化工学报 ›› 2025, Vol. 76 ›› Issue (6): 2559-2568.DOI: 10.11949/0438-1157.20241497

张亿韵1( ), 陈恒志1(

), 陈恒志1( ), 李洋1, 慕长安1, 王泉海2

), 李洋1, 慕长安1, 王泉海2

收稿日期:2024-12-24

修回日期:2025-02-04

出版日期:2025-06-25

发布日期:2025-07-09

通讯作者:

陈恒志

作者简介:张亿韵(2002—),女,硕士研究生,202418131194@stu.cqu.edu.cn

基金资助:

Yiyun ZHANG1( ), Hengzhi CHEN1(

), Hengzhi CHEN1( ), Yang LI1, Chang'an MU1, Quanhai WANG2

), Yang LI1, Chang'an MU1, Quanhai WANG2

Received:2024-12-24

Revised:2025-02-04

Online:2025-06-25

Published:2025-07-09

Contact:

Hengzhi CHEN

摘要:

针对模拟研究双组分流化床内气体扩散过程中出现的计算偏差,提出通过优化标准k-ε湍流模型常数提高计算精度,从而消除计算偏差。研究结果表明:采用Launder湍流模型常数时,计算获得流化床内流场湍流强度偏大,导致模拟结果与实验数据相差较大;通过调整湍流模型常数可以明显提高计算精度,模拟结果与实验数据更为一致。在气速较低时,湍流对气体径向扩散影响不大;但在气速较高时,采用新模型常数模拟结果与实验数据的吻合度明显提高。随着重组分颗粒的增加,流化床中心区示踪气体浓度呈现先降低后升高的变化趋势。第二组分颗粒的添加对流化床内湍流强度影响较为复杂。

中图分类号:

张亿韵, 陈恒志, 李洋, 慕长安, 王泉海. 湍流对双组分颗粒流化床气体径向扩散的影响[J]. 化工学报, 2025, 76(6): 2559-2568.

Yiyun ZHANG, Hengzhi CHEN, Yang LI, Chang'an MU, Quanhai WANG. Effects of turbulence on radial gas diffusion in binary particle fluidized bed[J]. CIESC Journal, 2025, 76(6): 2559-2568.

