化工学报 ›› 2025, Vol. 76 ›› Issue (7): 3477-3486.DOI: 10.11949/0438-1157.20241029

董泽明( ), 娄聚伟, 王楠, 陈良奇, 王江峰(

), 娄聚伟, 王楠, 陈良奇, 王江峰( ), 赵攀

), 赵攀

收稿日期:2024-09-13

修回日期:2025-03-18

出版日期:2025-07-25

发布日期:2025-08-13

通讯作者:

王江峰

作者简介:董泽明(2001—),男,硕士研究生,18223737710@stu.xjtu.edu.cn

基金资助:

Zeming DONG( ), Juwei LOU, Nan WANG, Liangqi CHEN, Jiangfeng WANG(

), Juwei LOU, Nan WANG, Liangqi CHEN, Jiangfeng WANG( ), Pan ZHAO

), Pan ZHAO

Received:2024-09-13

Revised:2025-03-18

Online:2025-07-25

Published:2025-08-13

Contact:

Jiangfeng WANG

摘要:

压缩二氧化碳储能系统因其往返效率高、储能密度大的优点受到广泛关注,被认为是一种极具发展前景的储能技术。提出了透平余热回收的超临界压缩二氧化碳储能系统并建立了系统热力学模型,基于热力学定律对系统进行关键参数分析及热力性分析;以系统的往返效率和储能密度为优化目标,采用遗传算法对系统4个关键参数分别进行单目标优化及多目标优化,获取了最优系统性能。结果显示,在给定参数下系统的往返效率为37.21%,㶲效率为33.44%,储能密度为8.31 kW∙h∙m-3;4个关键参数中,低压储罐压力和透平进口温度对系统性能影响更加明显;单目标优化获得最优系统的往返效率为52.69%,最优储能密度为17.16 kW∙h∙m-3;多目标优化获得一个综合性能良好的优化解,此时系统的往返效率为46.88%,储能密度为13.97 kW∙h∙m-3。

中图分类号:

董泽明, 娄聚伟, 王楠, 陈良奇, 王江峰, 赵攀. 含余热回收的超临界压缩二氧化碳储能系统热力学特性研究[J]. 化工学报, 2025, 76(7): 3477-3486.

Zeming DONG, Juwei LOU, Nan WANG, Liangqi CHEN, Jiangfeng WANG, Pan ZHAO. Research on thermodynamic properties of supercritical compressed carbon dioxide energy storage system with waste heat recovery[J]. CIESC Journal, 2025, 76(7): 3477-3486.

