化工学报 ›› 2023, Vol. 74 ›› Issue (9): 3888-3902.DOI: 10.11949/0438-1157.20230689

收稿日期:2023-07-05

修回日期:2023-09-05

出版日期:2023-09-25

发布日期:2023-11-20

通讯作者:

张玉明

作者简介:陈哲文(1990—),男,博士,讲师,2022880013@cup.edu.cn

基金资助:

Zhewen CHEN( ), Junjie WEI, Yuming ZHANG(

), Junjie WEI, Yuming ZHANG( )

)

Received:2023-07-05

Revised:2023-09-05

Online:2023-09-25

Published:2023-11-20

Contact:

Yuming ZHANG

摘要:

基于超临界水煤气化合成气的富氢特征,提出了一种超临界水煤气化耦合固体氧化物燃料电池(SOFC)及燃气轮机发电系统,气化产物的高温高压显焓由膨胀机回收,化学能由SOFC及燃气轮机先后利用发电,燃气轮机排气及SOFC阴极空气的大部分显热用于预热锅炉给水。在气化温度660℃、气化压力250 bar (1 bar=0.1 MPa)及气化室内煤浆浓度为11.3%(质量)条件下,系统发电效率可以达到54.01%,㶲效率为52.79%。相比于先进的1000 MW超超临界蒸汽朗肯循环燃煤电站,所提新系统可实现年减排CO239万吨。提出的煤基发电系统,进一步深化了煤炭化学能的梯级利用,实现了各子单元间的高效能级匹配,有助于实现双碳目标。

中图分类号:

陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902.

Zhewen CHEN, Junjie WEI, Yuming ZHANG. System integration and energy conversion mechanism of the power technology with integrated supercritical water gasification of coal and SOFC[J]. CIESC Journal, 2023, 74(9): 3888-3902.

图3 超临界水煤气化耦合SOFC及燃气轮机发电系统流程图1,2—气化产物;3,6—合成气;4,5—水;7,8—重整后合成气;9,10—变换后合成气;11,12—剩余燃料气;13~15—空气;16~21—SOFC阴极出口空气;22,23—锅炉给水;24~26—燃气轮机排气;27—锅炉排烟;28,29—水;30—气化煤;31—燃料煤

Fig.3 The flow diagram of the power system with integrated supercritical water gasification of coal, SOFC and gas turbine

| 参数 | 取值 | 参数 | 取值 |

|---|---|---|---|

| 气化压力/bar | 250 | 超临界透平等熵效率/% | 90 |

| 气化温度/℃ | 660 | 燃气透平等熵效率/% | 89 |

| 锅炉夹点温度/℃ | 10 | 透平1等熵效率/% | 93 |

| 换热器及省煤器夹点温度/℃ | 10 | 压气机等熵效率/% | 88 |

| 锅炉内过量空气系数 | 1.3 | 重整/变换反应压力/bar | 15 |

| 水泵效率/% | 80 | 燃气透平压比 | 15 |

| SOFC工作压力/bar | 15 |

表1 关键参数取值

Table 1 The key parameters and values

| 参数 | 取值 | 参数 | 取值 |

|---|---|---|---|

| 气化压力/bar | 250 | 超临界透平等熵效率/% | 90 |

| 气化温度/℃ | 660 | 燃气透平等熵效率/% | 89 |

| 锅炉夹点温度/℃ | 10 | 透平1等熵效率/% | 93 |

| 换热器及省煤器夹点温度/℃ | 10 | 压气机等熵效率/% | 88 |

| 锅炉内过量空气系数 | 1.3 | 重整/变换反应压力/bar | 15 |

| 水泵效率/% | 80 | 燃气透平压比 | 15 |

| SOFC工作压力/bar | 15 |

| 煤 | 工业分析/%(mass, ar) | 元素分析/%(mass, ar) | 低位热值/ (MJ/kg) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 水分 | 灰分 | 挥发分 | 固定碳 | 碳 | 氢 | 氧 | 氮 | 硫 | ||

| 气化煤 | 2.79 | 6.84 | 33.19 | 57.18 | 74.29 | 4.69 | 9.26 | 1.00 | 1.12 | 25.40 |

| 燃料煤 | 8.84 | 9.98 | 49.52 | 31.66 | 68.55 | 3.96 | 6.85 | 0.74 | 1.08 | 26.71 |

表2 气化煤和燃料煤的工业和元素分析及低位热值

Table 2 The proximate and ultimate analysis and the lower heating value of the gasified and fuel coal

| 煤 | 工业分析/%(mass, ar) | 元素分析/%(mass, ar) | 低位热值/ (MJ/kg) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 水分 | 灰分 | 挥发分 | 固定碳 | 碳 | 氢 | 氧 | 氮 | 硫 | ||

| 气化煤 | 2.79 | 6.84 | 33.19 | 57.18 | 74.29 | 4.69 | 9.26 | 1.00 | 1.12 | 25.40 |

| 燃料煤 | 8.84 | 9.98 | 49.52 | 31.66 | 68.55 | 3.96 | 6.85 | 0.74 | 1.08 | 26.71 |

