• •

陈源1( ), 郑施源1, 李运堂1(

), 郑施源1, 李运堂1( ), 熊典峰2, 王冰清1, 彭旭东3

), 熊典峰2, 王冰清1, 彭旭东3

收稿日期:2025-11-21

修回日期:2025-12-16

出版日期:2025-12-16

通讯作者:

李运堂

作者简介:陈源(1990—),男,博士,副教授,chenyuan_1221@163.com

基金资助:

Yuan CHEN1( ), Shiyuan ZHENG1, Yuntang LI1(

), Shiyuan ZHENG1, Yuntang LI1( ), Dianfeng XIONG2, bingqing WANG1, Xudong PENG3

), Dianfeng XIONG2, bingqing WANG1, Xudong PENG3

Received:2025-11-21

Revised:2025-12-16

Online:2025-12-16

Contact:

Yuntang LI

摘要:

基于气体动力润滑、弹性力学、传热学等相关理论,耦合变密度变粘度非等温雷诺方程、膜厚控制方程和三维能量方程,建立了箔片端面气膜密封热气弹多场耦合理论模型,在高速高温条件下,分析了膜温、膜压、变形、流速分布规律及工况和结构参数对密封性能的影响规律。结果表明:气体热效应增强了气膜的动压效应,使膜压和膜厚增大;高温区主要集中在楔形间隙的末端和水平区的外径处,且外径处的膜温显著高于其他位置;在本文参数研究范围内且保证箔片密封变形协调能力前提下,以提高开启力和气膜刚度、降低泄漏率和温升为优化目标,动压区和密封区箔片柔度系数在0.02~0.04、节距比在0.4~0.6、箔片数在6~8、箔坝比在1~2范围取值为宜。

中图分类号:

陈源, 郑施源, 李运堂, 熊典峰, 王冰清, 彭旭东. 高速高温箔片端面密封热气弹耦合性能分析[J]. 化工学报, DOI: 10.11949/0438-1157.20251293.

Yuan CHEN, Shiyuan ZHENG, Yuntang LI, Dianfeng XIONG, bingqing WANG, Xudong PENG. Thermo–gas–elastic coupling performance analysis of high-speed, high-temperature foil face seals[J]. CIESC Journal, DOI: 10.11949/0438-1157.20251293.

| 热阻参数 | 公式 |

|---|---|

| 平箔片热阻 Rt | tt /(ktAt) |

| 波箔片热阻 Rbp | tbp /(kbpAbp) |

| 空气间隙热阻 Rtb | hbp /(kairAtb) |

| 环基座热阻 Rb | tb /(kbAb) |

| 环境气体对流热阻 Re | 1/(heAe) |

表1 热阻参数及表达式

Table 1 Thermal resistance parameters and expressions

| 热阻参数 | 公式 |

|---|---|

| 平箔片热阻 Rt | tt /(ktAt) |

| 波箔片热阻 Rbp | tbp /(kbpAbp) |

| 空气间隙热阻 Rtb | hbp /(kairAtb) |

| 环基座热阻 Rb | tb /(kbAb) |

| 环境气体对流热阻 Re | 1/(heAe) |

| 参数名称 | 参数值 |

|---|---|

| 密封端面内半径 ri/mm | 45.5 |

| 密封端面外半径 ro/mm | 85.3 |

| 楔形高度 hd/μm | 10 |

| 平箔片厚度 tt/mm | 0.1524 |

| 波箔片厚度 tbp/mm | 0.1016 |

| 波箔高度 hbp/mm | 0.4 |

| 环基座厚度 hr/mm | 5 |

| 箔片弹性模量 E/GPa | 213 |

| 动压区箔片柔度系数 αout | 0.08 |

| 密封区箔片柔度系数 αin | 0.04 |

| 箔片数 Zg | 8 |

| 节距比 b | 0.4 |

| 箔坝比 γ | 2 |

| 环境压力 pa/MPa | 0.1 |

| 内径处压力 pin/MPa | 0.1 |

| 外径处压力 pout/MPa | 0.3 |

| 转速 n/(r/min) | 18000 |

| 空气粘度 μ0/(Pa·s) | 1.81×10-5 |

| 空气密度 ρ0/(kg/m3) | 1.205 |

| 环境温度 T0/K | 500 |

| 空气定压比热容 cp/(J/kg·K) | 1005 |

| 空气导热系数 kair/(W/K·m) | 0.026 |

| 平箔片导热系数 kt/(W/K·m) | 16.9 |

| 波箔片导热系数 kbp/(W/K·m) | 16.9 |

| 环基座导热系数 kb/(W/K·m) | 10 |

表2 CFFGS结构、工况和热特性参数

Table 2 Structural configuration, operating conditions, and thermal characteristics of the CFFGS

