化工学报 ›› 2019, Vol. 70 ›› Issue (8): 3040-3049.DOI: 10.11949/0438-1157.20190312

亚力昆江·吐尔逊null1( ),艾热提·阿不都艾尼null1,潘岳1,阿布力克木·阿布力孜null1,迪丽努尔·塔力甫null1,马凤云1,徐绍平2

),艾热提·阿不都艾尼null1,潘岳1,阿布力克木·阿布力孜null1,迪丽努尔·塔力甫null1,马凤云1,徐绍平2

收稿日期:2019-04-01

修回日期:2019-07-03

出版日期:2019-08-05

发布日期:2019-08-05

通讯作者:

亚力昆江·吐尔逊null

作者简介:亚力昆江·吐尔逊(1984—),男,博士,讲师,<email>yalkunjan54@ aliyun.com</email>

基金资助:

Tursun YALKUNJAN1( ),Abduhani HAIRAT1,Yue PAN1,Abulizi ABULIKEMU1,Talifu DILINUER1,Fengyun MA1,Shaoping XU2

),Abduhani HAIRAT1,Yue PAN1,Abulizi ABULIKEMU1,Talifu DILINUER1,Fengyun MA1,Shaoping XU2

Received:2019-04-01

Revised:2019-07-03

Online:2019-08-05

Published:2019-08-05

Contact:

Tursun YALKUNJAN

摘要:

