化工学报 ›› 2025, Vol. 76 ›› Issue (S1): 217-229.DOI: 10.11949/0438-1157.20241369

• 流体力学与传递现象 • 上一篇

曹庆泰1( ), 郭松源1, 李建强2, 蒋赞2, 汪彬2, 耑锐2, 吴静怡1, 杨光1(

), 郭松源1, 李建强2, 蒋赞2, 汪彬2, 耑锐2, 吴静怡1, 杨光1( )

)

收稿日期:2024-11-27

修回日期:2024-12-19

出版日期:2025-06-25

发布日期:2025-06-26

通讯作者:

杨光

作者简介:曹庆泰(1999—),男,硕士研究生,qingtaicao@sjtu.edu.cn

基金资助:

Qingtai CAO1( ), Songyuan GUO1, Jianqiang LI2, Zan JIANG2, Bin WANG2, Rui ZHUAN2, Jingyi WU1, Guang YANG1(

), Songyuan GUO1, Jianqiang LI2, Zan JIANG2, Bin WANG2, Rui ZHUAN2, Jingyi WU1, Guang YANG1( )

)

Received:2024-11-27

Revised:2024-12-19

Online:2025-06-25

Published:2025-06-26

Contact:

Guang YANG

摘要:

以典型运载器的液氧贮箱为研究对象,基于流体体积(VOF)法构建了监测气液界面的三维CFD仿真模型,采用该模型对不同孔板布置情况、不同初始液面状态、不同负过载程度下液氧流动行为进行模拟,对比了各工况液氧离开贮箱底部和气体下潜两种行为特性。多孔隔板可以有效降低液氧离开贮箱底部的流量,-0.20g负过载条件下流量减少95.63%;且该流量与负过载程度呈正相关。气体下潜速度受气泡形态与负过载程度等因素共同影响,当推进剂填充率为50.18%且发生10°倾斜的贮箱受到-0.20g负过载时,会形成气液循环通道使气泡迅速长大,有效下潜速度可达0.317 m/s,甚至大于负过载为-0.40g但贮箱不倾斜时的气体下潜速度。因此设计孔板位置时应综合考虑推进剂余量、箭体姿态和负过载程度等因素。

中图分类号:

曹庆泰, 郭松源, 李建强, 蒋赞, 汪彬, 耑锐, 吴静怡, 杨光. 负过载下多孔隔板对液氧贮箱蓄液性能的影响研究[J]. 化工学报, 2025, 76(S1): 217-229.

Qingtai CAO, Songyuan GUO, Jianqiang LI, Zan JIANG, Bin WANG, Rui ZHUAN, Jingyi WU, Guang YANG. Numerical study on influence of perforated plate on retention performance of liquid oxygen tank under negative gravity[J]. CIESC Journal, 2025, 76(S1): 217-229.

| 工况 | 负过载/(m/s2) | 孔板布置情况 | 液面初始化情况 | 填充率/% | 液面坐标描述 |

|---|---|---|---|---|---|

| 对照组 | -0.20g | 无多孔隔板 | 水平液面,位于正常情况的位置 | 50.18 | z=602 mm |

| 工况1 | -0.20g | 有多孔隔板 | 水平液面,高于孔板中截面30 mm | 52.68 | z=632 mm |

| 工况2 | -0.20g | 有多孔隔板 | 水平液面,低于孔板中截面30 mm | 47.68 | z=572 mm |

| 工况3 | -0.20g | 有多孔隔板 | 液面倾斜10°,液面中心位于孔板中截面上 | 50.18 | z=(tan10°)x + 602 mm |

| 工况4 | -0.03g | 有多孔隔板 | 水平液面,与孔板中截面重合 | 50.18 | z=602 mm |

| 工况5 | -0.10g | 有多孔隔板 | 水平液面,与孔板中截面重合 | 50.18 | z=602 mm |

| 工况6 | -0.20g | 有多孔隔板 | 水平液面,与孔板中截面重合 | 50.18 | z=602 mm |

| 工况7 | -0.40g | 有多孔隔板 | 水平液面,与孔板中截面重合 | 50.18 | z=602 mm |

表1 计算工况汇总

Table 1 Summary of working conditions

| 工况 | 负过载/(m/s2) | 孔板布置情况 | 液面初始化情况 | 填充率/% | 液面坐标描述 |

|---|---|---|---|---|---|

| 对照组 | -0.20g | 无多孔隔板 | 水平液面,位于正常情况的位置 | 50.18 | z=602 mm |

| 工况1 | -0.20g | 有多孔隔板 | 水平液面,高于孔板中截面30 mm | 52.68 | z=632 mm |

| 工况2 | -0.20g | 有多孔隔板 | 水平液面,低于孔板中截面30 mm | 47.68 | z=572 mm |

| 工况3 | -0.20g | 有多孔隔板 | 液面倾斜10°,液面中心位于孔板中截面上 | 50.18 | z=(tan10°)x + 602 mm |

| 工况4 | -0.03g | 有多孔隔板 | 水平液面,与孔板中截面重合 | 50.18 | z=602 mm |

| 工况5 | -0.10g | 有多孔隔板 | 水平液面,与孔板中截面重合 | 50.18 | z=602 mm |

| 工况6 | -0.20g | 有多孔隔板 | 水平液面,与孔板中截面重合 | 50.18 | z=602 mm |

| 工况7 | -0.40g | 有多孔隔板 | 水平液面,与孔板中截面重合 | 50.18 | z=602 mm |

| 物性参数 | 液氧 | 氧气 |

|---|---|---|

| 密度/(kg/m3) | 1142.70 | 5.34 |

| 动力黏度/(Pa·s) | 2.032×10-4 | 1.785×10-5 |

表2 液氧和氧气的物性参数

Table 2 Physical properties of liquid and gas oxygen

| 物性参数 | 液氧 | 氧气 |

|---|---|---|

| 密度/(kg/m3) | 1142.70 | 5.34 |

| 动力黏度/(Pa·s) | 2.032×10-4 | 1.785×10-5 |

| 网格数量/个 | 质心轴向位置/m | ||||||

|---|---|---|---|---|---|---|---|

| t=0.5 s | t=1.0 s | t=1.5 s | t=2.0 s | t=2.5 s | t=3.0 s | t=3.5 s | |

| 190万 | 0.316329 | 0.316900 | 0.321874 | 0.333099 | 0.347278 | 0.359630 | 0.370671 |