| 参数 | 取值 |

|---|---|

| 阳极厚度δan /m | 0.0001 |

| 阴极厚度δcat/m | 0.0022 |

| 电解质厚度δel/m | 0.00004 |

| 互连厚度δint/m | 0.000085 |

| 阳极电阻率ρan/(Ω·m) | |

| 阴极电阻率ρcat/(Ω·m) | |

| 电解液电阻率ρel /(Ω·m) | |

| 互连电阻率ρint/(Ω·m) |

表3 欧姆极化计算相关参数

Table 3 The relative parameters for calculating ohmic polarization

| 参数 | 取值 |

|---|---|

| 阳极厚度δan /m | 0.0001 |

| 阴极厚度δcat/m | 0.0022 |

| 电解质厚度δel/m | 0.00004 |

| 互连厚度δint/m | 0.000085 |

| 阳极电阻率ρan/(Ω·m) | |

| 阴极电阻率ρcat/(Ω·m) | |

| 电解液电阻率ρel /(Ω·m) | |

| 互连电阻率ρint/(Ω·m) |

| 单元 | 能量平衡 | 㶲平衡 |

|---|---|---|

| 超临界透平 | ||

| 燃烧室 | ||

| 压气机 | ||

| 燃气透平 | ||

| 换热器1 | ||

| 锅炉 | ||

| 换热器2 | ||

| 换热器3 | ||

| 省煤器1 | ||

| 省煤器2 | ||

| 重整反应 | ||

| 变换反应 | ||

| SOFC |

表4 发电系统不同单元或设备的能量及㶲平衡

Table 4 The energy and exergy balances of different units in the power system

| 单元 | 能量平衡 | 㶲平衡 |

|---|---|---|

| 超临界透平 | ||

| 燃烧室 | ||

| 压气机 | ||

| 燃气透平 | ||

| 换热器1 | ||

| 锅炉 | ||

| 换热器2 | ||

| 换热器3 | ||

| 省煤器1 | ||

| 省煤器2 | ||

| 重整反应 | ||

| 变换反应 | ||

| SOFC |

| 参数 | 文献[ | SOFC模型 |

|---|---|---|

| 发电量误差 | 0.82% | |

| 输出电压/V | 0.625 | 0.629 |

| 电池工作温度/K | 1173.15 | 1173.15 |

| 电流密度/( | 4000 | 4065 |

| SOFC发电量/kW | 465.63 | 469.43 |

表5 SOFC程序验证

Table 5 The verification of the SOFC program

| 参数 | 文献[ | SOFC模型 |

|---|---|---|

| 发电量误差 | 0.82% | |

| 输出电压/V | 0.625 | 0.629 |

| 电池工作温度/K | 1173.15 | 1173.15 |

| 电流密度/( | 4000 | 4065 |

| SOFC发电量/kW | 465.63 | 469.43 |

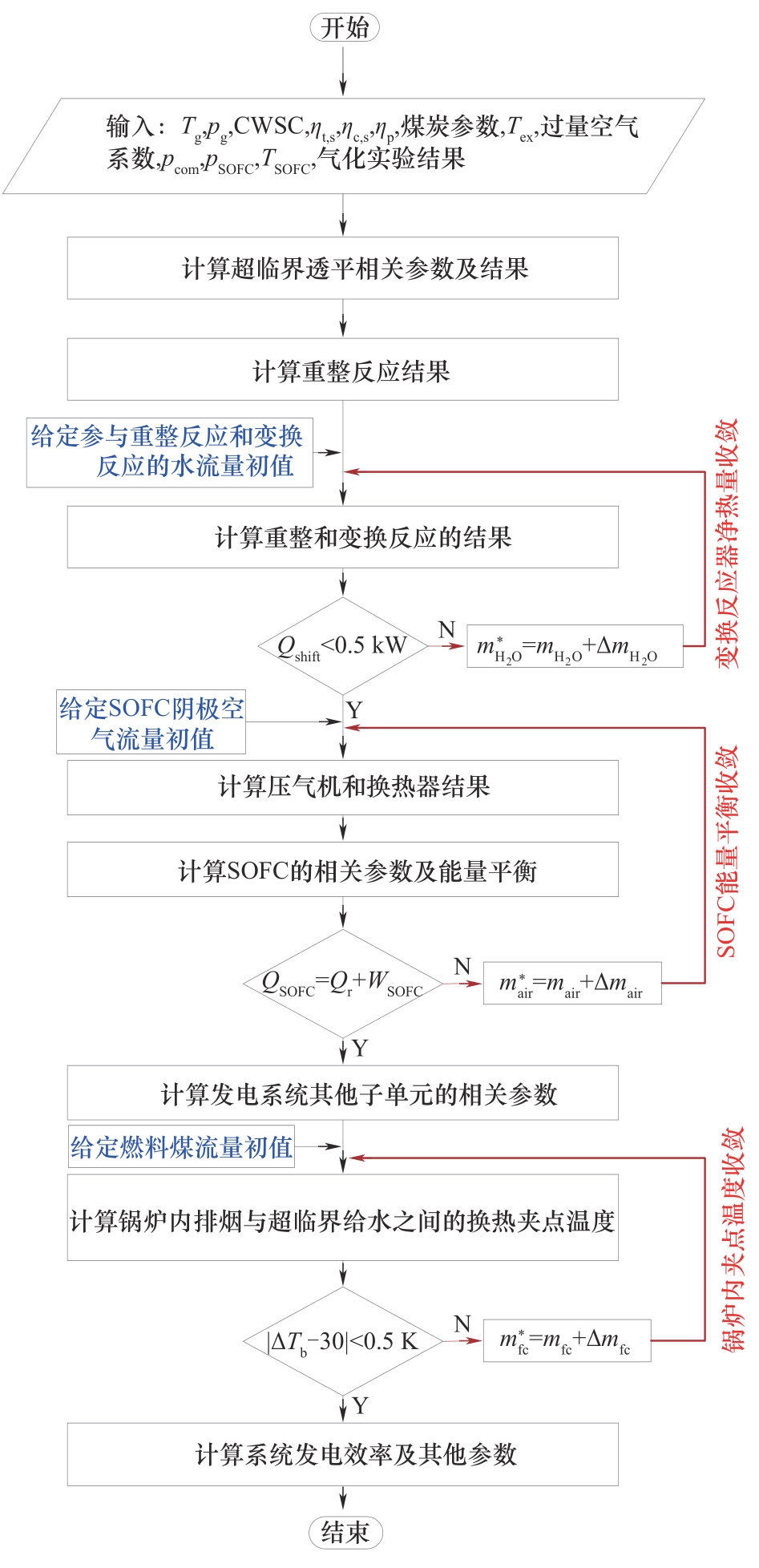

图5 超临界水煤气化耦合SOFC及燃气轮机发电系统计算框图

Fig.5 The computational flow diagram of the power system with integrated supercritical water gasification of coal, SOFC and gas turbine

