化工学报 ›› 2025, Vol. 76 ›› Issue (2): 554-563.DOI: 10.11949/0438-1157.20240924

• 流体力学与传递现象 • 上一篇

收稿日期:2024-08-14

修回日期:2024-09-25

出版日期:2025-03-25

发布日期:2025-03-10

通讯作者:

徐强,郭烈锦

作者简介:戴晓宇(1995—),男,博士研究生,DaiXiaoyu@stu.xjtu.edu.cn

基金资助:

Xiaoyu DAI( ), Qiang XU(

), Qiang XU( ), Chenyu YANG, Xiaobin SU, Liejin GUO(

), Chenyu YANG, Xiaobin SU, Liejin GUO( )

)

Received:2024-08-14

Revised:2024-09-25

Online:2025-03-25

Published:2025-03-10

Contact:

Qiang XU, Liejin GUO

摘要:

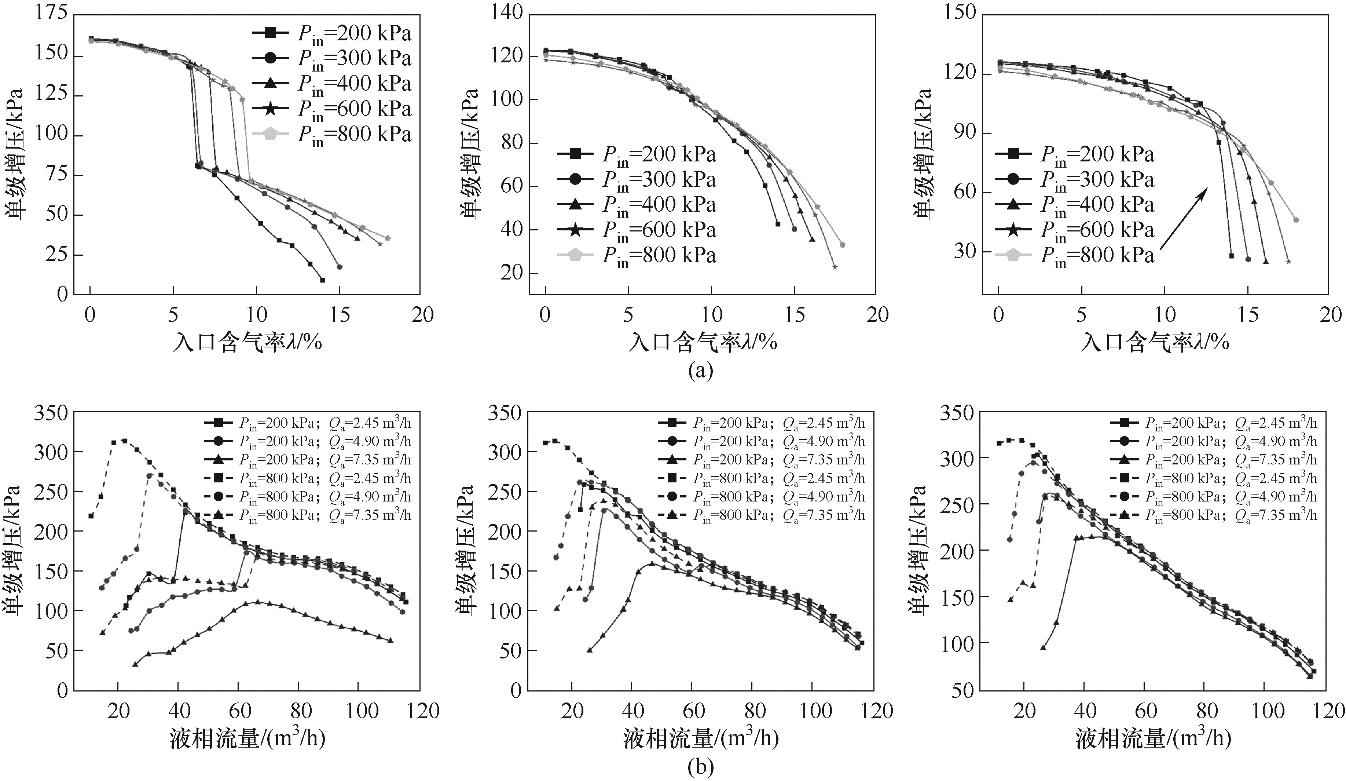

在高入口含气率下,混输泵的增压性能剧烈恶化,对化工生产过程的安全稳定运行构成威胁。采用surging test和mapping test两种测试方法,全方位探讨了多运行参数对三级混流式混输泵整体与级间气液两相增压特性的影响。