| [109] | Liu Z Q, Chen Y, Yang G M, et al. One-pot derived thermodynamically quasi-stable triple conducting nanocomposite as robust bifunctional air electrode for reversible protonic ceramic cells[J]. Applied Catalysis B: Environmental, 2022, 319: 121929. |

| [110] | Liang M Z, Wang Y H, Song Y F, et al. High-temperature water oxidation activity of a perovskite-based nanocomposite towards application as air electrode in reversible protonic ceramic cells[J]. Applied Catalysis B: Environmental, 2023, 331: 122682. |

| [111] | Liu Z Q, Lin Y X, Nie H Y, et al. Highly active nanocomposite air electrode with fast proton diffusion channels via Er doping-induced phase separation for reversible proton ceramic electrochemical cells[J]. Advanced Functional Materials, 2024, 34(7): 2311140. |

| [112] | Zou D, Yi Y N, Song Y F, et al. The BaCe0.16Y0.04Fe0.8O3- δ nanocomposite: a new high-performance cobalt-free triple-conducting cathode for protonic ceramic fuel cells operating at reduced temperatures[J]. Journal of Materials Chemistry A, 2022, 10(10): 5381-5390. |

| [113] | 周川, 刘威, 梅伟杰, 等. 钨酸镧系列质子导体的开发及应用[J]. 科学通报, 2022, 67(2): 163-172. |

| Zhou C, Liu W, Mei W J, et al. Development and application of lanthanum tungstate series proton conductors[J]. Chinese Science Bulletin, 2022, 67(2): 163-172. | |

| [114] | 周嵬, 王习习, 朱印龙, 等. 面向金属-空气电池和中低温固体氧化物燃料电池应用的钴基电催化剂综述[J]. 材料导报, 2018, 32(3): 337-356. |

| Zhou W, Wang X X, Zhu Y L, et al. A complete review of cobalt-based electrocatalysts applying to metal-air batteries and intermediate-low temperature solid oxide fuel cells[J]. Materials Review, 2018, 32(3): 337-356. | |

| [115] | 李文怀, 周嵬. 高氧离子电导钙钛矿的影响因素分析和设计策略[J]. 化工学报, 2022, 73(4): 1455-1471. |

| Li W H, Zhou W. Analysis of influencing factors and design strategies of high oxygen ion conductivity perovskite[J]. CIESC Journal, 2022, 73(4): 1455-1471. | |

| [116] | Liu M L, Lynch M E, Blinn K, et al. Rational SOFC material design: new advances and tools[J]. Materials Today, 2011, 14(11): 534-546. |

| [117] | Zhu Y L, Sunarso J, Zhou W, et al. Probing CO2 reaction mechanisms and effects on the SrNb0.1Co0.9- x Fe x O3- δ cathodes for solid oxide fuel cells[J]. Applied Catalysis B: Environmental, 2015, 172: 52-57. |

| [118] | 杨刚. 平管式燃料电池甲烷发电的电化学性能及衰减机理研究[D]. 赣州: 江西理工大学, 2022. |

| Yang G. Study on electrochemical performance and attenuation mechanism of methane power generation in flat tube fuel cell[D]. Ganzhou: Jiangxi University of Science and Technology, 2022. | |

| [119] | Cassidy M. Trends in the processing and manufacture of solid oxide fuel cells[J]. Wiley Interdisciplinary Reviews: Energy and Environment, 2017, 6(5): e248. |

| [1] | 张俊杰, 孙旺, 高啸天, 等. 固体氧化物电解池制氢关键技术及产业化进展[J]. 化工学报, 2023, 74(12): 4749-4763. |

| Zhang J J, Sun W, Gao X T, et al. Key technology and industrialization progress of hydrogen production by solid oxide electrolytic cell[J]. CIESC Journal, 2023, 74(12): 4749-4763. | |

| [2] | 王洪建, 王冬冬, 曹权, 等. 燃料电池分布式供能技术发展现状及分析[J]. 中国电机工程学报, 2024, 44(20): 8113-8126. |

| Wang H J, Wang D D, Cao Q, et al. Development status and analysis of fuel cell based distributed energy supply technology[J]. Proceedings of the CSEE, 2024, 44(20): 8113-8126. | |

| [3] | Wang Y Q, Shi J X, Gu X, et al. Toward mobility of solid oxide fuel cells[J]. Progress in Energy and Combustion Science, 2024, 102: 101141. |

| [4] | Rabuni M F, Li T, Othman M H D, et al. Progress in solid oxide fuel cells with hydrocarbon fuels[J]. Energies, 2023, 16(17): 6404. |

