化工学报 ›› 2025, Vol. 76 ›› Issue (5): 2397-2409.DOI: 10.11949/0438-1157.20241227

收稿日期:2024-10-31

修回日期:2024-12-12

出版日期:2025-05-25

发布日期:2025-06-13

通讯作者:

高守建,靳健

作者简介:朱迪(1998—),男,硕士研究生,1679692079@qq.com

基金资助:

Di ZHU1( ), Shoujian GAO2(

), Shoujian GAO2( ), Wangxi FANG2, Jian JIN1(

), Wangxi FANG2, Jian JIN1( )

)

Received:2024-10-31

Revised:2024-12-12

Online:2025-05-25

Published:2025-06-13

Contact:

Shoujian GAO, Jian JIN

摘要:

膜分离技术因高效率、低能耗、无须化学添加剂等优势已成为处理含油污水的重要手段。聚醚砜(PES)膜由于出色的热稳定性和机械强度被广泛应用于水处理,但制备具有高孔隙率海绵孔结构和稳定超亲水性的PES膜,实现含油污水高通量、抗污染分离仍是一个难题。在此,通过水蒸气诱导相分离(VIPS)方法,以PES为成膜材料、聚乙烯吡咯烷酮(PVP)为亲水添加剂、聚乙二醇(PEG)为制孔剂制备了海绵孔结构的超亲水PES膜。同时通过Na2S2O8引发膜内PVP自由基交联反应抑制PVP溶出流失,使PES膜保持长时间稳定的超亲水性质和抗油污染性能。此PES膜分离油/水乳液时分离效率高于99.8%,水通量达到3900 L·m-2·h-1·bar-1,并展现出优异的循环性能,通量衰减率低至5.4%,水冲洗后通量恢复率高于96.3%。

中图分类号:

朱迪, 高守建, 方望熹, 靳健. 水蒸气诱导相分离构筑海绵孔结构超亲水聚醚砜膜及其油/水乳液分离性能研究[J]. 化工学报, 2025, 76(5): 2397-2409.

Di ZHU, Shoujian GAO, Wangxi FANG, Jian JIN. Construction of PES membranes with sponge-like pores and stable super-hydrophilicity through vapor-induced phase separation for oil-in-water emulsion separation[J]. CIESC Journal, 2025, 76(5): 2397-2409.

图8 PES/PVP膜的动态水接触角(a)、动态水下油接触角(b)表征以及水中抗大豆油(c)和二氯乙烷(d)污染能力

Fig.8 Dynamicwater contact angles (a), underwater oil contact angles (b), antifouling ability to soybean oil (c) and dichloroethane (d) of the PES/PVP membrane