研究结果表明,随着液相流量的提升,增压性能曲线由三个增压级性能逐级恶化导致的波纹状下降趋势逐渐消失。多级混输泵增压性能的显著恶化主要归因于首个增压级性能的剧烈下滑。提高液相流量能有效减轻气体积聚,其对增压性能的正面促进作用显著超过了流动分离带来的负面影响,因而增压随液相流量变化曲线呈现骤升趋势。提高入口压力有助于缓解气团聚集对增压性能的负面影响。

中图分类号:

戴晓宇, 徐强, 杨晨宇, 苏筱斌, 郭烈锦. 多级混流式混输泵气液两相增压特性[J]. 化工学报, 2025, 76(2): 554-563.

Xiaoyu DAI, Qiang XU, Chenyu YANG, Xiaobin SU, Liejin GUO. Gas-liquid two-phase pressurization characteristics of multistage mixed-flow multiphase pump[J]. CIESC Journal, 2025, 76(2): 554-563.

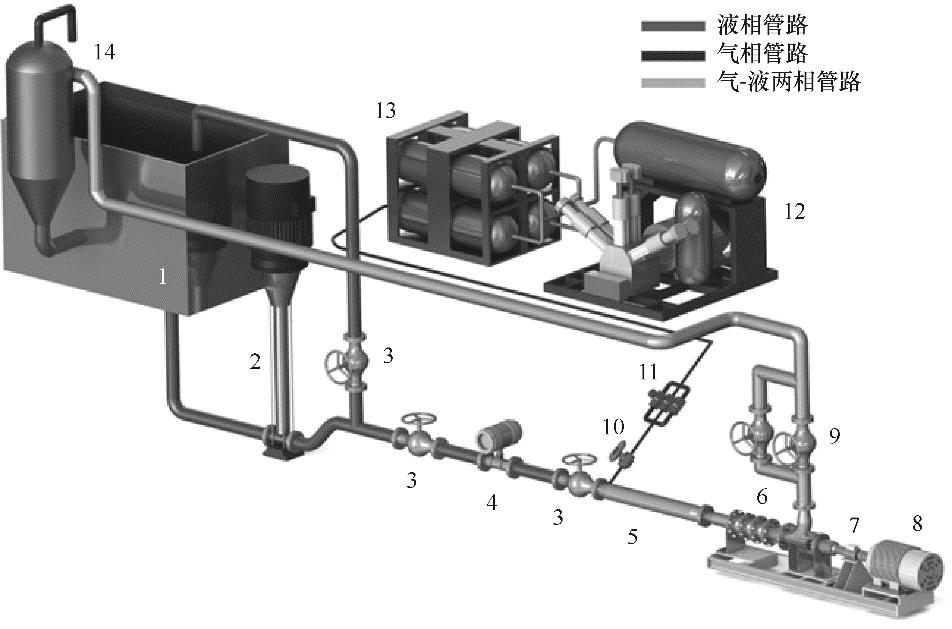

图1 三级混流式混输泵测试平台1—储液罐;2—给水泵;3—流量调节阀;4—液相流量计;5—静态混匀器;6—三级混流式混输泵;7—扭矩转速仪;8—变频电机;9—出口控制阀;10—高压截止阀;11—气相调节阀;12—空气压缩机;13—高压储气瓶;14—气液分离器