| 颗粒 | 密度/(kg/m3) | 粒径范围/μm | 平均粒径/μm | 最小流化速度/(m/s) | Geldart分类 |

|---|---|---|---|---|---|

硅胶 玻璃珠 | 750 2500 | 425~880 425~880 | 652 652 | 0.22 0.41 | B B |

表1 实验所用颗粒物性参数

Table 1 Physical properties of particles used in this work

| 颗粒 | 密度/(kg/m3) | 粒径范围/μm | 平均粒径/μm | 最小流化速度/(m/s) | Geldart分类 |

|---|---|---|---|---|---|

硅胶 玻璃珠 | 750 2500 | 425~880 425~880 | 652 652 | 0.22 0.41 | B B |

| Flow field | Unsteady |

|---|---|

| Pressure-velocity coupling | Phase Couple SIMPLE |

| Discretization | Second-order upwind |

| Solid pressure | Lun et al |

| Radial distribution | Lun et al |

| Granular temperature | Algebraic |

| Granular viscosity | Gidaspow |

| Granular bulk visosity | Lun et al |

| Frictional viscosity | Schaeffer |

| Frictional pressure | Based-KTGF |

| Angle of internal friction | 30.0° |

| Time step size | 5×10-4 s |

| Mesh size | 2 mm×5 mm |

表2 鼓泡流化床模拟参数

Table 2 Modeling parameters in bubbling fluidized bed

| Flow field | Unsteady |

|---|---|

| Pressure-velocity coupling | Phase Couple SIMPLE |

| Discretization | Second-order upwind |

| Solid pressure | Lun et al |

| Radial distribution | Lun et al |

| Granular temperature | Algebraic |

| Granular viscosity | Gidaspow |

| Granular bulk visosity | Lun et al |

| Frictional viscosity | Schaeffer |

| Frictional pressure | Based-KTGF |

| Angle of internal friction | 30.0° |

| Time step size | 5×10-4 s |

| Mesh size | 2 mm×5 mm |

| Case | Cμ | C1 | C2 |

|---|---|---|---|

| 1 | 0.03 | 1.84 | 1.42 |

| 2 | 0.05 | 1.64 | 1.62 |

| 3 | 0.09 | 1.44 | 1.92 |

| 4 | 0.12 | 1.2 | 2.2 |

表3 标准k-ε湍流模型常数

Table 3 Constants of standard k-ε turbulence model

| Case | Cμ | C1 | C2 |

|---|---|---|---|

| 1 | 0.03 | 1.84 | 1.42 |

| 2 | 0.05 | 1.64 | 1.62 |

| 3 | 0.09 | 1.44 | 1.92 |

| 4 | 0.12 | 1.2 | 2.2 |

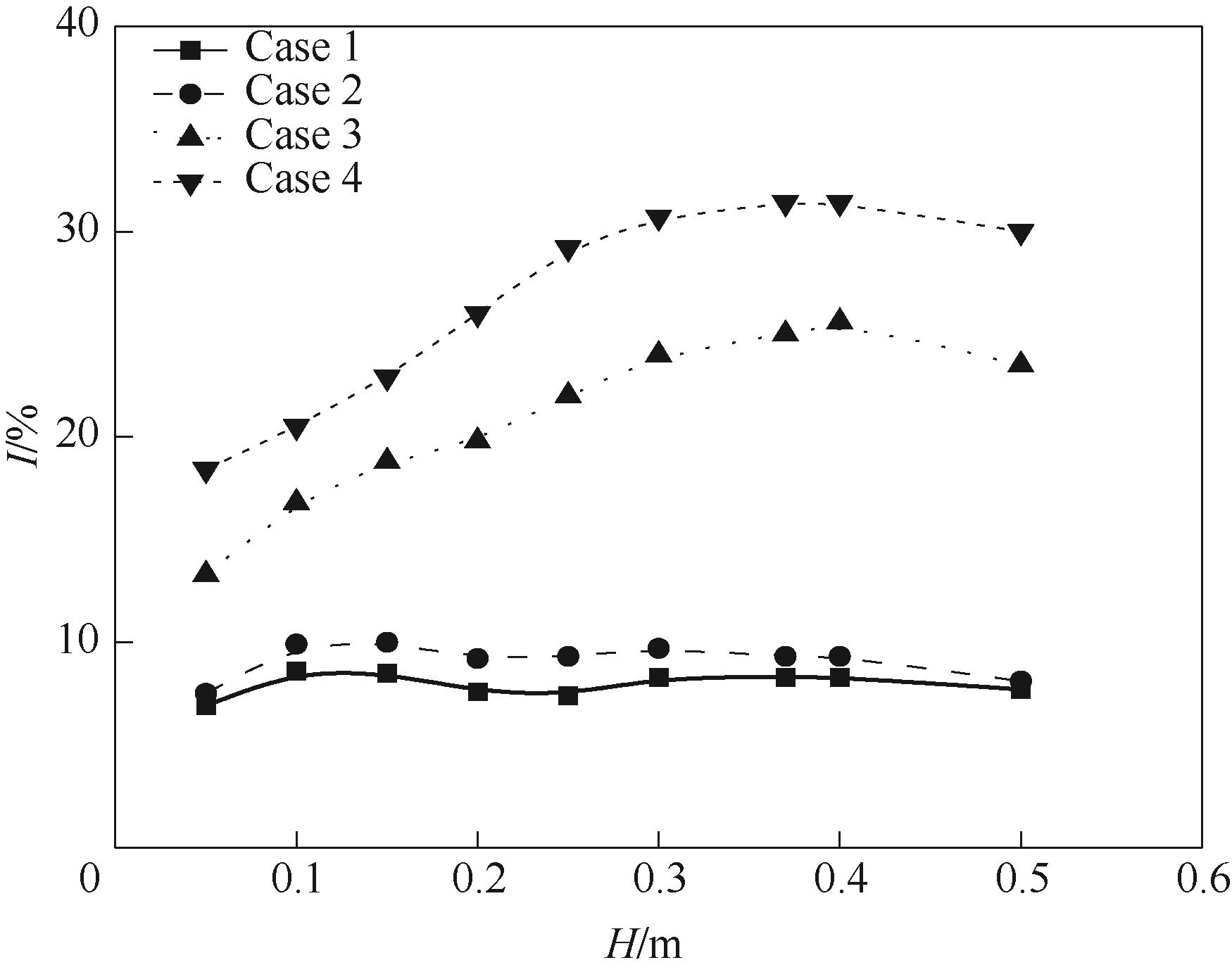

图3 比较4组模型参数计算获得的流化床内湍流强度(Ug= 0.66 m/s, XJ= 37.5%)

