化工学报 ›› 2025, Vol. 76 ›› Issue (10): 5414-5425.DOI: 10.11949/0438-1157.20250206

王芾涵1( ), 王慧儒1,2(

), 王慧儒1,2( ), 赵成卓1, 刘振宇3, 刘伟军1,2, 卞宏友1,2

), 赵成卓1, 刘振宇3, 刘伟军1,2, 卞宏友1,2

收稿日期:2025-03-03

修回日期:2025-05-30

出版日期:2025-10-25

发布日期:2025-11-25

通讯作者:

王慧儒

作者简介:王芾涵(1999—),男,硕士研究生,2721192334@qq.com

基金资助:

Fuhan WANG1( ), Huiru WANG1,2(

), Huiru WANG1,2( ), Chengzhuo ZHAO1, Zhenyu LIU3, Weijun LIU1,2, Hongyou BIAN1,2

), Chengzhuo ZHAO1, Zhenyu LIU3, Weijun LIU1,2, Hongyou BIAN1,2

Received:2025-03-03

Revised:2025-05-30

Online:2025-10-25

Published:2025-11-25

Contact:

Huiru WANG

摘要:

三周期极小曲面(triply periodic minimal surface,TPMS)结构因其独特的几何形貌、可调控的孔隙结构和优异的热性能,为相变蓄热系统设计提供了新的解决方案。通过激光选区熔化技术制备了四种典型的TPMS结构多孔AlSi10Mg合金,包括Gyroid-Sheet、Gyroid-Network、Diamond-Sheet和Diamond-Network结构,并与石蜡进行复合。采用侧面加热边界条件,基于可视化实验研究,探讨了孔隙率、胞元结构和类型对石蜡/TPMS结构多孔AlSi10Mg合金复合相变材料等效热导率、比表面积及蓄热性能的影响规律,探明了熔化过程中固液相界面的演变规律和温度分布特征,揭示了TPMS结构的强化蓄热机理。结果表明,TPMS结构复合相变材料在提高蓄热性能方面表现出显著优势,具有等效热导率高、比表面积大的特性,其蓄热速率较纯石蜡提高了60%以上。当孔隙率为70%~85%时,四种TPMS结构中,Diamond-Sheet结构的蓄热速率最快,温度均匀性最好。本研究旨在为TPMS结构多孔金属复合相变材料的结构设计提供指导,并为其应用提供实验数据支持。

中图分类号:

王芾涵, 王慧儒, 赵成卓, 刘振宇, 刘伟军, 卞宏友. 石蜡/TPMS结构多孔AlSi10Mg合金复合相变材料蓄热性能实验研究[J]. 化工学报, 2025, 76(10): 5414-5425.

Fuhan WANG, Huiru WANG, Chengzhuo ZHAO, Zhenyu LIU, Weijun LIU, Hongyou BIAN. Experimental study on thermal storage performance of paraffin/TPMS porous AlSi10Mg alloy composite materials[J]. CIESC Journal, 2025, 76(10): 5414-5425.

