化工学报 ›› 2021, Vol. 72 ›› Issue (10): 5310-5318.DOI: 10.11949/0438-1157.20210472

杨志权1,2( ),张朝阳1,吕会英2,陈国庆1,黄卿2,汪利平2,于强亮1,2(

),张朝阳1,吕会英2,陈国庆1,黄卿2,汪利平2,于强亮1,2( ),蔡美荣1,汤仲平2,周峰1

),蔡美荣1,汤仲平2,周峰1

收稿日期:2021-04-06

修回日期:2021-05-13

出版日期:2021-10-05

发布日期:2021-10-05

通讯作者:

于强亮

作者简介:杨志权(1995—),男,硕士研究生,基金资助:

Zhiquan YANG1,2( ),Chaoyang ZHANG1,Huiying LYU2,Guoqing CHEN1,Qing HUANG2,Liping WANG2,Qiangliang YU1,2(

),Chaoyang ZHANG1,Huiying LYU2,Guoqing CHEN1,Qing HUANG2,Liping WANG2,Qiangliang YU1,2( ),Meirong CAI1,Zhongping TANG2,Feng ZHOU1

),Meirong CAI1,Zhongping TANG2,Feng ZHOU1

Received:2021-04-06

Revised:2021-05-13

Online:2021-10-05

Published:2021-10-05

Contact:

Qiangliang YU

摘要:

为改善PAO10体系的润滑性能,合成了一种油溶性离子液体并与T321及二氧化硅进行对比。通过同步热分析仪测试PAO10润滑体系的热稳定性;通过SRV-IV微动摩擦磨损试验机对比评价不同离子液体的摩擦学性能;通过非接触式三维轮廓仪和扫描电子显微镜对磨斑形貌和磨损体积进行了表征;通过EDS和XPS元素分析对磨斑表面化学成分和化学变化进行分析。结果表明合成的油溶性离子液体可以显著提高PAO10体系的热稳定性,且无论在常温还是高温下,都具有优异的减摩抗磨性能,并极大地提高了PAO10体系的极压承载性能。通过实验结果推测极性元素P、S在摩擦过程中发生摩擦化学反应,生成的摩擦化学膜有效地抑制摩擦副之间的直接接触,提高了PAO10体系的减摩抗磨性能。

中图分类号:

杨志权,张朝阳,吕会英,陈国庆,黄卿,汪利平,于强亮,蔡美荣,汤仲平,周峰. 油溶性离子液体与T321及二氧化硅的协同润滑性能研究[J]. 化工学报, 2021, 72(10): 5310-5318.

Zhiquan YANG,Chaoyang ZHANG,Huiying LYU,Guoqing CHEN,Qing HUANG,Liping WANG,Qiangliang YU,Meirong CAI,Zhongping TANG,Feng ZHOU. Research on synergistic lubrication performance of oil-soluble ionic liquid, T321 and silica[J]. CIESC Journal, 2021, 72(10): 5310-5318.