Fig.3 Comparison of turbulence intensity in fluidized bed predicted with four groups of model constants

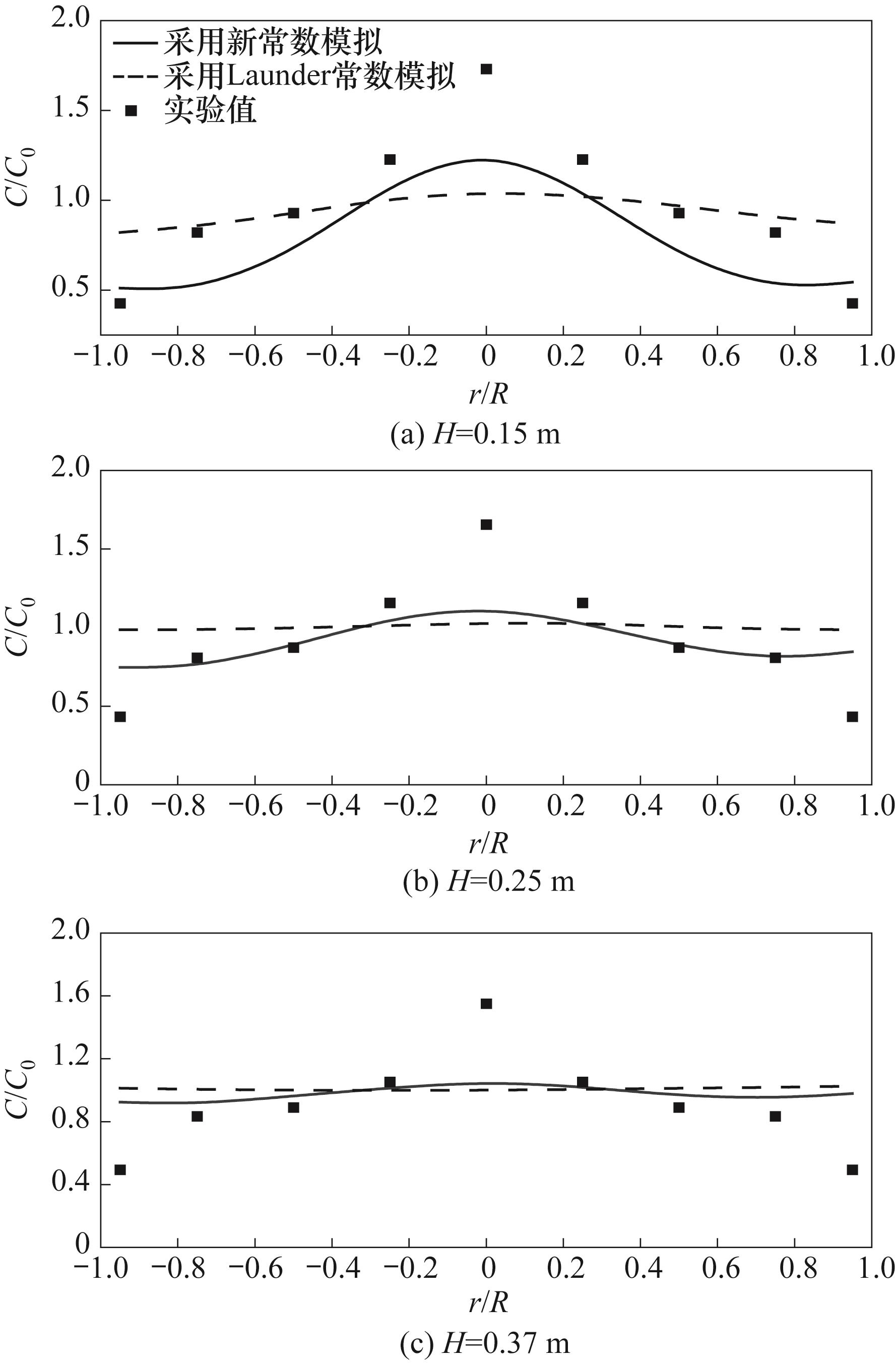

图4 不同模型参数计算的示踪气体浓度与实验数据的比较

Fig.4 Comparison of tracer gas concentration calculated by different model constants with experimental data (Ug= 0.995 m/s, XJ= 37.5%)

