化工学报 ›› 2025, Vol. 76 ›› Issue (8): 4194-4204.DOI: 10.11949/0438-1157.20250141

王泽( ), 胡琼(

), 胡琼( ), 陈雅静, 王衍(

), 陈雅静, 王衍( ), 耿佳旭, 沈斐然

), 耿佳旭, 沈斐然

收稿日期:2025-02-15

修回日期:2025-03-21

出版日期:2025-08-25

发布日期:2025-09-17

通讯作者:

胡琼,王衍

作者简介:王泽(2001—),男,硕士研究生,2645072370@qq.com

基金资助:

Ze WANG( ), Qiong HU(

), Qiong HU( ), Yajing CHEN, Yan WANG(

), Yajing CHEN, Yan WANG( ), Jiaxu GENG, Feiran SHEN

), Jiaxu GENG, Feiran SHEN

Received:2025-02-15

Revised:2025-03-21

Online:2025-08-25

Published:2025-09-17

Contact:

Qiong HU, Yan WANG

摘要:

液体自冲击密封是一种新型非接触式密封技术,具有零磨损、低能耗、长寿命及高稳定性等优势,可满足高压、高速工况下的严苛密封需求。通过数值模拟与多工况分析,系统研究了翼形、矩形及键形悬柱结构的泄漏特性与封严机理,并提出了基于欧姆定律类比的并联流道优化设计方法。研究发现,翼形悬柱结构在低黏液体(如超临界CO2)、高压(≥4 MPa)、高速(≥11000 r/min)及大间隙(≥0.18 mm)工况下抑漏能力最优,其性能源于支流道回流与多涡旋协同的“冲击阻塞”效应;键形与矩形结构在高黏液体、低压(≤4 MPa)及小间隙(≤0.18 mm)场景中表现相近,而键形封严效果更好;密封级数超过20级后抑漏增益显著减弱,且间隙缩小需权衡加工成本与可靠性;通过类比电路并联原理,提出支流道宽度为主流道0.5倍的优化方案,验证了该方法对高黏层流介质的适用性(误差<5%)。本研究揭示了液体自冲击密封的流动机理,为高压装备的低泄漏、高稳定性密封设计提供了理论依据,同时拓展了“冲击阻塞”理念的工程应用场景。

中图分类号:

王泽, 胡琼, 陈雅静, 王衍, 耿佳旭, 沈斐然. 液体自冲击密封泄漏特性、密封机理与优化设计[J]. 化工学报, 2025, 76(8): 4194-4204.

Ze WANG, Qiong HU, Yajing CHEN, Yan WANG, Jiaxu GENG, Feiran SHEN. Leakage characteristics, sealing mechanism, and optimization design of self-impacting liquid seals[J]. CIESC Journal, 2025, 76(8): 4194-4204.