| [5] | 龚思琦, 云再鹏, 许明, 等. 基于三元催化剂的固体氧化物燃料电池尾气催化燃烧数值模拟[J]. 发电技术, 2024, 45(2): 331-340. |

| Gong S Q, Yun Z P, Xu M, et al. Numerical simulation of solid oxide fuel cell tail gas catalytic combustion based on three-way catalyst[J]. Power Generation Technology, 2024, 45(2): 331-340. | |

| [6] | 王天闻, 闫肃, 赵梦园, 等. 固体氧化物电池空气电极铬中毒机理及抗铬性能研究进展[J]. 化工学报, 2024, 75(6): 2091-2108. |

| Wang T W, Yan S, Zhao M Y, et al. Mechanisms of chromium poisoning in solid oxide cell air electrodes and research advances in enhancing chromium-resistivity[J]. CIESC Journal, 2024, 75(6): 2091-2108. | |

| [7] | Hatef M, Gholamian E, Seyed Mahmoudi S M, et al. Enhancing efficiency and reduced CO2 emission in hybrid biomass gasification with integrated SOFC-MCFC system based on CO2 recycle[J]. Energy Conversion and Management, 2024, 313: 118611. |

| [8] | 刘琨, 黄辉, 陈曦, 等. 低温固体氧化物燃料电池发展及应用[J]. 稀土, 2024, 45(3): 135-142. |

| Liu K, Huang H, Chen X, et al. Development and application of low temperature solid oxide fuel cell[J]. Chinese Rare Earths, 2024, 45(3): 135-142. | |

| [9] | He S, Jiang S P. Electrode/electrolyte interface and interface reactions of solid oxide cells: recent development and advances[J]. Progress in Natural Science: Materials International, 2021, 31(3): 341-372. |

| [10] | Connor P A, Yue X L, Savaniu C D, et al. Tailoring SOFC electrode microstructures for improved performance[J]. Advanced Energy Materials, 2018, 8(23): 1800120. |

| [11] | Wang X Y, Li W H, Zhou C, et al. Enhanced proton conduction with low oxygen vacancy concentration and favorable hydration for protonic ceramic fuel cells cathode[J]. ACS Applied Materials & Interfaces, 2023, 15(1): 1339-1347. |

| [12] | Tarutina L R, Gordeeva M A, Matkin D E, et al. Why do BaCo0.4Fe0.4Zr0.1Y0.1O3– δ -derived complex oxides become one of the most promising electrodes for protonic ceramic electrochemical cells? An explanatory review[J]. Chemical Engineering Journal, 2024, 490: 151615. |

| [13] | 梁超余, 王家堂, 苗鹤, 等. 高温固体氧化物燃料电池多孔电极结构介尺度研究方法[J]. 化工进展, 2020, 39(3): 906-915. |

| Liang C Y, Wang J T, Miao H, et al. Review on the mesoscale research of porous electrode structure in SOFC[J]. Chemical Industry and Engineering Progress, 2020, 39(3): 906-915. | |

| [14] | Liu Z R, Shi J X, Wang Y Q, et al. NH3-fed patterned electrode solid oxide fuel cell: experimental performance characterization and elementary reaction modeling[J]. ECS Transactions, 2023, 111(6): 2189-2202. |

| [15] | Onbilgin S, Altan T, Timurkutluk C, et al. Boosting the performance of bolt-microtubular solid oxide fuel cells through surface pattern tuning[J]. Journal of the European Ceramic Society, 2024, 44(12): 7092-7102. |

| [16] | Grew K N, Chu Y S, Yi J, et al. Nondestructive nanoscale 3D elemental mapping and analysis of a solid oxide fuel cell anode[J]. Journal of the Electrochemical Society, 2010, 157(6): B783. |

| [17] | Vivet N, Chupin S, Estrade E, et al. 3D Microstructural characterization of a solid oxide fuel cell anode reconstructed by focused ion beam tomography[J]. Journal of Power Sources, 2011, 196(18): 7541-7549. |

| [18] | Jung W, Tuller H L. A new model describing solid oxide fuel cell cathode kinetics: model thin film SrTi1- x Fe x O3- δ mixed conducting oxides—a case study[J]. Advanced Energy Materials, 2011, 1(6): 1184-1191. |

| [19] | Ramadhani F, Hussain M A, Mokhlis H, et al. Optimization strategies for solid oxide fuel cell (SOFC) application: a literature survey[J]. Renewable and Sustainable Energy Reviews, 2017, 76: 460-484. |