| 244万 | 0.316330 | 0.316864 | 0.321895 | 0.331798 | 0.343617 | 0.359207 | 0.373889 |

| 326万 | 0.316339 | 0.316937 | 0.321092 | 0.328244 | 0.337817 | 0.351348 | 0.361177 |

表3 不同网格数下的质心轴向位置

Table 3 Axial position of center of mass for different number of meshes

| 网格数量/个 | 质心轴向位置/m | ||||||

|---|---|---|---|---|---|---|---|

| t=0.5 s | t=1.0 s | t=1.5 s | t=2.0 s | t=2.5 s | t=3.0 s | t=3.5 s | |

| 190万 | 0.316329 | 0.316900 | 0.321874 | 0.333099 | 0.347278 | 0.359630 | 0.370671 |

| 244万 | 0.316330 | 0.316864 | 0.321895 | 0.331798 | 0.343617 | 0.359207 | 0.373889 |

| 326万 | 0.316339 | 0.316937 | 0.321092 | 0.328244 | 0.337817 | 0.351348 | 0.361177 |

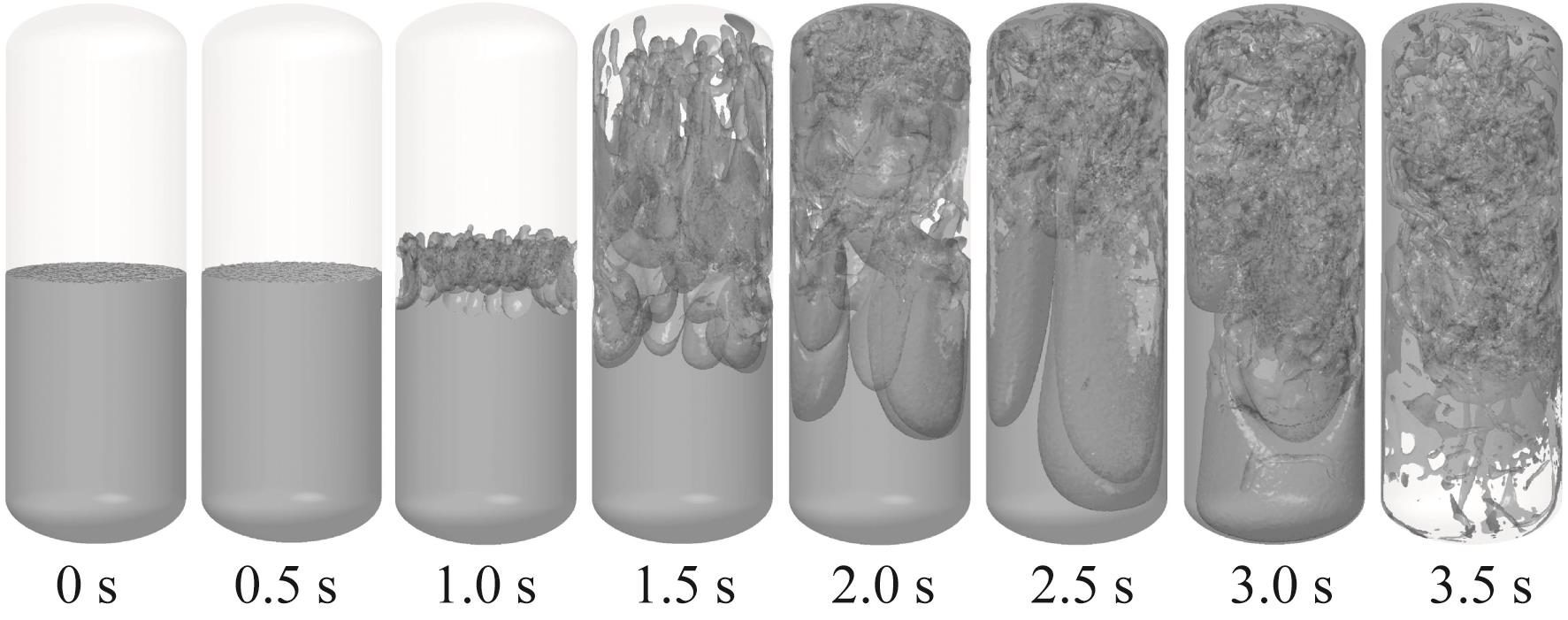

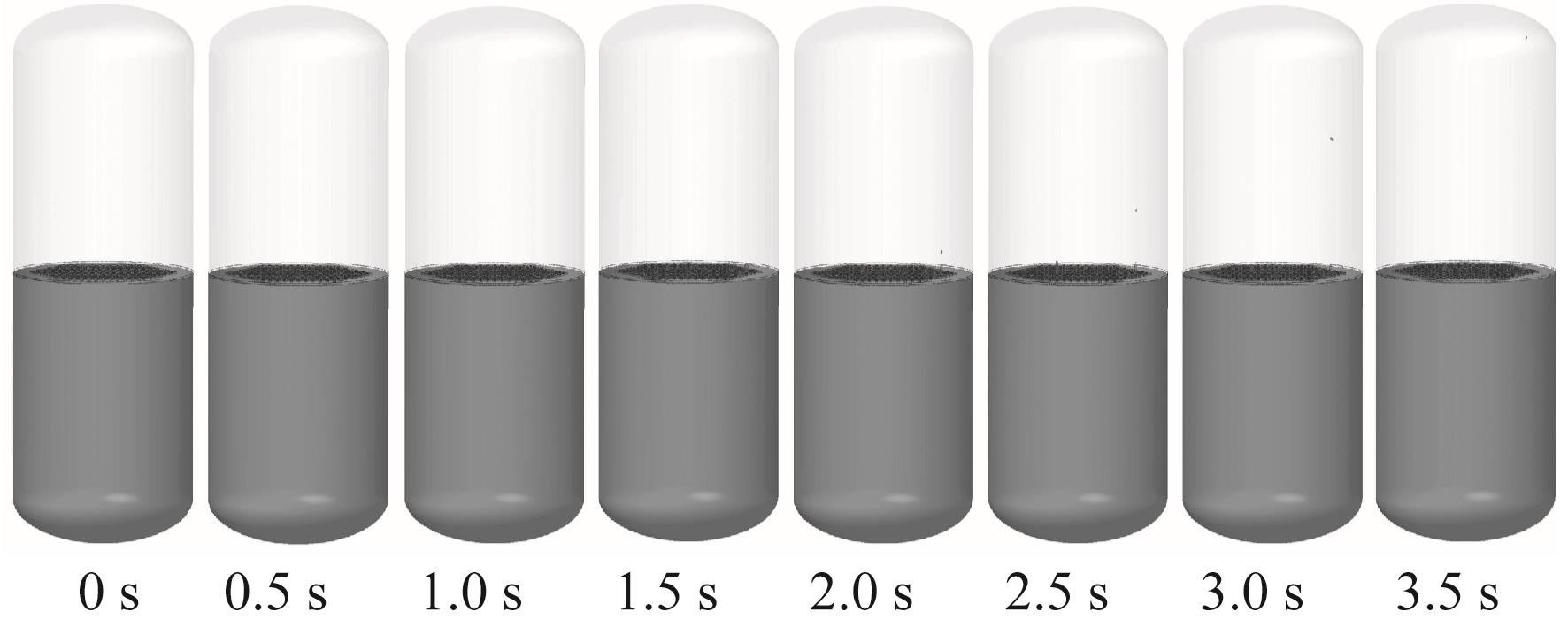

图8 对照组(无隔板,水平初始液面,液氧初始填充率50.18%,负过载-0.20g)液氧流动行为

Fig.8 Liquid oxygen flow behavior of control group (no perforated plate, horizontal initial liquid level with 50.18% initial liquid oxygen fill rate, -0.20g)