| 参数名称 | 参数值 |

|---|---|

| 密封端面内半径 ri/mm | 45.5 |

| 密封端面外半径 ro/mm | 85.3 |

| 楔形高度 hd/μm | 10 |

| 平箔片厚度 tt/mm | 0.1524 |

| 波箔片厚度 tbp/mm | 0.1016 |

| 波箔高度 hbp/mm | 0.4 |

| 环基座厚度 hr/mm | 5 |

| 箔片弹性模量 E/GPa | 213 |

| 动压区箔片柔度系数 αout | 0.08 |

| 密封区箔片柔度系数 αin | 0.04 |

| 箔片数 Zg | 8 |

| 节距比 b | 0.4 |

| 箔坝比 γ | 2 |

| 环境压力 pa/MPa | 0.1 |

| 内径处压力 pin/MPa | 0.1 |

| 外径处压力 pout/MPa | 0.3 |

| 转速 n/(r/min) | 18000 |

| 空气粘度 μ0/(Pa·s) | 1.81×10-5 |

| 空气密度 ρ0/(kg/m3) | 1.205 |

| 环境温度 T0/K | 500 |

| 空气定压比热容 cp/(J/kg·K) | 1005 |

| 空气导热系数 kair/(W/K·m) | 0.026 |

| 平箔片导热系数 kt/(W/K·m) | 16.9 |

| 波箔片导热系数 kbp/(W/K·m) | 16.9 |

| 环基座导热系数 kb/(W/K·m) | 10 |

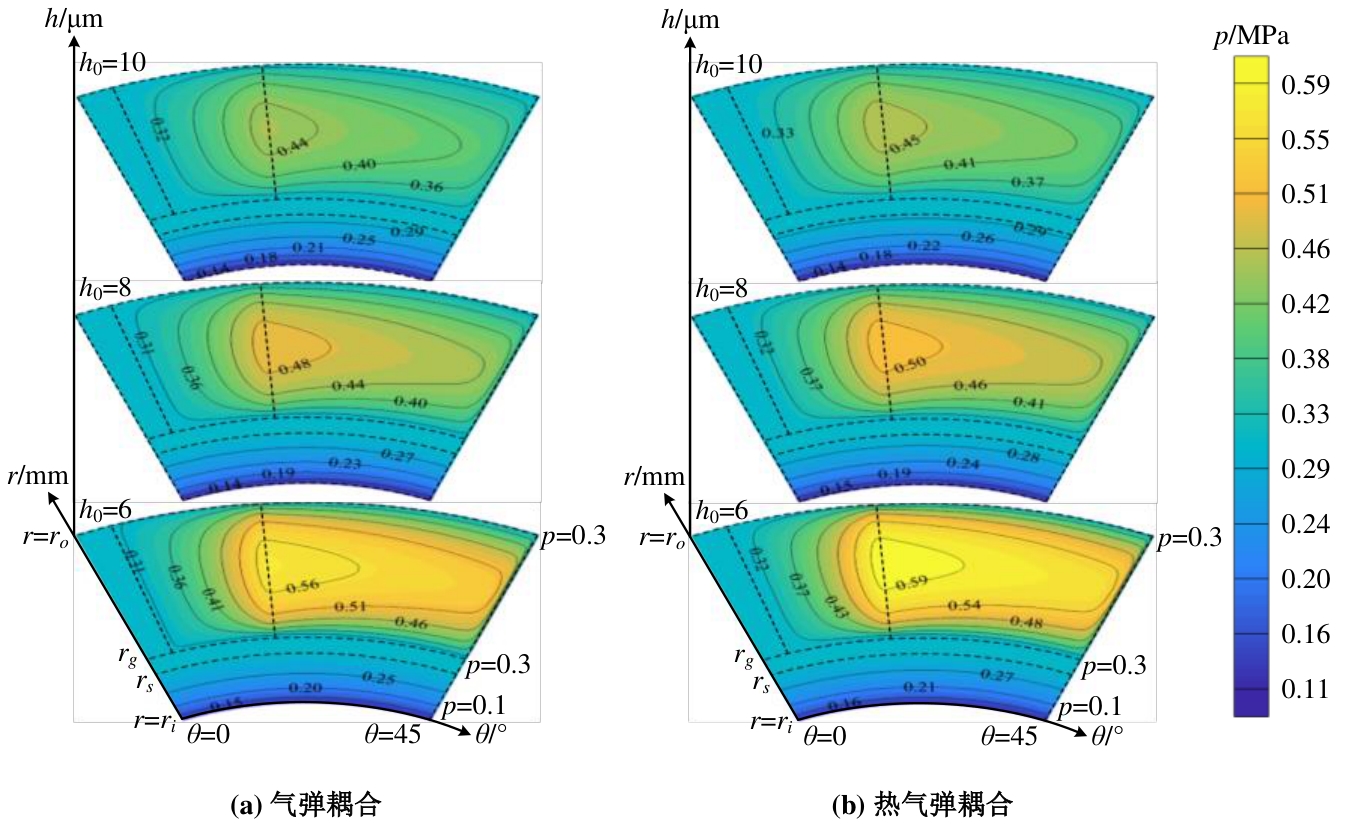

图9 气弹耦合和热气弹耦合模型下平衡膜厚对CFFGS膜压云图的影响规律

Fig. 9 Influence of equilibrium film thickness on pressure distribution contours of CFFGS under gas–elastic coupling and thermo–gas–elastic coupling models