| [20] | Timurkutluk B, Mat M D. A review on micro-level modeling of solid oxide fuel cells[J]. International Journal of Hydrogen Energy, 2016, 41(23): 9968-9981. |

| [21] | Yang G N, Nam S H, Han G, et al. Achieving fast oxygen reduction on oxide electrodes by creating 3D multiscale micro-nano structures for low-temperature solid oxide fuel cells[J]. ACS Applied Materials & Interfaces, 2023, 15(43): 50427-50436. |

| [22] | Basbus J F, Cademartori D, Asensio A M, et al. Study of a novel microstructured air electrode/electrolyte interface for solid oxide cells[J]. Applied Surface Science, 2024, 652: 159372. |

| [23] | Shao Z P, Zhou W, Zhu Z H. Advanced synthesis of materials for intermediate-temperature solid oxide fuel cells[J]. Progress in Materials Science, 2012, 57(4): 804-874. |

| [24] | Kalinina E, Pikalova E. Opportunities, challenges and prospects for electrodeposition of thin-film functional layers in solid oxide fuel cell technology[J]. Materials, 2021, 14(19): 5584. |

| [25] | Hedayat N, Du Y H, Ilkhani H. Review on fabrication techniques for porous electrodes of solid oxide fuel cells by sacrificial template methods[J]. Renewable and Sustainable Energy Reviews, 2017, 77: 1221-1239. |

| [26] | Mahmud L S, Muchtar A, Somalu M R. Challenges in fabricating planar solid oxide fuel cells: a review[J]. Renewable and Sustainable Energy Reviews, 2017, 72: 105-116. |

| [27] | Lee C, Shin S S, Kim J, et al. Tailoring an interface microstructure for high-performance reversible protonic ceramic electrochemical cells via soft lithography[J]. ACS Applied Materials & Interfaces, 2022, 14(28): 32124-32133. |

| [28] | Ahn S J, Lee J H, Kim J, et al. Single-chamber solid oxide fuel cell with micropatterned interdigitated electrodes[J]. Electrochemical and Solid-State Letters, 2006, 9(5): A228. |

| [29] | Zhang L, Porter T, Guillory S, et al. Patterning polymer electrolyte membrane for fuel cell and electrolysis applications[J]. ECS Transactions, 2017, 77(11): 1325-1335. |

| [30] | Lee C, Shin S S, Choi J, et al. A micro-patterned electrode/electrolyte interface fabricated by soft-lithography for facile oxygen reduction in solid oxide fuel cells[J]. Journal of Materials Chemistry A, 2020, 8(32): 16534-16541. |

| [31] | Cebollero J A, Lahoz R, Laguna-Bercero M A, et al. Tailoring the electrode-electrolyte interface of solid oxide fuel cells (SOFC) by laser micro-patterning to improve their electrochemical performance[J]. Journal of Power Sources, 2017, 360: 336-344. |

| [32] | Zhou T Y, Huang H, Meng Y Q, et al. Significantly enhanced performance of protonic ceramic fuel cells by laser engineering the electrolyte/cathode interface[J]. ACS Energy Letters, 2024, 9(9): 4557-4563. |

| [33] | Okabe T, Kim Y, Jiao Z J, et al. Fabrication process for micropatterned ceramics via UV-nanoimprint lithography using UV-curable binder[J]. Japanese Journal of Applied Physics, 2018, 57(10): 106501. |

| [34] | Akama R, Okabe T, Sato K, et al. Fabrication of a micropatterned composite electrode for solid oxide fuel cells via ultraviolet nanoimprint lithography[J]. Microelectronic Engineering, 2020, 225: 111277. |

| [35] | Shimura T. The use of anisotropic microstructures to modify solid oxide cell electrodes[M]//Nanoengineered Materials for Solid Oxide Cells. UK: IOP Publishing, 2023. |

| [36] | Seo H, Iwai H, Kishimoto M, et al. Microextrusion printing for increasing electrode-electrolyte interface in anode-supported solid oxide fuel cells[J]. Journal of Power Sources, 2020, 450: 227682. |

| [37] | Seo H. Microextrusion-based 3D printing for mesoscale interfacial structural designing in anode-supported solid oxide fuel cells[C]//2024 IEEE 19th International Conference on Nano/Micro Engineered and Molecular Systems (NEMS). IEEE, 2024. |

| [38] | Tsumori F, Tanaka Y, Xu Y, et al. Development of improved solid oxide fuel cell electrolyte sheet by microimprinting for layered material[J]. Japanese Journal of Applied Physics, 2014, 53(6S): 06JK02. |

