化工学报 ›› 2025, Vol. 76 ›› Issue (7): 3246-3258.DOI: 10.11949/0438-1157.20241414

收稿日期:2024-12-05

修回日期:2025-01-23

出版日期:2025-07-25

发布日期:2025-08-13

通讯作者:

王淑彦

作者简介:陈曦(1997—),女,博士研究生,chenxi123@stu.nepu.edu.cn

基金资助:

Xi CHEN( ), Shuyan WANG(

), Shuyan WANG( ), Baoli SHAO, Nuo DING, Lei XIE

), Baoli SHAO, Nuo DING, Lei XIE

Received:2024-12-05

Revised:2025-01-23

Online:2025-07-25

Published:2025-08-13

Contact:

Shuyan WANG

摘要:

在液固流化床中,由于液相黏附力的作用,液体附着在颗粒表面会形成一层薄膜,引起颗粒弹性恢复系数的变化,从而影响颗粒的碰撞行为。与此同时,颗粒的脉动特性也表现出各向异性。故基于双流体模型和各向异性颗粒动理学理论,考虑颗粒恢复系数的动态变化,建立了液膜作用下颗粒动态恢复系数二阶矩模型,以研究液固流化床中包裹液膜颗粒的各向异性流动行为。模拟结果表明,液膜的存在增强了颗粒碰撞时的能量耗散,并减小了颗粒速度脉动的各向异性。随着液体黏度与颗粒密度的增加,液膜厚度增大,颗粒速度脉动与各向异性减弱。另外,动态恢复系数二阶矩模型所预测的颗粒速度和孔隙率分布与Limtrakul的实验值吻合更好,可以更准确地捕捉流场的不均匀性和各向异性特征。

中图分类号:

陈曦, 王淑彦, 邵宝力, 丁诺, 谢磊. 基于颗粒动态恢复系数二阶矩模型的液固流化床数值模拟研究[J]. 化工学报, 2025, 76(7): 3246-3258.

Xi CHEN, Shuyan WANG, Baoli SHAO, Nuo DING, Lei XIE. Numerical simulation study of liquid-solid fluidized beds based on second-order moment model of particle dynamic restitution coefficient[J]. CIESC Journal, 2025, 76(7): 3246-3258.