Fig.1 Schematic of three-stage mixed-flow multiphase pump system1—liquid tank; 2—centrifugal pump; 3—flow regulating valve; 4—liquid flowmeter; 5—mixer; 6—three-stage mixed-flow pump; 7—torque tachometer; 8—variable frequency motor; 9—outlet control valve; 10—high-pressure globe valve; 11—gas-phase regulating valve; 12—air compressor; 13—high-pressure gas storage cylinders; 14—gas-liquid separator

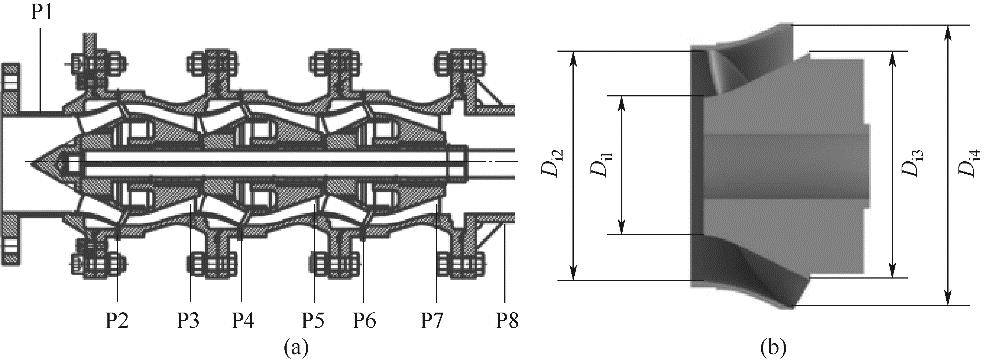

图2 三级混流式混输泵结构图:(a)叶轮与扩压器截面及传感器布置;(b)叶轮结构

Fig.2 Structure of the three-stage mixed-flow pump: (a) impeller and diffuser cross sections and sensor layout; (b) impeller structure