| Lubricants | TG temperature per mass loss/℃ | ||

|---|---|---|---|

| 10% | 20% | 50% | |

| PAO10 | 288.62 | 312.12 | 345.92 |

| 1% P.S. | 318.94 | 346.84 | 386.14 |

| 1% P.S.@SiO2 | 302.79 | 336.69 | 379.89 |

| 1% SiO2 | 293.32 | 322.52 | 365.82 |

| 1% T321 | 271.47 | 298.07 | 343.97 |

表1 热稳定性

Table 1 Thermal stability

| Lubricants | TG temperature per mass loss/℃ | ||

|---|---|---|---|

| 10% | 20% | 50% | |

| PAO10 | 288.62 | 312.12 | 345.92 |

| 1% P.S. | 318.94 | 346.84 | 386.14 |

| 1% P.S.@SiO2 | 302.79 | 336.69 | 379.89 |

| 1% SiO2 | 293.32 | 322.52 | 365.82 |

| 1% T321 | 271.47 | 298.07 | 343.97 |

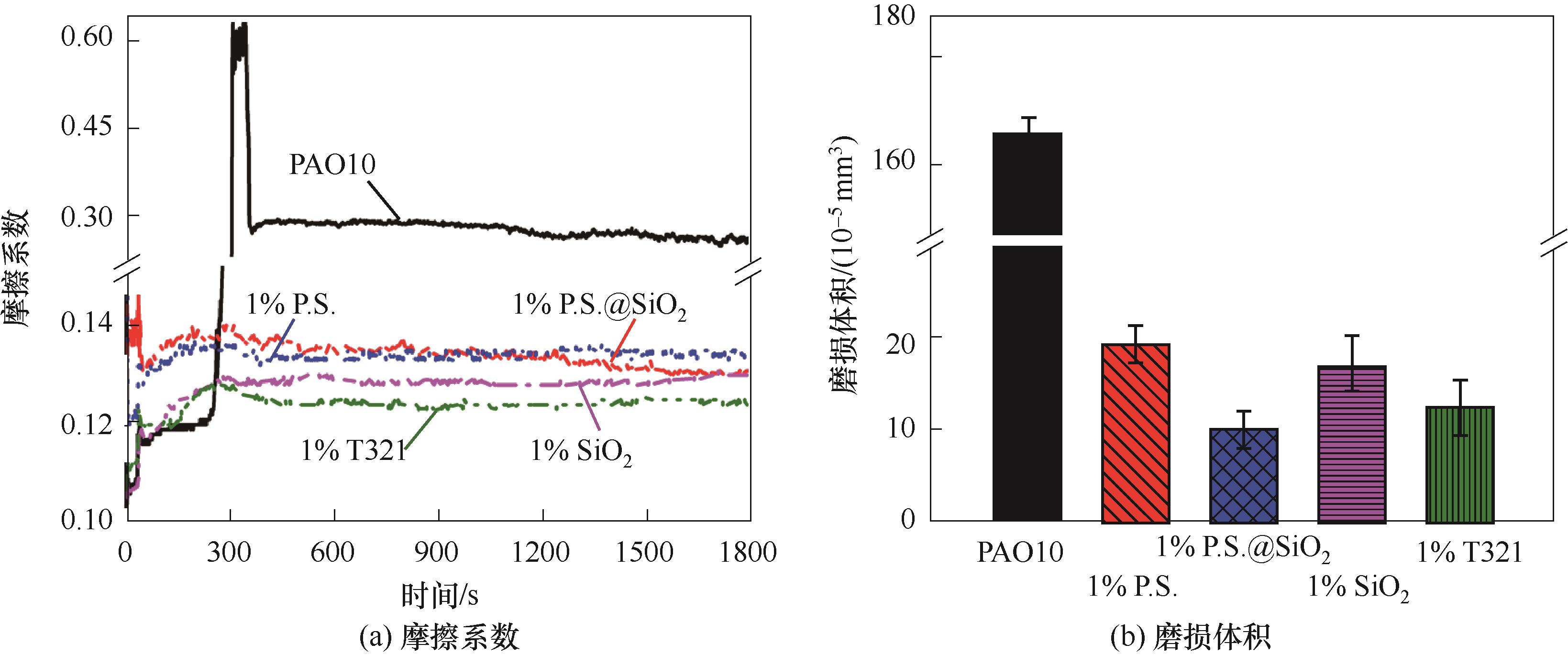

图3 常温下摩擦系数与磨损体积(SRV 温度:25℃,频率25 Hz,振幅1 mm,载荷200 N)

Fig.3 Friction coefficient and wear volume at room temperature(SRV: temperature 25℃, frequency 25 Hz, amplitude 1 mm, load 200 N)