| 参数 | 实验 | 模拟 |

|---|---|---|

| 床高/m | 1.5 | 1.5 |

| 床宽/m | 0.14 | 0.14 |

| 初始床高/m | 0.45 | 0.45 |

| 初始颗粒堆积浓度 | 0.598 | 0.598 |

| 液体黏度/(Pa·s) | 0.001 | 0.001 |

| 液体密度/(kg/m3) | 994 | 994 |

| 流体进口速度/(m/s) | 0.07 | 0.07 |

| 颗粒密度/(kg/m3) | 2500 | 2500 |

| 颗粒直径/mm | 3 | 3 |

| 泊松比 | 0.25 | 0.25 |

| 杨氏模量/GPa | 70 | 70 |

表1 液固流化床模拟参数

Table 1 Simulated parameters of liquid-solid fluidized bed

| 参数 | 实验 | 模拟 |

|---|---|---|

| 床高/m | 1.5 | 1.5 |

| 床宽/m | 0.14 | 0.14 |

| 初始床高/m | 0.45 | 0.45 |

| 初始颗粒堆积浓度 | 0.598 | 0.598 |

| 液体黏度/(Pa·s) | 0.001 | 0.001 |

| 液体密度/(kg/m3) | 994 | 994 |

| 流体进口速度/(m/s) | 0.07 | 0.07 |

| 颗粒密度/(kg/m3) | 2500 | 2500 |

| 颗粒直径/mm | 3 | 3 |

| 泊松比 | 0.25 | 0.25 |

| 杨氏模量/GPa | 70 | 70 |

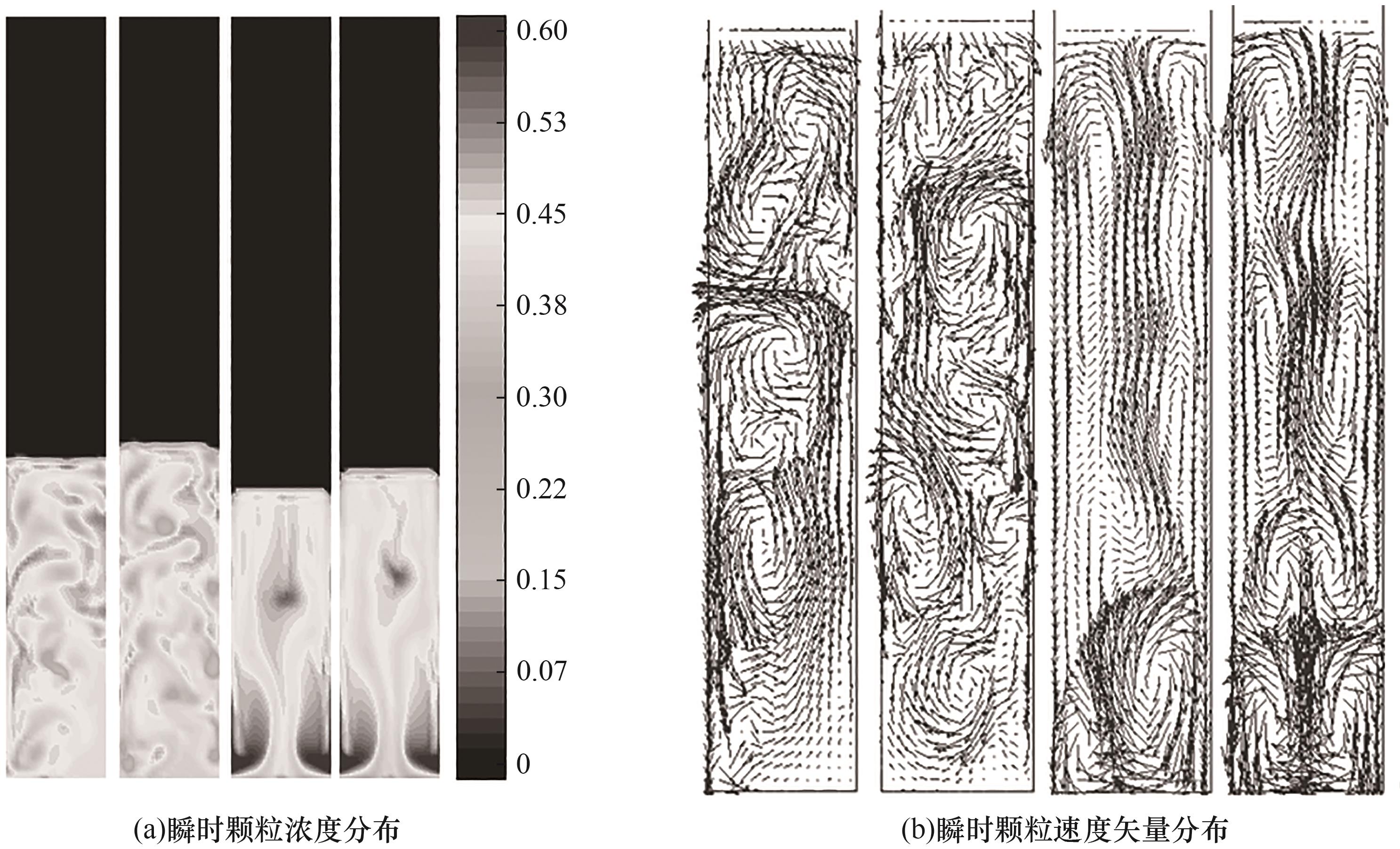

图4 瞬时颗粒浓度与速度矢量分布(从左到右依次为SOM-edynamic、SOM、KTGF-edynamic、KTGF模型)