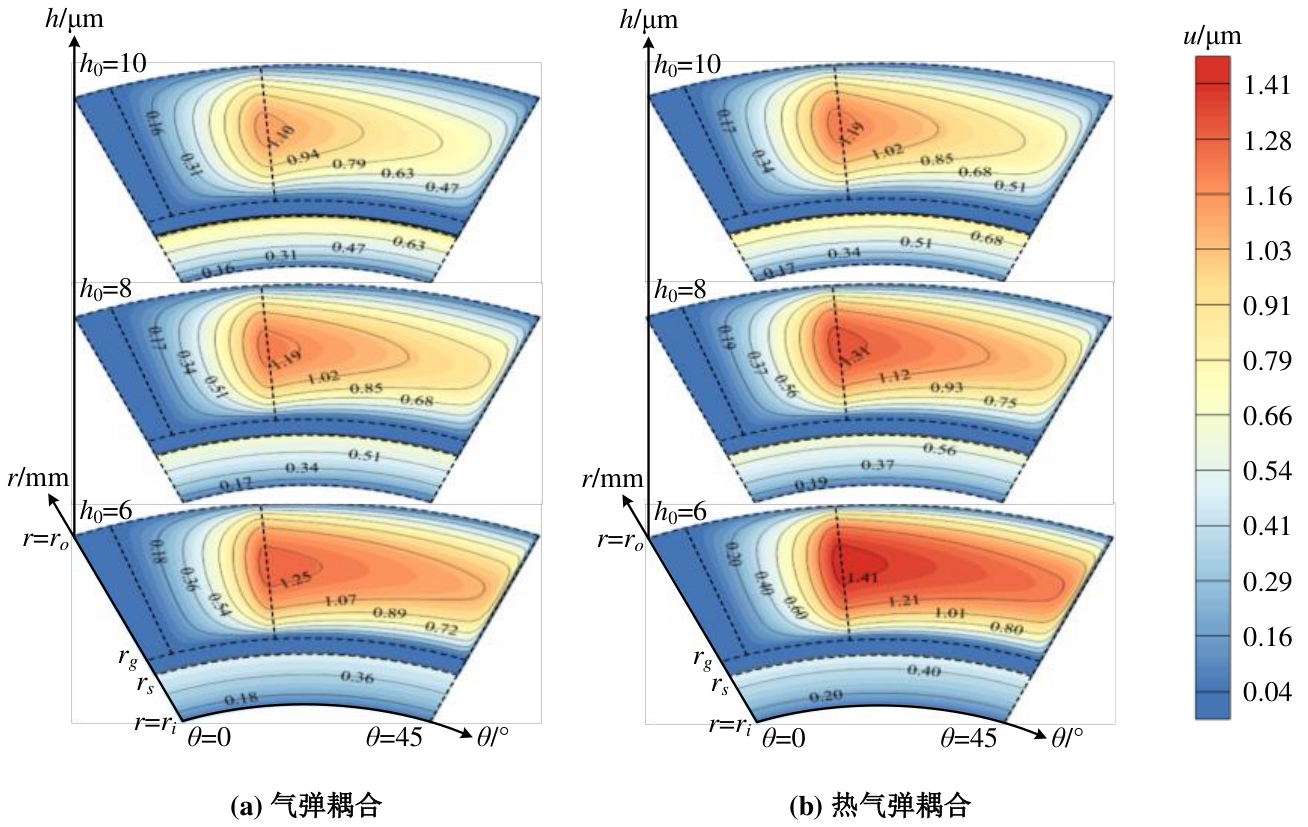

图10 气弹耦合和热气弹耦合模型下平衡膜厚对CFFGS变形云图的影响规律

Fig. 10 Influence of equilibrium film thickness on deformation contours of CFFGS under gas–elastic coupling and thermo–gas–elastic coupling models