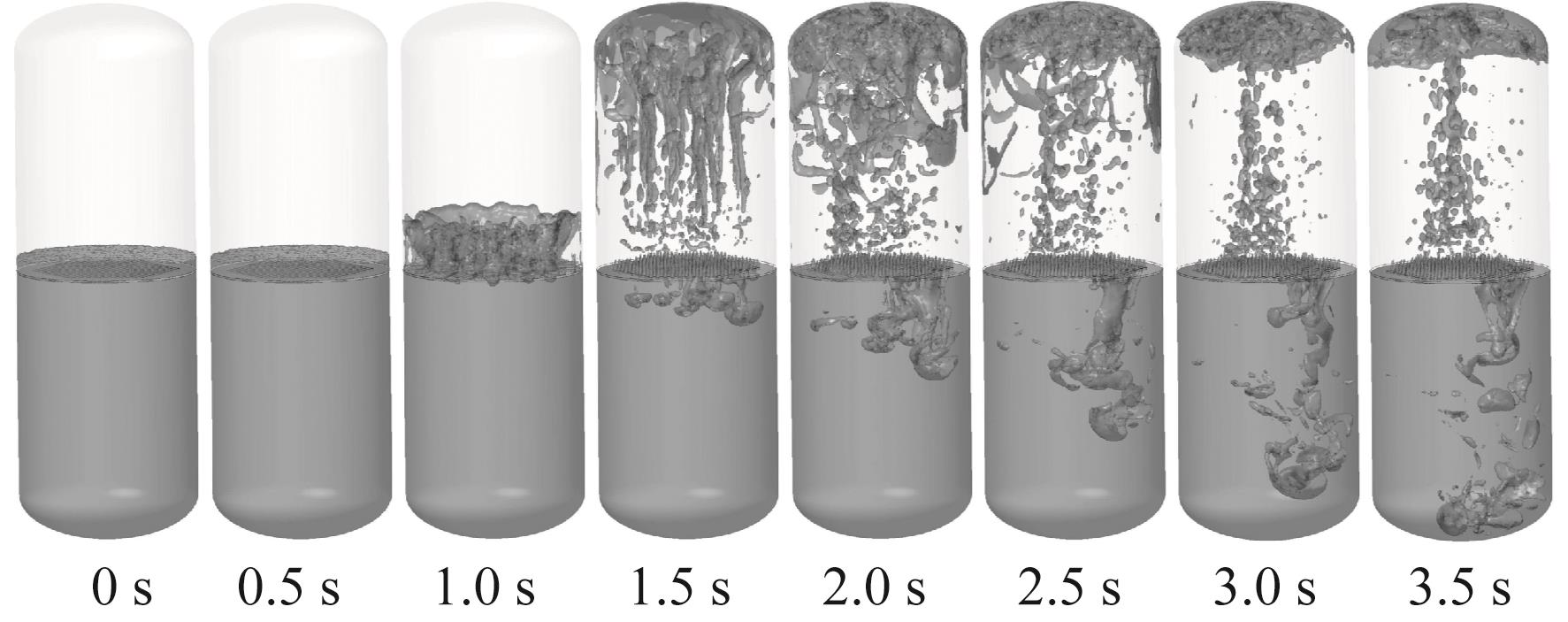

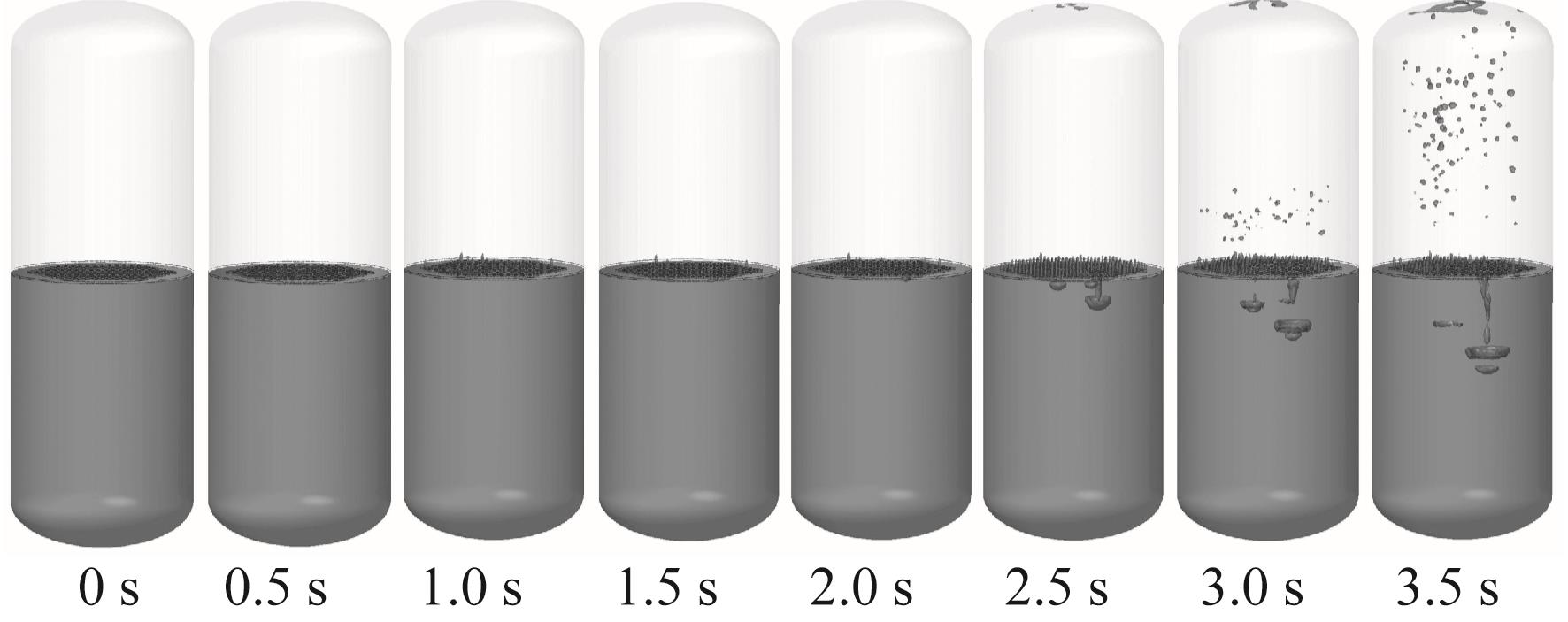

图9 工况6(有隔板,水平初始液面,液氧初始填充率50.18%,负过载-0.20g)液氧流动行为

Fig.9 Liquid oxygen flow behavior in Case 6 (with perforated plate, horizontal initial liquid level with 50.18% initial liquid oxygen fill rate, -0.20g)