| 物流 | 温度/℃ | 压力/bar | 摩尔流量/(kmol/s) |

|---|---|---|---|

| 1 | 660.0 | 250 | 0.484 |

| 2 | 92.0 | 1 | 0.484 |

| 3 | 25.0 | 1 | 0.112 |

| 4 | 25.0 | 1 | 0.372 |

| 5 | 26.9 | 250 | 0.436 |

| 6 | 960.0 | 1 | 0.112 |

| 7 | 750.0 | 15 | 0.186 |

| 8 | 90.0 | 15 | 0.186 |

| 9 | 220.0 | 15 | 0.226 |

| 10 | 640.0 | 15 | 0.226 |

| 11 | 979.4 | 15 | 0.226 |

| 12 | 538.5 | 15 | 0.226 |

| 13 | 25.0 | 1 | 0.420 |

| 14 | 407.8 | 15 | 0.420 |

| 15 | 640.0 | 15 | 0.420 |

| 16 | 979.4 | 15 | 0.365 |

| 17 | 724.4 | 15 | 0.365 |

| 18 | 429.1 | 15 | 0.365 |

| 19 | 163.0 | 15 | 0.365 |

| 20 | 161.8 | 15 | 0.187 |

| 21 | 25.0 | 1 | 0.178 |

| 22 | 152.3 | 250 | 0.436 |

| 23 | 229.3 | 250 | 0.436 |

| 24 | 901.0 | 15 | 0.402 |

| 25 | 475.8 | 1 | 0.402 |

| 26 | 120.0 | 1 | 0.402 |

| 27 | 120.0 | 1 | 0.452 |

| 28 | 650.0 | 15 | 0.035 |

| 29 | 454.4 | 15 | 0.04 |

| 30 | 25.0 | 1 | 1.000 |

| 31 | 25.0 | 1 | 1.123 |

表6 关键点物流参数

Table 6 The parameters of key points in the power system

| 物流 | 温度/℃ | 压力/bar | 摩尔流量/(kmol/s) |

|---|---|---|---|

| 1 | 660.0 | 250 | 0.484 |

| 2 | 92.0 | 1 | 0.484 |

| 3 | 25.0 | 1 | 0.112 |

| 4 | 25.0 | 1 | 0.372 |

| 5 | 26.9 | 250 | 0.436 |

| 6 | 960.0 | 1 | 0.112 |

| 7 | 750.0 | 15 | 0.186 |

| 8 | 90.0 | 15 | 0.186 |

| 9 | 220.0 | 15 | 0.226 |

| 10 | 640.0 | 15 | 0.226 |

| 11 | 979.4 | 15 | 0.226 |

| 12 | 538.5 | 15 | 0.226 |

| 13 | 25.0 | 1 | 0.420 |

| 14 | 407.8 | 15 | 0.420 |

| 15 | 640.0 | 15 | 0.420 |

| 16 | 979.4 | 15 | 0.365 |

| 17 | 724.4 | 15 | 0.365 |

| 18 | 429.1 | 15 | 0.365 |

| 19 | 163.0 | 15 | 0.365 |

| 20 | 161.8 | 15 | 0.187 |

| 21 | 25.0 | 1 | 0.178 |

| 22 | 152.3 | 250 | 0.436 |

| 23 | 229.3 | 250 | 0.436 |

| 24 | 901.0 | 15 | 0.402 |

| 25 | 475.8 | 1 | 0.402 |

| 26 | 120.0 | 1 | 0.402 |

| 27 | 120.0 | 1 | 0.452 |

| 28 | 650.0 | 15 | 0.035 |

| 29 | 454.4 | 15 | 0.04 |

| 30 | 25.0 | 1 | 1.000 |

| 31 | 25.0 | 1 | 1.123 |

| 参数 | 数值 |

|---|---|

| Nernst 电压/V | 1.026 |

| 欧姆活化损失/V | 0.093 |

| 活化极化损失/V | 0.134 |

| 浓差极化损失/V | 0.035 |

| SOFC工作电压/V | 0.764 |

| SOFC工作电流/A | 2.114×107 |

| SOFC电堆功率/kW | 16149.74 |

| 系统净发电量/kW | 29917.45 |

| 系统发电效率/% | 54.01 |

表7 系统计算结果与输出参数

Table 7 The calculation results of the system

| 参数 | 数值 |

|---|---|

| Nernst 电压/V | 1.026 |

| 欧姆活化损失/V | 0.093 |

| 活化极化损失/V | 0.134 |

| 浓差极化损失/V | 0.035 |

| SOFC工作电压/V | 0.764 |

| SOFC工作电流/A | 2.114×107 |

| SOFC电堆功率/kW | 16149.74 |

| 系统净发电量/kW | 29917.45 |

| 系统发电效率/% | 54.01 |

| 项目 | 本文 新系统 | 占比/% | 文献[ | 占比/% |

|---|---|---|---|---|

| 能量输入/kW | ||||

| 气化煤 | 25400.00 | 45.85 | 30275.76 | 54.65 |

| 燃料煤 | 29995.33 | 54.15 | 25119.57 | 45.35 |