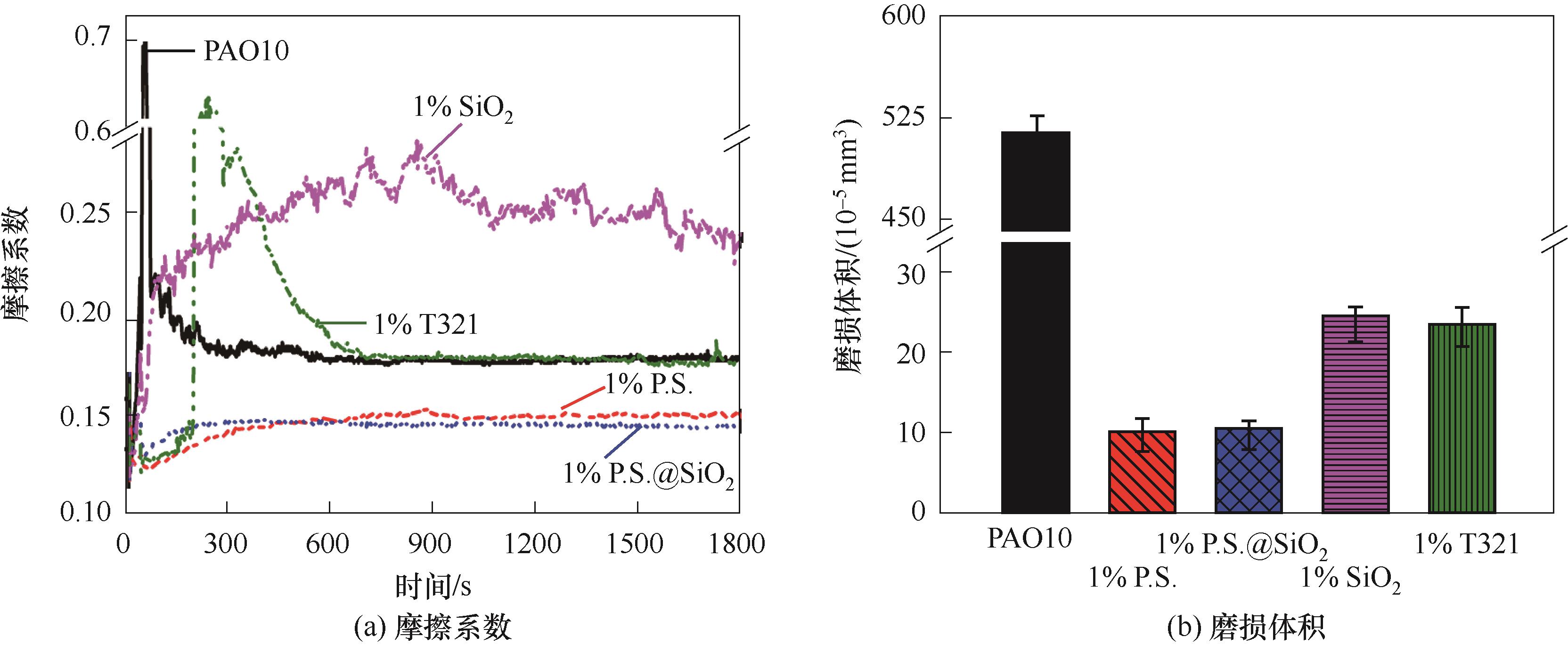

图5 高温下摩擦系数和磨损体积(SRV: 温度100℃,频率:25 Hz,振幅1 mm,载荷200 N)

Fig.5 Diagram of friction coefficient and wear volume at high temperature (SRV: temperature 100℃, frequency 25 Hz, amplitude 1 mm, load 200 N)