| Element | Content/%(mass) |

|---|---|

| Si | 9.64 |

| Mg | 0.38 |

| Ti | <0.01 |

| Ni | <0.01 |

| Mn | <0.01 |

| Cu | <0.01 |

| Fe | <0.01 |

| Zn | <0.01 |

| Pb | <0.01 |

| Sn | <0.01 |

| O | 0.036 |

| Al | balance |

表1 AlSi10Mg合金粉末的化学成分

Table 1 Chemical composition of AlSi10Mg alloy powder

| Element | Content/%(mass) |

|---|---|

| Si | 9.64 |

| Mg | 0.38 |

| Ti | <0.01 |

| Ni | <0.01 |

| Mn | <0.01 |

| Cu | <0.01 |

| Fe | <0.01 |

| Zn | <0.01 |

| Pb | <0.01 |

| Sn | <0.01 |

| O | 0.036 |

| Al | balance |

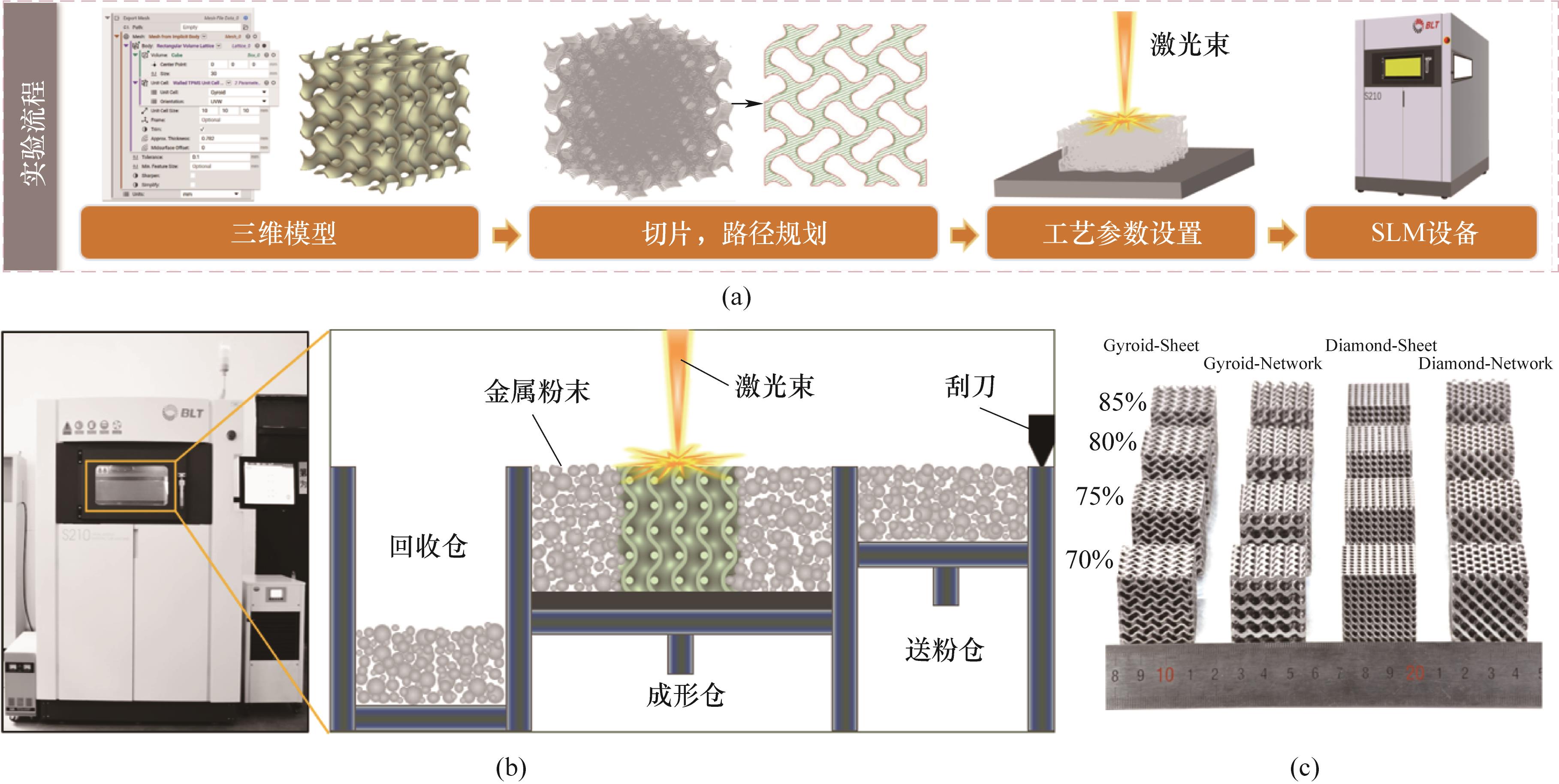

图3 SLM成形TPMS结构:(a)实验流程图;(b)SLM过程示意图;(c)样品实物图

Fig.3 SLM-fabricated TPMS structure: (a) experimental flowchart; (b) schematic diagram of SLM process; (c) photograph of the samples

| [1] | Khan J, Singh P. Review on phase change materials for spacecraft avionics thermal management[J]. Journal of Energy Storage, 2024, 87: 111369. |

| [2] | Chen H J, Abidi A, Hussein A K, et al. Investigation of the use of extended surfaces in paraffin wax phase change material in thermal management of a cylindrical lithium-ion battery: applicable in the aerospace industry[J]. Journal of Energy Storage, 2022, 45: 103685. |