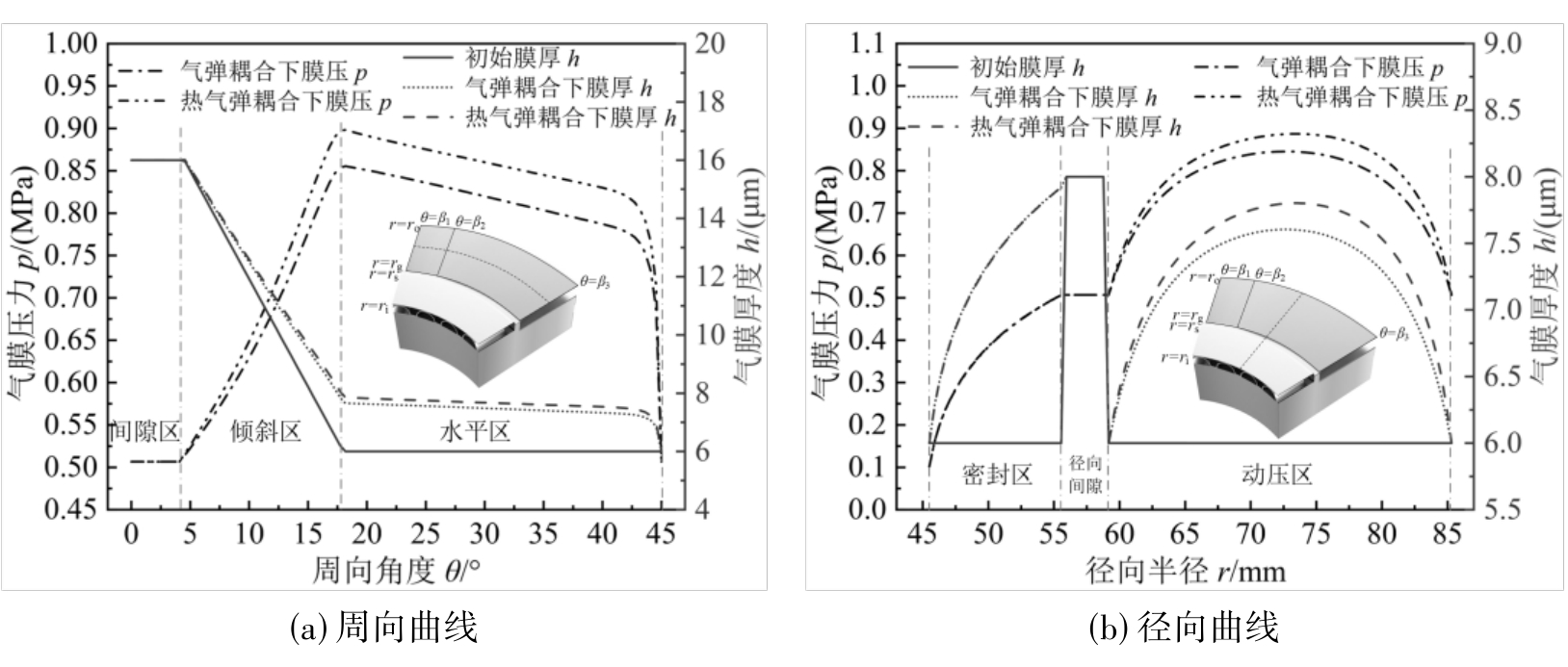

图11 气弹耦合和热气弹耦合模型下膜厚和膜压沿周向和径向的变化曲线

Fig. 11 Variation curves of film thickness and pressure along the circumferential and radial directions under gas–elastic coupling and thermo–gas–elastic coupling models

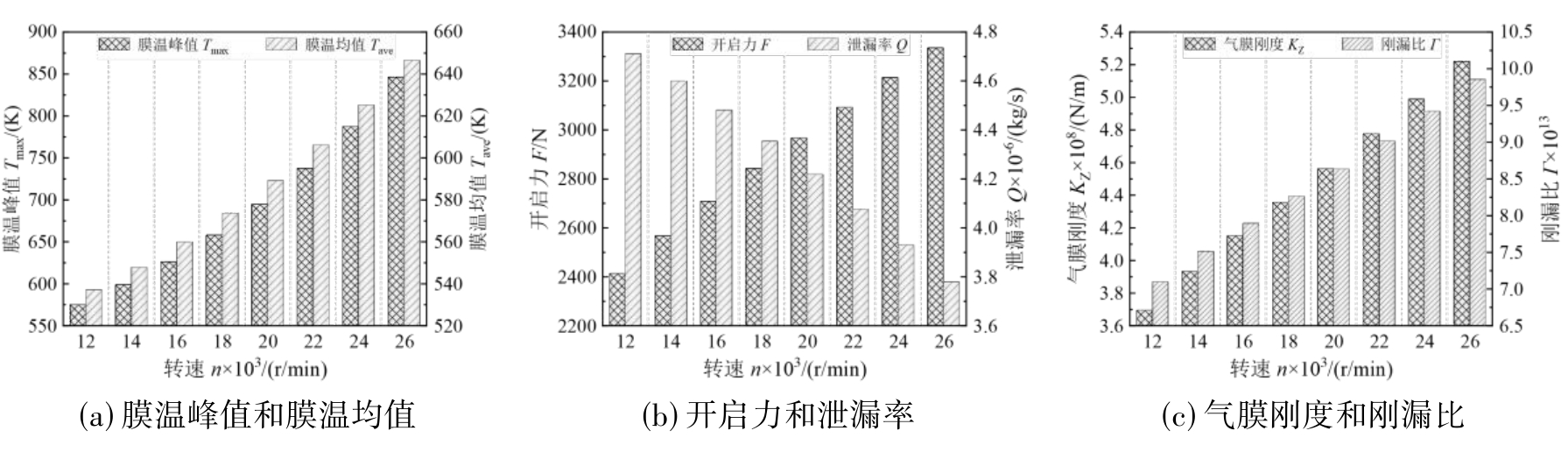

图12 转速n对CFFGS膜温峰值和均值以及密封性能参数的影响规律

Fig. 12 Influence of rotational speed n on the peak and mean film temperature as well as sealing performance parameters of the CFFGS