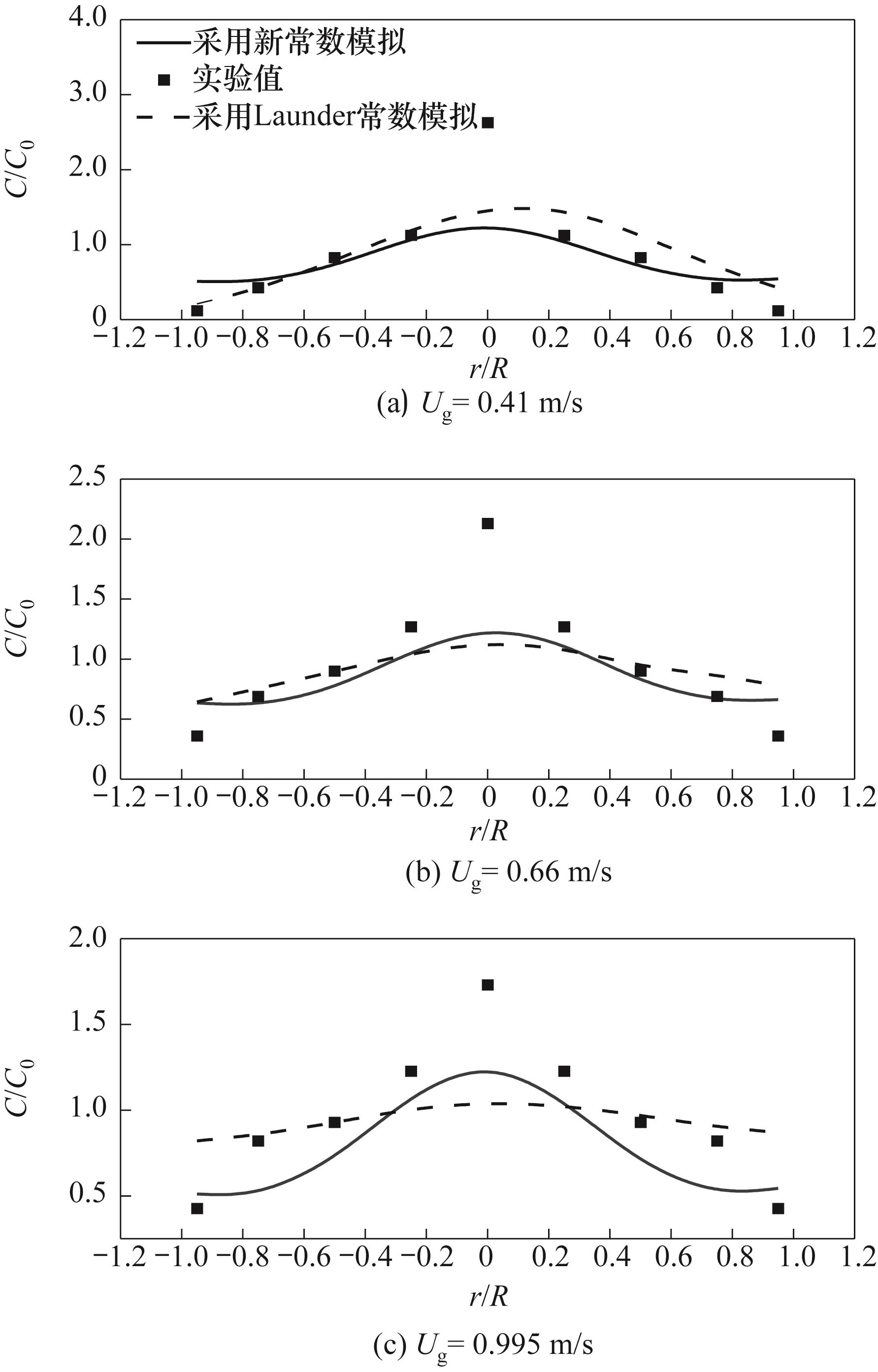

图8 不同气速下由不同模型计算的示踪气体浓度与实验数据的比较

Fig.8 Comparison of tracer gas concentration calculated by different model constants with experimental data at various gas velocities(XJ= 37.5%, H= 0.15 m)