| 参数 | 范围 | 相对不变量 |

|---|---|---|

| 流道宽度h/mm | 0.01~0.3 | 0.1 |

| 悬柱半径R/mm | 2.5 | — |

| 流距l/mm | 6 | — |

| 交错比k/mm | 2 | — |

| 分流角α/(°) | 48 | — |

| 入口压力Pin/MPa | 0.2~50.1 | 0.2 |

| 出口压力Pout/MPa | 0.1 | — |

| 转速N/(r/min) | 0~20000 | 0 |

| 介质黏度μ/(Pa·s) | 0.00000929~1 | 0.001 |

| 矩形宽度w/mm | 2.5 | — |

| 密封级数Z | 8~40 | 8 |

表1 三种自冲击密封的结构与工况参数

Table 1 Structural and operational parameters of three self-impact seals

| 参数 | 范围 | 相对不变量 |

|---|---|---|

| 流道宽度h/mm | 0.01~0.3 | 0.1 |

| 悬柱半径R/mm | 2.5 | — |

| 流距l/mm | 6 | — |

| 交错比k/mm | 2 | — |

| 分流角α/(°) | 48 | — |

| 入口压力Pin/MPa | 0.2~50.1 | 0.2 |

| 出口压力Pout/MPa | 0.1 | — |

| 转速N/(r/min) | 0~20000 | 0 |

| 介质黏度μ/(Pa·s) | 0.00000929~1 | 0.001 |

| 矩形宽度w/mm | 2.5 | — |

| 密封级数Z | 8~40 | 8 |

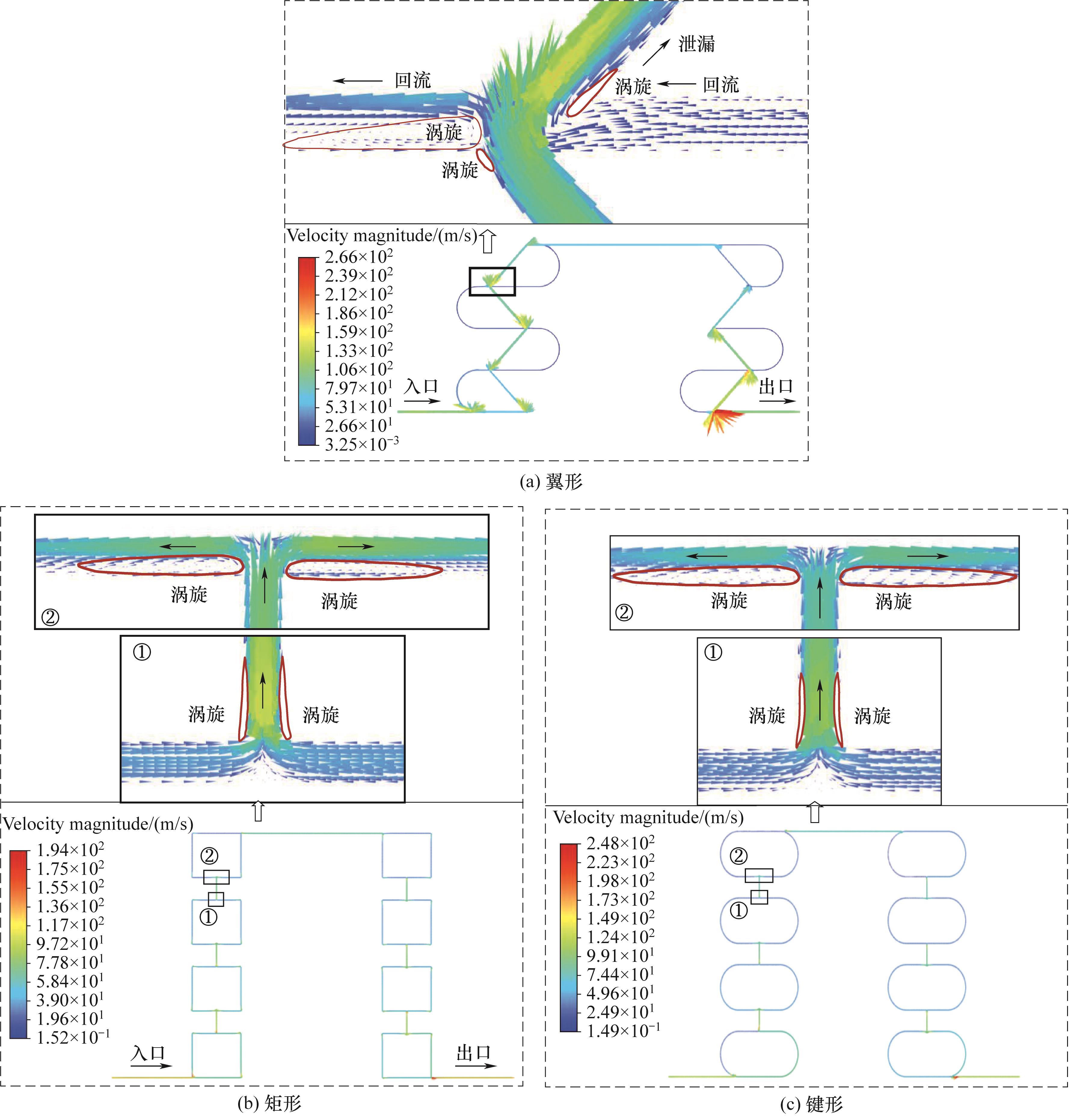

图12 不同悬柱形状液体自冲击密封微流场的速度分布(水,100 MPa压差、0.1 mm间隙、停机状态)

