化工学报 ›› 2024, Vol. 75 ›› Issue (7): 2656-2669.DOI: 10.11949/0438-1157.20240267

张亚斌1,2( ), 苏杨1,2, 张慧荣1,2, 宋一朋3, 李健4, 郭彦霞1,2(

), 苏杨1,2, 张慧荣1,2, 宋一朋3, 李健4, 郭彦霞1,2( )

)

收稿日期:2024-03-05

修回日期:2024-04-27

出版日期:2024-07-25

发布日期:2024-08-09

通讯作者:

郭彦霞

作者简介:张亚斌(1984—),男,博士,副教授,zhangyabin@sxu.edu.cn

基金资助:

Yabin ZHANG1,2( ), Yang SU1,2, Huirong ZHANG1,2, Yipeng SONG3, Jian LI4, Yanxia GUO1,2(

), Yang SU1,2, Huirong ZHANG1,2, Yipeng SONG3, Jian LI4, Yanxia GUO1,2( )

)

Received:2024-03-05

Revised:2024-04-27

Online:2024-07-25

Published:2024-08-09

Contact:

Yanxia GUO

摘要:

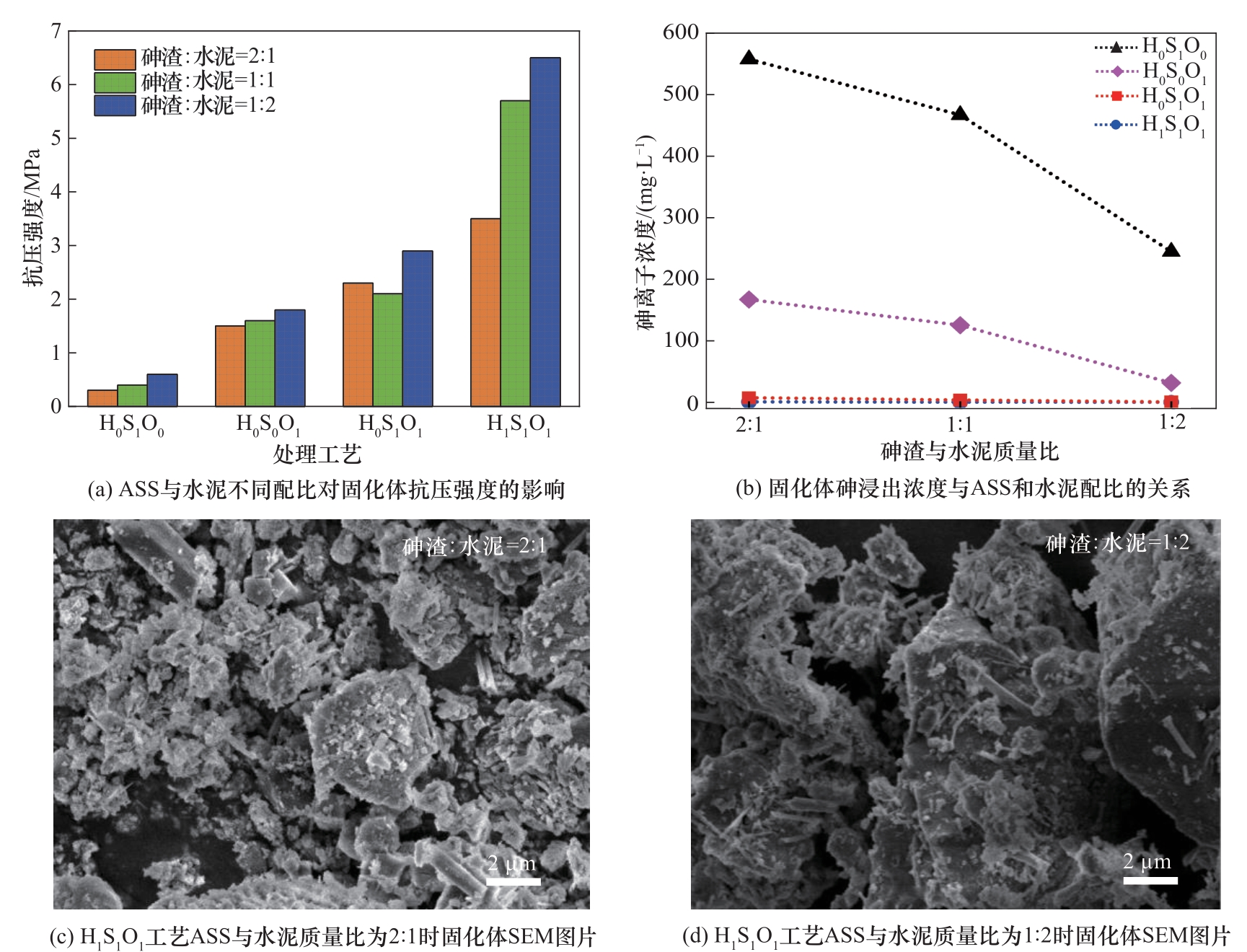

随着金属冶炼等工业的发展,难以处理的硫化砷渣大量堆存,对资源环境和人体健康造成严重危害。稳定化/固化技术是一种应用前景广阔的高效固砷技术,但是药剂消耗大、成本高、对复杂高浓度砷渣处理效果差等问题一直限制着该技术的发展。以低成本、高活性的钢渣和电石渣代替化学稳定剂,利用酸改性钢渣、铁离子和H2O2形成高级氧化/稳定化体系,随后在水泥作用下固化。通过XRD、FTIR、XPS等对上述过程进行表征,结果显示低价态砷、硫和有机物质被高效氧化成稳定的高价态钙铁盐,最终形成的固化体结构较为稳定。工艺优化后,1.0 g硫化砷渣在0.2 g钢渣、0.5 g H2O2、0.3 g电石渣和1.0 g水泥的分步协同稳定化/固化处理后,固化体抗压强度为5.7 MPa,砷浸出浓度仅为0.66 mg·L-1,远低于1.2 mg·L-1的安全填埋标准。

中图分类号:

张亚斌, 苏杨, 张慧荣, 宋一朋, 李健, 郭彦霞. 钢渣、电石渣增强硫化砷渣稳定化/固化机制[J]. 化工学报, 2024, 75(7): 2656-2669.