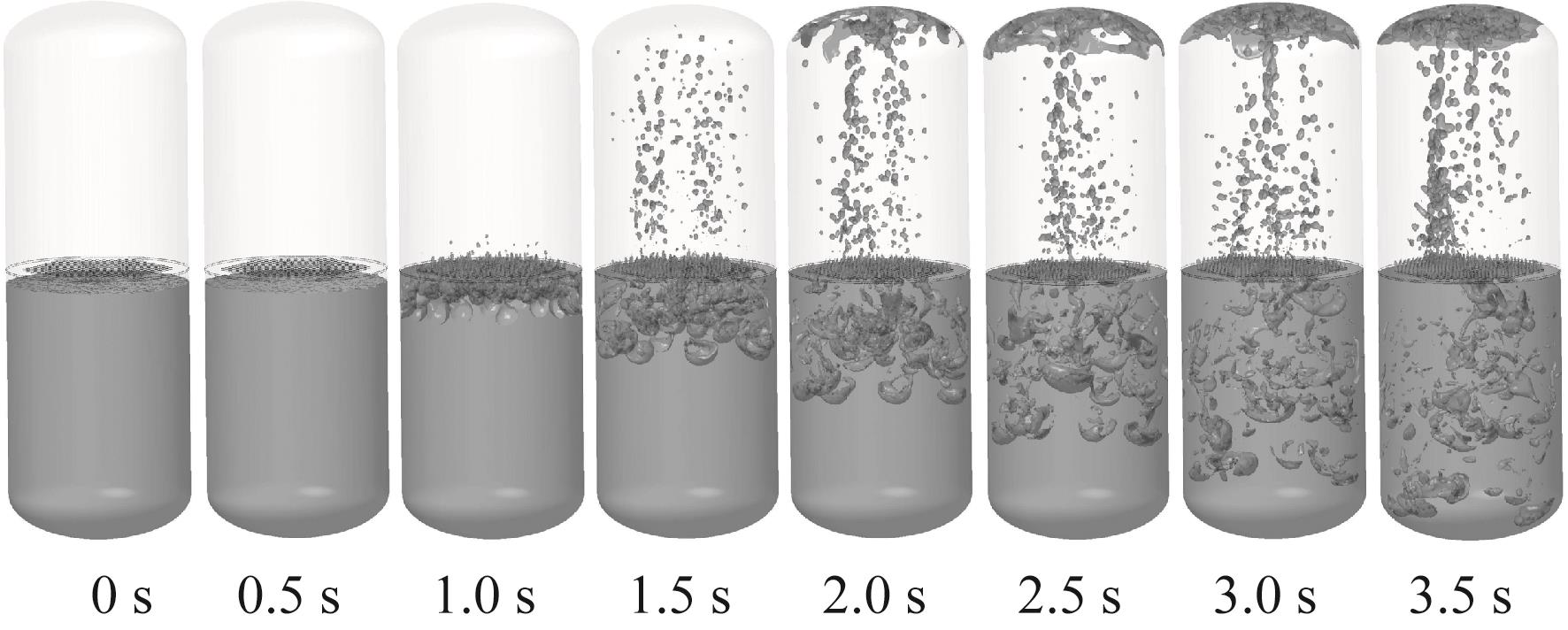

图12 工况1(有隔板,水平初始液面,液氧初始填充率52.68%,负过载-0.20g)液氧流动行为

Fig.12 Liquid oxygen flow behavior in Case 1 (with perforated plate, horizontal initial liquid level with 52.68% initial liquid oxygen fill rate, -0.20g)

图13 工况2(有隔板,水平初始液面,液氧初始填充率47.68%,负过载-0.20g)液氧流动行为

Fig.13 Liquid oxygen flow behavior in Case 2 (with perforated plate, horizontal initial liquid level with 47.68% initial liquid oxygen fill rate, -0.20g)

