化工学报 ›› 2025, Vol. 76 ›› Issue (10): 5300-5310.DOI: 10.11949/0438-1157.20250512

崔诣1( ), 胡耀伟1,2, 宋云彩1,2,3(

), 胡耀伟1,2, 宋云彩1,2,3( ), 冯杰1,2,3(

), 冯杰1,2,3( ), 李文英1,2,3

), 李文英1,2,3

收稿日期:2025-05-09

修回日期:2025-07-10

出版日期:2025-10-25

发布日期:2025-11-25

通讯作者:

宋云彩,冯杰

作者简介:崔诣(1999—),男,硕士研究生,cuiyi0980@link.tyut.edu.cn

基金资助:

Yi CUI1( ), Yaowei HU1,2, Yuncai SONG1,2,3(

), Yaowei HU1,2, Yuncai SONG1,2,3( ), Jie FENG1,2,3(

), Jie FENG1,2,3( ), Wenying LI1,2,3

), Wenying LI1,2,3

Received:2025-05-09

Revised:2025-07-10

Online:2025-10-25

Published:2025-11-25

Contact:

Yuncai SONG, Jie FENG

摘要:

孔隙结构是影响热解脱挥发分的重要因素之一。为了研究煤热解过程中孔隙的演变规律和分形特征及其对挥发分传质行为的影响,本文通过N2吸附法和分形理论对不同热解终温(393~1073 K)下半焦的孔隙结构进行了分析和定量描述。并基于半焦孔隙的演变规律和分形特征,从颗粒尺度上对热解过程中孔结构的演变进行了建模,模型考虑了焦油的二次裂解反应、挥发分在分形孔隙内的扩散,同时能预测煤颗粒的瞬态温度分布、挥发分的生成以及孔隙结构的变化。结果表明,半焦热解过程中以狭缝状介孔为主;影响孔隙演变的机制包括干燥脱气、有机质裂解与孔隙收缩;微孔存在增加了半焦孔结构的非均质性。孔结构主要通过改变焦油的扩散机制来影响挥发分的产率,对轻质气体的产率影响不大。

中图分类号:

崔诣, 胡耀伟, 宋云彩, 冯杰, 李文英. 长焰煤热解过程中孔的演变及其对挥发分传质影响[J]. 化工学报, 2025, 76(10): 5300-5310.

Yi CUI, Yaowei HU, Yuncai SONG, Jie FENG, Wenying LI. Pore evolution and its influence on volatile mass transfer during long-flame coal pyrolysis[J]. CIESC Journal, 2025, 76(10): 5300-5310.