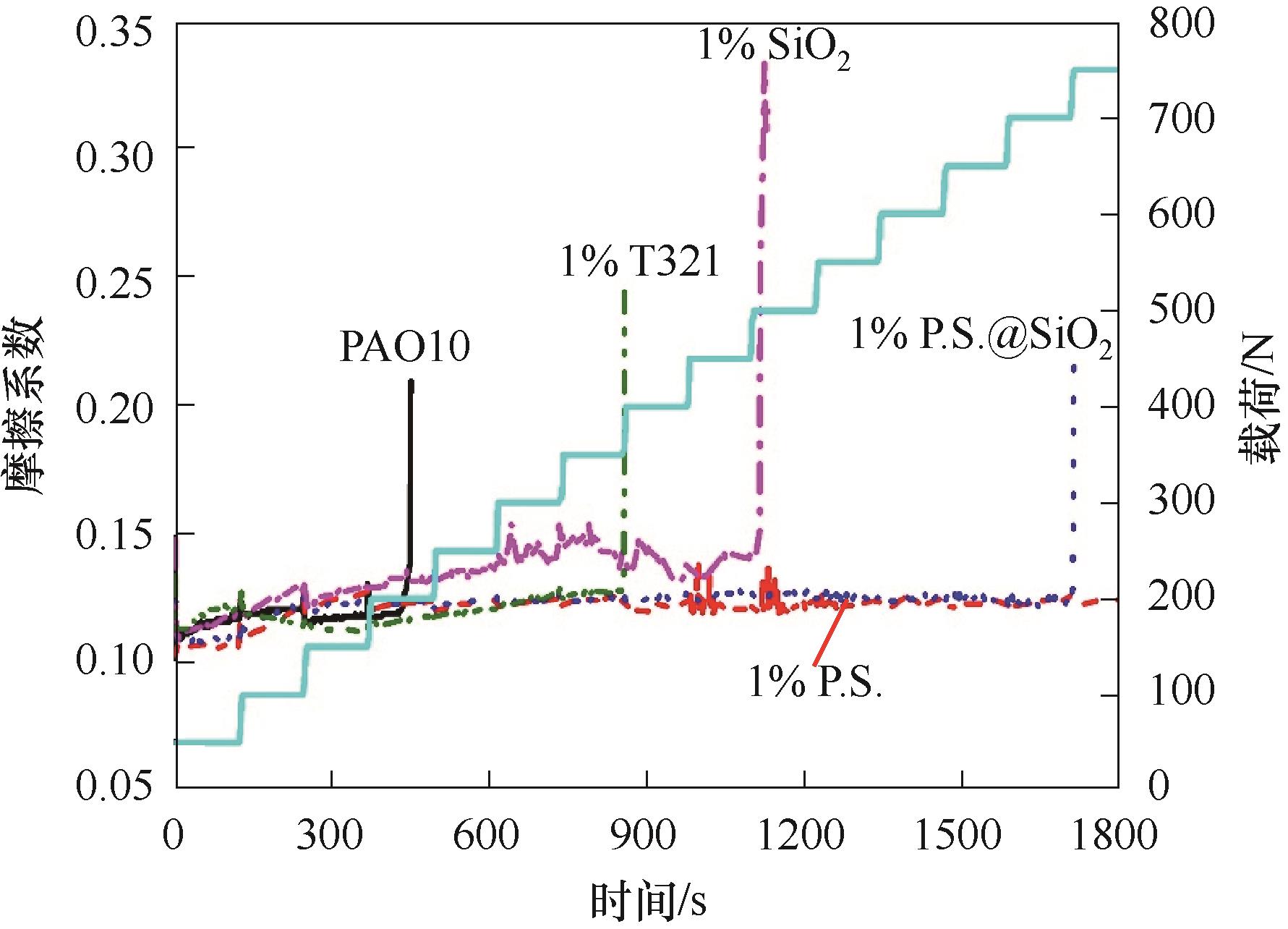

图7 高温极压摩擦系数曲线(SRV: 温度100℃,频率25 Hz,振幅1 mm)

Fig.7 High temperature extreme pressure friction coefficient curves(SRV: temperature 100℃, frequency 25 Hz, amplitude 1 mm)

| 1 | Lugt P M. A review on grease lubrication in rolling bearings[J]. Tribology Transactions, 2009, 52(4): 470-480. |

| 2 | 姜自超, 方建华, 江泽琦, 等. 纳米WS2润滑油添加剂在直流磁场下的摩擦磨损特性[J]. 化工学报, 2019, 70(7): 2636-2644. |

| Jiang Z C, Fang J H, Jiang Z Q, et al. Tribological properties of nano-WS2 lubricating oil additives under DC magnetic field[J]. CIESC Journal, 2019, 70(7): 2636-2644. | |

| 3 | 郑帅周, 周琦, 杨生荣, 等. 氟化石墨烯的制备及其作为润滑油添加剂的摩擦学性能研究[J]. 摩擦学学报, 2017, 37(3): 402-408. |