| [3] | Huang X, Alva G, Jia Y T, et al. Morphological characterization and applications of phase change materials in thermal energy storage: a review[J]. Renewable and Sustainable Energy Reviews, 2017, 72: 128-145. |

| [4] | Lin Y X, Jia Y T, Alva G, et al. Review on thermal conductivity enhancement, thermal properties and applications of phase change materials in thermal energy storage[J]. Renewable and Sustainable Energy Reviews, 2018, 82: 2730-2742. |

| [5] | Liu L K, Su D, Tang Y J, et al. Thermal conductivity enhancement of phase change materials for thermal energy storage: a review[J]. Renewable and Sustainable Energy Reviews, 2016, 62: 305-317. |

| [6] | Pielichowska K, Pielichowski K. Phase change materials for thermal energy storage[J]. Progress in Materials Science, 2014, 65: 67-123. |

| [7] | 施尚, 余建祖, 陈梦东, 等. 基于泡沫铜/石蜡的锂电池热管理系统性能[J]. 化工学报, 2017, 68(7): 2678-2683. |

| Shi S, Yu J Z, Chen M D, et al. Battery thermal management system using phase change materials and foam copper[J]. CIESC Journal, 2017, 68(7): 2678-2683. | |

| [8] | 韦攀, 喻家帮, 郭增旭, 等. 环形管填充金属泡沫强化相变蓄热可视化实验[J]. 化工学报, 2019, 70(3): 850-856. |

| Wei P, Yu J B, Guo Z X, et al. Experimental visualization on thermal energy storage enhancement through metal foam filled annuli[J]. CIESC Journal, 2019, 70(3): 850-856. | |

| [9] | Ding C, Shan Y J, Nie Q. Thermal performance of phase change material-based heat sink with hybrid fin-metal foam structure under hypergravity conditions[J]. International Journal of Energy Research, 2022, 46(5): 5811-5827. |

| [10] | Almesmari A, Alagha A N, Naji M M, et al. Recent advancements in design optimization of lattice-structured materials[J]. Advanced Engineering Materials, 2023, 25(17): 2201780. |

| [11] | Feng J W, Fu J Z, Yao X H, et al. Triply periodic minimal surface (TPMS) porous structures: from multi-scale design, precise additive manufacturing to multidisciplinary applications[J]. International Journal of Extreme Manufacturing, 2022, 4(2): 022001. |

| [12] | Samson S, Tran P, Marzocca P. Design and modelling of porous gyroid heatsinks: influences of cell size, porosity and material variation[J]. Applied Thermal Engineering, 2023, 235: 121296. |

| [13] | Cheng Z L, Xu R N, Jiang P X. Morphology, flow and heat transfer in triply periodic minimal surface based porous structures[J]. International Journal of Heat and Mass Transfer, 2021, 170: 120902. |

| [14] | Oh S H, An C H, Seo B, et al. Functional morphology change of TPMS structures for design and additive manufacturing of compact heat exchangers[J]. Additive Manufacturing, 2023, 76: 103778. |

| [15] | Fabrizio Q, Boschetto A, Rovatti L, et al. Replication casting of open-cell AlSi7Mg0.3 foams[J]. Materials Letters, 2011, 65(17/18): 2558-2561. |

| [16] | Cheng Y, Li Y X, Chen X, et al. Fabrication of aluminum foams with small pore size by melt foaming method[J]. Metallurgical and Materials Transactions B, 2017, 48(2): 754-762. |

| [17] | Huang R X, Ma S Q, Zhang M D, et al. Dynamic deformation and failure process of quasi-closed-cell aluminum foam manufactured by direct foaming technique[J]. Materials Science and Engineering: A, 2019, 756: 302-311. |

| [18] | Banhart J. Manufacture, characterisation and application of cellular metals and metal foams[J]. Progress in Materials Science, 2001, 46(6): 559-632. |

| [19] | Rodriguez-Contreras A, Punset M, Calero J A, et al. Powder metallurgy with space holder for porous titanium implants: a review[J]. Journal of Materials Science & Technology, 2021, 76: 129-149. |

| [20] | Yamanoglu R, Bahador A, Kondoh K. Fabrication methods of porous titanium implants by powder metallurgy[J]. Transactions of the Indian Institute of Metals, 2021, 74(11): 2555-2567. |