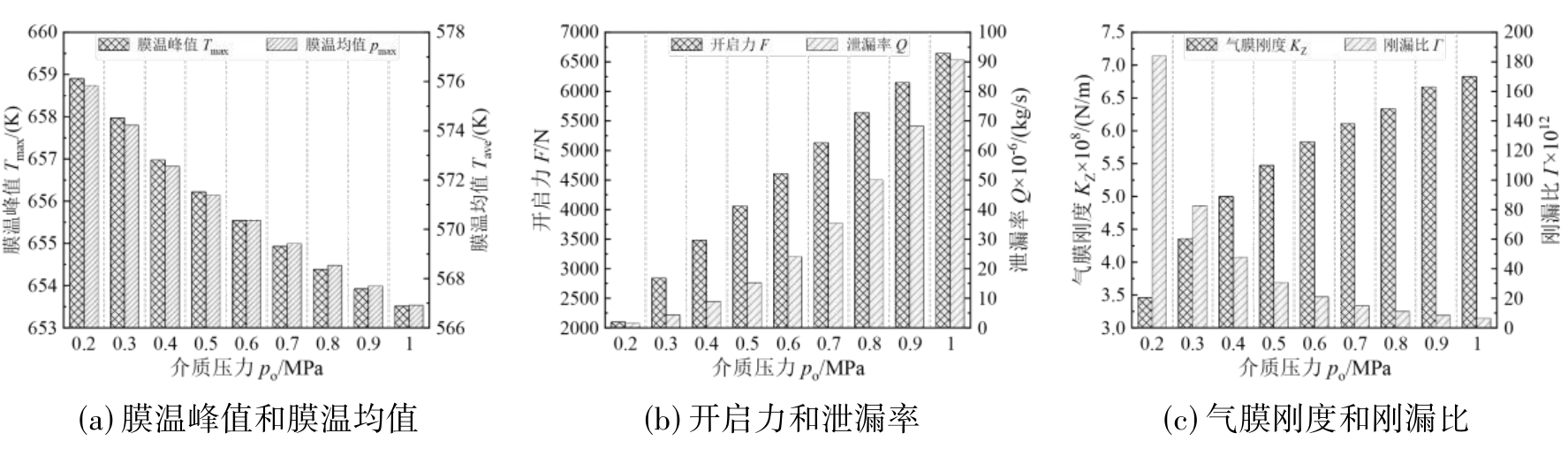

图13 介质压力po对CFFGS膜温峰值和均值以及密封性能参数的影响规律

Fig. 13 Influence of medium pressure p₀ on the peak and mean film temperature as well as sealing performance parameters of the CFFGS

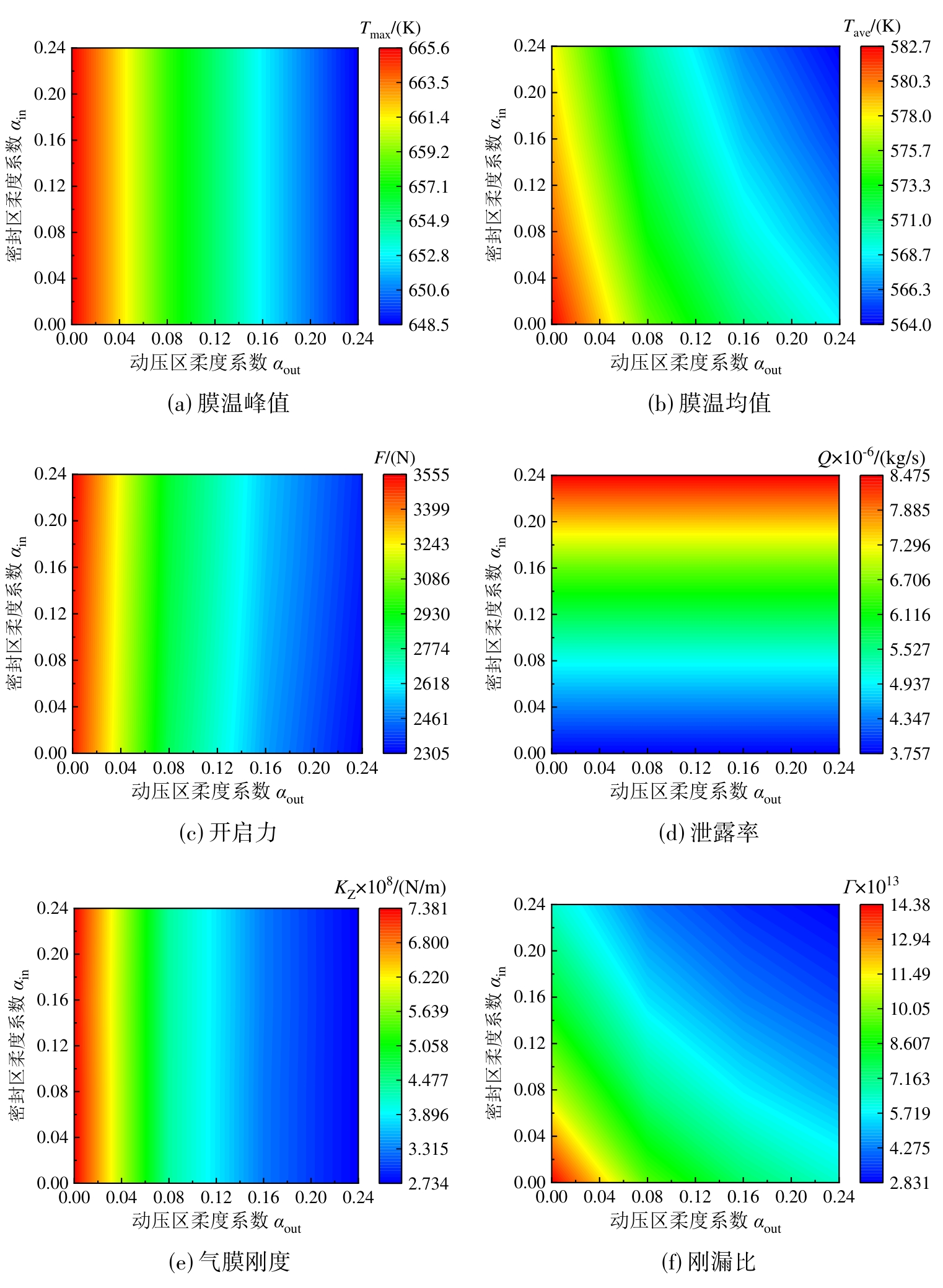

图14 动压区柔度系数αout和密封区柔度系数αin对CFFGS膜温峰值和均值以及密封性能参数的影响规律

Fig. 14 Influence of flexibility coefficients αout in the hydrodynamic region and αin in the sealing region on the peak and mean film temperature as well as sealing performance parameters of the CFFGS