| Zheng S Z, Zhou Q, Yang S R, et al. Preparation and tribological properties of fluorinated graphene nanosheets as additive in lubricating oil[J]. Tribology, 2017, 37(3): 402-408. | |

| 4 | Zhang F X, Zhang X Y, Zhang F L, et al. 3D/1D heterostructure of flower-like MoS2 nanospheres anchored on carbon nanotubes for enhanced friction and wear properties as oil additives[J]. Materials Research Express, 2020, 6(12): 1250f9. |

| 5 | Talukdar S, Ghosh P. Biodegradable vegetable oil polymer as a multifunctional lubricating oil additive[J]. Journal of Macromolecu-lar Science, Part A, 2020, 57(4): 244-249. |

| 6 | Beheshti A, Huang Y, Ohno K, et al. Improving tribological properties of oil-based lubricants using hybrid colloidal additives[J]. Tribology International, 2020, 144: 106130. |

| 7 | Yang M N, Fan S L, Huang H Y, et al. In-situ synthesis of calcium borate/cellulose acetate-laurate nanocomposite as efficient ex-treme pressure and anti-wear lubricant additives[J]. International Journal of Biological Macromolecules, 2020, 156: 280-288. |

| 8 | 于强亮, 王将兵, 范丰奇, 等. N/P无卤素离子液体润滑剂的链长与摩擦学性能的关系[J]. 摩擦学学报, 2020, 40(5): 673-679. |

| Yu Q L, Wang J B, Fan F Q, et al. The relationship between the chain length and tribological properties of N/P halogen-free ionic liquid lubricants[J]. Tribology, 2020, 40(5): 673-679. | |

| 9 | 凡明锦, 张朝阳, 文平, 等. 氨基酸离子液体润滑剂的结构与摩擦学行为的关系[J]. 中国表面工程, 2017, 30(3): 148-158. |

| Fan M J, Zhang C Y, Wen P, et al. Relationship between molecular structure and tribological performance of amino acid ionic liquid lub-ricant[J]. China Surface Engineering, 2017, 30(3): 148-158. | |

| 10 | Wang Y R, Yu Q L, Ma Z F, et al. Significant enhancement of anti-friction capability of cationic surfactant by phosphonate func-tionality as additive in water[J]. Tribology International, 2017, 112: 86-93. |

| 11 | 夏延秋, 韩钰, 冯欣. 离子液体润滑性及导电能力研究进展[J]. 摩擦学学报, 2016, 36(6): 794-802. |

| Xia Y Q, Han Y, Feng X. The research progress on lubrication and electrical conductivity of ionic liquids[J]. Tribology, 2016, 36(6): 794-802. | |

| 12 | 刘维民, 薛群基, 周静芳, 等. 纳米颗粒的抗磨作用及作为磨损修复添加剂的应用研究[J]. 中国表面工程, 2001, 14(3): 21-23, 29. |

| Liu W M, Xue Q J, Zhou J F, et al. Antiwear properties of nanoparticles and application study of nanoparticles as additives in the wear-repairing agent[J]. China Surface Engineering, 2001, 14(3): 21-23, 29. | |

| 13 | A S, D R, D S, et al. Chronic toxicity of treated and untreated aqueous solutions containing imidazole-based ionic liquids and their oxydized by-products[J]. Ecotoxicology and Environmental Safety, 2019, 180: 466-472. |

| 14 | Zhang L, Feng D P, Xu B, et al. The friction and wear characteristics and lubrication mechanism of imidazole phosphate ionic liquid[J]. Science in China Series E: Technological Sciences, 2009, 52(5): 1191-1194. |

| 15 | Huang G W, Yu Q L, Ma Z F, et al. Oil-soluble ionic liquids as antiwear and extreme pressure additives in poly-α-olefin for steel/steel contacts[J]. Friction, 2019, 7(1): 18-31. |

| 16 | Rohlmann P, Munavirov B, Furó I, et al. Non-halogenated ionic liquid dramatically enhances tribological performance of biode-gradable oils[J]. Frontiers in Chemistry, 2019, 7: 98. |