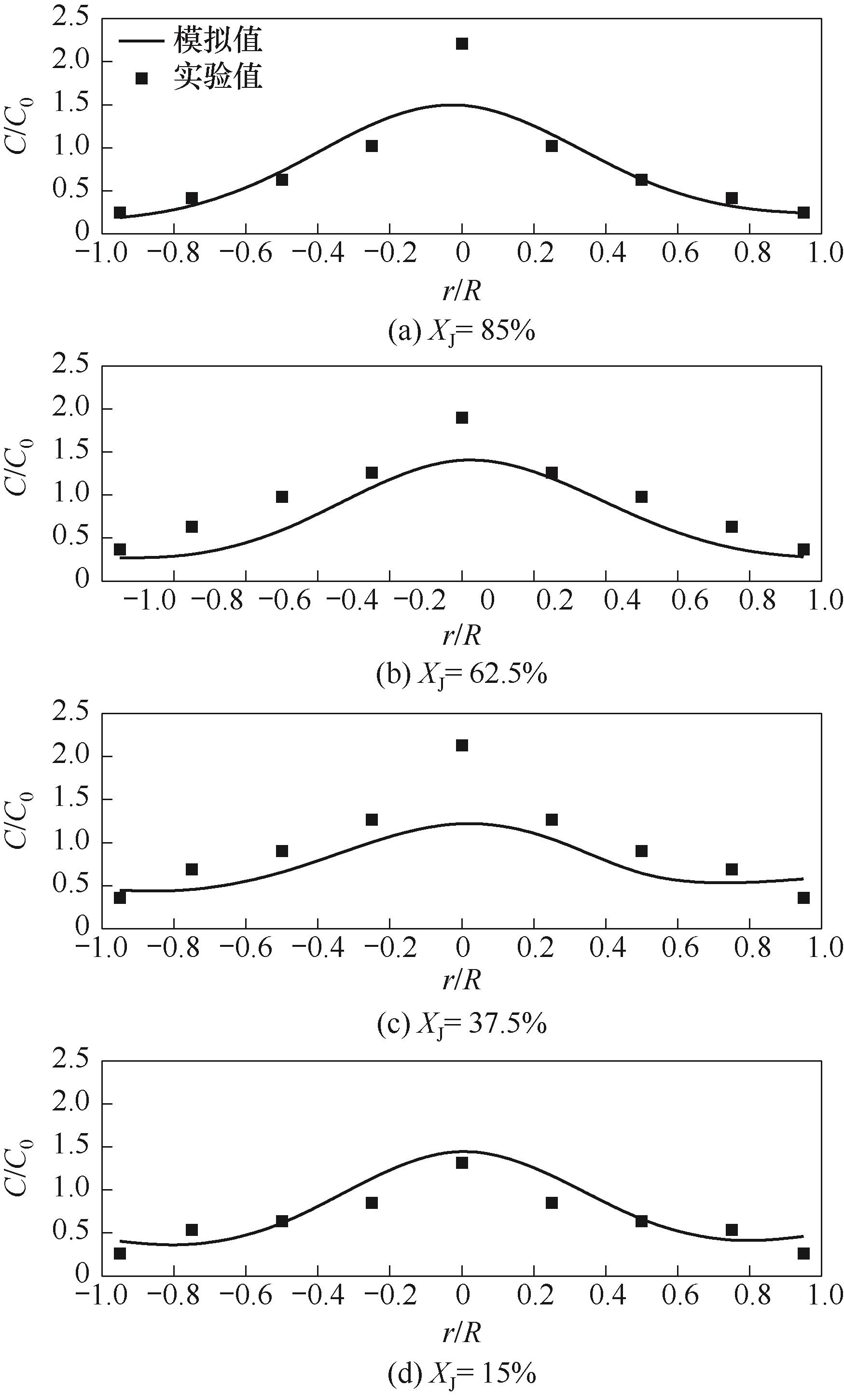

图10 不同颗粒组成下示踪气体浓度计算值与实验数据的比较

Fig.10 Comparison of predicted tracer concentration with experimental data at different particle composition(Ug= 0.995 m/s, H=0.15 m)