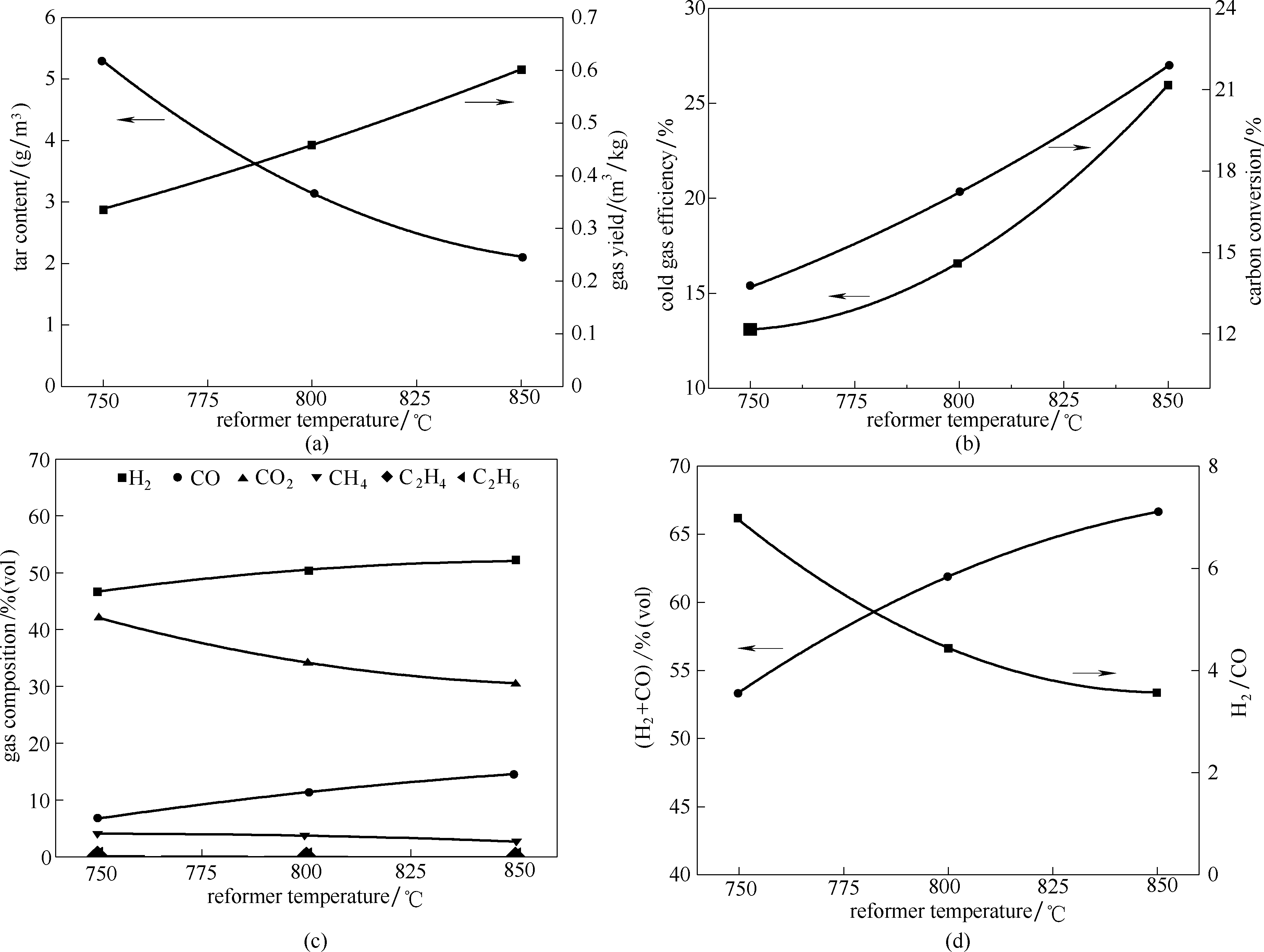

采用热解、重整、燃烧解耦分离的解耦三床气化(decoupled triple bed gasification,DTBG)系统,以橄榄石为原位焦油裂解催化床料,进行了煤催化气化实验。研究了煤种、煤进料速率、重整器温度以及水碳比(S/C)对煤热解焦油裂解/重整反应的影响。结果显示:随着煤挥发分含量增加,气体产率、碳转化率、冷煤气效率以及产气中的H2含量增加。由于半焦不参与气化反应,导致碳转化率和冷煤气效率偏低。煤和催化剂比例的改变会影响气体产率和产气组成,当煤的进料速率从0.12 kg/h增加到0.30 kg/h时,气体产率从0.28 m3/kg增加到0.46 m3/kg,H2含量从28.4%增加到50.5%。重整器温度的升高有利于促进煤焦油裂解转化,从而增加气体产率。当重整器温度为850℃、S/C为1.0时,气体产率达到了0.60 m3/kg, 橄榄石催化剂有效地降低了焦油含量,焦油产率仅为2.11g/m3。S/C的升高增强了焦油水蒸气重整反应,但引入过量的水蒸气会导致反应器内气体的流速加快,缩短了反应物的停留时间和反应时长,减缓了焦油水蒸气重整反应的反应程度。

中图分类号:

亚力昆江·吐尔逊null, 艾热提·阿不都艾尼null, 潘岳, 阿布力克木·阿布力孜null, 迪丽努尔·塔力甫null, 马凤云, 徐绍平. 热解-重整-燃烧解耦的煤气化特性[J]. 化工学报, 2019, 70(8): 3040-3049.

Tursun YALKUNJAN, Abduhani HAIRAT, Yue PAN, Abulizi ABULIKEMU, Talifu DILINUER, Fengyun MA, Shaoping XU. Gasification characteristics of coal in decoupled triple bed[J]. CIESC Journal, 2019, 70(8): 3040-3049.

| 原料 | 工业分析(ad)/%(mass) | 元素分析(daf)/%(mass) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 水分 | 灰分 | 挥发分 | 固定碳 | C | H | O | N | S | |

| WCW | 6.96 | 19.13 | 30.56 | 43.35 | 73.77 | 3.65 | 19.64 | 0.82 | 2.12 |

| NMG | 10.47 | 3.66 | 28.88 | 56.99 | 76.97 | 4.09 | 17.64 | 0.70 | 0.60 |

| HEM | 1.82 | 5.71 | 41.29 | 51.18 | 75.60 | 5.03 | 18.05 | 0.90 | 0.42 |

表1 煤的工业分析和元素分析结果

Table 1 Proximate and ultimate analysis of coal

| 原料 | 工业分析(ad)/%(mass) | 元素分析(daf)/%(mass) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 水分 | 灰分 | 挥发分 | 固定碳 | C | H | O | N | S | |