| 17 | Li W M, Kumara C, Luo H M, et al. Ultralow boundary lubrication friction by three-way synergistic interactions among ionic liquid, friction modifier, and dispersant[J]. ACS Applied Materials & Interfaces, 2020, 12(14): 17077-17090. |

| 18 | Ding H Y, Yang X H, Xu L N, et al. Tribological behavior of plant oil-based extreme pressure lubricant additive in water-ethylene glycol liquid[J]. Journal of Renewable Materials, 2019, 7(12): 1391-1401. |

| 19 | 韩宁, 水琳, 刘维民, 等. 硫化异丁烯润滑机理的研究[J]. 摩擦学学报, 2002, 22(1): 49-53. |

| Han N, Shui L, Liu W M, et al. Study of the lubrication mechanism of olefin sulfide[J]. Tribology, 2002, 22(1): 49-53. | |

| 20 | Yu Q L, Zhang C Y, Dong R, et al. Novel N, P-containing oil-soluble ionic liquids with excellent tribological and anti-corrosion performance[J]. Tribology International, 2019, 132: 118-129. |

| 21 | Yu Q L, Wang Y R, Huang G W, et al. Task-specific oil-miscible ionic liquids lubricate steel/light metal alloy: a tribochemistry study[J]. Advanced Materials Interfaces, 2018, 5(19): 1800791. |

| 22 | Desanker M, He X L, Lu J, et al. High-performance heterocyclic friction modifiers for boundary lubrication[J]. Tribology Letters, 2018, 66(1): 1-13. |

| 23 | Yu Q L, Zhang C Y, Wang J B, et al. Tribological performance and lubrication mechanism of new gemini quaternary phosphonium ionic liquid lubricants[J]. Journal of Molecular Liquids, 2021, 322: 114522. |

| 24 | 于强亮, 蔡美荣, 周峰, 等. 油溶性有机减摩抗磨添加剂的研究进展[J]. 表面技术, 2020, 49(9): 1-18. |

| Yu Q L, Cai M R, Zhou F, et al. Research progress of oil-soluble organic friction-reduction and anti-wear additives[J]. Surface Technology, 2020, 49(9): 1-18. | |

| 25 | Qu J, Barnhill W C, Luo H M, et al. Synergistic effects between phosphonium-alkylphosphate ionic liquids and zinc dialkyldithi-ophosphate (ZDDP) as lubricant additives[J]. Advanced Materials, 2015, 27(32): 4767-4774. |

| 26 | 盛德尊, 张会臣. 面接触下水合羟乙基纤维素的润滑特性研究[J]. 机械工程学报, 2019, 55(1): 120-128. |

| Sheng D Z, Zhang H C. Water-based lubricating properties of aqueous hydroxyethyl cellulose in surface contact[J]. Journal of Mechanical Engineering, 2019, 55(1): 120-128. | |

| 27 | 刘宸旭, 陈朝浪, 张继平, 等. 油水乳化液的边界润滑行为及机理分析[J]. 机械工程学报, 2019, 55(9): 48-54. |

| Liu C X, Chen C L, Zhang J P, et al. Boundary lubrication behavior and mechanism analysis of oil-water emulsion[J]. Journal of Mechanical Engineering, 2019, 55(9): 48-54. | |

| 28 | 何忠义, 贾广跃, 张萌萌, 等. 纳米六方氮化硼负载离子液体润滑添加剂的摩擦学特性[J]. 化工学报, 2020, 71(9): 4303-4313. |

| He Z Y, Jia G Y, Zhang M M, et al. Tribological performance of hexagonal boron nitride supported ionic liquid lubricant additives[J]. CIESC Journal, 2020, 71(9): 4303-4313. | |

| 29 | Yu Q L, Zhang C Y, Dong R, et al. Physicochemical and tribological properties of gemini-type halogen-free dicationic ionic liquids[J]. Friction, 2021, 9(2): 344-355. |

| 30 | Qu J, Bansal D G, Yu B, et al. Antiwear performance and mechanism of an oil-miscible ionic liquid as a lubricant additive[J]. ACS Applied Materials & Interfaces, 2012, 4(2): 997-1002. |