| 总计 | 55395.33 | 100.00 | 55395.33 | 100.00 |

| 能量输出/kW | ||||

| 气化室未反应碳 | 1455.16 | 2.63 | 1734.49 | 3.13 |

| 超临界透平输出功 | 10492.00 | 18.94 | 12506.04 | 22.58 |

| 冷凝器 | 15849.35 | 28.61 | 19518.07 | 35.23 |

| 燃气透平输出功 | 7205.78 | 13.01 | 27980.64 | 50.51 |

| SOFC发电量 | 16149.74 | 29.15 | — | — |

| 压气机和泵耗功 | -5064.15 | -9.14 | -13307.43 | -24.02 |

| SOFC阴极空气透平输出功 | 1134.07 | 2.05 | — | — |

| 燃气轮机排烟 | 6832.50 | 12.33 | 5840.60 | 10.54 |

| 余热锅炉排烟及灰尘 | 1340.88 | 2.42 | 1122.92 | 2.03 |

| 总计 | 55395.33 | 100.00 | 55395.33 | 100.00 |

| 发电效率/% | 54.01 | 49.06 | ||

表8 发电系统能量平衡

Table 8 The energy balances of the power systems

| 项目 | 本文 新系统 | 占比/% | 文献[ | 占比/% |

|---|---|---|---|---|

| 能量输入/kW | ||||

| 气化煤 | 25400.00 | 45.85 | 30275.76 | 54.65 |

| 燃料煤 | 29995.33 | 54.15 | 25119.57 | 45.35 |

| 总计 | 55395.33 | 100.00 | 55395.33 | 100.00 |

| 能量输出/kW | ||||

| 气化室未反应碳 | 1455.16 | 2.63 | 1734.49 | 3.13 |

| 超临界透平输出功 | 10492.00 | 18.94 | 12506.04 | 22.58 |

| 冷凝器 | 15849.35 | 28.61 | 19518.07 | 35.23 |

| 燃气透平输出功 | 7205.78 | 13.01 | 27980.64 | 50.51 |

| SOFC发电量 | 16149.74 | 29.15 | — | — |

| 压气机和泵耗功 | -5064.15 | -9.14 | -13307.43 | -24.02 |

| SOFC阴极空气透平输出功 | 1134.07 | 2.05 | — | — |

| 燃气轮机排烟 | 6832.50 | 12.33 | 5840.60 | 10.54 |

| 余热锅炉排烟及灰尘 | 1340.88 | 2.42 | 1122.92 | 2.03 |

| 总计 | 55395.33 | 100.00 | 55395.33 | 100.00 |

| 发电效率/% | 54.01 | 49.06 | ||

| 项目 | 本文新系统 | 占比/% | 文献[ | 占比/% |

|---|---|---|---|---|

| 㶲输入/kW | ||||

| 气化煤 | 26015.83 | 45.91 | 31003.27 | 54.71 |

| 燃料煤 | 30649.04 | 54.09 | 25661.60 | 45.29 |

| 总计 | 56664.87 | 100.00 | 56664.87 | 100.00 |

| 㶲输出/kW | ||||

| 气化室未反应碳 | 1415.26 | 2.50 | 1686.58 | 2.98 |

| 净输出功 | 29917.44 | 52.80 | 27173.52 | 47.95 |

| 冷却器 | 2523.90 | 4.45 | 2924.31 | 5.16 |

| 锅炉排烟 | 186.39 | 0.33 | 156.05 | 0.28 |

| 燃气轮机排烟 | 984.90 | 1.74 | 664.58 | 1.17 |

| 㶲损失/kW | ||||

| 气化室和锅炉 | 11485.31 | 20.27 | 8396.31 | 14.82 |

| 超临界透平 | 964.28 | 1.70 | 1149.14 | 2.03 |

| 燃气透平 | 383.98 | 0.68 | 1175.67 | 2.07 |

| 燃烧室 | 2788.18 | 4.92 | 9857.33 | 17.40 |

| 压气机 | 261.74 | 0.46 | 719.55 | 1.27 |

| 换热器 | — | — | 2761.83 | 4.87 |

| 换热器1 | 342.10 | 0.60 | — | — |

| 换热器2 | 637.12 | 1.12 | — | — |

| 换热器3 | 277.10 | 0.49 | — | — |

| 换热器4 | 893.21 | 1.58 | — | — |

| 省煤器1 | 1247.00 | 2.20 | — | — |

| 省煤器2 | 327.87 | 0.58 | — | — |

| 重整反应器 | 409.34 | 0.72 | — | — |

| 变换反应器 | 194.10 | 0.34 | — | — |

| SOFC | 1305.43 | 2.30 | — | — |

| SOFC阴极空气透平 | 120.22 | 0.21 | — | — |

| 总计 | 56664.87 | 100.00 | 56664.87 | 100.00 |

| 㶲效率/% | 52.79 | 47.95 | ||

表9 发电系统㶲平衡

Table 9 The exergy balances of the power systems

| 项目 | 本文新系统 | 占比/% | 文献[ | 占比/% |

|---|---|---|---|---|

| 㶲输入/kW | ||||