Yabin ZHANG, Yang SU, Huirong ZHANG, Yipeng SONG, Jian LI, Yanxia GUO. Mechanism of enhanced arsenic sulfide stabilization/solidification by using steel slag and carbide slag[J]. CIESC Journal, 2024, 75(7): 2656-2669.

| 成分 | 活化前 | 活化后 | ||||||

|---|---|---|---|---|---|---|---|---|

| CaO | Fe2O3 | SiO2 | Al2O3 | CaO | Fe2O3 | SiO2 | Al2O3 | |

| 质量分数/% | 58.4 | 13.5 | 10.1 | 7.3 | 37.7 | 21.2 | 16.2 | 11.2 |

表1 酸处理前后SS主要成分的XRF分析

Table 1 XRF analysis of main components of SS before and after acid treatment

| 成分 | 活化前 | 活化后 | ||||||

|---|---|---|---|---|---|---|---|---|

| CaO | Fe2O3 | SiO2 | Al2O3 | CaO | Fe2O3 | SiO2 | Al2O3 | |

| 质量分数/% | 58.4 | 13.5 | 10.1 | 7.3 | 37.7 | 21.2 | 16.2 | 11.2 |

| pH | Fe2+浓度/(mg·L-1) | Fe3+浓度/(mg·L-1) | Ca2+浓度/(mg·L-1) | ||||

|---|---|---|---|---|---|---|---|

| 25oC | 60oC | 25oC | 60oC | 25oC | 60oC | ||

| 1.0 | 165.9 | 185.0 | 89.0 | 131.0 | 4222.0 | 4300.0 | |

| 2.0 | 132.0 | 139.7 | 37.0 | 99.1 | 4140.0 | 4250.0 | |

| 3.0 | 82.7 | 96.3 | 20.3 | 42.5 | 3140.0 | 3600.0 | |

表2 不同酸处理条件下铁、钙浸出分析

Table 2 Investigation of iron and calcium leaching under various acid treatment conditions