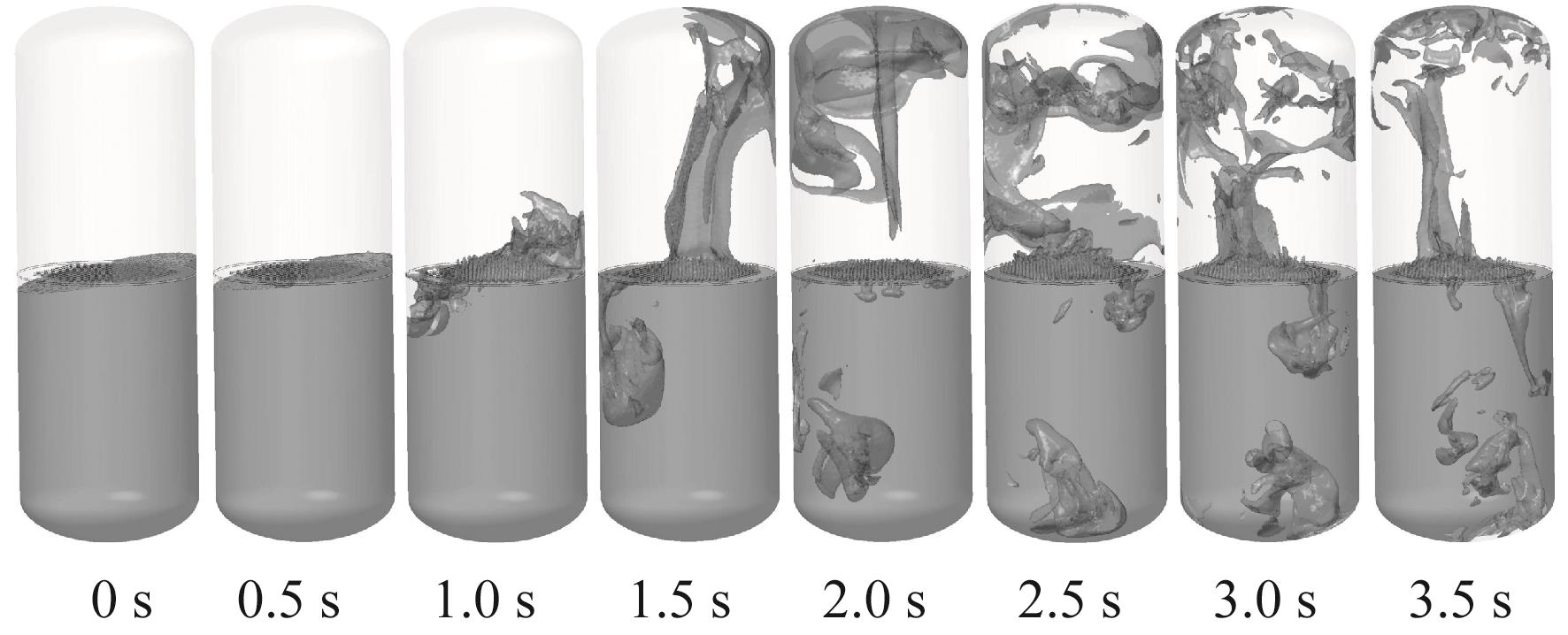

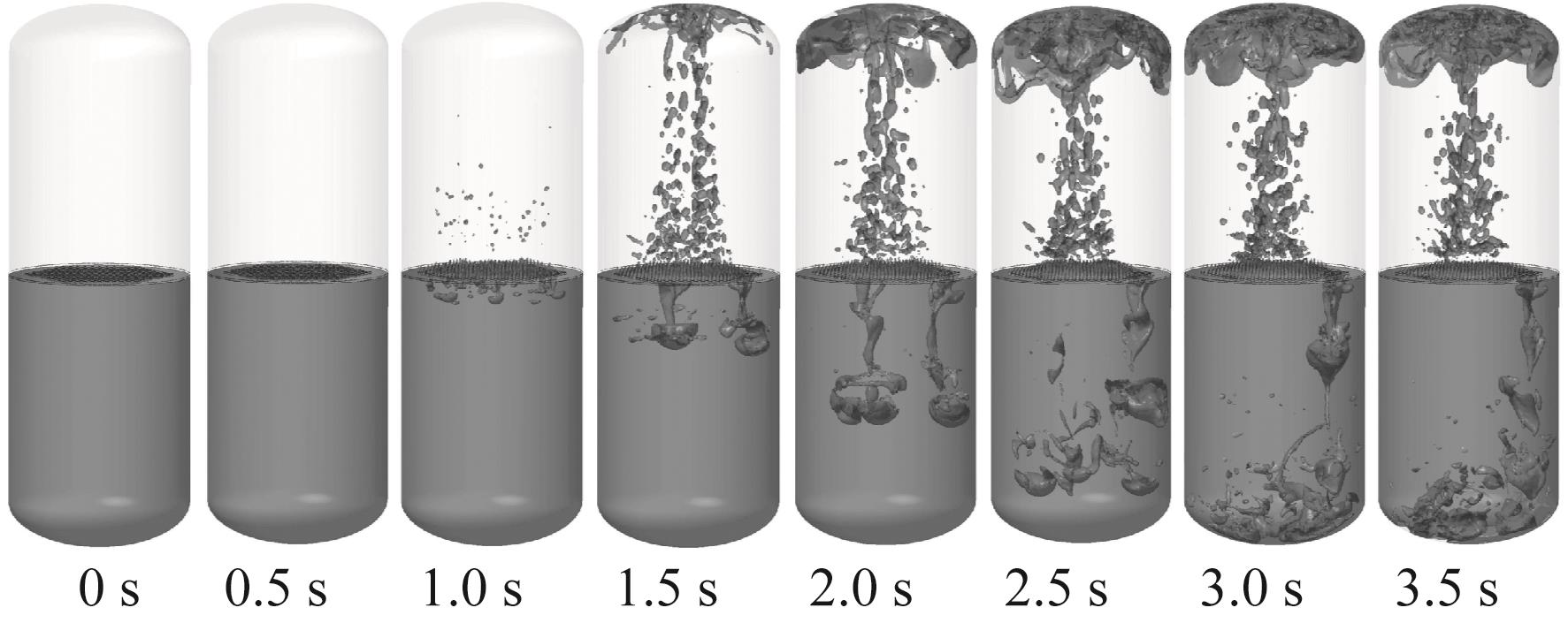

图14 工况3(有隔板,倾斜初始液面,液氧初始填充率50.18%,负过载-0.20g)液氧流动行为

Fig.14 Liquid oxygen flow behavior in Case 3 (with perforated plate, inclined initial liquid level with 50.18% initial liquid oxygen fill rate, -0.20g)

图19 工况4(有隔板,水平初始液面,液氧初始填充率50.18%,负过载-0.03g)液氧流动行为

Fig.19 Liquid oxygen flow behavior in Case 4 (with perforated plate, inclined initial liquid level with 50.18% initial liquid oxygen fill rate, -0.03g)

图20 工况5(有隔板,水平初始液面,液氧初始填充率50.18%,负过载-0.10g)液氧流动行为

Fig.20 Liquid oxygen flow behavior in Case 5 (with perforated plate, inclined initial liquid level with 50.18% initial liquid oxygen fill rate, -0.10g)

图21 工况7(有隔板,水平初始液面,液氧初始填充率50.18%,负过载-0.40g)液氧流动行为

Fig.21 Liquid oxygen flow behavior in Case 7 (with perforated plate, inclined initial liquid level with 50.18% initial liquid oxygen fill rate, -0.40g)