| 气化煤 | 26015.83 | 45.91 | 31003.27 | 54.71 |

| 燃料煤 | 30649.04 | 54.09 | 25661.60 | 45.29 |

| 总计 | 56664.87 | 100.00 | 56664.87 | 100.00 |

| 㶲输出/kW | ||||

| 气化室未反应碳 | 1415.26 | 2.50 | 1686.58 | 2.98 |

| 净输出功 | 29917.44 | 52.80 | 27173.52 | 47.95 |

| 冷却器 | 2523.90 | 4.45 | 2924.31 | 5.16 |

| 锅炉排烟 | 186.39 | 0.33 | 156.05 | 0.28 |

| 燃气轮机排烟 | 984.90 | 1.74 | 664.58 | 1.17 |

| 㶲损失/kW | ||||

| 气化室和锅炉 | 11485.31 | 20.27 | 8396.31 | 14.82 |

| 超临界透平 | 964.28 | 1.70 | 1149.14 | 2.03 |

| 燃气透平 | 383.98 | 0.68 | 1175.67 | 2.07 |

| 燃烧室 | 2788.18 | 4.92 | 9857.33 | 17.40 |

| 压气机 | 261.74 | 0.46 | 719.55 | 1.27 |

| 换热器 | — | — | 2761.83 | 4.87 |

| 换热器1 | 342.10 | 0.60 | — | — |

| 换热器2 | 637.12 | 1.12 | — | — |

| 换热器3 | 277.10 | 0.49 | — | — |

| 换热器4 | 893.21 | 1.58 | — | — |

| 省煤器1 | 1247.00 | 2.20 | — | — |

| 省煤器2 | 327.87 | 0.58 | — | — |

| 重整反应器 | 409.34 | 0.72 | — | — |

| 变换反应器 | 194.10 | 0.34 | — | — |

| SOFC | 1305.43 | 2.30 | — | — |

| SOFC阴极空气透平 | 120.22 | 0.21 | — | — |

| 总计 | 56664.87 | 100.00 | 56664.87 | 100.00 |

| 㶲效率/% | 52.79 | 47.95 | ||

| 参数 | 本文新系统 | 传统燃煤电站 | S-CO2燃煤电站 | |||||

|---|---|---|---|---|---|---|---|---|

| 文献[ | 文献[ | 文献[ | 文献[ | 文献[ | 文献[ | 文献[ | ||

| 最高温度/°C | 660 | 600 | 597 | 545 | 600 | 620 | 620 | 620 |

| 最高压力/bar | 250 | 300 | 240 | 260 | 253.4 | 300 | 300 | 300 |

| 发电效率/% | 54.01 | 41.00 | 45.00 | 43.00 | 43.19 | 47.80 | 48.37 | 47.99 |

表10 本文新系统与传统燃煤电站及S-CO2燃煤电站的性能对比

Table 10 Comparison between the proposed system and coal-fired supercritical power plants

| 参数 | 本文新系统 | 传统燃煤电站 | S-CO2燃煤电站 | |||||

|---|---|---|---|---|---|---|---|---|

| 文献[ | 文献[ | 文献[ | 文献[ | 文献[ | 文献[ | 文献[ | ||

| 最高温度/°C | 660 | 600 | 597 | 545 | 600 | 620 | 620 | 620 |

| 最高压力/bar | 250 | 300 | 240 | 260 | 253.4 | 300 | 300 | 300 |

| 发电效率/% | 54.01 | 41.00 | 45.00 | 43.00 | 43.19 | 47.80 | 48.37 | 47.99 |

| 参数 | 本文新系统 | 文献[ | 文献[ | 文献[ | 文献[ | 文献[ | 文献[ |

|---|---|---|---|---|---|---|---|

| 最高温度/°C | 660 | 660 | 650 | 660 | 660 | 660 | 560 |

| 最高压力/bar | 250 | 250 | 300 | 250 | 250 | 250 | 250 |

| 发电效率/% | 54.01 | 42.18 | 41.17 | 38.31 | 46.60 | 49.06 | 27.9 |

表11 本文新系统与其他超临界水煤气化发电系统的性能对比

Table 11 Comparison between the proposed system and power system based on SCWG of coal

| 参数 | 本文新系统 | 文献[ | 文献[ | 文献[ | 文献[ | 文献[ | 文献[ |

|---|---|---|---|---|---|---|---|

| 最高温度/°C | 660 | 660 | 650 | 660 | 660 | 660 | 560 |

| 最高压力/bar | 250 | 250 | 300 | 250 | 250 | 250 | 250 |

| 发电效率/% | 54.01 | 42.18 | 41.17 | 38.31 | 46.60 | 49.06 | 27.9 |

| 1 | 中国电力企业联合会. 中国电力行业年度发展报告2023[R]. 2023. |

| China Electric Power Enterprises Federation. Annual development report of China’s power industry 2023[R]. 2023. | |