| [39] | Tokumaru K, Tsumori F, Kudo K, et al. Development of multilayer imprint process for solid oxide fuel cells[J]. Japanese Journal of Applied Physics, 2017, 56(6S1): 06GL04. |

| [40] | Xu Y, Tsumori F, Kang H, et al. Fabrication of micro patterned ceramic structure by imprinting process[J]. Journal of the Japan Society of Powder and Powder Metallurgy, 2011, 58(11): 673-678. |

| [41] | Xu Y, Tsumori F, Osada T, et al. Improvement of solid oxide fuel cell by imprinted micropatterns on electrolyte[J]. Micro & Nano Letters, 2013, 8(10): 571-574. |

| [1] | 陈培强, 郑群, 姜玉廷, 熊春华, 陈今茂, 王旭东, 黄龙, 阮曼, 徐万里. 电液流量及电流密度对海水激活电池输出特性的影响[J]. 化工学报, 2025, 76(7): 3235-3245. |

| [2] | 李欣然, 常龙娇, 罗绍华, 李永兵, 杨瑞芬, 侯增磊, 邹杰. Ho掺杂诱导NCM622局域电子重构抑制阳离子混排的改性机制研究[J]. 化工学报, 2025, 76(7): 3733-3741. |

| [3] | 孙国庆, 李海波, 丁志阳, 郭文辉, 徐浩, 赵艳侠. 硅基负极材料的研究进展[J]. 化工学报, 2025, 76(7): 3197-3211. |

| [4] | 高凤凤, 程慧峰, 杨博, 郝晓刚. 电驱动NiFeMn LDH/CNTs/PVDF膜电极选择性提取钨酸根离子[J]. 化工学报, 2025, 76(7): 3350-3360. |

| [5] | 王珺仪, 夏章讯, 景粉宁, 王素力. 基于重整气的高温聚合物电解质膜燃料电池电化学阻抗谱弛豫时间分布研究[J]. 化工学报, 2025, 76(7): 3509-3520. |

| [6] | 吴鹂霄, 燕溪溪, 张素娜, 徐一鸣, 钱佳颖, 乔永民, 王利军. 磷掺杂微晶石墨的制备及其在锂离子电池负极材料中的电化学性能研究[J]. 化工学报, 2025, 76(7): 3615-3625. |

| [7] | 陆学瑞, 周帼彦, 方琦, 俞孟正, 张秀成, 涂善东. 固体氧化物燃料电池外重整器积炭效应数值模拟研究[J]. 化工学报, 2025, 76(7): 3295-3304. |

| [8] | 康佳, 刘欢, 李海燕, 罗茂亮, 姚洪. 宽温区HCl/NaOH热介质中碳钢腐蚀行为及涂层性能研究[J]. 化工学报, 2025, 76(6): 2872-2885. |

| [9] | 张畅, 解强, 沙雨桐, 王炳杰, 梁鼎成, 刘金昌. 低灰低硅竹炭的制备及衍生硬炭的电化学性能[J]. 化工学报, 2025, 76(6): 3073-3083. |

| [10] | 郭明钢, 杨晓航, 代岩, 米盼盼, 马世鑫, 贺高红, 肖武, 崔福军. 贫氦管输天然气提氦多元化产品耦合工艺优化设计[J]. 化工学报, 2025, 76(5): 2251-2261. |

| [11] | 梁铣, 张晓燕, 魏亦军, 郑云芳, 高全涵, 徐迈, 王凤武. 碱性膜燃料电池中聚电解质的耐久性研究进展[J]. 化工学报, 2025, 76(4): 1447-1462. |

| [12] | 李坤, 黄锐, 丛君, 马海涛, 常龙娇, 罗绍华. NCM622正极材料结构形态和储锂特性的同步演变[J]. 化工学报, 2025, 76(4): 1831-1840. |

| [13] | 吴迪, 刘世朋, 王文伟, 姜久春, 杨晓光. 机械压力对锂金属电池性能影响的研究进展[J]. 化工学报, 2025, 76(4): 1422-1431. |

| [14] | 林纬, 杜建, 姚晨, 朱家豪, 汪威, 郑小涛, 徐建民, 喻九阳. 电化学水软化过程中离子输运与成核机理研究[J]. 化工学报, 2025, 76(4): 1788-1799. |

| [15] | 刘孟扬, 孙雪剑, 毛文元, 邓晰文, 雷基林. 考虑微观表面分层特征密封环接触特性分析[J]. 化工学报, 2025, 76(3): 1156-1169. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号