| [21] | 刘伟, 李能, 周标, 等. 复杂结构与高性能材料增材制造技术进展[J]. 机械工程学报, 2019, 55(20): 128-151, 159. |

| Liu W, Li N, Zhou B, et al. Progress in additive manufacturing on complex structures and high-performance materials[J]. Journal of Mechanical Engineering, 2019, 55(20): 128-151, 159. | |

| [22] | Changdar A, Chakraborty S S, Li Y C, et al. Laser additive manufacturing of aluminum-based stochastic and nonstochastic cellular materials[J]. Journal of Materials Science & Technology, 2024, 183: 89-119. |

| [23] | Song B, Zhao X, Li S, et al. Differences in microstructure and properties between selective laser melting and traditional manufacturing for fabrication of metal parts: a review[J]. Frontiers of Mechanical Engineering, 2015, 10(2): 111-125. |

| [24] | Liu W J, Li W Q, Wang H R, et al. Surface modification of porous titanium and titanium alloy implants manufactured by selective laser melting: a review[J]. Advanced Engineering Materials, 2023, 25(21): 2300765. |

| [25] | 刘飞, 唐艺川, 谢海琼, 等. 选区激光熔化成形极小曲面点阵的结构和性能优化[J]. 中国激光, 2023, 50(12): 1202303. |

| Liu F, Tang Y C, Xie H Q, et al. Optimization of structure and performance of minimal surface lattice formed by selective laser melting[J]. Chinese Journal of Lasers, 2023, 50(12): 1202303. | |

| [26] | Yan C Z, Hao L, Hussein A, et al. Ti-6Al-4V triply periodic minimal surface structures for bone implants fabricated via selective laser melting[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2015, 51: 61-73. |

| [27] | Bobbert F S L, Lietaert K, Eftekhari A A, et al. Additively manufactured metallic porous biomaterials based on minimal surfaces: a unique combination of topological, mechanical, and mass transport properties[J]. Acta Biomaterialia, 2017, 53: 572-584. |

| [28] | Kotadia H R, Gibbons G, Das A, et al. A review of laser powder bed fusion additive manufacturing of aluminium alloys: microstructure and properties[J]. Additive Manufacturing, 2021, 46: 102155. |

| [29] | Biffi C A, Bassani P, Fiocchi J, et al. Investigation of high temperature behavior of AlSi10Mg produced by selective laser melting[J]. Materials Chemistry and Physics, 2021, 259: 123975. |

| [30] | Tan Q Y, Liu Y G, Fan Z Q, et al. Effect of processing parameters on the densification of an additively manufactured 2024 Al alloy[J]. Journal of Materials Science & Technology, 2020, 58: 34-45. |

| [31] | Mehta A, Zhou L, Huynh T, et al. Additive manufacturing and mechanical properties of the dense and crack free Zr-modified aluminum alloy 6061 fabricated by the laser-powder bed fusion[J]. Additive Manufacturing, 2021, 41: 101966. |

| [32] | Li G, Li X W, Guo C, et al. Investigation into the effect of energy density on densification, surface roughness and loss of alloying elements of 7075 aluminium alloy processed by laser powder bed fusion[J]. Optics & Laser Technology, 2022, 147: 107621. |

| [33] | Zhou Y, Ning F D, Zhang P, et al. Geometrical, microstructural, and mechanical properties of curved-surface AlSi10Mg parts fabricated by powder bed fusion additive manufacturing[J]. Materials & Design, 2021, 198: 109360. |

| [34] | Tian Y, Liu X L, Luo Q Y, et al. Sea urchin skeleton-inspired triply periodic foams for fast latent heat storage[J]. International Journal of Heat and Mass Transfer, 2023, 206: 123944. |

| [35] | Zhang T, Liu F, Deng X, et al. Experimental study on the thermal storage performance of phase change materials embedded with additively manufactured triply periodic minimal surface architected lattices[J]. International Journal of Heat and Mass Transfer, 2022, 199: 123452. |

| [36] | Qureshi Z A, Al-Omari S A B, Elnajjar E, et al. Nature-inspired triply periodic minimal surface-based structures in sheet and solid configurations for performance enhancement of a low-thermal-conductivity phase-change material for latent-heat thermal-energy-storage applications[J]. International Journal of Thermal Sciences, 2022, 173: 107361. |