| 工业分析wad/% | 元素分析wdaf/% | |||||||

|---|---|---|---|---|---|---|---|---|

| M | A | V | FC | C | H | N | S | O |

| 2.80 | 7.80 | 35.38 | 54.02 | 81.62 | 5.64 | 1.05 | 0.82 | 9.81 |

表1 曹家滩长焰煤的工业分析和元素分析

Table 1 Proximate and ultimate analysis of CJT

| 工业分析wad/% | 元素分析wdaf/% | |||||||

|---|---|---|---|---|---|---|---|---|

| M | A | V | FC | C | H | N | S | O |

| 2.80 | 7.80 | 35.38 | 54.02 | 81.62 | 5.64 | 1.05 | 0.82 | 9.81 |

| 方程类别 | 方程 |

|---|---|

| 能量守恒方程[ | |

| 有效比热容(ρcp )eff | |

| 有效热导率λeff | |

| 热源项Qtot[ | |

| 局部热通量q[ | |

| 动量传递控制方程[ | |

| 气体流速u | |

| 多孔基体的渗透率κ[ | |

| 理想气体状态方程[ | |

| 质量传递方程[ | |

| 对流质量通量[ | |

| 扩散通量Ji[ | |

| 分形扩散系数Di[ | |

| 分子运动的平均速率v[ | |

| 分子平均自由程δ[ | |

| 孔隙结构演变模型[ | |

| Nusselt数[ | |

| Reynolds数[ | |

| Prandtl数[ | |

| 反应速率常数k[ |

表2 反应过程中涉及到的数学模型

Table 2 Mathematical modeling involved in the reaction process

| 方程类别 | 方程 |

|---|---|

| 能量守恒方程[ | |

| 有效比热容(ρcp )eff | |

| 有效热导率λeff | |

| 热源项Qtot[ | |

| 局部热通量q[ | |

| 动量传递控制方程[ | |

| 气体流速u | |

| 多孔基体的渗透率κ[ | |

| 理想气体状态方程[ | |

| 质量传递方程[ | |

| 对流质量通量[ | |

| 扩散通量Ji[ | |

| 分形扩散系数Di[ | |

| 分子运动的平均速率v[ | |

| 分子平均自由程δ[ | |

| 孔隙结构演变模型[ | |

| Nusselt数[ | |

| Reynolds数[ | |

| Prandtl数[ | |

| 反应速率常数k[ |

| 反应 | 指前因子Ai /s-1 | 活化能Ei /(kJ·mol-1) | 反应热ΔH/(kJ·kg-1) |

|---|---|---|---|

| 1 | 4.38×109 | 152.7 | 80 |

| 2 | 1.08×1010 | 148 | 80 |

| 3 | 3.75×106 | 111.7 | 80 |

| 4 | 4.28×106 | 108 | -42 |

| 5 | 1×105 | 108 | -42 |

| 6 | 1.38×1010 | 161 | -300 |

表3 热解反应的动力学参数和反应热[20]

Table 3 Kinetic parameters and reaction heat of pyrolysis reactions[20]

| 反应 | 指前因子Ai /s-1 | 活化能Ei /(kJ·mol-1) | 反应热ΔH/(kJ·kg-1) |

|---|---|---|---|

| 1 | 4.38×109 | 152.7 | 80 |

| 2 | 1.08×1010 | 148 | 80 |

| 3 | 3.75×106 | 111.7 | 80 |

| 4 | 4.28×106 | 108 | -42 |

| 5 | 1×105 | 108 | -42 |

| 6 | 1.38×1010 | 161 | -300 |

| 物性参数 | 数值或表达式 |

|---|---|

| 比热容/(J·kg-1·K-1) | |

| 热导率/(W·m-1·K-1) | |

| 颗粒的初始密度/ (kg·m-3) | |

| 环境压力/Pa |

表4 模型中使用的物性参数或关系式[33]

Table 4 Physical property parameters or relationships used in the model[33]

| 物性参数 | 数值或表达式 |

|---|---|

| 比热容/(J·kg-1·K-1) | |

| 热导率/(W·m-1·K-1) | |

| 颗粒的初始密度/ (kg·m-3) | |

| 环境压力/Pa |

| 挥发分组成 | 摩尔质量M/ (kg·mol-1) | 有效分子碰撞 直径dm/m | 黏度μ/(Pa·s) |

|---|---|---|---|

| tar | 0.325 | 10-9 | 6.6, T0,tar= 313 K |

| gas | 0.02 | 3.4×10-10 | 3.79×10-5, T0,gas=298 K |

表5 煤热解挥发分组分的物性参数[34]

Table 5 Physical parameters of volatiles components of coal pyrolysis[34]

