化工学报 ›› 2025, Vol. 76 ›› Issue (3): 1018-1028.DOI: 10.11949/0438-1157.20240961

张亦鸣1( ), 杨鹏3, 纪献兵1,2(

), 杨鹏3, 纪献兵1,2( ), 任纪星1, 张磊1, 苗政1,2

), 任纪星1, 张磊1, 苗政1,2

收稿日期:2024-08-27

修回日期:2024-10-02

出版日期:2025-03-25

发布日期:2025-03-28

通讯作者:

纪献兵

作者简介:张亦鸣(2000—),男,硕士研究生,zym13811103752@163.com

基金资助:

Yiming ZHANG1( ), Peng YANG3, Xianbing JI1,2(

), Peng YANG3, Xianbing JI1,2( ), Jixing REN1, Lei ZHANG1, Zheng MIAO1,2

), Jixing REN1, Lei ZHANG1, Zheng MIAO1,2

Received:2024-08-27

Revised:2024-10-02

Online:2025-03-25

Published:2025-03-28

Contact:

Xianbing JI

摘要:

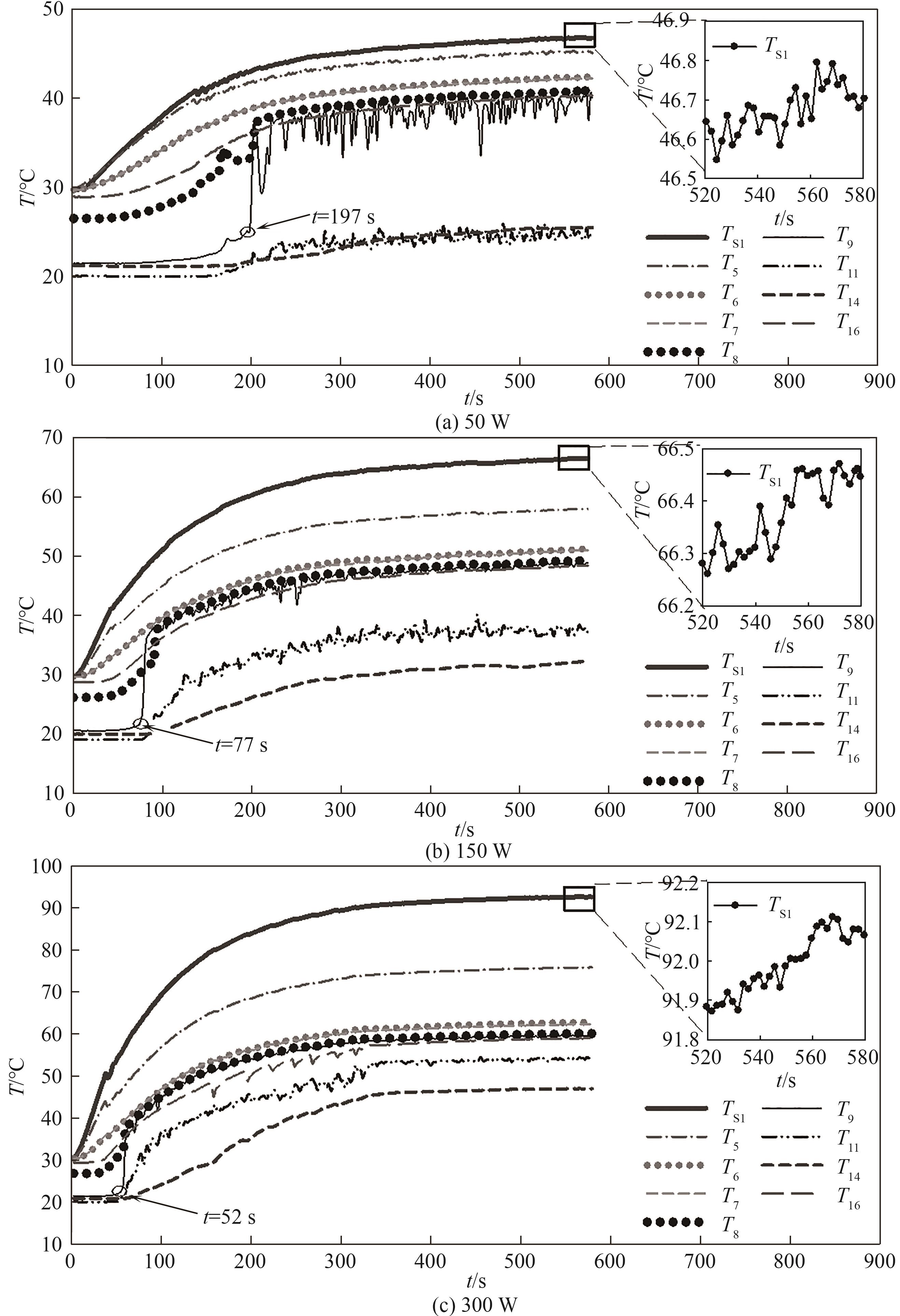

为解决高热通量电子元器件的散热问题,制备了一款尺寸为200 mm×150 mm×30 mm的新型多回路平板式环路热管,该热管采用多气液管路与微针肋阵列蒸发板耦合的设计,能够在有限空间内提高热量传输效率。研究了热通量、充液比和工质物性对环路热管传热特性的影响,测试了不同功率下环路热管的启动特性,并对单热源和多热源环境下的热性能进行了比较。结果显示:该新型环路热管启动迅速,300 W功率下启动时间仅为52 s,稳态后热源表面温度波动小于0.3℃。在3个热源同时加热,总输入功率为388.8 W(主热源热通量可达133 W/cm2)时,加热面的温度低于85℃,蒸发器内没有出现干烧现象,有效满足了大功率高热通量散热需求。

中图分类号:

张亦鸣, 杨鹏, 纪献兵, 任纪星, 张磊, 苗政. 多回路平板式环路热管热性能[J]. 化工学报, 2025, 76(3): 1018-1028.

Yiming ZHANG, Peng YANG, Xianbing JI, Jixing REN, Lei ZHANG, Zheng MIAO. Thermal performance of multi-loop flat loop heat pipes[J]. CIESC Journal, 2025, 76(3): 1018-1028.