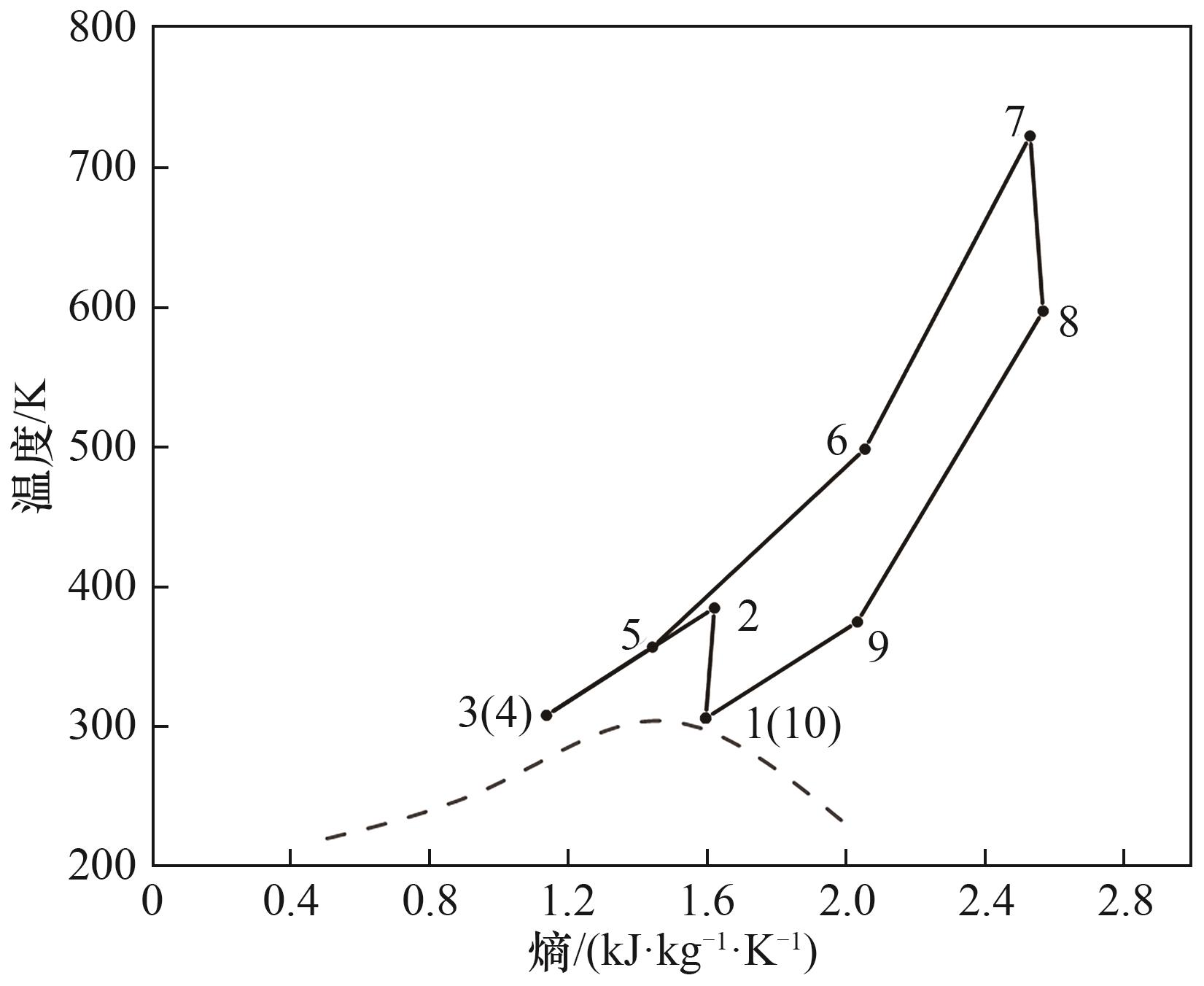

图3 超临界压缩二氧化碳储能系统温熵图(虚线为二氧化碳的饱和曲线)

Fig.3 Temperature entropy diagram of supercritical compressed carbon dioxide energy storage system (dashed line represents saturation curve of carbon dioxide)

| 参数 | 数值 |

|---|---|

| 环境温度/℃ | 32 |

| 环境压力/MPa | 0.1 |

| 高压储罐压力/MPa | 25.0 |

| 低压储罐压力/MPa | 7.5 |

| 透平进口温度/℃ | 450 |

| 压缩机进口温度/℃ | 33 |

| 透平等熵效率/% | 85 |

| 压缩机等熵效率/% | 80 |

| 水泵等熵效率/% | 75 |

| 燃烧室内温度/℃ | 727 |

| 回热器端差/℃ | 20 |

| 燃烧室加热功率/kW | 5000 |

表1 超临界压缩二氧化碳储能系统初始参数

Table 1 Initial parameters of supercritical compressed carbon dioxide energy storage system