| 结构参数 | 叶轮 | 扩压器 | ||

|---|---|---|---|---|

| 入口内径/mm | Di1 | 64 | Dd1 | 111 |

| 入口外径/mm | Di2 | 107 | Dd2 | 136 |

| 出口内径/mm | Di3 | 106 | Dd3 | 109 |

| 出口外径/mm | Di4 | 133 | Dd4 | 68 |

| 入口安放角/(°) | βi1 | 23 | βd1 | 23 |

| 出口安放角/(°) | βi2 | 30 | βd2 | 72 |

| 叶片数 | Bi | 4 | Bd | 7 |

| 包角/(°) | φi | 90 | φd | 90 |

表1 叶轮与扩压器结构参数

Table 1 Structural parameters of impeller and diffuser

| 结构参数 | 叶轮 | 扩压器 | ||

|---|---|---|---|---|

| 入口内径/mm | Di1 | 64 | Dd1 | 111 |

| 入口外径/mm | Di2 | 107 | Dd2 | 136 |

| 出口内径/mm | Di3 | 106 | Dd3 | 109 |

| 出口外径/mm | Di4 | 133 | Dd4 | 68 |

| 入口安放角/(°) | βi1 | 23 | βd1 | 23 |

| 出口安放角/(°) | βi2 | 30 | βd2 | 72 |

| 叶片数 | Bi | 4 | Bd | 7 |

| 包角/(°) | φi | 90 | φd | 90 |

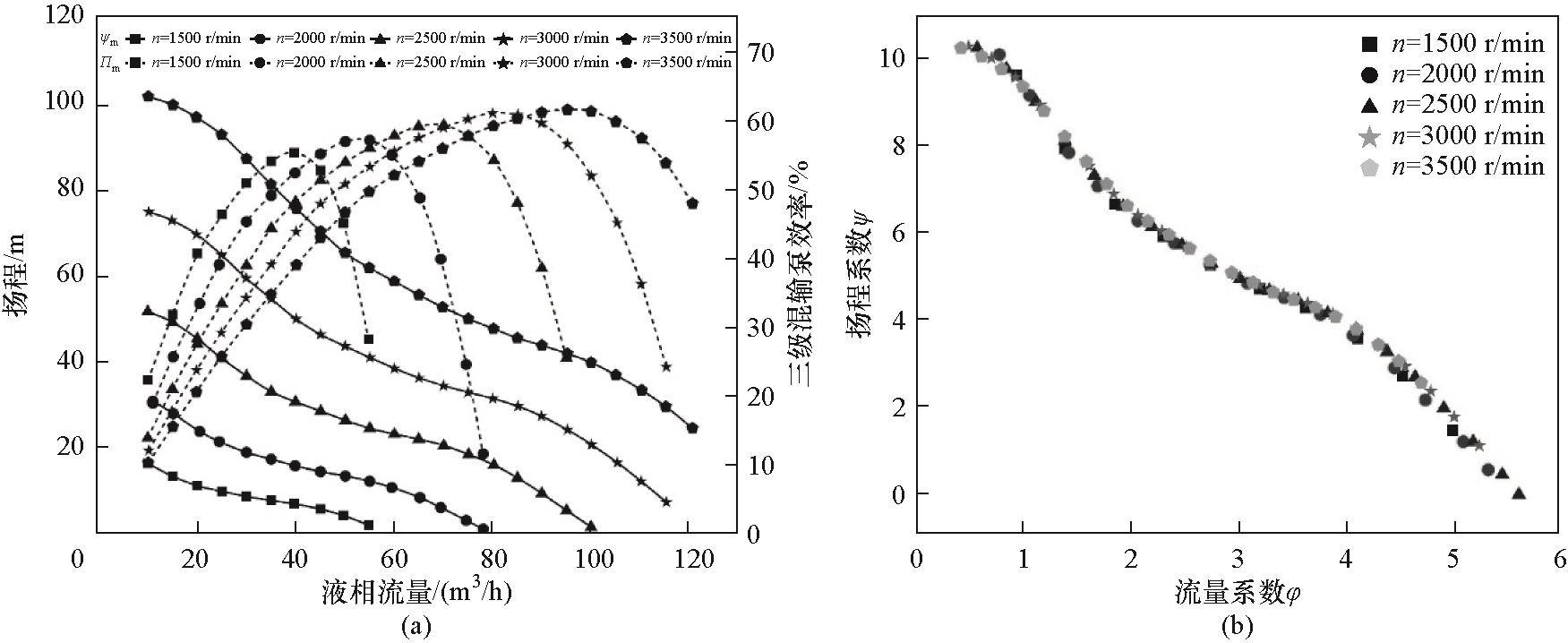

图3 单相水力特性:(a)增压与效率随液相流量变化曲线;(b)无量纲扬程系数随流量系数变化曲线

Fig.3 Single-phase hydraulic characteristics: (a) pressurization and efficiency curve with liquid flow rate; (b) dimensionless head coefficient curve with flow rate

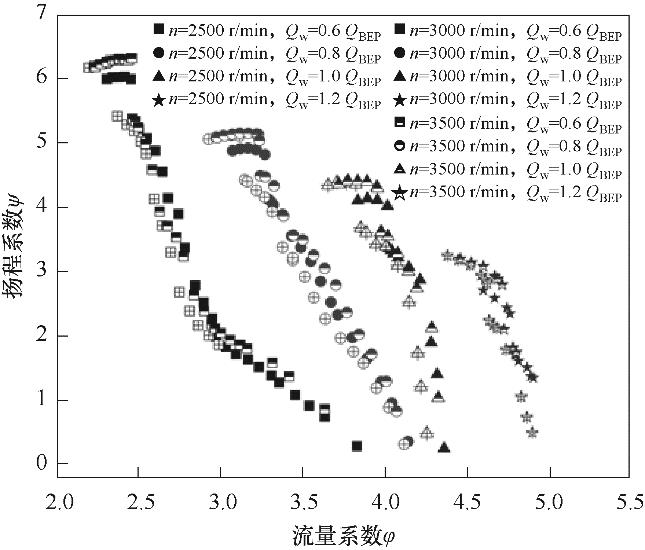

图6 三级混流式混输泵气液两相扬程系数随流量系数变化散点图

Fig.6 Scatter diagram of the gas-liquid two-phase head coefficient of the three-stage mixed-flow multiphase pump with the flow coefficient