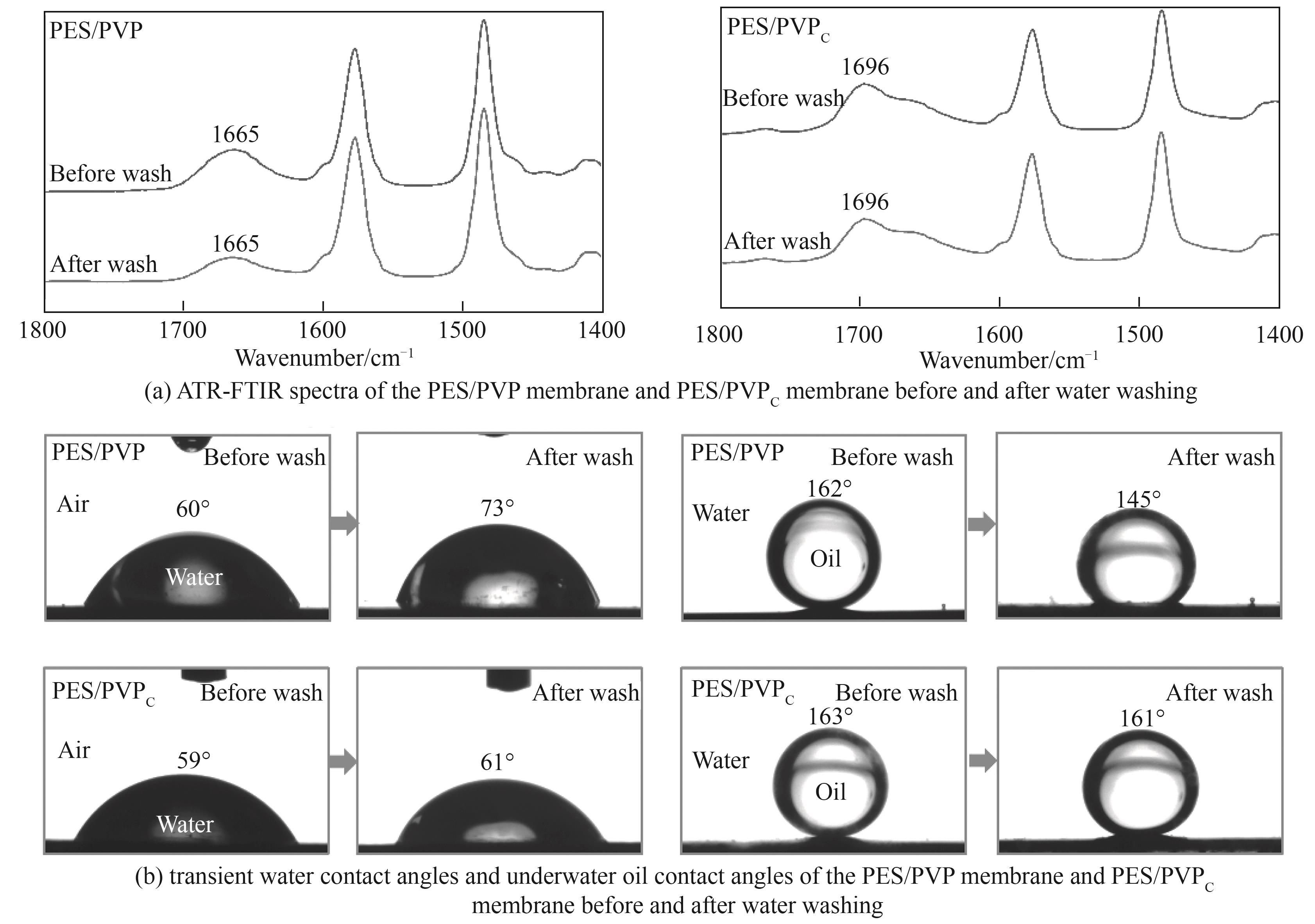

图11 PES/PVP膜与PES/PVPC膜在水冲刷7 d前后的表面组成和浸润性变化

Fig.11 Changes in surface composition and wettability of PES/PVP membrane and PES/PVPC membrane before and after water washing for 7 d

| 17 | Rahimpour A, Madaeni S S, Ghorbani S, et al. The influence of sulfonated polyethersulfone (SPES) on surface nano-morphology and performance of polyethersulfone (PES) membrane [J]. Applied Surface Science, 2010, 256(6): 1825-1831. |

| 18 | Susanto H, Stahra N, Ulbricht M. High performance polyethersulfone microfiltration membranes having high flux and stable hydrophilic property [J]. Journal of Membrane Science, 2009, 342(1): 153-164. |

| 19 | Su Y S, Kuo C Y, Wang D M, et al. Interplay of mass transfer, phase separation, and membrane morphology in vapor-induced phase separation [J]. Journal of Membrane Science, 2009, 338(1): 17-28. |

| 20 | Tateno M, Yanagishima T, Tanaka H. Microscopic structural origin behind slowing down of colloidal phase separation approaching gelation[J]. The Journal of Chemical Physics, 2022, 156(8). |

| 21 | Pochivalov K V, Basko A V, Ilyasova A N, et al. Experimental phase diagram for the PVDF - DMAc- water ternary system with new topology: method of construction, thermodynamics, and structure formation of membranes[J]. Polymer, 2023, 282: 126152. |

| 22 | Li N, Wu S, Dai H, et al. Thermal activation of persulfates for organic wastewater purification: heating modes, mechanism and influencing factors [J]. Chemical Engineering Journal, 2022, 450: 137976. |