| [1] | 郭慕孙, 李洪钟. 流态化手册[M]. 北京: 化学工业出版社, 2008. |

| Guo M S, Li H Z. Handbook of Fluidization[M]. Beijing: Chemical Industry Press, 2008. | |

| [2] | 李洪钟, 朱庆山, 谢朝晖, 等. 流化床结构传递理论与工业应用[M]. 北京: 科学出版社, 2020. |

| Li H Z, Zhu Q S, Xie Z H, et al. Structure Transfer Theory and Industrial Application of Fluidized Bed[M]. Beijing: Science Press, 2020. | |

| [3] | 刘明言, 马永丽, 白丁荣, 等. 多相流态化[M]. 北京: 科学出版社, 2022. |

| Liu M Y, Ma Y L, Bai D R, et al. Heterogeneous Fluidization[M]. Beijing: Science Press, 2022. | |

| [4] | Koenigsdorff R, Werther J. Gas-solids mixing and flow structure modeling of the upper dilute zone of a circulating fluidized bed[J]. Powder Technology, 1995, 82(3): 317-329. |

| [5] | Pan S Y, Ma J L, Chen X P, et al. Diffusion combustion of NH3 in a single bubble of fluidized bed[J]. Fuel, 2023, 352: 129080. |

| [6] | Yang F L, Hlavacek V. Carbochlorination kinetics of titanium dioxide with carbon and carbon monoxide as reductant[J]. Metallurgical and Materials Transactions B, 1998, 29(6): 1297-1307. |

| [7] | 杨建华, 杨海瑞, 岳光溪. 循环流化床提升段径向气体混合的试验研究[J]. 热能动力工程, 2008, 23(5): 494-499, 555. |

| Yang J H, Yang H R, Yue G X. Experimental study of radial gas mixing at the riser section of a circulating fluidized bed[J]. Journal of Engineering for Thermal Energy and Power, 2008, 23(5): 494-499, 555. | |

| [8] | Ji J Q, Cheng L M, Wei Y J, et al. Predictions of NO x /N2O emissions from an ultra-supercritical CFB boiler using a 2-D comprehensive CFD combustion model[J]. Particuology, 2020, 49: 77-87. |

| [9] | Dang T Y N, Gallucci F, van Sint Annaland M. Gas mixing study in freely bubbling and turbulent gas-solid fluidized beds with a novel infrared technique coupled with digital image analysis[J]. Chemical Engineering Science, 2014, 116: 38-48. |

| [10] | Chen H Z, Mu C A, Ding Y X. Investigating hydrodynamics and gas diffusion coefficient in CFB of binary particles with significant differences in particle properties[J]. Chemical Engineering and Processing - Process Intensification, 2024, 203: 109903. |

| [11] | Zhou C G, Rosén C, Engvall K. Biomass oxygen/steam gasification in a pressurized bubbling fluidized bed: agglomeration behavior[J]. Applied Energy, 2016, 172: 230-250. |

| [12] | Yang C G, Li S G, Song W L, et al. Pyrolysis behavior of large coal particles in a lab-scale bubbling fluidized bed[J]. Energy & Fuels, 2013, 27(1): 126-132. |

| [13] | Hemati M, Spieker K, Laguérie C, et al. Experimental study of sawdust and coal particle mixing in sand or catalyst fluidized beds[J]. The Canadian Journal of Chemical Engineering, 1990, 68(5): 768-772. |

| [14] | Joseph G G, Leboreiro J, Hrenya C M, et al. Experimental segregation profiles in bubbling gas-fluidized beds[J]. AIChE Journal, 2007, 53(11): 2804-2813. |

| [15] | Das M, Meikap B C, Saha R K. Characteristics of axial and radial segregation of single and mixed particle system based on terminal settling velocity in the riser of a circulating fluidized bed[J]. Chemical Engineering Journal, 2008, 145(1): 32-43. |

| [16] | Chen H Z, Tian X X, Gu S M, et al. Effect of mixing state of binary particles on bubble behavior in 2D fluidized bed[J]. Chemical Engineering Communications, 2018, 205(8): 1119-1128. |