| 2 | 帅永, 赵斌, 蒋东方, 等. 中国燃煤高效清洁发电技术现状与展望[J]. 热力发电, 2022, 51(1): 1-10. |

| Shuai Y, Zhao B, Jiang D F, et al. Status and prospect of coal-fired high efficiency and clean power generation technology in China[J]. Thermal Power Generation, 2022, 51(1): 1-10. | |

| 3 | Mu R Q, Liu M, Yan J J. Advanced exergy analysis on supercritical water gasification of coal compared with conventional O2-H2O and chemical looping coal gasification[J]. Fuel Processing Technology, 2023, 245: 107742. |

| 4 | Chen W Y, Xu R N. Clean coal technology development in China[J]. Energy Policy, 2010, 38(5): 2123-2130. |

| 5 | Xue X D, Liu C C, Han W, et al. Proposal and investigation of a high-efficiency coal-fired power generation system enabled by chemical recuperative supercritical water coal gasification[J]. Energy, 2023, 267: 126598. |

| 6 | Krüger M. Process development for integrated coal gasification solid oxide fuel cells hybrid power plants—investigations on solid oxide fuel cells/gas turbine hybrid power plants run on clean coal gas[J]. Applied Energy, 2019, 250: 19-31. |

| 7 | Wu W, Zheng L, Shi B, et al. Energy and exergy analysis of MSW-based IGCC power/polygeneration systems[J]. Energy Conversion and Management, 2021, 238: 114119. |

| 8 | 王哮江, 刘鹏, 李荣春, 等. “双碳”目标下先进发电技术研究进展及展望[J]. 热力发电, 2022, 51(1): 52-59. |

| Wang X J, Liu P, Li R C, et al. Research progress and prospects of advanced power generation technology under the goal of carbon emission peak and carbon neutrality[J]. Thermal Power Generation, 2022, 51(1): 52-59. | |

| 9 | 郭烈锦, 赵亮, 吕友军, 等. 煤炭超临界水气化制氢发电多联产技术[J]. 工程热物理学报, 2017, 38(3): 678-679. |

| Guo L J, Zhao L, Lyu Y J, et al. Multi-generation technology of hydrogen production and power generation by coal supercritical water gasification[J]. Journal of Engineering Thermophysics, 2017, 38(3): 678-679. | |

| 10 | Chen Z W, Zhang X S, Gao L, et al. Thermal analysis of supercritical water gasification of coal for power generation with partial heat recovery[J]. Applied Thermal Engineering, 2017, 111: 1287-1295. |

| 11 | 闫秋会, 苗海军, 张莉, 等. 超临界水中煤气化制氢热力发电系统的构建及其能量转化机理分析[J]. 煤炭技术, 2014, 33(8): 221-223. |

| Yan Q H, Miao H J, Zhang L, et al. Novel power generation system based on coal gasification in supercritical water and principle of its energy conversion[J]. Coal Technology, 2014, 33(8): 221-223. | |

| 12 | Ge Z W, Jin H, Guo L J. Hydrogen production by catalytic gasification of coal in supercritical water with alkaline catalysts: explore the way to complete gasification of coal[J]. International Journal of Hydrogen Energy, 2014, 39(34): 19583-19592. |

| 13 | Li Y L, Guo L J, Zhang X M, et al. Hydrogen production from coal gasification in supercritical water with a continuous flowing system[J]. International Journal of Hydrogen Energy, 2010, 35(7): 3036-3045. |

| 14 | Jin H, Lu Y J, Liao B, et al. Hydrogen production by coal gasification in supercritical water with a fluidized bed reactor[J]. International Journal of Hydrogen Energy, 2010, 35(13): 7151-7160. |

| 15 | Yan Q H, Guo L J, Lu Y J. Thermodynamic analysis of hydrogen production from biomass gasification in supercritical water[J]. Energy Conversion and Management, 2006, 47(11/12): 1515-1528. |

| 16 | Vostrikov A A, Psarov S A, Dubov D Y, et al. Kinetics of coal conversion in supercritical water[J]. Energy & Fuels, 2007, 21(5): 2840-2845. |

| 17 | Guo S M, Guo L J, Yin J R, et al. Supercritical water gasification of glycerol: intermediates and kinetics[J]. The Journal of Supercritical Fluids, 2013, 78: 95-102. |

| 18 | Azadi P, Farnood R, Vuillardot C. Estimation of heating time in tubular supercritical water reactors[J]. The Journal of Supercritical Fluids, 2011, 55(3): 1038-1045. |

| 19 | Jin H, Guo S M, Guo L J, et al. A mathematical model and numerical investigation for glycerol gasification in supercritical water with a tubular reactor[J]. The Journal of Supercritical Fluids, 2016, 107: 526-533. |

| 20 | Chen J W, Wang Q T, Xu Z Y, et al. Process in supercritical water gasification of coal: a review of fundamentals, mechanisms, catalysts and element transformation[J]. Energy Conversion and Management, 2021, 237: 114122. |

| 21 | Bermejo M D, Cocero M J, Fernández-Polanco F. A process for generating power from the oxidation of coal in supercritical water[J]. Fuel, 2004, 83(2): 195-204. |

| 22 | Yan Q H, Hou Y W, Luo J R, et al. The exergy release mechanism and exergy analysis for coal oxidation in supercritical water atmosphere and a power generation system based on the new technology[J]. Energy Conversion and Management, 2016, 129: 122-130. |

| 23 | Briola S, Gabbrielli R, Schiavetti M, et al. Supercritical water oxidation of coal in power plants with low CO2 emissions[C]//ECOS 2007. Padova, Italy, 2007. |