图9 三个增压级在不同入口压力与液相流量下的增压随入口含气率变化曲线

Fig.9 Pressurization curves of three booster stages with inlet gas volume fraction and liquid phase flow rate under different inlet pressures

| 1 | 严东寅, 于晓, 李焯超, 等. 国内外混输泵的发展与应用[J]. 当代化工研究, 2022(17): 118-122. |

| Yan D Y, Yu X, Li Z C, et al. Development and application of multiphase pumps in China and other countries[J]. Modern Chemical Research, 2022(17): 118-122. | |

| 2 | Li H C, Zhang W W, Hu L W, et al. Studies on flow characteristics of gas-liquid multiphase pumps applied in petroleum transportation engineering—a review[J]. Energies, 2023, 16(17): 6292. |

| 3 | Zhu H W, Zhu J J, Zhang H Q. Mechanistic modeling of gas effect on multi-stage electrical submersible pump (ESP) performance with experimental validation[J]. Chemical Engineering Science, 2022, 252: 117288. |

| 4 | Wang Q Y, Wang Y Y, Sun J B, et al. Hydrogen production from simulated seawater by microwave liquid discharge: a new way of green production[J]. Chemical Engineering Journal, 2023, 465: 142872. |

| 5 | 杨晨宇, 徐强, 常亮, 等. 含气率对深海多相混输泵性能影响的数值研究[J]. 工程热物理学报, 2021, 42(6): 1479-1485. |

| Yang C Y, Xu Q, Chang L, et al. Numerical study on the effect of gas void fraction on the performance of deep-sea multiphase pump[J]. Journal of Engineering Thermophysics, 2021, 42(6): 1479-1485. | |

| 6 | William M V, Jorge B, Cristhian E P, et al. Experimental investigation of pressure drop in failed electrical submersible pump (ESP) under liquid single-phase and gas-liquid two-phase flow[J]. Journal of Petroleum Science and Engineering, 2021, 198: 108127. |

| 7 | Luo X Q, Ge Z G, Feng J J, et al. Experimental investigation of pressure fluctuation in a mixed-flow pump under gas-liquid two-phase flow conditions[J]. Physics of Fluids, 2024, 36 (2): 023361. |

| 8 | Lea J F, Bearden J L. Effect of gaseous fluids on submersible pump performance[J]. Journal of Petroleum Technology, 1982, 34(12): 2922-2930. |

| 9 | Fu Q, Zhang F, Zhu R, et al. Effect of gas quantity on two-phase flow characteristics of a mixed-flow pump[J]. Advances in Mechanical Engineering, 2016, 8(4): 1687814016644578. |

| 10 | Chang L, Xu Q, Yang C Y, et al. Experimental study of gas-liquid pressurization performance and critical gas volume fractions of a multiphase pump[J]. Journal of Fluids Engineering, 2022, 144(5): 051404. |

| 11 | Zhu J J, Guo X Z, Liang F C, et al. Experimental study and mechanistic modeling of pressure surging in electrical submersible pump[J]. Journal of Natural Gas Science and Engineering, 2017, 45: 625-636. |

| 12 | Gamboa J, Prado M. Experimental study of two-phase performance of an electric-submersible-pump stage[J]. SPE Production & Operations, 2012, 27(4): 414-421. |