| 23 | Fogaça R, Catalani L H. PVP hydrogel membranes produced by electrospinning for protein release devices [J]. Soft Materials, 2013, 11(1): 61-68. |

| 24 | Anderson C C, Rodriguez F, Thurston D A. Crosslinking aqueous poly(vinyl pyrrolidone) solutions by persulfate [J]. Journal of Applied Polymer Science, 1979, 23(8): 2453-2462. |

| 25 | Schrader B. Infrared and Raman Spectroscopy: Methods and Applications [M]. New York: John Wiley & Sons, 2008. |

| 26 | Zhu X, Lu P, Chen W, et al. Studies of UV crosslinked poly (N-vinylpyrrolidone) hydrogels by FTIR, Raman and solid-state NMR spectroscopies [J]. Polymer, 2010, 51(14): 3054-3063. |

| 27 | Gonzalez Ortiz D, Nouxet M, Maréchal W, et al. Immobilization of poly(vinyl pyrrolidone) in polysulfone membranes by radically-initiated crosslinking using potassium persulfate [J]. Membranes, 2022, 12(7): 664. |

| 28 | Liu Z M, Xu Z K, Wan L S, et al. Surface modification of polypropylene microfiltration membranes by the immobilization of poly (N-vinyl-2-pyrrolidone): a facile plasma approach [J]. Journal of Membrane Science, 2005, 249(1): 21-31. |

| 1 | Deng Y, Wu Y, Chen G, et al. Metal-organic framework membranes: recent development in the synthesis strategies and their application in oil-water separation [J]. Chemical Engineering Journal, 2021, 405: 127004. |

| 2 | Wang A, Zhu Y, Fang W, et al. Zero-oil-fouling membrane with high coverage of grafted zwitterionic polymer for separation of oil-in-water emulsions [J]. Small Methods, 2024, 8(4): 2300247. |

| 3 | Ismail N H, Salleh W N W, Ismail A F, et al. Hydrophilic polymer-based membrane for oily wastewater treatment: a review [J]. Separation and Purification Technology, 2020, 233: 116007. |

| 4 | Baig N. Recent progress on the development of superhydrophobic and superoleophilic meshes for oil and water separation: a review [M]//Contaminants in Our Water: Identification and Remediation Methods. New York: American Chemical Society, 2020: 175-196. |

| 5 | Gupta R K, Dunderdale G J, England M W, et al. Oil/water separation techniques: a review of recent progresses and future directions [J]. Journal of Materials Chemistry A, 2017, 5(31): 16025-16058. |

| 6 | Padaki M, Surya Murali R, Abdullah M S, et al. Membrane technology enhancement in oil-water separation. A review [J]. Desalination, 2015, 357: 197-207. |

| 7 | Zhu Y, Wang D, Jiang L, et al. Recent progress in developing advanced membranes for emulsified oil/water separation [J]. NPG Asia Materials, 2014, 6(5): e101-e101. |

| 8 | Wang B, Liang W, Guo Z, Liu W, Biomimetic super-lyophobic and super-lyophilic materials applied for oil/water separation: a new strategy beyond nature[J]. Chemical Society Reviews, 2015, 44: 336-361. |

| 9 | Huisman I H, Prádanos P, Hernández A. The effect of protein-protein and protein-membrane interactions on membrane fouling in ultrafiltration[J]. Journal of Membrane Science, 2000, 179: 79-90. |

| 10 | Yang H C, Xie Y S, Chan H, et al. Crude-oil-repellent membranes by atomic layer deposition: oxide interface engineering[J]. ACS Nano, 2018, 12: 8678-8685. |

| 11 | Thomas R, Guillen-Burrieza E, Arafat H A. Pore structure control of PVDF membranes using a 2-stage coagulation bath phase inversion process for application in membrane distillation (MD) [J]. Journal of Membrane Science, 2014, 452: 470-480. |

| 12 | Alaei Shahmirzadi M A, Hosseini S S, Ruan G, et al. Tailoring PES nanofiltration membranes through systematic investigations of prominent design, fabrication and operational parameters [J]. RSC Advances, 2015, 5(61): 49080-49097. |