| 参数 | 数值 |

|---|---|

| 环境温度/℃ | 32 |

| 环境压力/MPa | 0.1 |

| 高压储罐压力/MPa | 25.0 |

| 低压储罐压力/MPa | 7.5 |

| 透平进口温度/℃ | 450 |

| 压缩机进口温度/℃ | 33 |

| 透平等熵效率/% | 85 |

| 压缩机等熵效率/% | 80 |

| 水泵等熵效率/% | 75 |

| 燃烧室内温度/℃ | 727 |

| 回热器端差/℃ | 20 |

| 燃烧室加热功率/kW | 5000 |

| 参数 | 数值 |

|---|---|

| 压缩机耗功/kW | 525.91 |

| 膨胀透平输出功/kW | 1349.34 |

| 往返效率/% | 37.21 |

| 㶲效率/% | 33.44 |

| 储能密度/(kW∙h∙m-3) | 8.13 |

表2 超临界压缩二氧化碳储能系统能量参数计算结果

Table 2 Calculation results of energy parameters of supercritical compressed carbon dioxide energy storage system

| 参数 | 数值 |

|---|---|

| 压缩机耗功/kW | 525.91 |

| 膨胀透平输出功/kW | 1349.34 |

| 往返效率/% | 37.21 |

| 㶲效率/% | 33.44 |

| 储能密度/(kW∙h∙m-3) | 8.13 |

| 参数 | 下限 | 上限 |

|---|---|---|

| 压缩机进口温度/℃ | 32 | 45 |

| 透平进口温度/℃ | 350 | 550 |

| 低压储罐压力/MPa | 7.4 | 15.0 |

| 高压储罐压力/MPa | 15.0 | 30.0 |

表3 超临界压缩二氧化碳储能系统参数变化范围

Table 3 Parameter range of supercritical compressed carbon dioxide energy storage system

| 参数 | 下限 | 上限 |

|---|---|---|

| 压缩机进口温度/℃ | 32 | 45 |

| 透平进口温度/℃ | 350 | 550 |

| 低压储罐压力/MPa | 7.4 | 15.0 |

| 高压储罐压力/MPa | 15.0 | 30.0 |

| 参数 | 数值 |

|---|---|

| 压缩机进口温度/℃ | 32.00 |

| 透平进口温度/℃ | 550.00 |

| 低压储罐压力/MPa | 13.42 |

| 高压储罐压力/MPa | 24.77 |

| 系统的往返效率/% | 52.69 |

表4 优化后的往返效率及关键参数

Table 4 Optimized round-trip efficiency and key parameters

| 参数 | 数值 |

|---|---|

| 压缩机进口温度/℃ | 32.00 |

| 透平进口温度/℃ | 550.00 |

| 低压储罐压力/MPa | 13.42 |

| 高压储罐压力/MPa | 24.77 |

| 系统的往返效率/% | 52.69 |

| 参数 | 数值 |

|---|---|

| 压缩机进口温度/℃ | 32.00 |

| 透平进口温度/℃ | 550.00 |

| 低压储罐压力/MPa | 8.05 |

| 高压储罐压力/MPa | 29.94 |

| 储能密度/(kW∙h∙m-3) | 17.16 |

表5 优化后的储能密度及设计参数

Table 5 Optimized energy storage density and design parameters

| 参数 | 数值 |

|---|---|

| 压缩机进口温度/℃ | 32.00 |

| 透平进口温度/℃ | 550.00 |

| 低压储罐压力/MPa | 8.05 |

| 高压储罐压力/MPa | 29.94 |

| 储能密度/(kW∙h∙m-3) | 17.16 |

| [1] | Jafari M, Botterud A, Sakti A. Decarbonizing power systems: a critical review of the role of energy storage[J]. Renewable and Sustainable Energy Reviews, 2022, 158: 112077. |

| [2] | Ali S, Stewart R A, Sahin O. Drivers and barriers to the deployment of pumped hydro energy storage applications: systematic literature review[J]. Cleaner Engineering and Technology, 2021, 5: 100281. |

| [3] | 王伟. 可再生能源并网系统中电池储能系统特性及优化[D]. 济南: 山东大学, 2022. |

| Wang W. Characteristics and optimization of battery energy storage system in renewable energy grid-connected system[D]. Jinan: Shandong University, 2022. | |