Fig.12 Velocity distribution of micro-flow field in self-impact seals with different suspension pillar shapes (water, 100 MPa pressure differential, 0.1 mm clearance and shutdown state condition)

| [1] | 勒贝克. 机械密封原理与设计[M]. 黄伟峰, 译. 北京: 机械工业出版社, 2016: 11. |

| Lebeck A O. Principles and Design of Mechanical Face Seals[M]. Huang W F, trans. Beijing: Mechanical Industry Press, 2016: 11. | |

| [2] | Morad O, Viitala R, Saikko V. Behavior of marine thruster lip seals under typical operating conditions[J]. Tribology International, 2025, 201: 110195. |

| [3] | 周易文, 栗付平, 虞晓峰. 一种标准地铁单元制动缸用橡胶皮碗密封性能仿真分析研究[J]. 特种橡胶制品, 2022, 43(6): 73-78. |

| Zhou Y W, Li F P, Yu X F. Simulation analysis on sealing performance of rubber cup for a standard subway unit brake cylinder[J]. Special Purpose Rubber Products, 2022, 43(6): 73-78. | |

| [4] | 王波, 王江阳, 赵崇胜, 等. 基于有限疲劳寿命的压裂泵盘根铜套优化设计[J]. 机械设计, 2023, 40(S2): 168-174. |

| Wang B, Wang J Y, Zhao C S, et al. Optimation design of fracturing pump packing copper sleeve based on finite fatigue life[J]. Journal of Machine Design, 2023, 40(S2): 168-174. | |

| [5] | 薛婷, 王瑜, 张凯, 等. 非接触式端面密封流体动压效应的研究进展[J]. 钻探工程, 2023, 50(S1): 38-43. |

| Xue T, Wang Y, Zhang K, et al. Research on progress of hydrodynamic pressure effect of non-contact face seal[J]. Drilling Engineering, 2023, 50(S1): 38-43. | |

| [6] | 刘孟扬, 孙雪剑, 毛文元, 等. 考虑微观表面分层特征密封环接触特性分析[J]. 化工学报, 2025, 76(3): 1156-1169. |

| Liu M Y, Sun X J, Mao W Y, et al. Contact characterization of sealing rings considering microscopic surface delamination features[J]. CIESC Journal, 2025, 76(3): 1156-1169. | |

| [7] | Zhao Y Y, Zhang G Y, Wang J Q, et al. Tribological properties of low-temperature time-dependent pretreated graphite for mechanical seal pairs in high-speed turbopump[J]. Friction, 2024, 12(2): 305-318. |

| [8] | Gibbons N, Goyne C. Form shear stress correction in bulk flow analysis of grooved seals based on effective film thickness[J]. Journal of Tribology, 2024, 146(1): 014401. |

| [9] | Ran Y, He Q, Huang W F, et al. Analysis of the coupling mechanism of the dynamic response and mechanical-thermal deformation in mechanical seals[J]. Tribology International, 2024, 192: 109257. |

| [10] | 李双喜, 刘安, 刘志远, 等. 高速涡轮泵动静压混合式气体隔离密封扰动性能[J]. 化工学报, 2025, 76(1): 311-323. |

| Li S X, Liu A, Liu Z Y, et al. Analysis of disturbance performance of dynamic and static pressure hybrid gas isolation seal of high-speed turbopumps and experimental study[J]. CIESC Journal, 2025, 76(1): 311-323. | |

| [11] | 张国渊, 黎旭康, 赵伟刚, 等. 低温高速动静结合型机械密封两相流仿真与实验[J]. 航空学报, 2023, 44(23): 628229. |

| Zhang G Y, Li X K, Zhao W G, et al. Theoretical and experimental on two-phase flow mechanism of low-temperature high-speed hydrodynamic mechanical seal[J]. Acta Aeronautica et Astronautica Sinica, 2023, 44(23): 628229. | |

| [12] | Migout F, Brunetière N, Tournerie B. Study of the fluid film vaporization in the interface of a mechanical face seal[J]. Tribology International, 2015, 92: 84-95. |

| [13] | 王衍, 谢雪非, 徐慧, 等. 新型非接触式自冲击密封结构设计与性能分析[J]. 机械工程学报, 2023, 59(15): 204-215. |

| Wang Y, Xie X F, Xu H, et al. Design and performance analysis of a new non-contact self-impact seal[J]. Journal of Mechanical Engineering, 2023, 59(15): 204-215. | |

| [14] | 孙巍伟, 刘跃, 李永健, 等. 多因素下迷宫密封泄漏分析及实验验证[J]. 清华大学学报(自然科学版), 2024, 64(8): 1414-1423. |

| Sun W W, Liu Y, Li Y J, et al. Analysis and experimental verification on the leakage of labyrinth seals under multiple factors[J]. Journal of Tsinghua University (Science and Technology), 2024, 64(8): 1414-1423. | |