| 挥发分组成 | 摩尔质量M/ (kg·mol-1) | 有效分子碰撞 直径dm/m | 黏度μ/(Pa·s) |

|---|---|---|---|

| tar | 0.325 | 10-9 | 6.6, T0,tar= 313 K |

| gas | 0.02 | 3.4×10-10 | 3.79×10-5, T0,gas=298 K |

| 热解温度/K | 微孔孔容/ (cm3·g-1) | 介孔孔容/ (cm3·g-1) | 大孔孔容/ (cm3·g-1) |

|---|---|---|---|

| 393 | 0.0018 | 0.0185 | 0.0109 |

| 473 | 0.0017 | 0.0217 | 0.0111 |

| 573 | 0.0017 | 0.0162 | 0.0094 |

| 673 | 0.0071 | 0.0240 | 0.014 |

| 773 | 0.0144 | 0.0321 | 0.0161 |

| 873 | 0.0400 | 0.0428 | 0.0183 |

| 973 | 0.0543 | 0.0407 | 0.0286 |

| 1073 | 0.0216 | 0.0346 | 0.0215 |

表6 不同热解温度下半焦的孔体积

Table 6 Pore volume of semicoke at different pyrolysis temperature

| 热解温度/K | 微孔孔容/ (cm3·g-1) | 介孔孔容/ (cm3·g-1) | 大孔孔容/ (cm3·g-1) |

|---|---|---|---|

| 393 | 0.0018 | 0.0185 | 0.0109 |

| 473 | 0.0017 | 0.0217 | 0.0111 |

| 573 | 0.0017 | 0.0162 | 0.0094 |

| 673 | 0.0071 | 0.0240 | 0.014 |

| 773 | 0.0144 | 0.0321 | 0.0161 |

| 873 | 0.0400 | 0.0428 | 0.0183 |

| 973 | 0.0543 | 0.0407 | 0.0286 |

| 1073 | 0.0216 | 0.0346 | 0.0215 |

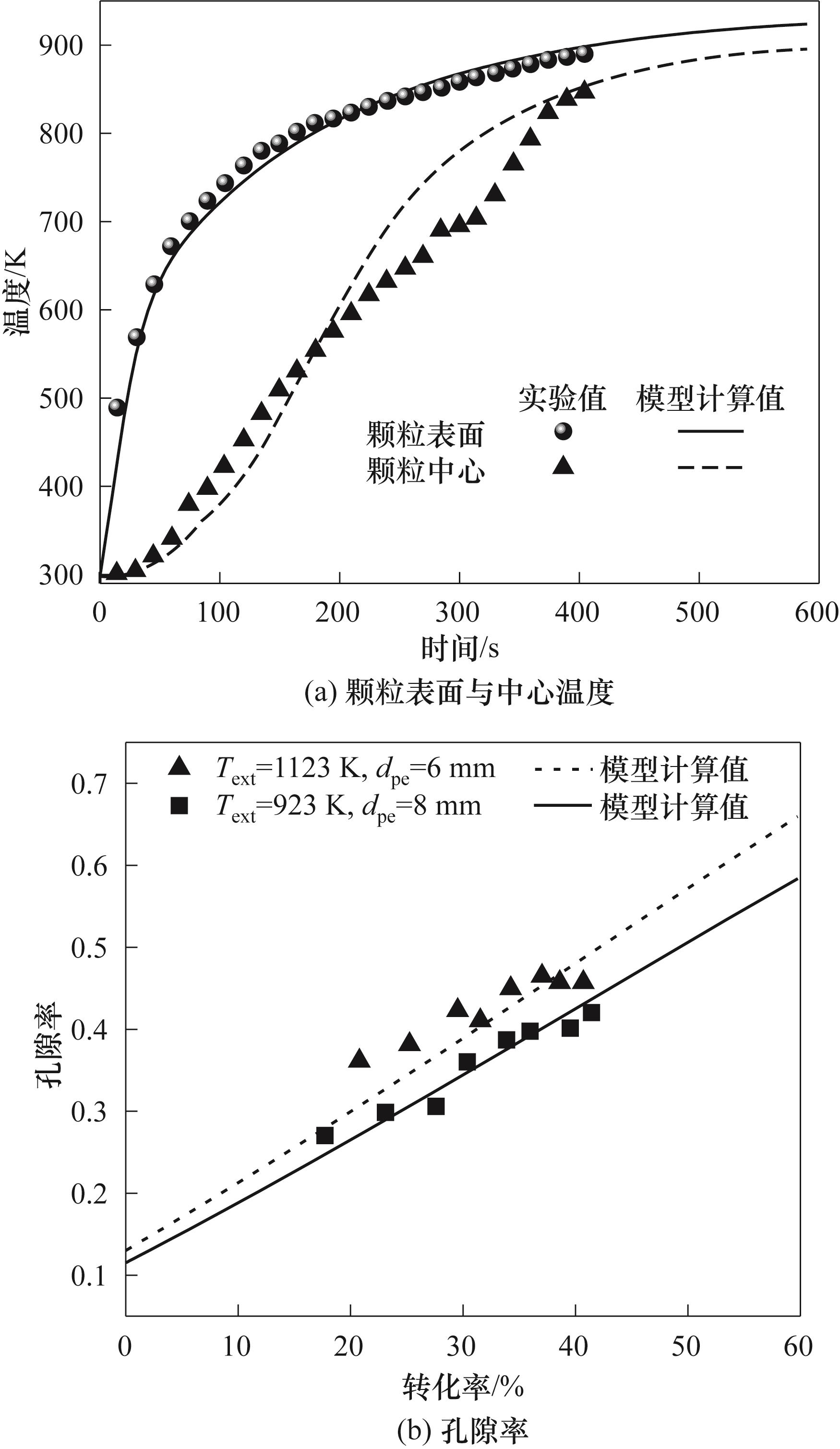

图6 不同工况条件下颗粒温度与孔隙率的模型预测值与实验值的对比

Fig.6 Comparison between model predictions and experimental results of particle temperature and porosity under different operating conditions