| 13 | Shi G T, Wang Z W. Research on the pressurization performance of an impeller in a multi-phase pump under different working conditions[J]. Advances in Mechanical Engineering, 2019, 11(3): 1-11. |

| 14 | Li H C, Yang J H, Zhang W W, et al. Energy performance and unsteady gas-liquid flow characteristics of a multiphase rotodynamic pump: an experiment[J]. Applied Energy, 2024, 375: 124112. |

| 15 | Xu Y, Cao S L, Sano T, et al. Experimental investigation on transient pressure characteristics in a helico-axial multiphase pump[J]. Energies, 2019, 12(3): 461. |

| 16 | Monte Verde W, Biazussi J L, Sassim N A, et al. Experimental study of gas-liquid two-phase flow patterns within centrifugal pumps impellers[J]. Experimental Thermal and Fluid Science, 2017, 85: 37-51. |

| 17 | Yang C Y, Xu Q, Chang L, et al. Interstage performance and power consumption of a multistage mixed-flow electrical submersible pump in gas-liquid conditions: an experimental study[J]. Journal of Fluids Engineering, 2024, 146(5): 051203. |

| 18 | He D H, Zhao L, Chang Z, et al. On the performance of a centrifugal pump under bubble inflow: effect of gas-liquid distribution in the impeller[J]. Journal of Petroleum Science and Engineering, 2021, 203: 108587. |

| 19 | Ji L L, Li W, Shi W D, et al. Influence of different blade numbers on the performance of “saddle zone” in a mixed flow pump[J]. Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy, 2022, 236(3): 477-489. |

| 20 | Bing H, Cao S L, He C L, et al. Experimental study of the effect of blade tip clearance and blade angle error on the performance of mixed-flow pump[J]. Science China Technological Sciences, 2013, 56(2): 293-298. |

| 21 | Ni D, Yang M. Numerical study on the effect of the diffuser blade trailing edge profile on flow instability in a nuclear reactor coolant pump[J]. Nuclear Engineering and Design, 2017, 322: 92-103. |

| 22 | Cui B L, Chen D S, Wang C F, et al. Research on performance of centrifugal pump with different-type open impeller[J]. Journal of Thermal Science, 2013, 22(6): 586-591. |

| 23 | Luo X Q, Yan S N, Sun S H, et al. Experimental study of gas-liquid two-phase operating characteristics and bubble evolution law of a semi-open mixed-flow pump[J]. Ocean Engineering, 2023, 272: 113733. |

| 24 | Hundshagen M, Mansour M, Thévenin D, et al. 3D simulation of gas-laden liquid flows in centrifugal pumps and the assessment of two-fluid CFD methods[J]. Experimental and Computational Multiphase Flow, 2021, 3(3): 186-207. |

| 25 | Wu D Z, Yan P, Chen X, et al. Effect of trailing-edge modification of a mixed-flow pump[J]. Journal of Fluids Engineering, 2015, 137(10): 101205. |

| 26 | Mansour M, Wunderlich B, Thévenin D. Experimental study of two-phase air/water flow in a centrifugal pump working with a closed or a semi-open impeller[C]//ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition. Oslo, Norway, 2018. |

| 27 | Dai X Y, Xu Q, Yang C Y, et al. Experimental and numerical study of hydraulic characteristics and pressurization deterioration mechanism of a three-stage mixed-flow electrical submersible pump under gas-liquid condition[J]. Journal of Fluids Engineering, 2024, 146(9): 091204. |

| 28 | Chang L, Xu Q, Yang C Y, et al. Experimental study on gas-liquid performance and prediction of shaft power and efficiency by dimensionless coefficients in a multistage electrical submersible pump[J]. Journal of Fluids Engineering, 2023, 145(7): 071204. |

| 29 | Zhou L, Han Y, Lv W N, et al. Numerical calculation of energy performance and transient characteristics of centrifugal pump under gas-liquid two-phase condition[J]. Micromachines, 2020, 11(8): 728. |