| [4] | 万明忠, 王元媛, 李峻, 等. 压缩空气储能技术研究进展及未来展望[J]. 综合智慧能源, 2023, 45(9): 26-31. |

| Wan M Z, Wang Y Y, Li J, et al. Research progress and future prospect of compressed air energy storage technology[J]. Integrated Intelligent Energy, 2023, 45(9): 26-31. | |

| [5] | 何青, 王珂. 等温压缩空气储能技术及其研究进展[J]. 热力发电, 2022, 51(8): 11-19. |

| He Q, Wang K. Research progress of isothermal compressed air energy storage technology[J]. Thermal Power Generation, 2022, 51(8): 11-19. | |

| [6] | 傅昊, 张毓颖, 崔岩, 等. 压缩空气储能技术研究进展[J]. 科技导报, 2016, 34(23): 81-87. |

| Fu H, Zhang Y Y, Cui Y, et al. Research progress of compressed air energy storage systems[J]. Science & Technology Review, 2016, 34(23): 81-87. | |

| [7] | 赵攀, 张仕强, 许文盼, 等. 具备近似等压放电过程的近似等温压缩CO2储能系统特性研究[J]. 西安交通大学学报, 2023, 57(1): 34-44. |

| Zhao P, Zhang S Q, Xu W P, et al. Performance analysis of a near-isothermal compressed carbon dioxide energy storage system with near constant discharge process[J]. Journal of Xi'an Jiaotong University, 2023, 57(1): 34-44. | |

| [8] | 高超. 超临界二氧化碳储能发电系统设计优化[D]. 北京: 华北电力大学, 2023. |

| Gao C. Design optimization of supercritical carbon dioxide energy storage power generation system[D]. Beijing: North China Electric Power University, 2023. | |

| [9] | 张家俊, 李晓琼, 张振涛, 等. 压缩二氧化碳储能系统研究进展[J]. 储能科学与技术, 2023, 12(6): 1928-1945. |

| Zhang J J, Li X Q, Zhang Z T, et al. Research progress of compressed carbon dioxide energy storage system[J]. Energy Storage Science and Technology, 2023, 12(6): 1928-1945. | |

| [10] | 郝佳豪, 越云凯, 张家俊, 等. 二氧化碳储能技术研究现状与发展前景[J]. 储能科学与技术, 2022, 11(10): 3285-3296. |

| Hao J H, Yue Y K, Zhang J J, et al. Research status and development prospect of carbon dioxide energy-storage technology[J]. Energy Storage Science and Technology, 2022, 11(10): 3285-3296. | |

| [11] | 李玉平. 压缩二氧化碳储能系统的热力学性能分析[D]. 北京: 华北电力大学, 2018. |

| Li Y P. Thermodynamic performance analysis of compressed carbon dioxide energy storage system[D]. Beijing: North China Electric Power University, 2018. | |

| [12] | 吴毅, 胡东帅, 王明坤, 等. 一种新型的跨临界CO2储能系统[J]. 西安交通大学学报, 2016, 50(3): 45-49, 100. |

| Wu Y, Hu D S, Wang M K, et al. A novel transcritical CO2 energy storage system[J]. Journal of Xi'an Jiaotong University, 2016, 50(3): 45-49, 100. | |

| [13] | 郝银萍. 跨临界压缩二氧化碳储能系统热力学特性及技术经济性研究[D]. 北京: 华北电力大学, 2021. |

| Hao Y P. Study on thermodynamic characteristics and technical economy of transcritical compressed carbon dioxide energy storage system[D]. Beijing: North China Electric Power University, 2021. | |

| [14] | 赵俊朋. 含二氧化碳储能的冷热电联产系统运行优化研究[D]. 沈阳: 东北大学, 2020. |

| Zhao J P. Study on operation optimization of CCHP system with carbon dioxide energy storage[D]. Shenyang: Northeastern University, 2020. | |