| 负过载 | 质心轴向移动速度/(m/s) |

|---|---|

| -0.03g | 2.05×10-5 |

| -0.10g | 2.11×10-3 |

| -0.20g | 1.75×10-2 |

| -0.40g | 2.97×10-2 |

表4 不同负过载工况最终0.5 s质心的轴向移动速度

Table 4 Velocity of axial center of mass movement at the late stage of different negative gravity

| 负过载 | 质心轴向移动速度/(m/s) |

|---|---|

| -0.03g | 2.05×10-5 |

| -0.10g | 2.11×10-3 |

| -0.20g | 1.75×10-2 |

| -0.40g | 2.97×10-2 |

| 1 | 包为民. 可重复使用运载火箭技术发展综述[J]. 航空学报, 2023, 44(23): 8-33, 3. |

| Bao W M. A review of reusable launch vehicle technology development[J]. Acta Aeronautica et Astronautica Sinica, 2023, 44(23): 8-33, 3. | |

| 2 | 宋征宇, 黄兵, 汪小卫, 等. 重复使用航天运载器的发展及其关键技术[J]. 前瞻科技, 2022, 1(1): 62-74. |

| Song Z Y, Huang B, Wang X W, et al. Development and key technologies of reusable launch vehicle[J]. Science and Technology Foresight, 2022, 1(1): 62-74. | |