| WCW | 6.96 | 19.13 | 30.56 | 43.35 | 73.77 | 3.65 | 19.64 | 0.82 | 2.12 |

| NMG | 10.47 | 3.66 | 28.88 | 56.99 | 76.97 | 4.09 | 17.64 | 0.70 | 0.60 |

| HEM | 1.82 | 5.71 | 41.29 | 51.18 | 75.60 | 5.03 | 18.05 | 0.90 | 0.42 |

| MgO | TiO2 | Al2O3 | Fe2O3 | CaO | NiO | SiO2 | K2O |

|---|---|---|---|---|---|---|---|

| 42.95 | 0.06 | 1.00 | 9.57 | 1.09 | 0.38 | 44.77 | 0.05 |

表2 橄榄石的XRF化学组成分析

Table 2 Chemical composition of olivine by XRF/%(mass)

| MgO | TiO2 | Al2O3 | Fe2O3 | CaO | NiO | SiO2 | K2O |

|---|---|---|---|---|---|---|---|

| 42.95 | 0.06 | 1.00 | 9.57 | 1.09 | 0.38 | 44.77 | 0.05 |

| Parameter | Value |

|---|---|

| total bed material inventory /kg | 5.0 |

| circulating rate of bed material /(kg/h) | 4.5 |

| coal feeding rate/ (kg/h) | 0.12-0.30 |

| bed materials particle size /mm | 0.45-0.90 |

| coal particle size /mm | 0.45-0.90 |

| residence time of solid in reformer/min | 30 |

| residence time of solid in pyrolyzer /min | 7 |

| bed height in the pyrolyzer /mm | 200 |

| reformer temperature /℃ | 750-850 |

| pyrolyzer temperature /℃ | 700 |

| combustor temperature /℃ | 850 |

| air flow rate of combustor/ (m3/h) | 4.2-4.6 |

| operation pressure/MPa | 0.1 |

表3 气化系统运行参数

Table 3 Operation parameters of gasification system

| Parameter | Value |

|---|---|

| total bed material inventory /kg | 5.0 |

| circulating rate of bed material /(kg/h) | 4.5 |

| coal feeding rate/ (kg/h) | 0.12-0.30 |

| bed materials particle size /mm | 0.45-0.90 |

| coal particle size /mm | 0.45-0.90 |

| residence time of solid in reformer/min | 30 |

| residence time of solid in pyrolyzer /min | 7 |

| bed height in the pyrolyzer /mm | 200 |

| reformer temperature /℃ | 750-850 |

| pyrolyzer temperature /℃ | 700 |

| combustor temperature /℃ | 850 |

| air flow rate of combustor/ (m3/h) | 4.2-4.6 |

| operation pressure/MPa | 0.1 |

图5 重整器温度对气体产率、焦油含量、气体组成、碳转化率和冷煤气效率的影响

Fig.5 Effect of reformer temperature on gas yield, tar content, gas composition, carbon conversion and cold gas efficiency

| 1 | 王亚雄, 杨景轩, 张忠林, 等. 低阶煤热解-气化-燃烧TBCFB系统模拟及优化[J]. 化工学报, 2018, 69(8): 3596-3604. |

| WangY X, YangJ X, ZhangZ L, et al. TBCFB system simulation and optimization for pyrolysis-gasification-combustion of low rank coal [J]. CIESC Journal, 2018, 69(8): 3596-3604. | |

| 2 | ZhangJ, WangY, DongL, et al. Decoupling gasification: approach principle and technology justification [J]. Energy Fuels, 2010, 24(12): 6223-6232. |

| 3 | KoppatzS, PfeiferC, RauchR, et al. H2 rich product gas by steam gasification of biomass with in situ CO2 absorption in a dual fluidized bed system of 100MW fuel input[J]. Fuel Processing Technology, 2009, 90(7/8): 914-921. |

| 4 | RehlingB, HofbauerH, RauchR, et al. BioSNG—process simulation and comparison with first results from a 1-MW demonstration plant[J]. Biomass Conversion and Biorefinery, 2011, 1(2): 111-119. |