| [15] | Ahmadi M H, Mehrpooya M, Pourfayaz F. Thermodynamic and exergy analysis and optimization of a transcritical CO2 power cycle driven by geothermal energy with liquefied natural gas as its heat sink[J]. Applied Thermal Engineering, 2016, 109: 640-652. |

| [16] | Ahmadi M H, Mehrpooya M, Pourfayaz F. Exergoeconomic analysis and multi objective optimization of performance of a carbon dioxide power cycle driven by geothermal energy with liquefied natural gas as its heat sink[J]. Energy Conversion and Management, 2016, 119: 422-434. |

| [17] | Naseri A, Bidi M, Ahmadi M H, et al. Exergy analysis of a hydrogen and water production process by a solar-driven transcritical CO2 power cycle with Stirling engine[J]. Journal of Cleaner Production, 2017, 158: 165-181. |

| [18] | Kim Y M, Shin D G, Lee S Y, et al. Isothermal transcritical CO2 cycles with TES (thermal energy storage) for electricity storage[J]. Energy, 2013, 49: 484-501. |

| [19] | Ghazizade-Ahsaee H, Ameri M. Energy and exergy investigation of a carbon dioxide direct-expansion geothermal heat pump[J]. Applied Thermal Engineering, 2018, 129: 165-178. |

| [20] | Bai T, Yu J L, Yan G. Advanced exergy analyses of an ejector expansion transcritical CO2 refrigeration system[J]. Energy Conversion and Management, 2016, 126: 850-861. |

| [21] | Tian H, Chang L W, Shu G Q, et al. Multi-objective optimization of the carbon dioxide transcritical power cycle with various configurations for engine waste heat recovery[J]. Energy Conversion and Management, 2017, 148: 477-488. |

| [22] | Enriquez L C, Munoz-Anton J, Penalosa J M M V. Thermodynamic optimization of supercritical CO2 Brayton power cycles coupled to line-focusing solar fields[J]. Journal of Solar Energy Engineering, 2017, 139(6):061005. |

| [23] | Morandin M, Maréchal F, Mercangöz M, et al. Conceptual design of a thermo-electrical energy storage system based on heat integration of thermodynamic cycles (Part B): Alternative system configurations[J]. Energy, 2012, 45(1): 386-396. |

| [24] | 张远. 风电与先进绝热压缩空气储能技术的系统集成与仿真研究[D]. 北京: 中国科学院工程热物理研究所, 2014. |

| Zhang Y. System integration and simulation of wind power and advanced adiabatic compressed air energy storage technology[D]. Beijing: Institute of Engineering Thermophysics, Chinese Academy of Sciences, 2014. | |

| [25] | Wang M K, Zhao P, Wu Y, et al. Performance analysis of a novel energy storage system based on liquid carbon dioxide[J]. Applied Thermal Engineering, 2015, 91: 812-823. |

| [26] | Liu Z, Liu Z H, Xin X, et al. Proposal and assessment of a novel carbon dioxide energy storage system with electrical thermal storage and ejector condensing cycle: energy and exergy analysis[J]. Applied Energy, 2020, 269: 115067. |

| [27] | 刘辉. 超临界压缩二氧化碳储能系统热力学特性与热经济性研究[D]. 北京: 华北电力大学, 2017. |

| Liu H. Study on thermodynamic characteristics and thermal economy of supercritical compressed carbon dioxide energy storage system[D]. Beijing: North China Electric Power University, 2017. | |

| [28] | Span R, Wagner W. A new equation of state for carbon dioxide covering the fluid region from the triple-point temperature to 1100 K at pressures up to 800 MPa[J]. Journal of Physical and Chemical Reference Data, 1996, 25(6): 1509-1596. |

| [29] | 傅秦生. 能量系统的热力学分析方法[M]. 西安: 西安交通大学出版社, 2005: 289. |

| Fu Q S. Thermodynamic Analysis Method of Energy System[M]. Xi'an: Xi'an Jiaotong University Press, 2005: 289. | |