| 24 | Guo L J, Jin H. Boiling coal in water: hydrogen production and power generation system with zero net CO2 emission based on coal and supercritical water gasification[J]. International Journal of Hydrogen Energy, 2013, 38(29): 12953-12967. |

| 25 | Chen Z W, Zhang X S, Han W, et al. A power generation system with integrated supercritical water gasification of coal and CO2 capture[J]. Energy, 2018, 142: 723-730. |

| 26 | Chen Z W, Zhang X S, Li S, et al. Novel power generation models integrated supercritical water gasification of coal and parallel partial chemical heat recovery[J]. Energy, 2017, 134: 933-942. |

| 27 | Ud Din Z, Zainal Z A. Biomass integrated gasification-SOFC systems: technology overview[J]. Renewable and Sustainable Energy Reviews, 2016, 53: 1356-1376. |

| 28 | Zhang H C, Kong W, Dong F F, et al. Application of cascading thermoelectric generator and cooler for waste heat recovery from solid oxide fuel cells[J]. Energy Conversion and Management, 2017, 148: 1382-1390. |

| 29 | Wu Z, Zhu P F, Yao J, et al. Combined biomass gasification, SOFC, IC engine, and waste heat recovery system for power and heat generation: energy, exergy, exergoeconomic, environmental (4E) evaluations[J]. Applied Energy, 2020, 279: 115794. |

| 30 | Perna A, Minutillo M, Jannelli E, et al. Performance assessment of a hybrid SOFC/MGT cogeneration power plant fed by syngas from a biomass down-draft gasifier[J]. Applied Energy, 2018, 227: 80-91. |

| 31 | Roy D, Ghosh S. Energy and exergy analyses of an integrated biomass gasification combined cycle employing solid oxide fuel cell and organic Rankine cycle[J]. Clean Technologies and Environmental Policy, 2017, 19(6): 1693-1709. |

| 32 | El-Emam R S, Dincer I, Naterer G F. Energy and exergy analyses of an integrated SOFC and coal gasification system[J]. International Journal of Hydrogen Energy, 2012, 37(2): 1689-1697. |

| 33 | Romano M C, Spallina V, Campanari S. Integrating IT-SOFC and gasification combined cycle with methanation reactor and hydrogen firing for near zero-emission power generation from coal[J]. Energy Procedia, 2011, 4: 1168-1175. |

| 34 | Li C X, Yun L L, Zhang Y, et al. Microstructure, performance and stability of Ni/Al2O3 cermet-supported SOFC operating with coal-based syngas produced using supercritical water[J]. International Journal of Hydrogen Energy, 2012, 37(17): 13001-13006. |

| 35 | Li C X, Li C J, Guo L J. Performance of a Ni/Al2O3 cermet-supported tubular solid oxide fuel cell operating with biomass-based syngas through supercritical water[J]. International Journal of Hydrogen Energy, 2010, 35(7): 2904-2908. |

| 36 | Aloui T, Halouani K. Analytical modeling of polarizations in a solid oxide fuel cell using biomass syngas product as fuel[J]. Applied Thermal Engineering, 2007, 27(4): 731-737. |

| 37 | Guo L J, Jin H, Ge Z W, et al. Industrialization prospects for hydrogen production by coal gasification in supercritical water and novel thermodynamic cycle power generation system with no pollution emission[J]. Science China Technological Sciences, 2015, 58(12): 1989-2002. |

| 38 | Guo L J, Jin H, Lu Y J. Supercritical water gasification research and development in China[J]. The Journal of Supercritical Fluids, 2015, 96: 144-150. |

| 39 | 金辉, 吕友军, 赵亮, 等. 煤炭超临界水气化制氢发电多联产技术进展[J]. 中国基础科学, 2018, 20(4): 4-9, 16. |

| Jin H, Lyu Y J, Zhao L, et al. Development in the plolygeneration-technology based on steaming coal with supercritical water gasification[J]. China Basic Science, 2018, 20(4): 4-9, 16. | |

| 40 | Lanzini A, Leone P, Guerra C, et al. Durability of anode supported solid oxides fuel cells (SOFC) under direct dry-reforming of methane[J]. Chemical Engineering Journal, 2013, 220: 254-263. |

| 41 | Aguiar P, Adjiman C S, Brandon N P. Anode-supported intermediate temperature direct internal reforming solid oxide fuel cell (Ⅰ): Model-based steady-state performance[J]. Journal of Power Sources, 2004, 138(1/2): 120-136. |

| 42 | Alzate-Restrepo V, Hill J M. Effect of anodic polarization on carbon deposition on Ni/YSZ anodes exposed to methane[J]. Applied Catalysis A: General, 2008, 342(1/2): 49-55. |

| 43 | Koo T, Kim Y S, Lee D, et al. System simulation and exergetic analysis of solid oxide fuel cell power generation system with cascade configuration[J]. Energy, 2021, 214: 119087. |

| 44 | 史翊翔. 固体氧化物燃料电池反应机理及模型研究[D]. 北京: 清华大学, 2010. |

| Shi Y X. The reaction mechanism and model study on the solid oxide fuel cell[D]. Beijing: Tsinghua University, 2010. | |

| 45 | Zhang X S, Chen Z W, Chen Z B, et al. Exergy analysis of a novel chemical looping hydrogen generation system integrated with SOFC[J]. Journal of Thermal Science, 2021, 30(1): 313-323. |