| [37] | Bian Z, Hou F, Wang H, et al. Experimental and numerical investigations of enhanced thermal energy storage performance for foam/paraffin composite under different heating conditions[J]. Journal of Energy Storage, 2022, 55: 105506. |

| [38] | Tang W, Zhou H, Zeng Y, et al. Analysis on the convective heat transfer process and performance evaluation of triply periodic minimal surface (TPMS) based on Diamond, Gyroid and Iwp[J]. International Journal of Heat and Mass Transfer, 2023, 201: 123642. |

| [39] | Spierings A B, Schneider M, Eggenberger R. Comparison of density measurement techniques for additive manufactured metallic parts[J]. Rapid Prototyping Journal, 2011, 17(5): 380-386. |

| [40] | Catchpole-Smith S, Sélo R R J, Davis A W, et al. Thermal conductivity of TPMS lattice structures manufactured via laser powder bed fusion[J]. Additive Manufacturing, 2019, 30: 100846. |

| [1] | 袁琳慧, 王瑜. 单服务器浸没射流式液冷系统散热性能[J]. 化工学报, 2025, 76(S1): 160-169. |

| [2] | 赵子祥, 段钟弟, 孙浩然, 薛鸿祥. 大温差两相流动诱导水锤冲击的数值模型[J]. 化工学报, 2025, 76(S1): 170-180. |

| [3] | 黄博, 黄灏, 王文, 贺隆坤. 薄膜型LNG船液货舱温度场计算分析[J]. 化工学报, 2025, 76(S1): 195-204. |

| [4] | 汪思远, 刘国强, 熊通, 晏刚. 窗式空调器轴流风机的风速非均匀分布特性及其对冷凝器流路优化设计的影响规律[J]. 化工学报, 2025, 76(S1): 205-216. |

| [5] | 孔俊龙, 毕扬, 赵耀, 代彦军. 储能电池直冷热管理系统的模拟实验[J]. 化工学报, 2025, 76(S1): 289-296. |

| [6] | 张圣美, 李明, 张莹, 易茜, 杨依婷, 刘雅莉. 乳化剂和温度对相变微胶囊性能的影响分析[J]. 化工学报, 2025, 76(S1): 444-452. |

| [7] | 郭松源, 周晓庆, 缪五兵, 汪彬, 耑锐, 曹庆泰, 陈成成, 杨光, 吴静怡. 火箭上升段含多孔板液氧贮箱增压输运数值研究[J]. 化工学报, 2025, 76(S1): 62-74. |

| [8] | 任现超, 谷雅秀, 段少斌, 贾文竹, 李汉林. 翅片式椭圆套管蒸发式冷凝器传热传质性能实验研究[J]. 化工学报, 2025, 76(S1): 75-83. |

| [9] | 罗海梅, 王泓, 孙照明, 尹艳华. 同向双螺杆传热系数计算模型的分析与验证[J]. 化工学报, 2025, 76(9): 4809-4823. |

| [10] | 赵维, 邢文乐, 韩朝旭, 袁兴中, 蒋龙波. g-C3N4基非金属异质结光催化降解水中有机污染物的研究进展[J]. 化工学报, 2025, 76(9): 4752-4769. |

| [11] | 胡金琦, 闵春华, 李小龙, 范元鸿, 王坤. 振动叶片耦合柔性板强化流体混沌混合与传热研究[J]. 化工学报, 2025, 76(9): 4824-4837. |

| [12] | 吴林凯, 林志敏, 王良璧. 基于热质传递效应的准稳态结霜模型改进及数值验证[J]. 化工学报, 2025, 76(8): 4004-4016. |

| [13] | 龚路远, 果正龙, 赵登辉, 郭亚丽, 周健, 韩倩倩, 沈胜强. 不同疏水性表面冷凝传热性能及动力学特征研究[J]. 化工学报, 2025, 76(8): 3932-3943. |

| [14] | 陈科拯, 高蓬辉, 焉富春, 程博. 考虑液滴动态行为的亲-疏水复合结构表面冷凝特性影响因素分析[J]. 化工学报, 2025, 76(8): 3976-3989. |

| [15] | 周航, 张斯婧, 刘剑, 张小松. 小通道内非共沸工质流动沸腾换热数值分析[J]. 化工学报, 2025, 76(8): 3864-3872. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号