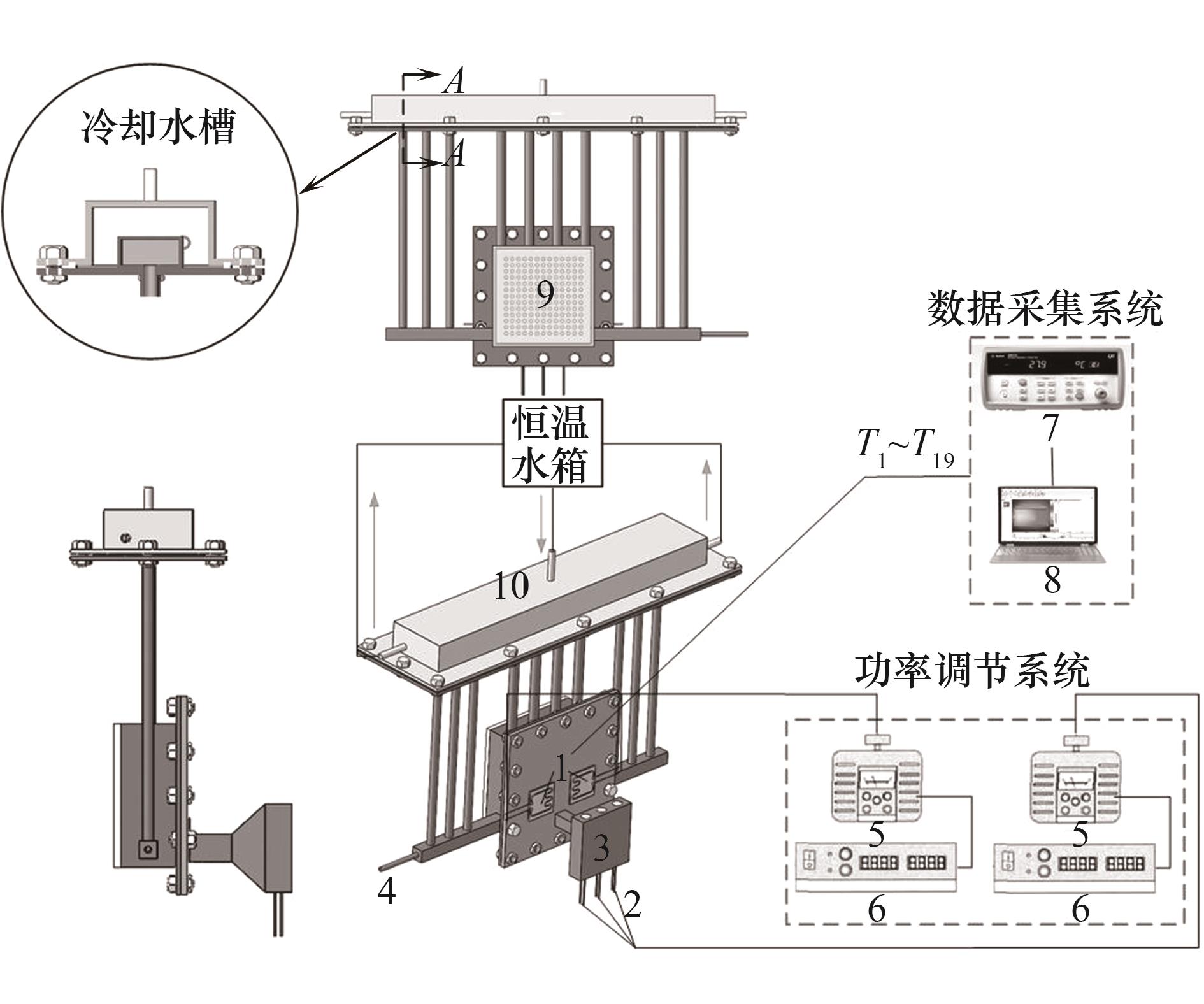

图1 实验系统1—钢基加热片;2—加热棒;3—加热铜块;4—注液管;5—调压器;6—功率计;7—数据采集仪;8—计算机;9—蒸发器;10—冷凝器

Fig.1 Experimental system1—steel based heating sheet; 2—heating rod; 3—heating copper; 4—liquid injection pipe; 5—voltage regulator; 6—power display; 7—data acquisition instrument; 8—computer; 9—evaporator; 10—condenser