| pH | Fe2+浓度/(mg·L-1) | Fe3+浓度/(mg·L-1) | Ca2+浓度/(mg·L-1) | ||||

|---|---|---|---|---|---|---|---|

| 25oC | 60oC | 25oC | 60oC | 25oC | 60oC | ||

| 1.0 | 165.9 | 185.0 | 89.0 | 131.0 | 4222.0 | 4300.0 | |

| 2.0 | 132.0 | 139.7 | 37.0 | 99.1 | 4140.0 | 4250.0 | |

| 3.0 | 82.7 | 96.3 | 20.3 | 42.5 | 3140.0 | 3600.0 | |

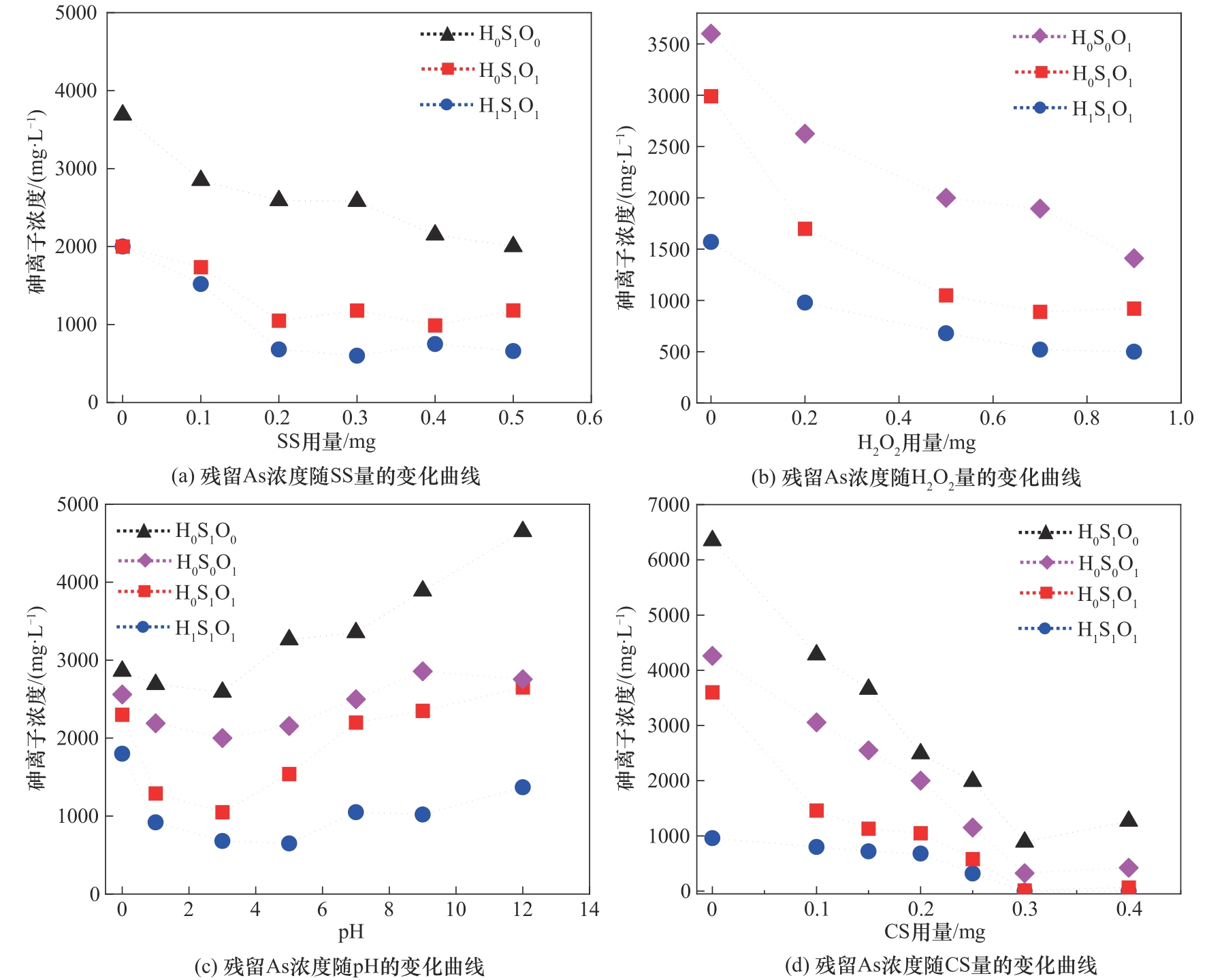

图5 H0S1O0、H0S0O1、H0S1O1、H1S1O1 4种稳定化工艺不同条件下砷离子浓度变化曲线

Fig.5 Arsenic ion concentration variation curves under different conditions for four stabilization processes: H0S1O0, H0S0O1, H0S1O1, and H1S1O1