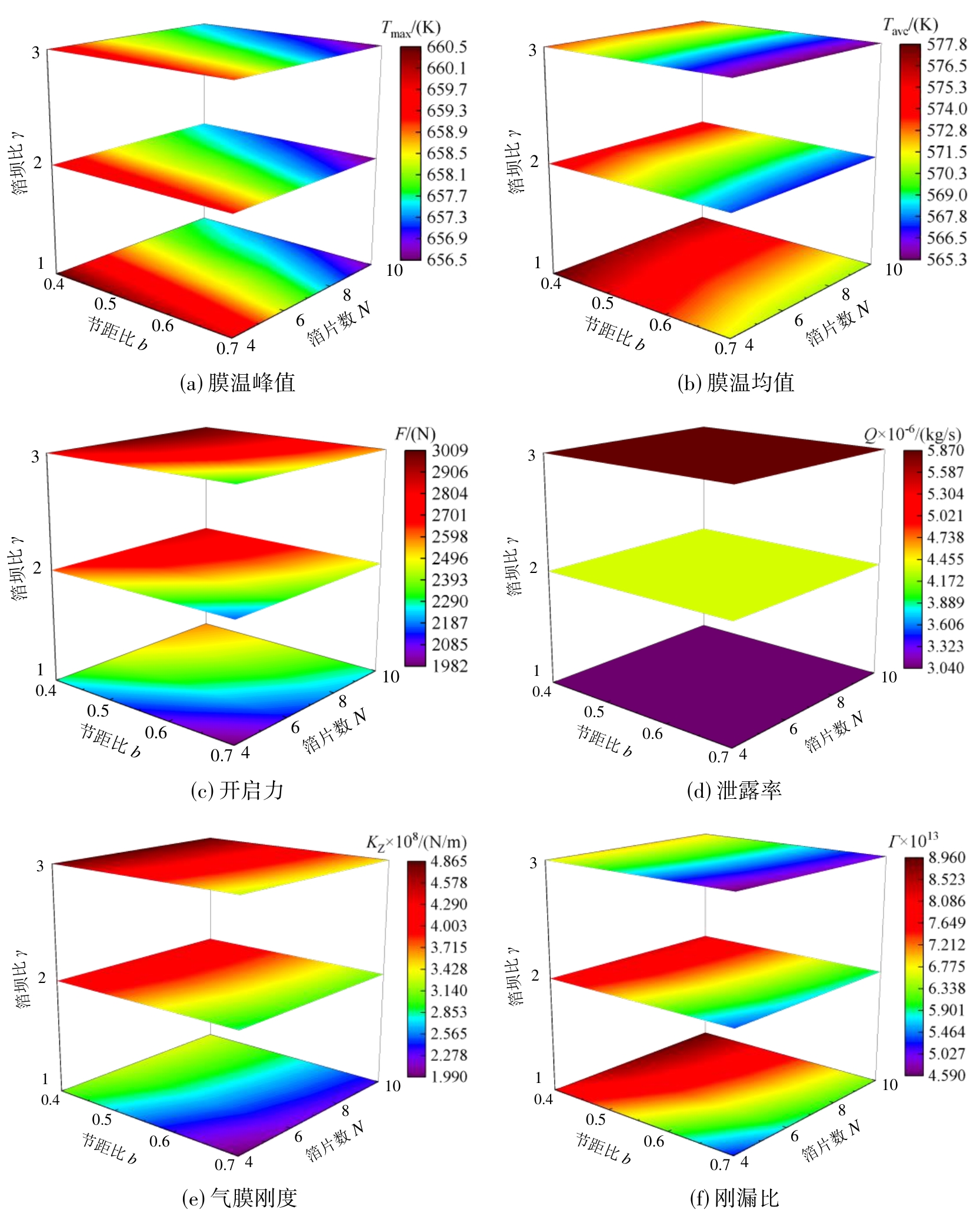

图15 节距比b、箔片数N和箔坝比γ对CFFGS膜温峰值和均值以及密封性能参数的影响规律

Fig. 15 Influence of pitch ratio b, number of foils N, and dam-to-foil ratio γ on the peak and mean film temperature as well as sealing performance parameters of the CFFGS

| [1] | Zirkelback N. Parametric study of spiral groove gas face seals[J]. Tribology Transactions, 2000, 43(2): 337-343. |

| [2] | Liu Y C, Shen X M, Xu W F, et al. Performance comparison and parametric study on spiral groove gas film face seals[J]. Science in China Series G: Physics, Mechanics and Astronomy, 2004, 47(1): 29-36. |

| [3] | Saxena M N. Dry gas seals and support systems: benefits and options[J]. Hydrocarbon Processing, 2003, 82(11): 37-42. |