| 3 | 容易, 刘辉, 于子文, 等. 可重复使用运载火箭返回段低温流体行为特性[J]. 航空学报, 2023, 44(23): 105-116. |

| Rong Y, Liu H, Yu Z W, et al. Behavior of cryogenic propellant in return stage of reusable launch vehicle[J]. Acta Aeronautica et Astronautica Sinica, 2023, 44(23): 105-116. | |

| 4 | 高朝辉, 刘宇, 肖肖, 等. 垂直着陆重复使用运载火箭对动力技术的挑战[J]. 火箭推进, 2015, 41(3): 1-6, 45. |

| Gao Z H, Liu Y, Xiao X, et al. Challenge to propulsion technology for vertical landing reusable launch vehicle[J]. Journal of Rocket Propulsion, 2015, 41(3): 1-6, 45. | |

| 5 | Zuo Z Q, Zhu W X, Huang Y H, et al. A review of cryogenic quasi-steady liquid-vapor phase change: theories, models, and state-of-the-art applications[J]. International Journal of Heat and Mass Transfer, 2023, 205: 123916. |

| 6 | Dodge F T. Fluid management in low gravity[M]//Low-Gravity Fluid Dynamics and Transport Phenomena. Washington D C: AIAA, 1990: 3-14. |

| 7 | 尕永婧, 王浩苏, 张青松, 等. 垂直着陆过程推进剂流动行为特性及影响分析[J]. 深空探测学报, 2021, 8(1): 42-50. |

| Ga Y J, Wang H S, Zhang Q S, et al. Propellant flow characteristics in tank and related impact analysis during the vertical landing stage[J]. Journal of Deep Space Exploration, 2021, 8(1): 42-50. | |

| 8 | 王晔, 张婉雨, 汪彬, 等. 多孔网幕泡破压力预测模型的建立及实验验证[J]. 化工学报, 2022, 73(3): 1102-1110. |

| Wang Y, Zhang W Y, Wang B, et al. Analytical model of bubble point pressure for metal wire screens and experimental validation[J]. CIESC Journal, 2022, 73(3): 1102-1110. | |

| 9 | Hartwig J W. Liquid Acquisition Devices for Advanced In-Space Cryogenic Propulsion Systems[M]. New York: Academic Press, 2016. |

| 10 | Himeno T, Watanabe T, Nonaka S, et al. Numerical and experimental investigation on sloshing in rocket tanks with damping devices[C]//43rd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit. AIAA, 2007: AIAA2007-5557. |

| 11 | Chen L, Liu J T. Numerical simulation of fluid flow in the vane type tank on orbital refuelling process[J]. IOP Conference Series: Earth and Environmental Science, 2018, 163: 012085. |

| 12 | 杨唱, 孙冰, 方杰. 航天器贮箱出流过程液体晃动及防晃[J]. 航空动力学报, 2018, 33(12): 3065-3072. |

| Yang C, Sun B, Fang J. Liquid sloshing and anti-sloshing of spacecraft tank during outflow[J]. Journal of Aerospace Power, 2018, 33(12): 3065-3072. | |

| 13 | Ohashi A, Furuichi Y, Haba D C, et al. Experimental and numerical investigation on pressure change in cryogenic sloshing with a ring baffle[C]//53rd AIAA/SAE/ASEE Joint Propulsion Conference. AIAA, 2017: AIAA2017-4760. |

| 14 | Liu Z, Li C. Influence of slosh baffles on thermodynamic performance in liquid hydrogen tank[J]. Journal of Hazardous Materials, 2018, 346: 253-262. |

| 15 | 肖明堃, 黄永华, 吴静怡, 等. 非均匀磁场力作用下微重力液氧气液界面特性[J]. 制冷技术, 2020, 40(6): 1-11. |

| Xiao M K, Huang Y H, Wu J Y, et al. Gas-liquid interface behavior of liquid oxygen in compensated microgravity field with inhomogeneous magnetic force[J]. Chinese Journal of Refrigeration Technology, 2020, 40(6): 1-11. | |

| 16 | Hartwig J W. Propellant management devices for low-gravity fluid management: past, present, and future applications[J]. Journal of Spacecraft and Rockets, 2017, 54(4): 808-824. |

| 17 | Liu Z, Yuan K F, Liu Y L, et al. Fluid sloshing thermo-mechanical characteristic in a cryogenic fuel storage tank under different gravity acceleration levels[J]. International Journal of Hydrogen Energy, 2022, 47(59): 25007-25021. |

| 18 | Berglund M D, Bassett C E, Kelso J M, et al. The boeing delta Ⅳ launch vehicle—pulse-settling approach for second-stage hydrogen propellant management[J]. Acta Astronautica, 2007, 61(1/2/3/4/5/6): 416-424. |

| 19 | Space Exploration Technologies Corporation. SpaceX Demo Flight 2 Flight Review Update[EB/OL]. [2007-06-16]. . |

| 20 | Space Systems Engineering Website. The NEAR Rendezvous Burn Anomaly of December 1998[DS/OL]. [1999-11]. . |

| 21 | Hubert C. Behavior of spinning space vehicles with onboard liquids [R]. Technical Report, 2008: B8030. |

| 22 | Hartwig J, Esser N, Jain S, et al. CFD modeling of bidirectional PMDs inside cryogenic propellant tanks onboard parabolic flights[J]. Journal of Spacecraft and Rockets, 2024, 61(1): 296-312. |