| 13 | Hwang J R, Sefton M V. The effects of polymer concentration and a pore-forming agent (PVP) on HEMA-MMA microcapsule structure and permeability [J]. Journal of Membrane Science, 1995, 108(3): 257-268. |

| 29 | Feng R, Wang C, Xu X, et al. Highly effective antifouling performance of N-vinyl-2-pyrrolidone modified polypropylene non-woven fabric membranes by ATRP method [J]. Journal of Membrane Science, 2011, 369(1): 233-242. |

| 30 | El-Sawy N M, Elassar A Z A. Some modification on radiation graft polymerization of N-vinyl-2-pyrrolidone onto low density polyethylene with α,β-unsaturated nitrile [J]. European Polymer Journal, 1998, 34(8): 1073-1080. |

| 31 | Tian M, Liao Y, Wang R. Engineering a superwetting thin film nanofibrous composite membrane with excellent antifouling and self-cleaning properties to separate surfactant-stabilized oil-in-water emulsions [J]. Journal of Membrane Science, 2020, 596: 117721. |

| 32 | Yu Q, Zhou L, Su Y, et al. Assembly of self-cleaning perfluoroalkyl coating on separation membrane surface [J]. Applied Surface Science, 2019, 496: 143674. |

| 33 | Xu C, Yan F, Wang M, et al. Fabrication of hyperbranched polyether demulsifier modified PVDF membrane for demulsification and separation of oil-in-water emulsion [J]. Journal of Membrane Science, 2020, 602: 117974. |

| 34 | Yang C, Long M, Ding C, et al. Antifouling graphene oxide membranes for oil-water separation via hydrophobic chain engineering [J]. Nature Communications, 2022, 13(1): 7334. |

| 35 | Bhalani D V, Singh Chandel A K, Trivedi J S, et al. High molecular weight poly(vinyl pyrrolidone) induces hierarchical surface morphology in poly(vinylidene fluoride) membrane and facilitates separation of oil-water emulsions [J]. Journal of Membrane Science, 2018, 566: 415-427. |

| 36 | Ma S, Lin L, Wang Q, et al. Modification of supramolecular membranes with 3D hydrophilic slide-rings for the improvement of antifouling properties and effective separation [J]. ACS Applied Materials & Interfaces, 2019, 11(31): 28527-28537. |

| 37 | Cao J, Su Y, Liu Y, et al. Self-assembled MOF membranes with underwater superoleophobicity for oil/water separation [J]. Journal of Membrane Science, 2018, 566: 268-277. |

| 38 | Zhu Y, Wang J, Zhang F, et al. Zwitterionic nanohydrogel grafted PVDF membranes with comprehensive antifouling property and superior cycle stability for oil-in-water emulsion separation [J]. Advanced Functional Materials, 2018, 28(40): 1804121. |

| 39 | Gao S, Zhu Y, Wang J, et al. Layer-by-layer construction of Cu2+/alginate multilayer modified ultrafiltration membrane with bioinspired superwetting property for high-efficient crude-oil-in-water emulsion separation [J]. Advanced Functional Materials, 2018, 28(49): 1801944. |

| 40 | Zhang L, Lin Y, Wu H, et al. An ultrathin in situ silicification layer developed by an electrostatic attraction force strategy for ultrahigh-performance oil–water emulsion separation [J]. Journal of Materials Chemistry A, 2019, 7(42): 24569-24582. |

| 41 | Islam M S, McCutcheon J R, Rahaman M S. A high flux polyvinyl acetate-coated electrospun nylon 6/SiO2 composite microfiltration membrane for the separation of oil-in-water emulsion with improved antifouling performance [J]. Journal of Membrane Science, 2017, 537: 297-309. |

| 14 | Alenazi N A, Hussein M A, Alamry K A, et al. Modified polyether-sulfone membrane: a mini review [J]. Designed Monomers and Polymers, 2017, 20(1): 532-546. |