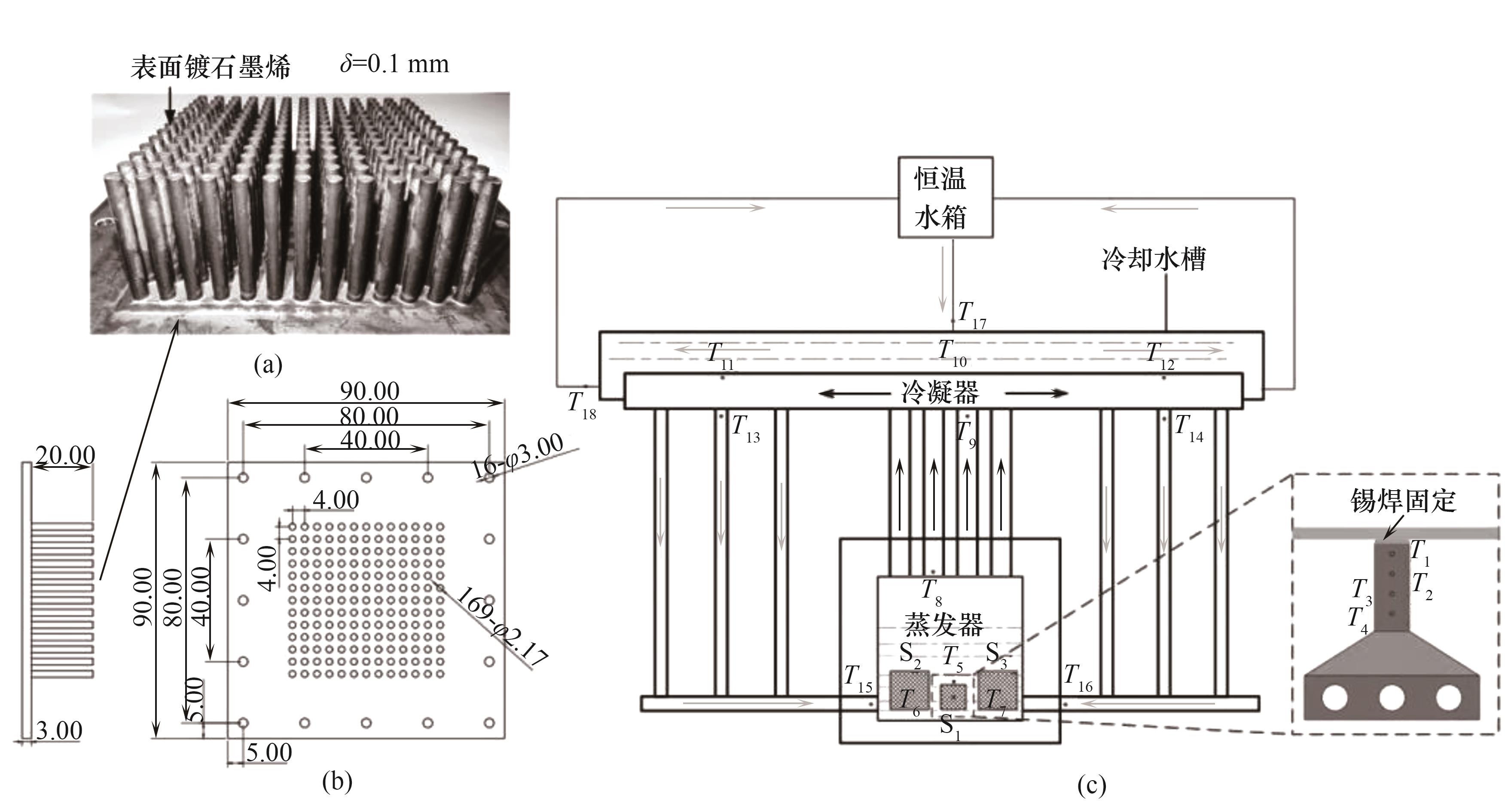

| 部件 | 参数 | 数值 |

|---|---|---|

| 蒸发器 | 腔体尺寸 | 65.0 mm×65.0 mm×25.0 mm;δ=2.0 mm |

| 加热面 | 90.0 mm×90.0 mm×2.0 mm | |

| 铜肋针 | φ=2.17 mm;d=4.0 mm;h=20.0 mm | |

| 顶盖(石英玻璃) | 65.0 mm×65.0 mm×3.0 mm | |

| 蒸气通道 | 长 内/外径 | 78.0 mm 5.0 mm/6.0 mm |

| 液体通道 | 长 内/外径 | 130.0 mm 4.0 mm/5.0 mm |

| 冷凝器 | 腔体尺寸 | 200.0 mm×20.0 mm×10.0 mm;δ=1.5 mm |

表1 回路热管及针肋结构参数

Table 1 Loop heat pipe and pin-fin structure parameters

| 部件 | 参数 | 数值 |

|---|---|---|

| 蒸发器 | 腔体尺寸 | 65.0 mm×65.0 mm×25.0 mm;δ=2.0 mm |

| 加热面 | 90.0 mm×90.0 mm×2.0 mm | |

| 铜肋针 | φ=2.17 mm;d=4.0 mm;h=20.0 mm | |

| 顶盖(石英玻璃) | 65.0 mm×65.0 mm×3.0 mm | |

| 蒸气通道 | 长 内/外径 | 78.0 mm 5.0 mm/6.0 mm |

| 液体通道 | 长 内/外径 | 130.0 mm 4.0 mm/5.0 mm |

| 冷凝器 | 腔体尺寸 | 200.0 mm×20.0 mm×10.0 mm;δ=1.5 mm |

图2 (a)针肋蒸发底板实物图;(b)针肋蒸发底板结构图;(c)工作原理及热电偶分布

Fig.2 (a) Physical diagram of pin-fin evaporation base plate; (b) Structure diagram of pin-fin evaporation base plate; (c) Working principle and thermocouple distribution

图4 不同功率下环路热管的启动特性(40%充液比,工质为去离子水,单热源环境)