| [15] | 张彤, 李德才, 李艳文. 磁性液体密封与迷宫密封组合密封的结构设计及优化[J]. 机械工程学报, 2022, 58(9): 172-181. |

| Zhang T, Li D C, Li Y W. Design and optimization of combined magnetic fluid seal and labyrinth seal[J]. Journal of Mechanical Engineering, 2022, 58(9): 172-181. | |

| [16] | Ghosh S, Fernandez E, Kapat J. Fluid-thermal topology optimization of gas turbine blade internal cooling ducts[J]. Journal of Mechanical Design, 2022, 144(5): 051703. |

| [17] | Wang J, Wang J B, Long Z Y, et al. Design and application of a cooling device based on peltier effect coupled with electrohydrodynamics[J]. International Journal of Thermal Sciences, 2021, 162: 106761. |

| [18] | 张惠涛, 李德才. 分瓣式密封装置磁性液体平面密封研究[J]. 机械工程学报, 2018, 54(5): 149-155. |

| Zhang H T, Li D C. Studies of magnetic fluid plane sealing in split sealing device[J]. Journal of Mechanical Engineering, 2018, 54(5): 149-155. | |

| [19] | Szczech M, Horak W. Tightness testing of rotary ferromagnetic fluid seal working in water environment[J]. Industrial Lubrication and Tribology, 2015, 67(5): 455-459. |

| [20] | 靳志鸿, 李志刚, 李军, 等. 液氧涡轮泵新型螺旋阻尼密封泄漏特性研究[J]. 西安交通大学学报, 2022, 56(8): 62-72. |

| Jin Z H, Li Z G, Li J, et al. Investigation on the leakage characteristics of a novel helical damper seal for the liquid oxygen turbopump[J]. Journal of Xi'an Jiaotong University, 2022, 56(8): 62-72. | |

| [21] | Nikola T. Valvular conduit: US1329559[P]. 1920-02-03. |

| [22] | 翁祥宇, 严生虎, 张跃, 等. 一种基于特斯拉阀结构的微混合器设计、模拟及其试验研究[J]. 化工进展, 2021, 40(8): 4173-4178. |

| Weng X Y, Yan S H, Zhang Y, et al. Design, simulation and experimental study of a micromixer based on Tesla valve structure[J]. Chemical Industry and Engineering Progress, 2021, 40(8): 4173-4178. | |

| [23] | Jang D S, Ham S H, Shin H H, et al. Thermal performance improvement of a radial pulsating heat pipe with diverging channels by adopting Tesla valves at various heat fluxes[J]. Applied Thermal Engineering, 2024, 237: 121799. |

| [24] | Zhang Y, He S R, Jiang X H, et al. Performance and configuration optimization of proton exchange membrane fuel cell considering dual symmetric Tesla valve flow field[J]. Energy, 2024, 288: 129791. |

| [25] | Wang P F, Hu P L, Liu L, et al. On the diodicity enhancement of multistage Tesla valves[J]. Physics of Fluids, 2023, 35(5): 052010. |

| [26] | Wahidi T, Chandavar R A, Yadav A K. Stability enhancement of supercritical CO2 based natural circulation loop using a modified Tesla valve[J]. Journal of Supercritical Fluids, 2020, 166: 105020. |

| [27] | Monika K, Chakraborty C, Roy S, et al. A numerical analysis on multi-stage Tesla valve based cold plate for cooling of pouch type Li-ion batteries[J]. International Journal of Heat and Mass Transfer, 2021, 177: 121560. |

| [28] | Zhao P C, Wang H B, Wang Y Z, et al. A time sequential microfluid sensor with Tesla valve channels[J]. Nano Research, 2023, 16(9): 11667-11673. |

| [29] | 胡琼, 王锦华, 陈阳, 等. 一种具有自修复式超滑表面的高载低摩摩擦副设计方法: 202310678988.6[P]. 2024-2-2. |

| Hu Q, Wang J H, Chen Y, et al. A design method for high-load, low-friction tribo-pairs with self-healing, ultra-smooth surfaces: 202310678988.6[P]. 2024-2-2. | |

| [30] | Hu Q, Wang J H, Zhu L, et al. Numerical and experimental investigations into characteristics of liquid film seals featuring various groove shapes based on super-slip groove design[J]. Tribology International, 2024, 199: 109978. |