| 23 | Varghese A P, Hartwig J W, Lieber S C, et al. Numerical design of a flow restrictor for tanked liquid nitrogen undergoing reduced-gravity flights[J]. Aerospace Science and Technology, 2024, 154: 109539. |

| 24 | Cheng G H, Jing W X, Gao C S. Recovery trajectory planning for the reusable launch vehicle[J]. Aerospace Science and Technology, 2021, 117: 106965. |

| 25 | Hirt C W, Nichols B D. Volume of fluid (VOF) method for the dynamics of free boundaries[J]. Journal of Computational Physics, 1981, 39(1): 201-225. |

| 26 | Morton K W. Numerical Methods for Fluid Dynamics[M]//Baines M J. New York: Academic Press, 1982: 273-486. |

| 27 | Guo S Y, Xiao M K, Xie F, et al. Optimization of helium consumption for feedback pressurization in liquid oxygen tanks[J]. International Journal of Heat and Mass Transfer, 2024, 230: 125739. |

| 28 | 刘辉, 王亚军, 黄兵, 等. 推进剂重定位过程仿真与分析[J]. 南京航空航天大学学报, 2021, 53(S1): 17-24. |

| Liu H, Wang Y J, Huang B, et al. Simulation and analysis of propellant reorientation process[J]. Journal of Nanjing University of Aeronautics & Astronautics, 2021, 53(S1): 17-24. | |

| 29 | Brackbill J U, Kothe D B, Zemach C. A continuum method for modeling surface tension[J]. Journal of Computational Physics, 1992, 100(2): 335-354. |

| 30 | 陈虹, 高旭, 王向南, 等. 过冷液氧增压排液过程数值模拟研究[J]. 低温工程, 2023(1): 20-25, 36. |

| Chen H, Gao X, Wang X N, et al. Numerical investigation on pressurization discharge of subcooled liquid oxygen[J]. Cryogenics, 2023(1): 20-25, 36. | |

| 31 | Lemmon E W, Bell I H, Huber M L, et al. NIST Standard Reference Database 23: Reference Fluid Thermodynamic and Transport Properties-REFPROP, Version 10.0 [M]. Gaithersburg, 2018. |

| 32 | Salzman J, Masica W, Lacovic R. Low gravity reorientation in a scale-model Centaur liquid-hydrogen tank[R]. NASA, 1967. |

| [1] | 燕子腾, 詹飞龙, 丁国良. 空调用套管式分流器结构设计及分流效果验证[J]. 化工学报, 2025, 76(S1): 152-159. |

| [2] | 赵子祥, 段钟弟, 孙浩然, 薛鸿祥. 大温差两相流动诱导水锤冲击的数值模型[J]. 化工学报, 2025, 76(S1): 170-180. |

| [3] | 黄灏, 王文, 贺隆坤. LNG船薄膜型液货舱预冷过程模拟与分析[J]. 化工学报, 2025, 76(S1): 187-194. |

| [4] | 汪思远, 刘国强, 熊通, 晏刚. 窗式空调器轴流风机的风速非均匀分布特性及其对冷凝器流路优化设计的影响规律[J]. 化工学报, 2025, 76(S1): 205-216. |

| [5] | 刘璐, 万开, 王文玥, 王太, 汤建成, 王少恒. 基于氦膨胀制冷的正仲氢转化耦合流动换热研究[J]. 化工学报, 2025, 76(4): 1513-1522. |

| [6] | 张翼辰, 张文彪, 李浩洋, 宁晓阳. 基于双差压模型的文丘里管气液两相CO2流量测量[J]. 化工学报, 2025, 76(4): 1493-1503. |

| [7] | 许成城, 邵索拉, 魏文建, 郑旭. 多工况下直凝式蓄热型铝制辐射板换热器供暖性能研究[J]. 化工学报, 2025, 76(4): 1545-1558. |

| [8] | 贾文龙, 肖欢, 冷翔宇, 黄巧竞, 刘程玮, 吴瑕. 原油储罐重质沉积物超声波空化微射流清洗实验及数值模拟[J]. 化工学报, 2025, 76(3): 1288-1296. |

| [9] | 张亦鸣, 杨鹏, 纪献兵, 任纪星, 张磊, 苗政. 多回路平板式环路热管热性能[J]. 化工学报, 2025, 76(3): 1018-1028. |

| [10] | 贾晶宇, 孔德齐, 沈圆辉, 张东辉, 李文彬, 唐忠利. 合成氨反应器尾气变压吸附氨分离工艺的模拟与分析[J]. 化工学报, 2025, 76(2): 718-730. |

| [11] | 何传超, 周静红, 曹约强, 施尧, 周兴贵. Ag/SiO2催化草酸酯加氢制乙醇酸甲酯的床层-颗粒双尺度耦合模拟研究[J]. 化工学报, 2025, 76(2): 654-666. |

| [12] | 李舒月, 王欢, 周少强, 毛志宏, 张永民, 王军武, 吴秀花. 重质颗粒流态化研究现状与展望[J]. 化工学报, 2025, 76(2): 466-483. |

| [13] | 戴晓宇, 徐强, 杨晨宇, 苏筱斌, 郭烈锦. 多级混流式混输泵气液两相增压特性[J]. 化工学报, 2025, 76(2): 554-563. |

| [14] | 姚佳逸, 张东辉, 唐忠利, 李文彬. 基于二级双回流的变压吸附捕碳工艺研究[J]. 化工学报, 2025, 76(2): 744-754. |

| [15] | 黄云龙, 许剑, 刘通, 元昕彤, 徐强. 气藏水平井温度分布特征及流量测试实验研究[J]. 化工学报, 2025, 76(2): 612-622. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号