Fig.4 Start-up characteristics of loop heat pipes at different powers (η=40%, working fluid is deionized water, single heat source environment)

| 工质 | 常压下沸点/℃ | 汽化潜热/(kJ/kg) | 热导率/(W/(m∙K)) | 表面张力/(mN/m) | 黏度/(mPa·s) |

|---|---|---|---|---|---|

| FCM-47 | 49.0 | 121.7 | 0.221 | 12.20 | 1.2 |

| 无水乙醇 | 78.2 | 962.5 | 0.1625 | 22.40 | 1.2 |

| 去离子水 | 100.0 | 2257.2 | 0.614 | 71.97 | 1.00 |

| 丙酮 | 57.0 | 520.6 | 0.1514 | 18.80 | 0.31 |

| R1233zd | 18.7 | 183.5 | 0.0769 | 15.10 | 0.47 |

表2 工质物性参数

Table 2 Physical property parameters of working fluid

| 工质 | 常压下沸点/℃ | 汽化潜热/(kJ/kg) | 热导率/(W/(m∙K)) | 表面张力/(mN/m) | 黏度/(mPa·s) |

|---|---|---|---|---|---|

| FCM-47 | 49.0 | 121.7 | 0.221 | 12.20 | 1.2 |

| 无水乙醇 | 78.2 | 962.5 | 0.1625 | 22.40 | 1.2 |

| 去离子水 | 100.0 | 2257.2 | 0.614 | 71.97 | 1.00 |

| 丙酮 | 57.0 | 520.6 | 0.1514 | 18.80 | 0.31 |

| R1233zd | 18.7 | 183.5 | 0.0769 | 15.10 | 0.47 |

图8 单热源与多热源加热条件下各表面中心温度Tw与输入功率Q的关系

Fig.8 Relationship between surface temperature and input power under single heat source and multi-heat source heating condition

| 1 | Li J, Zhou G H, Tian T, et al. A new cooling strategy for edge computing servers using compact looped heat pipe[J]. Applied Thermal Engineering, 2021, 187: 116599. |

| 2 | Zhang K, Zhang Y W, Liu J X, et al. Recent advancements on thermal management and evaluation for data centers[J]. Applied Thermal Engineering, 2018, 142: 215-231. |

| 3 | Chen G, Jia M Z, Zhang S W, et al. Pool boiling enhancement of novel interconnected microchannels with reentrant cavities for high-power electronics cooling[J]. International Journal of Heat and Mass Transfer, 2020, 156: 119836. |

| 4 | 杨世铭, 陶文铨. 传热学[M]. 4版. 北京: 高等教育出版社, 2006. |

| Yang S M, Tao W Q. Heat Transfer[M]. 4th ed. Beijing: Higher Education Press, 2006. | |

| 5 | Zhang Y H. Experimental study on working characteristics of loop heat pipe[J]. Science and Technology Innovation Guide, 2016, 13(16): 43-44. |

| 6 | 黄洁, 王乃华, 程林. 环路热管启动特性模拟[J]. 化工学报, 2014, 65(S1): 297-302. |

| Huang J, Wang N H, Cheng L. Simulation of start-up characteristics of loop heat pipe[J]. CIESC Journal, 2014, 65(S1): 297-302. | |

| 7 | Tang H, Tang Y, Wan Z P, et al. Review of applications and developments of ultra-thin micro heat pipes for electronic cooling[J]. Applied Energy, 2018, 223: 383-400. |

| 8 | Bastakoti D, Zhang H N, Li D, et al. An overview on the developing trend of pulsating heat pipe and its performance[J]. Applied Thermal Engineering, 2018, 141: 305-332. |

| 9 | Anand A R, Jaiswal A, Ambirajan A, et al. Experimental studies on a miniature loop heat pipe with flat evaporator with various working fluids[J]. Applied Thermal Engineering, 2018, 144: 495-503. |

| 10 | Zhao T Y, Ma Z Y, Zhang Z K, et al. Experimental investigation of a loop heat pipe with a flat evaporator and cupric oxide nanofluids as working fluid[J]. Energy Reports, 2021, 7: 7693-7703. |

| 11 | Gai D X, Liu Z C, Liu W, et al. Experimental investigation of temperature oscillation in miniature loop heat pipe[C]//AIP Conference Proceedings. AIP, 2010, 1207(1): 465-470. |

| 12 | 孙志坚. 电子器件回路型热管散热器的数值模拟与试验研究[D]. 杭州: 浙江大学, 2007. |

| Sun Z J. Numerical simulation and experimental study on loop heat pipe radiator for electronic devices[D]. Hangzhou: Zhejiang University, 2007. | |