| [4] | Kolomoets A, Dotsenko V. Experimental investigation «Dry» gas-dynamic seals used for gas-compressor unit[J]. Procedia Engineering, 2012, 39: 379-386. |

| [5] | 江锦波, 彭旭东, 白少先, 等. 仿生集束螺旋槽干式气体密封特性的数值分析[J]. 机械工程学报, 2015, 51(15): 20-26. |

| Jiang J B, Peng X D, Bai S X, et al. Numerical analysis of characteristics of a bionic cluster spiral groove dry gas seal[J]. Journal of Mechanical Engineering, 2015, 51(15): 20-26. | |

| [6] | 王衍, 胡琼, 肖业祥, 等. 超高速干气密封扰流效应及抑扰机制[J]. 航空学报, 2019, 40(10): 116-125. |

| Wang Y, Hu Q, Xiao Y X, et al. Turbulence effect and suppression mechanism of dry gas seal at ultra-high speeds[J]. Acta Aeronautica et Astronautica Sinica, 2019, 40(10): 116-125. | |

| [7] | Chen Y, Wang Q G, Peng X D, et al. Flow field and sealing performance analysis of compliant foil face gas seal[J]. Advances in Mechanical Engineering, 2022, 14(6): 16878132221108488. |

| [8] | Munson J, Grant D, Agrawal G. Foil face seal development[C]//37th Joint Propulsion Conference and Exhibit. 08 July 2001 - 11 July 2001, Salt Lake City, UT. Reston, Virginia: AIAA, 2001: 3483. |

| [9] | Munson J, Grant D, Agrawal G. Foil film riding face seal proof-of-concept testing[C]//38th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit. 07 July 2002 - 10 July 2002, Indianapolis, Indiana. Reston, Virginia: AIAA, 2002: 3791. |

| [10] | Heshmat H, Walton J. Innovative high-temperature compliant surface foil face seal development[C]//44th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit. 21 July 2008 - 23 July 2008, Hartford, CT. Reston, Virginia: AIAA, 2008: 4505. |

| [11] | Heshmat H, Ren Z H, Hunsberger A, et al. The emergence of compliant foil bearing and seal technologies in support of 21st century compressors and turbine engines[C]//ASME 2010 International Mechanical Engineering Congress and Exposition, November 12–18, 2010, Vancouver, British Columbia, Canada. 2012: 95-103. |

| [12] | Chen Y, Chen K, Peng X D, et al. Transient elasto-aerodynamically coupling behavior and performance analysis of bump-type compliant foil face gas seal at ultra-high speeds[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2023, 45(7): 369. |

| [13] | Chen Y, Chen K, Peng X D, et al. Research on the operation mechanism and performance of bump-type compliant foil face gas seal[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2022, 44(8): 325. |

| [14] | 王庆港, 陈源, 彭旭东, 等. 三自由度微扰下箔片端面气膜密封动态特性分析[J]. 中国机械工程, 2022, 33(15): 1828-1840. |

| Wang Q G, Chen Y, Peng X D, et al. Analysis on dynamic characteristics of compliant foil face gas seals with three degrees of freedom perturbation[J]. China Mechanical Engineering, 2022, 33(15): 1828-1840. | |

| [15] | Chen Y, Li Y S, Li Y T, et al. Leakage control design and performance analysis on upstream pumping compliant foil face gas seal[J]. Industrial Lubrication and Tribology, 2025, 77(4): 516-525. |

| [16] | 潘永健, 陈源, 李运堂, 等. 超临界二氧化碳柔性坝箔片端面气膜密封运行机理及性能分析[J]. 摩擦学学报(中英文), 2025, 45(11): 1640-1652. |

| Pan Y J, Chen Y, Li Y T, et al. Operating mechanism and performance analysis of flexible dam compliant foil face gas seal in supercritical carbon dioxide[J]. Tribology, 2025, 45(11): 1640-1652. | |

| [17] | Salehi M, Swanson E, Heshmat H. Thermal features of compliant foil bearings: theory and experiments[J]. Journal of Tribology, 2001, 123(3): 566-571. |

| [18] | Feng K, Kaneko S. Thermohydrodynamic study of multiwound foil bearing using lobatto point quadrature[J]. Journal of Tribology, 2009, 131(2): 021702. |

| [19] | Feng K, Kaneko S. A thermohydrodynamic sparse mesh model of bump-type foil bearings[J]. Journal of Engineering for Gas Turbines and Power, 2013, 135(2): 022501. |

| [20] | Lee D, Kim D. Three-dimensional thermohydrodynamic analyses of Rayleigh step air foil thrust bearing with radially arranged bump foils[J]. Tribology Transactions, 2011, 54(3): 432-448. |

| [21] | Lehn A, Mahner M, Schweizer B. A thermo-elasto-hydrodynamic model for air foil thrust bearings including self-induced convective cooling of the rotor disk and thermal runaway[J]. Tribology International, 2018, 119: 281-298. |

| [22] | Zhang J Y, Qiao X Y, Chen W D, et al. Numerical investigation of Thermo-aerodynamic characteristics of gas foil thrust bearing[J]. Thermal Science and Engineering Progress, 2022, 31: 101296. |

| [23] | Liu X M, Li C L, Du J J, et al. The fluid-structure-thermal performance analysis of gas foil thrust bearing by using computational fluid dynamics[J]. Lubricants, 2022, 10(11): 294. |