| [31] | 王衍, 谢雪非, 何一鸣, 等. 基于特斯拉阀的新型非接触式流体密封技术研究[J]. 摩擦学学报, 2023, 43(9): 975-985. |

| Wang Y, Xie X F, He Y M, et al. A new non-contact fluid seal technology based on Tesla valve[J]. Tribology, 2023, 43(9): 975-985. | |

| [32] | ANSYS Inc. ANSYS Fluent Theory Guide(2020 R1)[M]. Canonsburg: ANSYS Inc, 2020. |

| [33] | 胡琼, 肖洋, 卢迪, 等. 环形间隙密封泄漏率计算方法研究[J]. 流体机械, 2021, 49(12): 49-54, 61. |

| Hu Q, Xiao Y, Lu D, et al. Study on leakage calculation methods of annular clearance seals[J]. Fluid Machinery, 2021, 49(12): 49-54, 61. |

| [1] | 孙九春, 桑运龙, 王海涛, 贾浩, 朱艳. 泥水盾构仓体内射流对泥浆输送特性影响研究[J]. 化工学报, 2025, 76(S1): 246-257. |

| [2] | 郭松源, 周晓庆, 缪五兵, 汪彬, 耑锐, 曹庆泰, 陈成成, 杨光, 吴静怡. 火箭上升段含多孔板液氧贮箱增压输运数值研究[J]. 化工学报, 2025, 76(S1): 62-74. |

| [3] | 王梦娇, 胡凯学, 孟祥铠, 江锦波, 彭旭东. 碳化硅表面微织构尺寸和面密度对滑动密封面摩擦学性能的影响[J]. 化工学报, 2025, 76(8): 4165-4176. |

| [4] | 马永丽, 安澍, 杨捷, 刘明言. 气液固流化床直接数值模拟研究进展[J]. 化工学报, 2025, 76(8): 3772-3788. |

| [5] | 苏国庆, 田学梅, 李彦, 张建文, 张志军. 气力输送系统弯管三通的冲蚀分析及改进[J]. 化工学报, 2025, 76(8): 3894-3904. |

| [6] | 夏天炜, 王谙词, 句子涵, 孙晓霞, 胡定华. 基于三周期极小曲面结构的高密度储热器蓄放热特性研究[J]. 化工学报, 2025, 76(7): 3605-3614. |

| [7] | 陈曦, 王淑彦, 邵宝力, 丁诺, 谢磊. 基于颗粒动态恢复系数二阶矩模型的液固流化床数值模拟研究[J]. 化工学报, 2025, 76(7): 3246-3258. |

| [8] | 王子恒, 李文怀, 周嵬. 图形电极在固体氧化物燃料电池中的应用[J]. 化工学报, 2025, 76(7): 3153-3171. |

| [9] | 潘嘉阳, 江锦波, 彭旭东, 孟祥铠, 马艺. 双面开槽石墨圆周密封分层计算模型及开槽位置影响研究[J]. 化工学报, 2025, 76(6): 2886-2899. |

| [10] | 余嘉桐, 孟祥铠, 赵文静, 刘磊, 张力豪, 彭旭东. 热力耦合作用下涡轮泵用镶装式机械密封端面变形规律研究[J]. 化工学报, 2025, 76(6): 2900-2912. |

| [11] | 江锦波, 陈竹鑫, 肖洋溢, 彭新, 陈源, 于辰, 孟祥铠, 彭旭东. 运行工况对超临界CO2干气密封端面热力学过程及稳态性能影响研究[J]. 化工学报, 2025, 76(6): 2913-2928. |

| [12] | 王富玉, 周晅毅. 结合非定常伴随方程和遗传算法的化工区反演[J]. 化工学报, 2025, 76(6): 3104-3114. |

| [13] | 张亿韵, 陈恒志, 李洋, 慕长安, 王泉海. 湍流对双组分颗粒流化床气体径向扩散的影响[J]. 化工学报, 2025, 76(6): 2559-2568. |

| [14] | 谷德银, 杨豪, 李昌树, 刘作华. 分形穿流桨搅拌槽内假塑性流体的混合行为[J]. 化工学报, 2025, 76(6): 2569-2579. |

| [15] | 牛宏斌, 邱丽, 杨景轩, 张忠林, 郝晓刚, 赵忠凯, 阿布里提, 官国清. 筒体直径对旋风分离器性能的影响及其流场机制[J]. 化工学报, 2025, 76(5): 2367-2376. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号