| 13 | Tsai T E, Wu H H, Chang C C, et al. Two-phase closed thermosyphon vapor-chamber system for electronic cooling[J]. International Communications in Heat and Mass Transfer, 2010, 37(5): 484-489. |

| 14 | 田亚玲, 张海南, 徐洪波, 等. 紧凑型平板环路热管实验研究[J]. 化工学报, 2021, 72(6): 3288-3295. |

| Tian Y L, Zhang H N, Xu H B, et al. Experimental study on compact plate loop heat pipe[J]. CIESC Journal, 2021, 72(6): 3288-3295. | |

| 15 | Zhou W, Ling W S, Duan L, et al. Development and tests of loop heat pipe with multi-layer metal foams as wick structure[J]. Applied Thermal Engineering, 2016, 94: 324-330. |

| 16 | 陈曦, 林毅, 邵帅. 倾角及加热功率对乙烷脉动热管传热性能的影响[J]. 化工学报, 2019, 70(4): 1383-1389. |

| Chen X, Lin Y, Shao S. Influences of inclination angle and heating power on heat transfer performance of ethane pulsating heat pipe[J]. CIESC Journal, 2019, 70(4): 1383-1389. | |

| 17 | 龙延, 魏进家, 吕虓. 不同倾角下平板型环路热管的实验研究[J]. 西安交通大学学报, 2013, 47(5): 38-43. |

| Long Y, Wei J J, Lü X. Experimental study on loop heat pipe with flat evaporator at different tilt angles[J]. Journal of Xi’an Jiaotong University, 2013, 47(5): 38-43. | |

| 18 | Hong S H, Zhang X Q, Tang Y L, et al. Experiment research on the effect of the evaporator’s configuration design of an innovative ultra-thin looped heat pipe[J]. International Journal of Heat and Mass Transfer, 2016, 92: 497-506. |

| 19 | Xu J Y, Wang Z Y, Xu H, et al. Experimental research on the heat performance of a flat copper-water loop heat pipe with different inventories[J]. Experimental Thermal and Fluid Science, 2017, 84: 110-119. |

| 20 | Solomon A B, Mahto A K, Joy R C, et al. Application of bio-wick in compact loop heat pipe[J]. Applied Thermal Engineering, 2020, 169: 114927. |

| 21 | Boo J H, Chung W B. Thermal performance of a loop heat pipe having polypropylene wick in a flat evaporator[C]//Heat Transfer: Volume 4. San Francisco, California, USA: ASMEDC, 2005: 473-478. |

| 22 | 曲燕, 张坤峰. 环路热管双孔径分布毛细结构的研究进展[J]. 粉末冶金工业, 2014, 24(3): 48-55. |

| Qu Y, Zhang K F. Review of bi-porous wick structure for loop heat pipe[J]. Powder Metallurgy Industry, 2014, 24(3): 48-55. | |

| 23 | 张畅, 谢荣建, 张添, 等. 液氮温区平板蒸发器环路热管实验研究[J]. 北京航空航天大学学报, 2019, 45(6): 1211-1217. |

| Zhang C, Xie R J, Zhang T, et al. Experimental study on a liquid nitrogen temperature region loop heat pipe with flat evaporator[J]. Journal of Beijing University of Aeronautics and Astronautics, 2019, 45(6): 1211-1217. | |

| 24 | Mizutani T, Watanabe N, Aso S, et al. Experimental and analytical investigation of a 0.3-mm-thick loop heat pipe for 10 W-class heat dissipation[J]. International Journal of Heat and Mass Transfer, 2022, 193: 122950. |

| 25 | 郭浩. 热管内气液相分离及传热性能实验研究[D]. 北京: 华北电力大学, 2021. |

| Guo H. Experimental study on gas-liquid separation and heat transfer performance in heat pipe[D]. Beijing: North China Electric Power University, 2021. | |

| 26 | 顾孝烈, 鲍峰, 程效军. 测量学[M]. 3版. 上海: 同济大学出版社, 2006. |

| Gu X L, Bao F, Cheng X J. Elementary Surveying[M]. 3rd ed. Shanghai: Tongji University Press, 2006. | |

| 27 | Yan L P, Zhang P, Xu H, et al. Visualization of thermo-hydrodynamic behavior in flat-plate pulsating heat pipe with HFE-347[J]. Journal of Thermal Science, 2021, 30(3): 926-938. |