| [8] | Hu S, Li M, Xiang J, et al. Fractal characteristic of three Chinese coals[J]. Fuel, 2004, 83(10): 1307-1313. |

| [9] | Lu G W, Wang J L, Wei C T, et al. Pore fractal model applicability and fractal characteristics of seepage and adsorption pores in middle rank tectonic deformed coals from the Huaibei coal field[J]. Journal of Petroleum Science and Engineering, 2018, 171: 808-817. |

| [10] | Liu X F, Nie B S. Fractal characteristics of coal samples utilizing image analysis and gas adsorption[J]. Fuel, 2016, 182: 314-322. |

| [11] | Wang F, Cheng Y P, Lu S Q, et al. Influence of coalification on the pore characteristics of middle-high rank coal[J]. Energy & Fuels, 2014, 28(9): 5729-5736. |

| [12] | Yao Y B, Liu D M, Tang D Z, et al. Fractal characterization of adsorption-pores of coals from North China: an investigation on CH4 adsorption capacity of coals[J]. International Journal of Coal Geology, 2008, 73(1): 27-42. |

| [13] | Shi J Q, Durucan S. A bidisperse pore diffusion model for methane displacement desorption in coal by CO2 injection[J]. Fuel, 2003, 82(10): 1219-1229. |

| [14] | Simons G A. Coal pyrolysis ( Ⅰ ) : Pore evolution theory[J]. Combustion and Flame, 1983, 53(1/2/3): 83-92. |

| [15] | Li S F, Yang H, Fletcher T H, et al. Model for the evolution of pore structure in a lignite particle during pyrolysis[J]. Energy & Fuels, 2015, 29(8): 5322-5333. |

| [16] | Guo F H, Zhao X, Guo Y, et al. Fractal analysis and pore structure of gasification fine slag and its flotation residual carbon[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2020, 585: 124148. |

| [17] | Tang J W, Feng L, Li Y J, et al. Fractal and pore structure analysis of Shengli lignite during drying process[J]. Powder Technology, 2016, 303: 251-259. |

| [18] | Shi X G, Gao J S, Lan X Y. Modeling the pyrolysis of a centimeter-sized biomass particle[J]. Chemical Engineering & Technology, 2019, 42(12): 2574-2579. |

| [19] | Di Blasi C. Heat, momentum and mass transport through a shrinking biomass particle exposed to thermal radiation[J]. Chemical Engineering Science, 1996, 51(7): 1121-1132. |

| [1] | Wang Z D, Jiang P F, Yang F, et al. Study on pore structure and fractal characteristics of tar-rich coal during pyrolysis by mercury intrusion porosimetry (MIP)[J]. Geofluids, 2022, 2022: 2067228. |

| [2] | Chen Y L, Ma L, He R. Development of improved lattice fragmentation and diffusion model for coal pyrolysis(part 1): Steady-state intra-porous gas diffusivity[J]. Combustion Science and Technology, 2014, 186(6): 747-765. |

| [3] | Solomon P R, Serio M A, Despande G V, et al. Cross-linking reactions during coal conversion[J]. Energy & Fuels, 1990, 4(1): 42-54. |

| [4] | Ma L Y, Zhang L, Wang D M, et al. Pore structure evolution during lean-oxygen combustion of pyrolyzed residual from low-rank coal and its effect on internal oxygen diffusion mechanism[J]. Fuel, 2022, 319: 123850. |

| [5] | Sun L N, Tuo J C, Zhang M F, et al. Formation and development of the pore structure in Chang 7 member oil-shale from Ordos Basin during organic matter evolution induced by hydrous pyrolysis[J]. Fuel, 2015, 158: 549-557. |

| [6] | Xu P, Chen Z Y, Qiu S X, et al. An analytical model for pore and tortuosity fractal dimensions of porous media[J]. Fractals, 2021, 29(6): 2150156-20. |

| [7] | Li H J, Chang Q H, Gao R, et al. Fractal characteristics and reactivity evolution of lignite during the upgrading process by supercritical CO2 extraction[J]. Applied Energy, 2018, 225: 559-569. |