| [24] | 刘晖. 实际气体温度绝热指数和容积绝热指数的计算[J]. 石油化工高等学校学报, 2000, 13(4): 42-45. |

| Liu H. Calculation of the isentropic temperature change exponent and isentropic volume change exponent of real gases[J]. Journal of Petrochemical Universities, 2000, 13(4): 42-45. | |

| [25] | García-Camprubí M, Izquierdo S, Fueyo N. Challenges in the electrochemical modelling of solid oxide fuel and electrolyser cells[J]. Renewable and Sustainable Energy Reviews, 2014, 33: 701-718. |

| [26] | White F M. Viscous Fluid Flow[M]. New York: McGraw-Hill, 1974: 27-32. |

| [27] | Salehi M, Heshmat H. On the fluid flow and thermal analysis of a compliant surface foil bearing and seal[J]. Tribology Transactions, 2000, 43(2): 318-324. |

| [28] | Jiang J B, Zhao W J, Peng X D, et al. A novel design for discrete surface texture on gas face seals based on a superposed groove model[J]. Tribology International, 2020, 147: 106269. |

| [29] | Iordanoff I. Maximum load capacity profiles for gas thrust bearings working under high compressibility number conditions[J]. Journal of Tribology, 1998, 120(3): 571-576. |

| [30] | 闫佳佳, 刘占生, 王铮, 等. 基于Newton-Raphson迭代的动压气体止推箔片轴承特性研究[J]. 汽轮机技术, 2017, 59(2): 116-120, 124. |

| Yan J J, Liu Z S, Wang Z, et al. Performance analysis of hydrodynamic gas foil thrust bearing based on Newton-raphson iterative method[J]. Turbine Technology, 2017, 59(2): 116-120, 124. | |

| [31] | Liu X M, Li C L, Du J J, et al. Thermal characteristics study of the bump foil thrust gas bearing[J]. Applied Sciences, 2021, 11(9): 4311. |

| [1] | 郭松源, 周晓庆, 缪五兵, 汪彬, 耑锐, 曹庆泰, 陈成成, 杨光, 吴静怡. 火箭上升段含多孔板液氧贮箱增压输运数值研究[J]. 化工学报, 2025, 76(S1): 62-74. |

| [2] | 任现超, 谷雅秀, 段少斌, 贾文竹, 李汉林. 翅片式椭圆套管蒸发式冷凝器传热传质性能实验研究[J]. 化工学报, 2025, 76(S1): 75-83. |

| [3] | 袁琳慧, 王瑜. 单服务器浸没射流式液冷系统散热性能[J]. 化工学报, 2025, 76(S1): 160-169. |

| [4] | 赵子祥, 段钟弟, 孙浩然, 薛鸿祥. 大温差两相流动诱导水锤冲击的数值模型[J]. 化工学报, 2025, 76(S1): 170-180. |

| [5] | 黄博, 黄灏, 王文, 贺隆坤. 薄膜型LNG船液货舱温度场计算分析[J]. 化工学报, 2025, 76(S1): 195-204. |

| [6] | 汪思远, 刘国强, 熊通, 晏刚. 窗式空调器轴流风机的风速非均匀分布特性及其对冷凝器流路优化设计的影响规律[J]. 化工学报, 2025, 76(S1): 205-216. |

| [7] | 孙九春, 桑运龙, 王海涛, 贾浩, 朱艳. 泥水盾构仓体内射流对泥浆输送特性影响研究[J]. 化工学报, 2025, 76(S1): 246-257. |

| [8] | 孔俊龙, 毕扬, 赵耀, 代彦军. 储能电池直冷热管理系统的模拟实验[J]. 化工学报, 2025, 76(S1): 289-296. |

| [9] | 贾志勇, 沈宪琨, 蓝晓程, 王铁峰. 气体密度对高压流态化影响的CFD-DEM模拟[J]. 化工学报, 2025, 76(9): 4383-4397. |

| [10] | 曹潇风, 张华海, 王江云, 王利民. 锥形气体层流元件结构设计及流动特性研究[J]. 化工学报, 2025, 76(9): 4440-4448. |

| [11] | 陈昇, 李子争, 苗超, 白学刚, 李飞, 刘家璇, 李天天, 杨爽, 吕蓉蓉, 王江云. 大尺度密集场景高危氯气非均匀湍流扩散特性三维CFD模拟[J]. 化工学报, 2025, 76(9): 4630-4643. |

| [12] | 胡金琦, 闵春华, 李小龙, 范元鸿, 王坤. 振动叶片耦合柔性板强化流体混沌混合与传热研究[J]. 化工学报, 2025, 76(9): 4824-4837. |

| [13] | 解勤勤, 翁俊旗, 林振利, 叶光华, 周兴贵. 固定床反应器中甲醇制芳烃工业催化剂结构影响的研究[J]. 化工学报, 2025, 76(9): 4487-4498. |

| [14] | 罗海梅, 王泓, 孙照明, 尹艳华. 同向双螺杆传热系数计算模型的分析与验证[J]. 化工学报, 2025, 76(9): 4809-4823. |

| [15] | 张帅, 徐嘉宇, 华蕾娜, 葛蔚. 气固系统的CG-DPM与MP-PIC耦合模拟方法[J]. 化工学报, 2025, 76(9): 4412-4424. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号