Fig.4 Distributions of instantaneous particle concentration and velocity vector (from left to right: SOM-edynamic, SOM, KTGF-edynamic, KTGF models)

| [1] | Thombare M A, Chavan P V, Bankar S B, et al. Solid-liquid circulating fluidized bed: a way forward[J]. Reviews in Chemical Engineering, 2018, 35(1): 1-44. |

| [2] | Gui L T, Yang H T, Huang H, et al. Liquid solid fluidized bed crystallization granulation technology: development, applications, properties, and prospects[J]. Journal of Water Process Engineering, 2022, 45: 102513. |

| [3] | Dabbagh F, Schneiderbauer S. Anisotropy characterization of turbulent fluidization[J]. Physical Review Fluids, 2022, 7(9): 094301. |

| [4] | Jiang Z C, Hagemeier T, Bück A, et al. Experimental measurements of particle collision dynamics in a pseudo-2D gas-solid fluidized bed[J]. Chemical Engineering Science, 2017, 167: 297-316. |

| [5] | Vaidheeswaran A, Shaffer F, Gopalan B. Statistics of velocity fluctuations of Geldart A particles in a circulating fluidized bed riser[J]. Physical Review Fluids, 2017, 2(11): 112301. |

| [6] | Tartan M, Gidaspow D. Measurement of granular temperature and stresses in risers[J]. AIChE Journal, 2004, 50(8): 1760-1775. |

| [7] | Jung J, Gidaspow D, Gamwo I K. Measurement of two kinds of granular temperatures, stresses, and dispersion in bubbling beds[J]. Industrial & Engineering Chemistry Research, 2005, 44(5): 1329-1341. |

| [8] | Peng W G, He Y R, Wang T Y. Granular temperature with discrete element method simulation in a bubbling fluidized bed[J]. Advanced Powder Technology, 2014, 25(3): 896-903. |

| [9] | Gidaspow D, Jung J, Singh R K. Hydrodynamics of fluidization using kinetic theory: an emerging paradigm 2002 Flour-Daniel lecture[J]. Powder Technology, 2004, 148(2/3): 123-141. |

| [10] | Ng B H, Ding Y L, Ghadiri M. Assessment of the kinetic-frictional model for dense granular flow[J]. Particuology, 2008, 6(1): 50-58. |

| [11] | Liu Y, Liu J T, Li X L, et al. Large eddy simulation of particle hydrodynamic characteristics in a dense gas-particle bubbling fluidized bed[J]. Powder Technology, 2024, 433: 119285. |

| [12] | Sun D. Gas-particle flow of pneumatic conveying in vertical pipes simulated using four-way coupled second-order moment method[J]. Powder Technology, 2023, 416: 118225. |

| [13] | Chen J H, Shi X, Wang S, et al. Investigation into fluctuating anisotropy for biomass gasification in bubbling fluidized bed gasifier[J]. Applied Thermal Engineering, 2018, 138: 774-782. |

| [14] | Lu H, Chen J H, Liu G D, et al. Simulated second-order moments of clusters and dispersed particles in riser[J]. Chemical Engineering Science, 2013, 101: 800-812. |

| [15] | Liu H L, Li G H, Liu Y. Hydrodynamic predictions of the ultralight particle dispersions in a bubbling fluidized bed[J]. Processes, 2022, 10(7): 1390. |

| [16] | Zhong H B, Zhang Y N, Xiong Q G, et al. Two-fluid modeling of a wet spouted fluidized bed with wet restitution coefficient model[J]. Powder Technology, 2020, 364: 363-372. |

| [17] | Zhu L H, Zhao Z Y, Liu C, et al. CFD-DEM simulations of a gas-solid-liquid fluidization system: effects on the flow field and particle behavior of semi-dry desulfurization fluidized bed[J]. Journal of Environmental Chemical Engineering, 2023, 11(3): 109973. |

| [18] | Buck B, Heinrich S. Collision dynamics of wet particles: comparison of literature models to new experiments[J]. Advanced Powder Technology, 2019, 30(12): 3241-3252. |