| [20] | Park W C, Atreya A, Baum H R. Experimental and theoretical investigation of heat and mass transfer processes during wood pyrolysis[J]. Combustion and Flame, 2010, 157(3): 481-494. |

| [21] | Li S N, Cao B Y. Vortex characteristics in Fourier and non-Fourier heat conduction based on heat flux rotation[J]. International Journal of Heat and Mass Transfer, 2017, 108: 2403-2407. |

| [22] | Atangana A. Fractional variable order derivatives//Fractional Operators with Constant and Variable Order with Application to Geo-hydrology[M]. Pittsburgh: Academic Press, 2018: 221-243. |

| [23] | Dallavalle J M. Book reviews: flow of gases through porous media[J]. Science, 1956, 124(3234): 1254-1255. |

| [24] | Grønli M G, Melaaen M C. Mathematical model for wood pyrolysis comparison of experimental measurements with model predictions[J]. Energy & Fuels, 2000, 14(4): 791-800. |

| [25] | 曾子粤, 杨建森, 魏永起. 脱硫石膏灌芯墙脱水过程的仿真模拟与分析[J]. 材料导报, 2022, 36(5): 89-94. |

| Zeng Z Y, Yang J S, Wei Y Q. The simulation and analysis of dehydration process of FGD gypsum grouted wall[J]. Materials Reports, 2022, 36(5): 89-94. | |

| [26] | Flores R M. Coal and Coalbed Gas: Fueling the Future[M]. Amsterdam, Netherlands: Elsevier Science, 2013. |

| [27] | 马亮, 何榕. 分形多孔介质中气体稳态扩散[J]. 清华大学学报(自然科学版), 2013, 53(10): 1459-1463. |

| Ma L, He R. Steady-state gas diffusion in fractal porous media[J]. Journal of Tsinghua University (Science and Technology), 2013, 53(10): 1459-1463. | |

| [28] | Zhang L Z. A fractal model for gas permeation through porous membranes[J]. International Journal of Heat and Mass Transfer, 2008, 51(21/22): 5288-5295. |

| [29] | Gómez M A, Porteiro J, Chapela S, et al. An Eulerian model for the simulation of the thermal conversion of a single large biomass particle[J]. Fuel, 2018, 220: 671-681. |

| [30] | Adesanya B A, Pham H N. Mathematical modelling of devolatilization of large coal particles in a convective environment[J]. Fuel, 1995, 74(6): 896-902. |

| [31] | Wakao N, Kaguei S, Funazkri T. Effect of fluid dispersion coefficients on particle-to-fluid heat transfer coefficients in packed beds: correlation of nusselt numbers[J]. Chemical Engineering Science, 1979, 34(3): 325-336. |

| [32] | 李方舟, 李文英, 冯杰. 固体热载体法褐煤热解过程中的传质传热特性[J]. 化工学报, 2016, 67(4): 1136-1144. |

| Li F Z, Li W Y, Feng J. Characteristics of mass and heat transfer in lignite pyrolysis with solid heat carrier[J]. CIESC Journal, 2016, 67(4): 1136-1144. | |

| [33] | Li F Z, Feng J, Li X H, et al. A model of devolatilization behavior in lignite pyrolysis with solid heat carriers[J]. AIChE Journal, 2019, 65(6): e16590. |

| [34] | Bliek A, Van Poelje W M, Van Swaaij W P M, et al. Effects of intraparticle heat and mass transfer during devolatilization of a single coal particle[J]. AIChE Journal, 1985, 31(10): 1666-1681. |

| [35] | Wang J, Ku X K, Liu Z W. Three-dimensional simulation of the pyrolysis of a thermally thick biomass particle[J]. Energy & Fuels, 2023, 37(6): 4413-4428. |

| [36] | Sing K S W. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity (Recommendations 1984)[J]. Pure and Applied Chemistry, 1985, 57(4): 603-619. |

| [37] | Gregg S J, Sing K S W, Salzberg H W. Adsorption surface area and porosity[J]. Journal of the Electrochemical Society, 1967, 114(11): 279C. |

| [38] | Jia L, Fan B G, Li B, et al. Effects of pyrolysis mode and particle size on the microscopic characteristics and mercury adsorption characteristics of biomass char[J]. BioResources, 2018, 13(3): 5450-5471. |