图9 不同工艺砷钙渣不同配比条件下固化体抗压强度、砷浸出浓度及微观形貌分析

Fig.9 Analysis of compressive strength, As leaching concentration, and microstructure of solidified bodies prepared with different processes and different proportions

| 1 | 徐建兵, 沈强华, 陈雯, 等. 含砷废渣处理现状及对策[J]. 矿冶, 2017, 26(3): 82-86. |

| Xu J B, Shen Q H, Chen W, et al. The present situation and the countermeasure of the processing of arsenic residues[J]. Mining and Metallurgy, 2017, 26(3): 82-86. | |

| 2 | Mandal B K, Suzuki K T. Arsenic round the world: a review[J]. Talanta, 2002, 58(1): 201-235. |

| 3 | Su C, Jiang L Q, Zhang W J. A review on heavy metal contamination in the soil worldwide: situation, impact and remediation techniques[J]. Environmental Skeptics and Critics, 2014, 3(2): 24-38. |

| 4 | 龙冬清, 贾军峰, 何田妹, 等. 硫化砷渣稳定化/固化处理及其效果评价[J]. 环保科技, 2014, 20(3): 7-11. |

| Long D Q, Jia J F, He T M, et al. Stabilization/solidification of arsenic sulfide residue and effect evaluation[J]. Environmental Protection and Technology, 2014, 20(3): 7-11. | |

| 5 | 李艺. 有色多金属矿山砷污染对生态环境的影响及其治理分析[J]. 地球与环境, 2008, 36(3): 256-260. |

| Li Y. Impacts of arsenic pollution from nonferrous multi-metal mines on ecological environment and its governance analysis[J]. Earth and Environment, 2008, 36(3): 256-260. | |

| 6 | Zhao H R, Xia B C, Fan C, et al. Human health risk from soil heavy metal contamination under different land uses near Dabaoshan Mine, Southern China[J]. Science of the Total Environment, 2012, 417/418: 45-54. |

| 7 | Shibayama A, Takasaki Y, William T, et al. Treatment of smelting residue for arsenic removal and recovery of copper using pyro-hydrometallurgical process[J]. Journal of Hazardous Materials, 2010, 181(1/2/3): 1016-1023. |

| 8 | Song S, Lopez-Valdivieso A, Hernandez-Campos D J, et al. Arsenic removal from high-arsenic water by enhanced coagulation with ferric ions and coarse calcite[J]. Water Research, 2006, 40(2): 364-372. |

| 9 | De Klerk R J, Jia Y F, Daenzer R, et al. Continuous circuit coprecipitation of arsenic(Ⅴ) with ferric iron by lime neutralization: process parameter effects on arsenic removal and precipitate quality[J]. Hydrometallurgy, 2012, 111: 65-72. |

| 10 | 卢琼, 杜颖, 杜冬云. 从硫化砷渣回收单质硫和砷[J]. 硫酸工业, 2016(1): 24-27. |

| Lu Q, Du Y, Du D Y. Recovery of sulphur and arsenic from arsenic sulphide residue [J]. Sulphuric Acid Industry, 2016(1): 24-27. | |

| 11 | 王青, 廖亚龙, 周娟, 等. 含砷物料制备As2O3的研究进展[J]. 环境工程, 2015, 33(3): 97-101, 105. |

| Wang Q, Liao Y L, Zhou J, et al. Reviewer on preparation of arsenic oxide from materials containing arsenic[J]. Environmental Engineering, 2015, 33(3): 97-101, 105. | |

| 12 | Mollah M Y A, Kesmez M, Cocke D L. An X-ray diffraction (XRD) and Fourier transform infrared spectroscopic (FT-IR) investigation of the long-term effect on the solidification/stabilization (S/S) of arsenic(Ⅴ) in Portland cement type-V[J]. Science of the Total Environment, 2004, 325(1/2/3): 255-262. |

| 13 | 王永良, 杨晓玲, 董永霞, 等. pH调整剂对含砷酸性废水中氧化Fe(Ⅱ)共沉淀固砷行为的影响[J]. 化工学报, 2019, 70(9): 3511-3516. |

| Wang Y L, Yang X L, Dong Y X, et al. Effect of pH adjustment on immobilization of arsenic by coprecipitation through oxidizing Fe(Ⅱ) in acidic wastewater containing arsenic[J]. CIESC Journal, 2019, 70(9): 3511-3516. | |

| 14 | 于冰冰, 颜湘华, 王兴润, 等. 不同稳定化材料对废渣中As的固定效果[J]. 中国环境科学, 2019, 39(9): 3887-3896. |

| Yu B B, Yan X H, Wang X R, et al. Stabilization effects of different materials on arsenic-containing slag[J]. China Environmental Science, 2019, 39(9): 3887-3896. | |