| 15 | Tavangar T, Jalali K, Alaei Shahmirzadi M A, et al. Toward real textile wastewater treatment: membrane fouling control and effective fractionation of dyes/inorganic salts using a hybrid electrocoagulation-nanofiltration process [J]. Separation and Purification Technology, 2019, 216: 115-125. |

| 16 | Marbelia L, Bilad M R, Vankelecom I F J. Gradual PVP leaching from PVDF/PVP blend membranes and its effects on membrane fouling in membrane bioreactors [J]. Separation and Purification Technology, 2019, 213: 276-282. |

| [1] | 顾栋, 皮行健, 张叠, 张瑛. 不同粒径CAU-1/PI混合基质膜的构建与H2/CO2分离性能研究[J]. 化工学报, 2025, 76(5): 2410-2418. |

| [2] | 安昊天, 韩章烨, 陆慕瑶, 周阿武, 李建荣. 推进MOF产业化应用:宏量制备与成型[J]. 化工学报, 2025, 76(5): 2011-2025. |

| [3] | 郭明钢, 杨晓航, 代岩, 米盼盼, 马世鑫, 贺高红, 肖武, 崔福军. 贫氦管输天然气提氦多元化产品耦合工艺优化设计[J]. 化工学报, 2025, 76(5): 2251-2261. |

| [4] | 张耀辉, 班宇杰, 杨维慎. 以蒸气加工法制备和修饰金属-有机框架膜[J]. 化工学报, 2025, 76(5): 2070-2086. |

| [5] | 杨紫博, 王有发, 岳寒松, 远双杰, 耿付江, 李晴晴, 奥德, 李斌, 叶茂, 顾振杰, 乔志华. MOF玻璃基气体分离膜的研究进展[J]. 化工学报, 2025, 76(5): 2158-2168. |

| [6] | 程刘惠美, 闫军营, 刘慧情, 王治澎, 王报英, 徐铜文, 汪耀明. 双极膜电渗析在醇水体系的应用研究进展[J]. 化工学报, 2025, 76(5): 1960-1972. |

| [7] | 高冰冰, 许诺, 白云翔, 张春芳, 杨永强, 董亮亮. 氦气分离聚合物膜[J]. 化工学报, 2025, 76(5): 2119-2135. |

| [8] | 李紫鹃, 谭晓艳, 吴永盛, 杨陈怡, 陈红, 毕小刚, 刘捷, 喻发全. 分子模拟研究三维扭曲催化芳烃-降冰片烯环化聚合物膜的CO2/N2分离机理[J]. 化工学报, 2025, 76(5): 2348-2357. |

| [9] | 花敬贤, 罗宇荣, 顾亚伟, 吴婷婷, 潘宜昌, 邢卫红. 超薄取向ZIF-8膜的制备及乙烯/乙烷高效分离[J]. 化工学报, 2025, 76(5): 2209-2218. |

| [10] | 刘鑫, 郑皓仁, 陈强, 丁静怡, 黄康, 徐至. 全钒液流电池用纤维素纳米晶掺杂混合基质膜[J]. 化工学报, 2025, 76(5): 2294-2303. |

| [11] | 王金月, 谢恩泽, 马翰泽, 袁晟, 何光伟, 姜忠义. 单原子层分离膜:进展与展望[J]. 化工学报, 2025, 76(5): 1943-1959. |

| [12] | 陆艳秋, 狄扬, 石文博, 殷聪聪, 汪勇. 基于新型有机多孔聚合物的智能响应膜研究进展[J]. 化工学报, 2025, 76(5): 2101-2118. |

| [13] | 赵浩帆, 任豪杰, 刘宗凯, 董冠英, 张亚涛. MOFs玻璃膜在气体分离领域的研究进展[J]. 化工学报, 2025, 76(5): 2042-2054. |

| [14] | 张越, 刘佳鑫, 马敬, 刘毅. 金属有机骨架膜应用于海水提铀研究进展[J]. 化工学报, 2025, 76(5): 2087-2100. |

| [15] | 徐泽海, 刘超, 张国亮. 聚合物基疏水渗透汽化膜及其溶剂回收应用[J]. 化工学报, 2025, 76(5): 2055-2069. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号