| [39] | Zhang F C, Tavakkol S, Galeazzo F C C, et al. Particle-resolved simulation of the pyrolysis process of a single plastic particle[J]. Heat and Mass Transfer, 2024, 61(1): 12. |

| [40] | Mou P W, Pan J N, Niu Q H, et al. Coal pores: methods, types, and characteristics[J]. Energy & Fuels, 2021, 35(9): 7467-7484. |

| [41] | 柏静儒, 林卫生, 潘朔, 等. 油页岩低温热解过程中轻质气体的析出特性[J]. 化工学报, 2015, 66(3): 1104-1110. |

| Bai J R, Lin W S, Pan S, et al. Characteristics of light gases evolution during oil shale pyrolysis[J]. CIESC Journal, 2015, 66(3): 1104-1110. |

| [1] | 彭建斌, 李明, 谢军龙, 陈建业. 液氢接收终端液氢泄漏扩散及爆炸超压研究[J]. 化工学报, 2025, 76(S1): 453-461. |

| [2] | 段浩磊, 陈浩远, 梁坤峰, 王林, 陈彬, 曹勇, 张晨光, 李硕鹏, 朱登宇, 何亚茹, 杨大鹏. 纯电动车热管理系统低GWP工质替代方案性能分析与综合评价[J]. 化工学报, 2025, 76(S1): 54-61. |

| [3] | 郭松源, 周晓庆, 缪五兵, 汪彬, 耑锐, 曹庆泰, 陈成成, 杨光, 吴静怡. 火箭上升段含多孔板液氧贮箱增压输运数值研究[J]. 化工学报, 2025, 76(S1): 62-74. |

| [4] | 王俊鹏, 冯佳琪, 张恩搏, 白博峰. 曲折式与阵列式迷宫阀芯结构内流动与空化特性研究[J]. 化工学报, 2025, 76(S1): 93-105. |

| [5] | 赵子祥, 段钟弟, 孙浩然, 薛鸿祥. 大温差两相流动诱导水锤冲击的数值模型[J]. 化工学报, 2025, 76(S1): 170-180. |

| [6] | 黄灏, 王文, 贺隆坤. LNG船薄膜型液货舱预冷过程模拟与分析[J]. 化工学报, 2025, 76(S1): 187-194. |

| [7] | 汪思远, 刘国强, 熊通, 晏刚. 窗式空调器轴流风机的风速非均匀分布特性及其对冷凝器流路优化设计的影响规律[J]. 化工学报, 2025, 76(S1): 205-216. |

| [8] | 曹庆泰, 郭松源, 李建强, 蒋赞, 汪彬, 耑锐, 吴静怡, 杨光. 负过载下多孔隔板对液氧贮箱蓄液性能的影响研究[J]. 化工学报, 2025, 76(S1): 217-229. |

| [9] | 郭纪超, 徐肖肖, 孙云龙. 基于植物工厂中的CO2浓度气流模拟及优化研究[J]. 化工学报, 2025, 76(S1): 237-245. |

| [10] | 孙九春, 桑运龙, 王海涛, 贾浩, 朱艳. 泥水盾构仓体内射流对泥浆输送特性影响研究[J]. 化工学报, 2025, 76(S1): 246-257. |

| [11] | 何婷, 黄舒阳, 黄坤, 陈利琼. 基于余热利用的天然气化学吸收脱碳-高温热泵耦合流程研究[J]. 化工学报, 2025, 76(S1): 297-308. |

| [12] | 吴梓航, 徐震原, 游锦方, 潘权稳, 王如竹. 基于吸附式储冷技术的深井钻探设备冷却系统[J]. 化工学报, 2025, 76(S1): 309-317. |

| [13] | 刘奕扬, 邢志祥, 刘烨铖, 彭明, 李玉洋, 李云浩, 沈宁舟. 加氢站液氢泄漏扩散特性与安全监测数值模拟研究[J]. 化工学报, 2025, 76(9): 4694-4708. |

| [14] | 黄正宗, 刘科成, 李泽方, 曾平生, 刘永富, 闫红杰, 刘柳. 锌精馏炉砖砌式换热室数值模拟与场协同优化[J]. 化工学报, 2025, 76(9): 4425-4439. |

| [15] | 杨开源, 陈锡忠. 颗粒破碎的离散元及有限离散元模拟方法比较[J]. 化工学报, 2025, 76(9): 4398-4411. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号