| [17] | de Munck M J A, Marrevee D P F, Peters E A J F, et al. Experimental study on binary solids drying in a vibro-fluidized bed[J]. Powder Technology, 2024, 435: 119437. |

| [18] | 李静海, 欧阳洁, 高士秋, 等. 颗粒流体复杂系统的多尺度模拟[M]. 北京: 科学出版社, 2005. |

| Li J H, Ouyang J, Gao S Q, et al. Multi-scale Simulation of Particle-fluid Complex Systems[M]. Beijing: Science Press, 2005 | |

| [19] | 王维, 洪坤, 鲁波娜, 等. 流态化模拟: 基于介尺度结构的多尺度CFD[J]. 化工学报, 2013, 64(1): 95-106. |

| Wang W, Hong K, Lu B N, et al. Fluidized bed simulation: structure-dependent multiscale CFD[J]. CIESC Journal, 2013, 64(1): 95-106. | |

| [20] | Wang J W. A review of eulerian simulation of geldart A particles in gas-fluidized beds[J]. Industrial & Engineering Chemistry Research, 2009, 48(12): 5567-5577. |

| [21] | Hou B L, Li H Z, Zhu Q S. Relationship between flow structure and mass transfer in fast fluidized bed[J]. Chemical Engineering Journal, 2010, 163(1/2): 108-118. |

| [22] | Chen H Z, Gu S M, Li H Z. Simulation gas-solid flow in the downer with new structure-based drag model[J]. Powder Technology, 2018, 323: 163-175. |

| [23] | 祝赫, 张仪, 齐娜娜, 等. 欧拉-欧拉双流体模型中颗粒黏性对液固散式流态化的影响[J]. 化工学报, 2024, 75(9): 3103-3112. |

| Zhu H, Zhang Y, Qi N N, et al. Effect of particle viscosity in two-fluid model on homogeneous liquid-solid fluidization under Euler-Euler framework[J]. CIESC Journal, 2024, 75(9): 3103-3112. | |

| [24] | 刘岑凡, 张楠, 王维. 鼓泡床中基于气泡结构的多相反应模型[J]. 化工学报, 2018, 69(5): 2057-2062. |

| Liu C F, Zhang N, Wang W. Multiphase reaction model based on bubble structures in bubbling bed[J]. CIESC Journal, 2018, 69(5): 2057-2062. | |

| [25] | Spalart P R, Moser R D, Rogers M M. Spectral methods for the Navier-Stokes equations with one infinite and two periodic directions[J]. Journal of Computational Physics, 1991, 96(2): 297-324. |

| [26] | He P. A high order finite difference solver for massively parallel simulations of stably stratified turbulent channel flows[J]. Computers & Fluids, 2016, 127: 161-173. |

| [27] | Hu J J, Lu Z, Yang Y. Improving prediction of preferential concentration in particle-laden turbulence using the neural-network interpolation[J]. Physical Review Fluids, 2024, 9(3): 034606. |

| [28] | Tsuji Y, Morikawa Y, Shiomi H. LDV measurements of an air-solid two-phase flow in a vertical pipe[J]. Journal of Fluid Mechanics, 1984, 139: 417-434. |

| [29] | Tanaka T, Eaton J K. Classification of turbulence modification by dispersed spheres using a novel dimensionless number[J]. Physical Review Letters, 2008, 101(11): 114502. |

| [30] | 王兵, 刘毅, 王希麟. 颗粒粒径和气载比改变时湍流调制的变化[J]. 航空动力学报, 2009, 24(8): 1818-1823. |

| Wang B, Liu Y, Wang X L. Turbulence modulations caused by change of particle size and particle mass loading ratio[J]. Journal of Aerospace Power, 2009, 24(8): 1818-1823. | |

| [31] | Panarese A, Bruno D, Colonna G, et al. A Monte Carlo model for determination of binary diffusion coefficients in gases[J]. Journal of Computational Physics, 2011, 230(14): 5716-5721. |

| [32] | Launder B E, Spalding D B. Lectures in Mathematical Models of Turbulence[M]. London: Academic Press, 1972. |

| [33] | Launder B E. Second-moment closure: present and future[J]. International Journal of Heat and Fluid Flow, 1989, 10(4): 282-300. |