| [19] | Pan S Y, Ma J L, Liu D Y, et al. Theoretical and experimental insight into the homogeneous expansion of wet particles in a fluidized bed[J]. Powder Technology, 2022, 397: 117016. |

| [20] | Tian R C, Wang S Y, Li X, et al. Hydrodynamics of wet particles in liquid-solid fluidized beds using kinetic theory of rough spheres model[J]. Powder Technology, 2021, 392: 524-535. |

| [21] | Ren A X, Tang T Q, He Y R. Evolution of mesoscale structure in fluidized beds with non-spherical dry and wet particles[J]. Advanced Powder Technology, 2022, 33(11): 103794. |

| [22] | Liu G D, Yu F, Lu H L, et al. CFD-DEM simulation of liquid-solid fluidized bed with dynamic restitution coefficient[J]. Powder Technology, 2016, 304: 186-197. |

| [23] | Gao Z Y, Liu G D, Guo X Y, et al. A dynamic coefficient of restitution applied to two-fluid model in liquid-solid fluidized bed[J]. Powder Technology, 2022, 402: 117335. |

| [24] | Yuan Z H, Wang S Y, Shao B L, et al. Simulation study on the flow behavior of wet particles in the power-law liquid-solid fluidized bed[J]. Powder Technology, 2023, 415: 118117. |

| [25] | Gollwitzer F, Rehberg I, Kruelle C A, et al. Coefficient of restitution for wet particles[J]. Physical Review E. Statistical, Nonlinear, and Soft Matter Physics, 2012, 86(1 Pt 1): 011303. |

| [26] | Davis R H, Serayssol J M, Hinch E J. The elastohydrodynamic collision of two spheres[J]. Journal of Fluid Mechanics, 1986, 163: 479-497. |

| [27] | Barnocky G, Davis R H. Elastohydrodynamic collision and rebound of spheres: experimental verification[J]. Physics of Fluids, 1988, 31(6): 1324-1329. |

| [28] | Davis R H, Rager D A, Good B T. Elastohydrodynamic rebound of spheres from coated surfaces[J]. Journal of Fluid Mechanics, 2002, 468(1): 107-119. |

| [29] | Sun D, Wang S Y, Lu H L, et al. A second-order moment method of dense gas-solid flow for bubbling fluidization[J]. Chemical Engineering Science, 2009, 64(23): 5013-5027. |

| [30] | Sun D, Wang J Z, Lu H L, et al. Numerical simulation of gas-particle flow with a second-order moment method in bubbling fluidized beds[J]. Powder Technology, 2010, 199(3): 213-225. |

| [31] | Grad H. On the kinetic theory of rarefied gases[J]. Communications on Pure and Applied Mathematics, 1949, 2(4): 331-407. |

| [32] | Jenkins J T, Richman M W. Grad's 13-moment system for a dense gas of inelastic spheres[J]. Archive for Rational Mechanics and Analysis, 1985, 87(4): 355-377. |

| [33] | Peirano E, Leckner B. Fundamentals of turbulent gas-solid flows applied to circulating fluidized bed combustion[J]. Progress in Energy and Combustion Science, 1998, 24(4): 259-296. |

| [34] | Gidaspow D. Multiphase Flow and Fluidization: Continuum and Kinetic Theory Descriptions[M]. Boston: Academic Press, 1994. |

| [35] | Koch D L, Sangani A S. Particle pressure and marginal stability limits for a homogeneous monodisperse gas-fluidized bed: kinetic theory and numerical simulations[J]. Journal of Fluid Mechanics, 1999, 400: 229-263. |

| [36] | Johnson P C, Nott P, Jackson R. Frictional-collisional equations of motion for participate flows and their application to chutes[J]. Journal of Fluid Mechanics, 1990, 210: 501-535. |

| [37] | Johnson P C, Jackson R. Frictional-collisional constitutive relations for granular materials, with application to plane shearing[J]. Journal of Fluid Mechanics, 1987, 176: 67-93. |