| 5 | GuanG, FushimiC, TsutsumiA. Prediction of flow behavior of the riser in a novel high solids flux circulating fluidized bed for steam gasification of coal or biomass[J]. Chemical Engineering Journal, 2010, 164(1): 221-229. |

| 6 | GuanG, FushimiC, TsutsumiA, et al. High-density circulating fluidized bed gasifier for advanced IGCC/IGFC—advantages and challenges [J]. Particuology, 2010, 8(6): 602-606. |

| 7 | XuG, MurakamiT, SudaT, et al. Two-stage dual fluidized bed gasification: its conception and application to biomass[J]. Fuel Processing Technology, 2009, 90(1): 137-144. |

| 8 | ZengX, ShaoR, WangF, et al. Industrial demonstration plant for the gasification of herb residue by fluidized bed two-stage process[J]. Bioresource Technology, 2016, 206: 93-98. |

| 9 | HenriksenU, AhrenfeldtJ, JensenT K, et al. The design, construction and operation of a 75 kW two-stage gasifier[J]. Energy, 2006, 31(10/11): 1542-1553. |

| 10 | 张志远, 陈鸿伟, 赵争辉, 等. 钠盐对准东煤CO2吸附能力及气化特性的影响 [J]. 化工学报, 2017, 68(4): 1629-1636. |

| ZhangZ Y, ChenH W, ZhaoZ H, et al. Effect of sodium salts on CO2 adsorption capacity and gasification of Zhundong coal [J]. CIESC Journal, 2017, 68(4): 1629-1636. | |

| 11 | MarinkovicJ, ThunmanH, KnutssonP, et al. Characteristics of olivine as a bed material in an indirect biomass gasifier[J]. Chemical Engineering Journal, 2015, 279: 555-566. |

| 12 | ChristodoulouC, GrimekisD, PanopoulosK D, et al. Comparing calcined and un-treated olivine as bed materials for tar reduction in fluidized bed gasification [J]. Fuel Processing Technology, 2014, 124(5): 275-285. |

| 13 | 李兰兰, 郑安庆, 冯宜鹏, 等. 橄榄石对甲苯催化重整反应的影响[J]. 燃料化学学报, 2015, 43(7): 806-815. |

| LiL L, ZhengA Q, FengY P, et al. Effects of olivine on catalytic reforming of toluene[J]. Journal of Fuel Chemistry and Technology, 2015, 43(7): 806-815. | |

| 14 | 岳宝华, 卜宪昵, 汪学广, 等. 焙烧温度对橄榄石催化甲苯裂解性能的影响[J]. 化工学报, 2009, 60(2): 378-383. |

| YueB H, BuX N, WangX G, et al. Effect of calcination temperature on catalytic performance of olivine for toluene cracking[J]. CIESC Journal, 2009, 60(2): 378-383. | |

| 15 | ArandaG, DriftA V D, VreugdenhilB J, et al. Comparing direct and indirect fluidized bed gasification: effect of redox cycle on olivine activity (pages 711—720)[J]. Environmental Progress & Sustainable Energy, 2014, 33(3): 711-720. |

| 16 | FredrikssonH O A, LanceeR J, ThüneP C, et al. Olivine as tar removal catalyst in biomass gasification: catalyst dynamics under model conditions[J]. Applied Catalysis B: Environmental, 2013, 130/131(complete): 168-177. |

| 17 | ŚwierczyńskiD, CoursonC, BedelL, et al. Oxidation reduction behavior of iron-bearing olivines (FexMg1-x)2SiO4 used as catalysts for biomass gasification [J]. Chem. Mater., 2006, 18(4): 897-905. |

| 18 | DeviL, PtasinskiK J, JanssenF J. Pretreated olivine as tar removal catalyst for biomass gasifiers: investigation using naphthalene as model biomass tar [J]. Fuel Processing Technology, 2005, 86(6): 707-730. |

| 19 | DeviL, PtasinskiK J, JanssenF J. Decomposition of naphthalene as a biomass tar over pretreated olivine: effect of gas composition, kinetic approach, and reaction scheme [J]. Industrial & Engineering Chemistry Research, 2005, 44(24): 9096-9104. |