| 28 | Xing M B, Wang R X, Xu R J. Experimental study on thermal performance of a pulsating heat pipe with surfactant aqueous solution[J]. International Journal of Heat and Mass Transfer, 2018, 127: 903-909. |

| 29 | Su Z P, Hu Y X, Zheng S B, et al. Recent advances in visualization of pulsating heat pipes: a review[J]. Applied Thermal Engineering, 2023, 221: 119867. |

| 30 | Fritz W. Maximum volume of vapor bubbles[J]. Physics, 1935, 36: 379-388. |

| 31 | 杨洪海. 闭式回路脉动热管运行性能的研究[D]. 上海: 东华大学, 2006. |

| Yang H H. Investigations of the operational performance of closed loop pulsating heat pipes[D]. Shanghai: Donghua University, 2006. |

| [1] | 肖俊兵, 钟湘宇, 任建地, 钟芳芳, 刘昌会, 贾传坤. 基于生物碳材料强化的硬脂酸相变材料储热性能研究[J]. 化工学报, 2025, 76(3): 1312-1322. |

| [2] | 田浩辰, 马志先, 王之浩. R1234ze(E)水平三维肋管外膜状凝结特性实验研究[J]. 化工学报, 2025, 76(3): 975-984. |

| [3] | 齐珂, 王迪, 谢喆, 陈东升, 周云龙, 孙灵芳. 考虑多物理场耦合特性的固体氧化物燃料电池瞬态特性研究[J]. 化工学报, 2025, 76(3): 1264-1274. |

| [4] | 孙芹, 周国庆, 翟万领, 高山, 罗倩倩, 屈健. 局部多热源下拓扑优化通道平板脉动热管的传热特性[J]. 化工学报, 2025, 76(3): 1006-1017. |

| [5] | 张先开, 王博宇, 郭亚丽, 沈胜强. 水平圆管降膜蒸发式冷凝器热力性能计算分析[J]. 化工学报, 2025, 76(3): 995-1005. |

| [6] | 李科, 忻碧平, 文键. 液氢储罐中耦合蒸气冷却屏的连续变密度多层绝热的序列二次规划优化[J]. 化工学报, 2025, 76(3): 985-994. |

| [7] | 禹言芳, 张埔瑜, 孟辉波, 孙雯, 李雯, 乔文龙, 张梦琼. 仿生海螺型静态混合器传热与湍流脉动特性实验研究[J]. 化工学报, 2025, 76(3): 1040-1049. |

| [8] | 张履胜, 王治红, 柳青, 李雪雯, 谭仁敏. 液-液相变吸收剂捕集二氧化碳研究进展[J]. 化工学报, 2025, 76(3): 933-950. |

| [9] | 肖俊兵, 邹博, 任建地, 刘昌会, 贾传坤. 基于相图分析的氯化物复合熔盐储热性能研究[J]. 化工学报, 2025, 76(3): 963-974. |

| [10] | 戴晓宇, 徐强, 杨晨宇, 苏筱斌, 郭烈锦. 多级混流式混输泵气液两相增压特性[J]. 化工学报, 2025, 76(2): 554-563. |

| [11] | 黄云龙, 许剑, 刘通, 元昕彤, 徐强. 气藏水平井温度分布特征及流量测试实验研究[J]. 化工学报, 2025, 76(2): 612-622. |

| [12] | 黄鑫, 李逸龙, 李卫东, 施鸿翔, 尹鹏博, 李臻超, 滕霖, 江莉龙. 液氨-成品油混合体系相平衡及减压相变规律研究[J]. 化工学报, 2025, 76(1): 71-80. |

| [13] | 李彦, 郭红利, 苏国庆, 张建文. 加氢装置空冷器气液两相流动与冲刷腐蚀问题[J]. 化工学报, 2025, 76(1): 141-150. |

| [14] | 李海东, 张奇琪, 杨路, AKRAM Naeem, 常承林, 莫文龙, 申威峰. 采用智能进化算法的管壳式换热器详细设计[J]. 化工学报, 2025, 76(1): 241-255. |

| [15] | 陈晗, 蔡畅, 刘红, 尹洪超. 正戊醇添加剂强化喷雾冷却传热实验研究[J]. 化工学报, 2025, 76(1): 131-140. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号