| 46 | 罗丽琦, 王绍荣. 以气化煤气为燃料的固体氧化物燃料电池热电联供系统设计[J]. 洁净煤技术, 2023(29): 1-15. |

| Luo L Q, Wang S R. Design of combined heat and power supply system based on coal gas SOFC (IGFC-CHP) system[J]. Clean Coal Technology, 2023(29): 1-15. | |

| 47 | Chen Z W, Zhou Q, Zhang Y M, et al. Energy, exergy and economic (3E) evaluations of a novel power generation system combining supercritical water gasification of coal with chemical heat recovery[J]. Energy Conversion and Management, 2023, 276: 116531. |

| 48 | Breeze P. Coal-fired power plants[M]//Power Generation Technologies. Amsterdam: Elsevier, 2014: 29-65. |

| 49 | Zhang D K. Introduction to advanced and ultra-supercritical fossil fuel power plants[M]//Ultra-Supercritical Coal Power Plants. UK: Woodhead Publishing, 2013: 1-20. |

| 50 | Hentschel J, Zindler H, Spliethoff H. Modelling and transient simulation of a supercritical coal-fired power plant: dynamic response to extended secondary control power output[J]. Energy, 2017, 137: 927-940. |

| 51 | Sanpasertparnich T, Aroonwilas A. Simulation and optimization of coal-fired power plants[J]. Energy Procedia, 2009, 1(1): 3851-3858. |

| 52 | Mecheri M, Le Moullec Y. Supercritical CO2 Brayton cycles for coal-fired power plants[J]. Energy, 2016, 103: 758-771. |

| 53 | Xu J L, Sun E H, Li M J, et al. Key issues and solution strategies for supercritical carbon dioxide coal fired power plant[J]. Energy, 2018, 157: 227-246. |

| 54 | Sun E H, Xu J L, Hu H, et al. Overlap energy utilization reaches maximum efficiency for S-CO2 coal fired power plant: a new principle[J]. Energy Conversion and Management, 2019, 195: 99-113. |

| 55 | Donatini F, Gigliucci G, Riccardi J, et al. Supercritical water oxidation of coal in power plants with low CO2 emissions[J]. Energy, 2009, 34(12): 2144-2150. |

| [1] | 刘远超, 关斌, 钟建斌, 徐一帆, 蒋旭浩, 李耑. 单层XSe2(X=Zr/Hf)的热电输运特性研究[J]. 化工学报, 2023, 74(9): 3968-3978. |

| [2] | 曹跃, 余冲, 李智, 杨明磊. 工业数据驱动的加氢裂化装置多工况切换过渡状态检测[J]. 化工学报, 2023, 74(9): 3841-3854. |

| [3] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [4] | 郑玉圆, 葛志伟, 韩翔宇, 王亮, 陈海生. 中高温钙基材料热化学储热的研究进展与展望[J]. 化工学报, 2023, 74(8): 3171-3192. |

| [5] | 余娅洁, 李静茹, 周树锋, 李清彪, 詹国武. 基于天然生物模板构建纳米材料及集成催化剂研究进展[J]. 化工学报, 2023, 74(7): 2735-2752. |

| [6] | 李贵贤, 曹阿波, 孟文亮, 王东亮, 杨勇, 周怀荣. 耦合固体氧化物电解槽的CO2制甲醇过程设计与评价研究[J]. 化工学报, 2023, 74(7): 2999-3009. |

| [7] | 文兆伦, 李沛睿, 张忠林, 杜晓, 侯起旺, 刘叶刚, 郝晓刚, 官国清. 基于自热再生的隔壁塔深冷空分工艺设计及优化[J]. 化工学报, 2023, 74(7): 2988-2998. |

| [8] | 王光, 单发顺, 钱禹丞, 焦建芳. 基于集成学习传递熵的化工过程微小故障检测方法[J]. 化工学报, 2023, 74(7): 2967-2978. |

| [9] | 江锦波, 彭新, 许文烜, 门日秀, 刘畅, 彭旭东. 泵出型螺旋槽油气密封泄漏特性及参数影响研究[J]. 化工学报, 2023, 74(6): 2538-2554. |

| [10] | 邵远哲, 赵忠盖, 刘飞. 基于共同趋势模型的非平稳过程质量相关故障检测方法[J]. 化工学报, 2023, 74(6): 2522-2537. |

| [11] | 孙永尧, 高秋英, 曾文广, 王佳铭, 陈艺飞, 周永哲, 贺高红, 阮雪华. 面向含氮油田伴生气提质利用的膜耦合分离工艺设计优化[J]. 化工学报, 2023, 74(5): 2034-2045. |

| [12] | 刘尚豪, 贾胜坤, 罗祎青, 袁希钢. 基于梯度提升决策树的三组元精馏流程结构最优化[J]. 化工学报, 2023, 74(5): 2075-2087. |

| [13] | 周必茂, 许世森, 王肖肖, 刘刚, 李小宇, 任永强, 谭厚章. 烧嘴偏转角度对气化炉渣层分布特性的影响[J]. 化工学报, 2023, 74(5): 1939-1949. |

| [14] | 王泽栋, 石至平, 刘丽艳. 考虑气泡非均匀耗散的矩形反应器声流场数值模拟及结构优化[J]. 化工学报, 2023, 74(5): 1965-1973. |

| [15] | 许文烜, 江锦波, 彭新, 门日秀, 刘畅, 彭旭东. 宽速域三种典型型槽油气密封泄漏与成膜特性对比研究[J]. 化工学报, 2023, 74(4): 1660-1679. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号