| 20 | 杨小芹, 徐绍平, 胡冠, 等. 不同矿源橄榄石对催化苯水蒸气重整的影响 [J]. 催化学报, 2009, 30(6): 497-502. |

| YangX Q, XuS P, HuG, et al. Effects of olivines from different quarries on the steam reforming of benzene[J]. Chinese Journal of Catalysis, 2009, 30(6): 497-502. | |

| 21 | StefanK, PfeiferC, HofbauerH. Comparison of the performance behaviour of silica sand and olivine in a dual fluidised bed reactor system for steam gasification of biomass at pilot plant scale[J]. Chemical Engineering Journal, 2011, 175(22): 468-483. |

| 22 | 宋洋博, 徐绍平, 李伶俐, 等. Cu-橄榄石载氧体煤焦化学链气化实验研究[J]. 燃料化学学报, 2017, 45(8): 916-923. |

| SongY B, XuS P, LiL L, alet . Chemical looping gasification of coal char with Cu-olivine oxygen carriers[J]. Journal of Fuel Chemistry and Technology, 2017, 45(8): 916-923. | |

| 23 | 邓靖, 李文英, 李晓红, 等. 橄榄石基固体热载体影响褐煤热解产物分布的分析[J]. 燃料化学学报, 2013, 41: 937-942. |

| DengJ, LiW Y, LiX H, et al. Product distribution of lignite pyrolysis with olivine-based solid heat carrier[J]. Journal of Fuel Chemistry and Technology, 2013, 41: 937-942. | |

| 24 | 亚力昆江·吐尔逊, 潘岳, 别尔德汗·瓦提汗, 等. 基于热解-重整-燃烧解耦三床气化系统的生物质催化制富氢气体[J]. 农业工程学报, 2018, (1): 222-228. |

| YalkunjanT, PanY, BieerdehanW, et al. Catalytic biomass gasification for hydrogen rich gas production in decoupled-triple-bed gasification system[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, (1): 222-228. | |

| 25 | TursunY, XuS, AbulikemuA, et al. Biomass gasification for hydrogen rich gas in a decoupled triple bed gasifier with olivine and NiO/olivine [J]. Bioresour. Technol., 2019, 272: 241-248. |

| 26 | TursunY, XuS, WangG, et al. Tar formation during co-gasification of biomass and coal under different gasification condition[J]. Journal of Analytical and Applied Pyrolysis, 2015, 111: 191-199. |

| 27 | XiaoY, XuS, TursunY, et al. Catalytic steam gasification of lignite for hydrogen-rich gas production in a decoupled triple bed reaction system [J]. Fuel, 2017, 189: 57-65. |

| 28 | 魏立纲, 徐绍平, 刘长厚, 等. 预煅烧对橄榄石生物质气化催化性能的影响[J]. 燃料化学学报, 2008, 36: 426-430. |

| WeiL G, XuS P, LiuC H, et al. Effects of precalcination on catalytic activity of olivine in biomass gasification[J]. Journal of Fuel Chemistry and Technology, 2008, 36: 426-430. | |

| 29 | 崔银萍. 西部弱还原性煤在N2气氛中的热转化特性研究[D]. 太原: 太原理工大学, 2007. |

| CuiY P. The study on conversion character during pyrolysis of Chinese Western coals[D]. Taiyuan: Taiyuan University of Technology, 2007. | |

| 30 | 张志丰, 王亦飞, 朱龙雏, 等. 基于铁基载氧体的无烟煤化学链燃烧过程中硫分布特性[J]. 化工学报, 2018, 69(4): 1578-1585 |

| ZhangZ F, WangY F, ZhuL C, et al. Distribution of sulfur in chemical looping combustion of anthracite based on Fe-based oxygen carrier[J]. CIESC Journal, 2018, 69(4): 1578-1585. | |

| 31 | 田斌, 杨芳芳, 庞亚恒, 等. 气化温度对型煤加压固定床气化反应特性的影响[J]. 中国电机工程学报, 2013, 33(z1): 128-134. |