| 31 | 于强亮, 张朝阳, 范丰奇, 等. 四种油溶性离子液体复合锂基润滑脂理化性能和摩擦学性能[J]. 石油学报, 2021, 37(4): 900-908. |

| Yu Q L, Zhang C Y, Fan F Q, et al. Study on the physiochemical properties and tribological properties of four oil-soluble ionic liquid complex lithium greases[J]. Journal of Petroleum, 2021, 37(4): 900-908. |

| [1] | 陈美思, 陈威达, 李鑫垚, 李尚予, 吴有庭, 张锋, 张志炳. 硅基离子液体微颗粒强化气体捕集与转化的研究进展[J]. 化工学报, 2023, 74(9): 3628-3639. |

| [2] | 葛运通, 王玮, 李楷, 肖帆, 于志鹏, 宫敬. 多相分散体系中微油滴与改性二氧化硅表面间作用力的AFM研究[J]. 化工学报, 2023, 74(4): 1651-1659. |

| [3] | 任金胜, 刘克润, 焦志伟, 刘家祥, 于源. 涡流空气分级机近导叶处团聚体解团机理研究[J]. 化工学报, 2023, 74(4): 1528-1538. |

| [4] | 张鑫, 许蕊, 路馨语, 牛永安. SiO2@BiOCl-Bi24O31Cl10核壳微球的合成及光催化[J]. 化工学报, 2022, 73(8): 3636-3646. |

| [5] | 戴文华, 辛忠. Si掺杂对Cu/ZrO2催化CO2加氢制甲醇性能的影响[J]. 化工学报, 2022, 73(8): 3586-3596. |

| [6] | 张锐, 邵琦, 张华宇, 金泽龙, 张小亮. 硼掺杂二氧化硅杂化膜的制备及渗透汽化脱盐性能[J]. 化工学报, 2021, 72(4): 2317-2327. |

| [7] | 孙艳, 刘士涛, 邓尚, 余丽芸, 吕东伟, 马军, 刘献斌. 负载羧基化球状介孔纳米颗粒TFN膜的研究[J]. 化工学报, 2020, 71(S1): 454-460. |

| [8] | 何璐铭,辛忠,高文莉,顾佳,孟鑫. 静电纺丝法制备高活性多孔Ni/SiO2甲烷化催化剂[J]. 化工学报, 2020, 71(11): 5007-5015. |

| [9] | 徐彦芹, 秦钊, 王烨, 曹渊, 陈昌国, 王丹. NH2-MCM-41的改性及其pH响应性释药的研究[J]. 化工学报, 2020, 71(10): 4783-4791. |

| [10] | 蒋壮飞, 何家垣, 马蓉蓉, 李清瑶, 杨莉莉, 谭玲, 张起辉. 核-壳结构分子印迹材料用于定向脱苦的研究[J]. 化工学报, 2020, 71(10): 4704-4710. |

| [11] | 于强, 鹿院卫, 张晓盼, 吴玉庭. 纳米粒子对熔盐复合蓄热材料热物性的影响[J]. 化工学报, 2019, 70(S1): 217-225. |

| [12] | 尚志新, 张香兰. γ-巯丙基三乙氧基硅烷水解程度对纳米二氧化硅接枝机理影响的DFT研究[J]. 化工学报, 2019, 70(5): 1663-1673. |

| [13] | 王彩红, 孙婧, 季书馨, 王燕子, 刘文芳. 聚乙烯亚胺/多巴胺改性氧化硅固定碳酸酐酶[J]. 化工学报, 2019, 70(5): 1887-1893. |

| [14] | 李龙, 葛天舒, 吴宣楠, 代彦军. 硅胶嵌入多孔纸基对苯蒸气吸附性能[J]. 化工学报, 2019, 70(3): 951-959. |

| [15] | 王凯, 王德武, 侯得印, 袁子怡, 王军. 自组装法制备PVDF-SiO2/PVSQ超疏水复合膜及膜蒸馏抗污染性能[J]. 化工学报, 2019, 70(1): 298-308. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号