| [38] | Limtrakul S, Chen J W, Ramachandran P A, et al. Solids motion and holdup profiles in liquid fluidized beds[J]. Chemical Engineering Science, 2005, 60(7): 1889-1900. |

| [1] | 孙九春, 桑运龙, 王海涛, 贾浩, 朱艳. 泥水盾构仓体内射流对泥浆输送特性影响研究[J]. 化工学报, 2025, 76(S1): 246-257. |

| [2] | 郭松源, 周晓庆, 缪五兵, 汪彬, 耑锐, 曹庆泰, 陈成成, 杨光, 吴静怡. 火箭上升段含多孔板液氧贮箱增压输运数值研究[J]. 化工学报, 2025, 76(S1): 62-74. |

| [3] | 王芳, 马素霞, 田营, 刘众元. 基于LSTM动态修正一维机理模型的CFB机组NO x 排放浓度预测方法[J]. 化工学报, 2025, 76(7): 3416-3425. |

| [4] | 夏天炜, 王谙词, 句子涵, 孙晓霞, 胡定华. 基于三周期极小曲面结构的高密度储热器蓄放热特性研究[J]. 化工学报, 2025, 76(7): 3605-3614. |

| [5] | 王富玉, 周晅毅. 结合非定常伴随方程和遗传算法的化工区反演[J]. 化工学报, 2025, 76(6): 3104-3114. |

| [6] | 陈巨辉, 陈轲, 李丹, 杨天一, ZHURAVKOV Michael, LAPATSIN Siarhel, 姜文锐. 基于多组分DQMOM模型的FCC辅助纳米颗粒混合体系流化研究[J]. 化工学报, 2025, 76(6): 2616-2625. |

| [7] | 张亿韵, 陈恒志, 李洋, 慕长安, 王泉海. 湍流对双组分颗粒流化床气体径向扩散的影响[J]. 化工学报, 2025, 76(6): 2559-2568. |

| [8] | 郭江悦, 常守金, 胡海涛. 水平管内甲醇流动冷凝数值模拟研究[J]. 化工学报, 2025, 76(6): 2580-2588. |

| [9] | 王令颁, 孙漪霏, 卜禹豪, 许振彬, 孙贤, 邵瀚锋, 孙长宇, 陈光进. 大尺度扇柱形反应釜内甲烷水合物降压开采规律研究[J]. 化工学报, 2025, 76(6): 2958-2973. |

| [10] | 谷德银, 杨豪, 李昌树, 刘作华. 分形穿流桨搅拌槽内假塑性流体的混合行为[J]. 化工学报, 2025, 76(6): 2569-2579. |

| [11] | 牛宏斌, 邱丽, 杨景轩, 张忠林, 郝晓刚, 赵忠凯, 阿布里提, 官国清. 筒体直径对旋风分离器性能的影响及其流场机制[J]. 化工学报, 2025, 76(5): 2367-2376. |

| [12] | 徐东菱, 马跃, 龚露, 马桂丽, 王金可, 郭丰志, 王浩伦, 李思佳, 李术元, 岳长涛. 油页岩与烟煤混合流化热解实验研究[J]. 化工学报, 2025, 76(4): 1742-1753. |

| [13] | 徐东亮, 赵彬彬, 孙逸玫, 刘婷婷, 刘筱然, 陈明功. 基于修正多孔介质模型的RPB模拟与流场特性研究[J]. 化工学报, 2025, 76(4): 1569-1582. |

| [14] | 姚国家, 王志, 苏昂, 冯东阁, 唐宏, 孙灵芳. 空气系数对煤粉预热解燃烧特性的影响分析[J]. 化工学报, 2025, 76(3): 1243-1252. |

| [15] | 李舒月, 王欢, 周少强, 毛志宏, 张永民, 王军武, 吴秀花. 重质颗粒流态化研究现状与展望[J]. 化工学报, 2025, 76(2): 466-483. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号