| [30] | Liu X, Yan X W, Liu X L, et al. Comprehensive evaluation of a novel liquid carbon dioxide energy storage system with cold recuperator: energy, conventional exergy and advanced exergy analysis[J]. Energy Conversion and Management, 2021, 250: 114909. |

| [31] | Zhao P, Xu W P, Zhang S Q, et al. Components design and performance analysis of a novel compressed carbon dioxide energy storage system: a pathway towards realizability[J]. Energy Conversion and Management, 2021, 229: 113679. |

| [1] | 段浩磊, 陈浩远, 梁坤峰, 王林, 陈彬, 曹勇, 张晨光, 李硕鹏, 朱登宇, 何亚茹, 杨大鹏. 纯电动车热管理系统低GWP工质替代方案性能分析与综合评价[J]. 化工学报, 2025, 76(S1): 54-61. |

| [2] | 郭松源, 周晓庆, 缪五兵, 汪彬, 耑锐, 曹庆泰, 陈成成, 杨光, 吴静怡. 火箭上升段含多孔板液氧贮箱增压输运数值研究[J]. 化工学报, 2025, 76(S1): 62-74. |

| [3] | 沙鑫权, 胡然, 丁磊, 蒋珍华, 吴亦农. 空间用单机两级有阀线性压缩机研制及测试[J]. 化工学报, 2025, 76(S1): 114-122. |

| [4] | 苏伟, 赵大海, 金旭, 刘忠彦, 李静, 张小松. 吸湿液滴与混合润湿性表面协同抑霜特性研究[J]. 化工学报, 2025, 76(S1): 140-151. |

| [5] | 燕子腾, 詹飞龙, 丁国良. 空调用套管式分流器结构设计及分流效果验证[J]. 化工学报, 2025, 76(S1): 152-159. |

| [6] | 臧子晴, 李修真, 谈莹莹, 刘晓庆. 分凝器对两级分离自复叠制冷循环特性影响研究[J]. 化工学报, 2025, 76(S1): 17-25. |

| [7] | 汪思远, 刘国强, 熊通, 晏刚. 窗式空调器轴流风机的风速非均匀分布特性及其对冷凝器流路优化设计的影响规律[J]. 化工学报, 2025, 76(S1): 205-216. |

| [8] | 孙云龙, 徐肖肖, 黄永方, 郭纪超, 陈卫卫. 水平光滑管内CO2流动沸腾的非绝热可视化研究[J]. 化工学报, 2025, 76(S1): 230-236. |

| [9] | 郭纪超, 徐肖肖, 孙云龙. 基于植物工厂中的CO2浓度气流模拟及优化研究[J]. 化工学报, 2025, 76(S1): 237-245. |

| [10] | 李银龙, 刘国强, 晏刚. 分馏与闪蒸分离耦合自复叠制冷循环性能分析[J]. 化工学报, 2025, 76(S1): 26-35. |

| [11] | 石一帆, 柯钢, 陈浩, 黄孝胜, 叶芳, 李成娇, 郭航. 大型高低温环境实验室温度控制仿真[J]. 化工学报, 2025, 76(S1): 268-280. |

| [12] | 孔繁臣, 张硕, 唐明生, 邹慧明, 胡舟航, 田长青. 二氧化碳直线压缩机气体轴承模拟[J]. 化工学报, 2025, 76(S1): 281-288. |

| [13] | 孔俊龙, 毕扬, 赵耀, 代彦军. 储能电池直冷热管理系统的模拟实验[J]. 化工学报, 2025, 76(S1): 289-296. |

| [14] | 黄琮琪, 邵双全. 液冷数据中心余热驱动的压缩-吸收式制冷系统特性研究[J]. 化工学报, 2025, 76(S1): 326-335. |

| [15] | 朱腾飞, 刘晔. 低GWP制冷剂在新能源汽车空调应用性能分析[J]. 化工学报, 2025, 76(S1): 343-350. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号