| 30 | Si Q R, Asad A, Wang B B, et al. Numerical study on gas-liquid two phase flow characteristic of multistage electrical submersible pump by using a novel multiple-size group (MUSIG) model[J]. Physics of Fluids, 2022; 34 (6): 063311. |

| 31 | Barrios L, Prado M G. Modeling two-phase flow inside an electrical submersible pump stage[J]. Journal of Energy Resources Technology, 2011, 133(4): 042902. |

| [1] | 李彦, 郭红利, 苏国庆, 张建文. 加氢装置空冷器气液两相流动与冲刷腐蚀问题[J]. 化工学报, 2025, 76(1): 141-150. |

| [2] | 徐英宇, 杨国强, 彭璟, 孙海宁, 张志炳. 微界面高级氧化处理煤化工废水的研究[J]. 化工学报, 2024, 75(S1): 283-291. |

| [3] | 杜得辉, 冯威, 张江辉, 项燕龙, 乔高攀, 李蔚. 微型翅片疏水复合强化管管内流动沸腾换热预测模型[J]. 化工学报, 2024, 75(S1): 95-107. |

| [4] | 王皓宇, 杨杨, 荆文婕, 杨斌, 唐雨, 刘毅. 不同旋流器作用下气液螺旋环状流动特性研究[J]. 化工学报, 2024, 75(8): 2744-2755. |

| [5] | 赵亮, 李雨桥, 张德, 沈胜强. 螺旋喷嘴内外流场特性的实验研究[J]. 化工学报, 2024, 75(8): 2777-2786. |

| [6] | 罗正航, 李敬宇, 陈伟雄, 种道彤, 严俊杰. 摇摆运动下低流率蒸汽冷凝换热特性和气泡受力数值模拟[J]. 化工学报, 2024, 75(8): 2800-2811. |

| [7] | 曲玖哲, 杨鹏, 杨绪飞, 张伟, 宇波, 孙东亮, 王晓东. 硅基微柱簇阵列微通道流动沸腾实验研究[J]. 化工学报, 2024, 75(8): 2840-2851. |

| [8] | 李彦熹, 王晔春, 谢向东, 王进芝, 王江, 周煜, 潘盈秀, 丁文涛, 郭烈锦. 蜗壳式多通道气液旋流分离器结构优化及分离特性研究[J]. 化工学报, 2024, 75(8): 2875-2885. |

| [9] | 吕方明, 包志铭, 王博文, 焦魁. 气体扩散层侵入流道对燃料电池水管理影响研究[J]. 化工学报, 2024, 75(8): 2929-2938. |

| [10] | 李新泽, 张双星, 杨洪海, 杜文静. 基于电池冷却用新型脉动热管性能的实验研究[J]. 化工学报, 2024, 75(6): 2222-2232. |

| [11] | 杨艳, 郭亚丽, 于硕文, 潘泊年, 沈胜强. 液氨喷射泵热力性能的计算分析[J]. 化工学报, 2024, 75(6): 2134-2142. |

| [12] | 师毓辉, 邢继远, 姜雪晗, 叶爽, 黄伟光. 基于PBM的离心式叶轮内气泡破碎合并数值模拟[J]. 化工学报, 2024, 75(5): 1816-1829. |

| [13] | 关朝阳, 黄国庆, 张一喃, 陈宏霞, 杜小泽. 泡沫铜导离气泡强化流动沸腾换热实验研究[J]. 化工学报, 2024, 75(5): 1765-1776. |

| [14] | 王娟, 李秀明, 邵炜涛, 丁续, 霍莹, 付连超, 白云宇, 李迪. 多孔板鼓泡塔流动与传质特性数值模拟[J]. 化工学报, 2024, 75(3): 801-814. |

| [15] | 陈思睿, 毕景良, 王雷, 李元媛, 陆规. 气液两相流流型特征无监督提取的卷积自编码器:机理及应用[J]. 化工学报, 2024, 75(3): 847-857. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号