| TianB, YangF F, PangY H, et al. Effect of temperature on the reactivity characteristics of briquette during high pressure fixed-bed gasification[J]. Proceedings of the CSEE, 2013, 33(z1): 128-134. | |

| 32 | 乌晓江, 张忠孝, 朴桂林, 等. 煤粉加压气流床气化特性实验研究[J]. 工程热物理学报, 2008, 29(8): 1431-1434. |

| WuX J, ZhangZ X, PuG L, et al. Experimental study on gasification characteristics of coal in lab-scale down flow gasifier[J]. Journal of Engineering Thermophysics, 2008, 29(8): 1431-1434. | |

| 33 | 王勤辉, 揭涛, 李小敏, 等. 反应气氛对不同煤灰烧结温度影响的研究[J]. 燃料化学学报, 2010, 38(1): 17-22. |

| WangQ H, JieT, LiX M, et al. Experiments of the effects of reaction atmosphere on the coal ash sintering temperature[J]. Journal of Fuel Chemistry and Technology, 2010, 38(1): 17-22. |

| [1] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [2] | 韩晨, 司徒友珉, 朱斌, 许建良, 郭晓镭, 刘海峰. 协同处理废液的多喷嘴粉煤气化炉内反应流动研究[J]. 化工学报, 2023, 74(8): 3266-3278. |

| [3] | 李亚芾, 付亮亮, 白浩隆, 白丁荣, 许光文. 菱镁矿浮选尾矿直接合成同时制备镁橄榄石和镁砂研究[J]. 化工学报, 2022, 73(8): 3679-3687. |

| [4] | 张利合, 张凡, 李昌伦, 许德平, 徐振刚, 王永刚. BGL煤气化动力学模型构建与验证[J]. 化工学报, 2022, 73(10): 4668-4678. |

| [5] | 汪达, 王倩, 张建胜. 不同温度和冷却速率下高温灰渣的结晶行为[J]. 化工学报, 2018, 69(5): 2183-2190. |

| [6] | 周雷皓, 刘桂莲. 复杂反应的代数分析建模方法[J]. 化工学报, 2018, 69(3): 1030-1037. |

| [7] | 朱龙雏, 王亦飞, 陆志峰, 李季林, 王辅臣. 煤焦在气化合成气中高温气化反应特性[J]. 化工学报, 2017, 68(11): 4249-4260. |

| [8] | 赖登国, 战金辉, 陈兆辉, 韩振南, 武荣成, 许光文. 内构件移动床固体热载体油页岩热解技术[J]. 化工学报, 2017, 68(10): 3647-3657. |

| [9] | 李方舟, 李文英, 冯杰. 固体热载体法褐煤热解过程中的传质传热特性[J]. 化工学报, 2016, 67(4): 1136-1144. |

| [10] | 张润楠, 范晓晨, 贺明睿, 苏延磊, 姜忠义. 煤气化废水深度处理与回用研究进展[J]. 化工学报, 2015, 66(9): 3341-3349. |

| [11] | 钟伟民, 牛进伟, 梁毅, 孔祥东, 钱锋. 多策略果蝇优化算法及其应用[J]. 化工学报, 2015, 66(12): 4888-4894. |

| [12] | 诸林,张政,范峻铭. 基于化学链制氧的煤气化集成系统工艺参数分析[J]. 化工进展, 2014, 33(08): 1997-2003. |

| [13] | 桂霞1,王陈魏1,云志1,张玲1,汤志刚2. 燃烧前CO2捕集技术研究进展[J]. 化工进展, 2014, 33(07): 1895-1901. |

| [14] | 王灵萍, 王亦飞, 郭强强, 颜留成, 于广锁. 洗涤冷却管内垂直降膜流动特性[J]. 化工学报, 2013, 64(6): 1959-1968. |

| [15] | 张宇, 鄢烈祥, 李国建, 史彬. 非支配排序进化策略求解煤气化多目标优化问题[J]. 化工学报, 2013, 64(12): 4628-4633. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号