| 15 | 陶志超, 周新涛, 罗中秋, 等. 含砷废渣水泥固化/稳定化技术研究进展[J]. 材料导报, 2016, 30(9): 132-136, 143. |

| Tao Z C, Zhou X T, Luo Z Q, et al. Progress on the solidification/immobilization of arsenic-bearing waste cement[J]. Materials Reports, 2016, 30(9): 132-136, 143. | |

| 16 | Palfy P, Vircikova E, Molnar L. Processing of arsenic waste by precipitation and solidification[J]. Waste Management, 1999, 19(1): 55-59. |

| 17 | 张微. 硫化砷渣预氧化转型-水泥固化技术处理研究[J]. 中国有色冶金, 2020, 49(5): 67-74. |

| Zhang W. Study on the pre-oxidation transformation-cement fixation technology for arsenic sulfide residues[J]. China Nonferrous Metallurgy, 2020, 49(5): 67-74. | |

| 18 | 钟琦, 任雪娇, 李行德. 酸性高砷污泥稳定化固化的初步研究[J]. 云南化工, 2021, 48(10): 50-51, 58. |

| Zhong Q, Ren X J, Li H D. Preliminary study on stabilization and solidification of acidic high arsenic sludge[J]. Yunnan Chemical Technology, 2021, 48(10): 50-51, 58. | |

| 19 | 柯平超, 刘志宏, 刘智勇, 等. 固砷矿物臭葱石组成与结构及其浸出稳定性研究现状[J]. 化工学报, 2016, 67(11): 4533-4540. |

| Ke P C, Liu Z H, Liu Z Y, et al. Research status on composition, structure, and leaching stability of an arsenic solidification mineral scorodite[J]. CIESC Journal, 2016, 67(11): 4533-4540. | |

| 20 | 刘守庆, 罗中秋, 和森, 等. 高炉矿渣-粉煤灰地聚合物胶凝材料固化砷钙渣[J]. 化工进展, 2017, 36(7): 2660-2666. |

| Liu S Q, Luo Z Q, He S, et al. Solidification/stabilization of calcium arsenate waste with blast furnace slag and fly ash geopolymer materials[J]. Chemical Industry and Engineering Progress, 2017, 36(7): 2660-2666. | |

| 21 | Pan S Y, Adhikari R, Chen Y H, et al. Integrated and innovative steel slag utilization for iron reclamation, green material production and CO2 fixation via accelerated carbonation[J]. Journal of Cleaner Production, 2016, 137: 617-631. |

| 22 | 赵立文, 朱干宇, 李少鹏, 等. 电石渣特性及综合利用研究进展[J]. 洁净煤技术, 2021, 27(3):13-26. |

| Zhao L W, Zhu G Y, Li S P, et al. Research progress on characteristics and comprehensive utilization of calcium carbide slag[J]. Clean Coal Technology, 2021, 27(3): 13-26. | |

| 23 | 郝峰焱. 钢渣基活性材料固砷机理及其应用[D]. 昆明: 昆明理工大学, 2020. |

| Hao F Y. Arsenic fixation mechanism of steel slag-based active materials and its application [D]. Kunming: Kunming University of Science and Technology, 2020. | |

| 24 | 夏娜娜. 改性钢渣对海水中汞和砷的吸附性能研究[D]. 青岛: 中国海洋大学, 2013. |

| Xia N N. Adsorption properties of modified steel slag for removal of mercury and arsenic from seawater[D]. Qingdao: Ocean University of China, 2013. | |

| 25 | 芦柏年. 电石渣对含砷污泥的稳定化处理及其机制研究[D]. 武汉: 华中科技大学, 2020. |

| Lu B N. Stabilization of arsenic-bearing sludge by carbide slag[D]. Wuhan: Huazhong University of Science and Technology, 2020. | |

| 26 | 徐媛. 含砷石膏渣水泥固化及强化机制研究[D]. 昆明: 昆明理工大学, 2017. |

| Xu Y. Study on solidification and strengthening mechanism of arsenic-containing gypsum slag cement[D]. Kunming: Kunming University of Science and Technology, 2017. | |

| 27 | 国家环境保护总局. 危险废物鉴别标准 腐蚀性鉴别: [S]. 北京: 中国环境科学出版社, 2007. |

| State Environmental Protection Administration of the People’s Republic of China. Identification for standards hazardous wastes- Identification for corrosivity: [S]. Beijing: China Environmental Science Press, 2007. | |

| 28 | 任云亮, 王晨晔, 张洪恩, 等. 有机-无机复合介质浸出对钢渣中含铁物相的影响[J]. 过程工程学报, 2015, 15(3): 430-434. |