| [34] | Zou Z, Li H Z, Zhu Q S. The bubbling behavior of cohesive particles in the 2D fluidized beds[J]. Powder Technology, 2011, 212(1): 258-266. |

| [35] | Cano-Pleite E, Shimizu Y, Acosta-Iborra A, et al. Effect of vertical vibration and particle size on the solids hold-up and mean bubble behavior in a pseudo-2D fluidized bed[J]. Chemical Engineering Journal, 2016, 304: 384-398. |

| [1] | 赵子祥, 段钟弟, 孙浩然, 薛鸿祥. 大温差两相流动诱导水锤冲击的数值模型[J]. 化工学报, 2025, 76(S1): 170-180. |

| [2] | 曹庆泰, 郭松源, 李建强, 蒋赞, 汪彬, 耑锐, 吴静怡, 杨光. 负过载下多孔隔板对液氧贮箱蓄液性能的影响研究[J]. 化工学报, 2025, 76(S1): 217-229. |

| [3] | 孙九春, 桑运龙, 王海涛, 贾浩, 朱艳. 泥水盾构仓体内射流对泥浆输送特性影响研究[J]. 化工学报, 2025, 76(S1): 246-257. |

| [4] | 孔俊龙, 毕扬, 赵耀, 代彦军. 储能电池直冷热管理系统的模拟实验[J]. 化工学报, 2025, 76(S1): 289-296. |

| [5] | 燕子腾, 詹飞龙, 丁国良. 空调用套管式分流器结构设计及分流效果验证[J]. 化工学报, 2025, 76(S1): 152-159. |

| [6] | 段浩磊, 陈浩远, 梁坤峰, 王林, 陈彬, 曹勇, 张晨光, 李硕鹏, 朱登宇, 何亚茹, 杨大鹏. 纯电动车热管理系统低GWP工质替代方案性能分析与综合评价[J]. 化工学报, 2025, 76(S1): 54-61. |

| [7] | 郭松源, 周晓庆, 缪五兵, 汪彬, 耑锐, 曹庆泰, 陈成成, 杨光, 吴静怡. 火箭上升段含多孔板液氧贮箱增压输运数值研究[J]. 化工学报, 2025, 76(S1): 62-74. |

| [8] | 王俊鹏, 冯佳琪, 张恩搏, 白博峰. 曲折式与阵列式迷宫阀芯结构内流动与空化特性研究[J]. 化工学报, 2025, 76(S1): 93-105. |

| [9] | 谷德银, 杨豪, 李昌树, 刘作华. 分形穿流桨搅拌槽内假塑性流体的混合行为[J]. 化工学报, 2025, 76(6): 2569-2579. |

| [10] | 米晓天, 刘宏臣, 王克军, 唐文娜, 徐永伟, 杨梅. 微通道内两相吸收剂TETA/DEEA吸收CO2过程的传质研究[J]. 化工学报, 2025, 76(6): 2667-2677. |

| [11] | 王富玉, 周晅毅. 结合非定常伴随方程和遗传算法的化工区反演[J]. 化工学报, 2025, 76(6): 3104-3114. |

| [12] | 陈巨辉, 陈轲, 李丹, 杨天一, ZHURAVKOV Michael, LAPATSIN Siarhel, 姜文锐. 基于多组分DQMOM模型的FCC辅助纳米颗粒混合体系流化研究[J]. 化工学报, 2025, 76(6): 2616-2625. |

| [13] | 何昌秋, 田加猛, 陈义齐, 朱宇琛, 刘鑫, 王海, 王贞涛, 王军锋, 周致富, 陈斌. 电场-宏观结构表面协同强化薄液膜沸腾传热特性[J]. 化工学报, 2025, 76(6): 2589-2602. |

| [14] | 牛宏斌, 邱丽, 杨景轩, 张忠林, 郝晓刚, 赵忠凯, 阿布里提, 官国清. 筒体直径对旋风分离器性能的影响及其流场机制[J]. 化工学报, 2025, 76(5): 2367-2376. |

| [15] | 徐东菱, 马跃, 龚露, 马桂丽, 王金可, 郭丰志, 王浩伦, 李思佳, 李术元, 岳长涛. 油页岩与烟煤混合流化热解实验研究[J]. 化工学报, 2025, 76(4): 1742-1753. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号