| Ren Y L, Wang C Y, Zhang H E, et al. Change of iron-containing phases in steelmaking slag in leaching process with organic-inorganic composite medium[J]. The Chinese Journal of Process Engineering, 2015, 15(3): 430-434. | |

| 29 | Zhang A Y, Huang N H, Zhang C, et al. Heterogeneous Fenton decontamination of organoarsenicals and simultaneous adsorption of released arsenic with reduced secondary pollution[J]. Chemical Engineering Journal, 2018, 344: 1-11. |

| 30 | 邹敏, 沈玉, 刘娟红. 钢渣粉在水泥基材料中应用研究综述[J]. 硅酸盐通报, 2021, 40(9): 2964-2977. |

| Zou M, Shen Y, Liu J H. Review on application of steel slag powder in cement-based materials[J]. Bulletin of the Chinese Ceramic Society, 2021, 40(9): 2964-2977. |

| [1] | 张林, 张子怡, 李勇, 童少平. Fe-MOF-74前体制备铁-碳/氮复合材料及其活化过硫酸盐性能[J]. 化工学报, 2024, 75(5): 1882-1889. |

| [2] | 李琢宇, 金鹏, 陈孝彦, 赵泽玉, 王庆宏, 陈春茂, 詹亚力. 零价铁活化过氧乙酸降解水中双酚A的效果与机制[J]. 化工学报, 2024, 75(3): 987-999. |

| [3] | 李瑞康, 何盈盈, 卢维鹏, 王园园, 丁皓东, 骆勇名. 电化学强化钴基阴极活化过一硫酸盐的研究[J]. 化工学报, 2023, 74(5): 2207-2216. |

| [4] | 杨庆云, 李青松, 陈泽铭, 邓靖, 李玉瑛, 杨帆, 陈国元, 李国新. UV/PMS、UV/PDS、UV/SPC工艺降解尼泊金甲酯[J]. 化工学报, 2023, 74(3): 1322-1331. |

| [5] | 郑杰元, 张先伟, 万金涛, 范宏. 丁香酚环氧有机硅树脂的制备及其固化动力学研究[J]. 化工学报, 2023, 74(2): 924-932. |

| [6] | 刘佳宁, 马嘉浩, 张军营, 程珏. 顺序双重热固化的硫醇-丙烯酸酯-环氧树脂三维网络的构建及性能[J]. 化工学报, 2022, 73(9): 4173-4186. |

| [7] | 靳文章, 张玉玲, 贾晓宇. 电化学高级氧化对HEDP的降解效能研究[J]. 化工学报, 2022, 73(9): 4062-4069. |

| [8] | 陆遥, 董杰, 孙大为, 谢乐天, 卢家勇, 杜晓宁. 织构PNN-PZT陶瓷的光固化成型制备及其电学性能研究[J]. 化工学报, 2022, 73(8): 3768-3775. |

| [9] | 王建, 雷子萱, 姚家钰, 李建, 刘育红. 对苯二甲醛酚醛树脂的制备及其固化动力学研究[J]. 化工学报, 2022, 73(3): 1403-1415. |

| [10] | 王哲, 祖愿, 胡方圆, 蹇锡高. 含杂萘联苯结构的环氧树脂固化动力学分析[J]. 化工学报, 2022, 73(2): 681-688. |

| [11] | 韩维辰, 王佳铭, 贺曼罗, 贺高红, 焉晓明, 阮雪华. 潜伏型环氧固化剂甲基异丁基酮二亚胺的合成及工艺优化[J]. 化工学报, 2021, 72(7): 3832-3838. |

| [12] | 王柯晴, 徐劼, 沈芷璇, 陈家斌, 吴玮. LaCoO3钙钛矿活化过一硫酸盐降解萘普生[J]. 化工学报, 2020, 71(3): 1326-1334. |

| [13] | 王海军, 王露雨, 马明明, 万里强, 黄发荣. 新型聚三唑酯和聚三唑醚树脂的合成及性能[J]. 化工学报, 2019, 70(9): 3527-3536. |

| [14] | 尹飞, 王翠, 童少平. rGO-Fe3O4活化过硫酸盐处理酸性红73[J]. 化工学报, 2019, 70(1): 207-213. |

| [15] | 朱国建, 范天锋, 王德海, 鲍刘兵. 自由基型紫外光固化氧阻聚作用的定量描述[J]. 化工学报, 2018, 69(8): 3740-3746. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号