化工学报 ›› 2025, Vol. 76 ›› Issue (9): 4487-4498.DOI: 10.11949/0438-1157.20250378

收稿日期:2025-04-11

修回日期:2025-05-22

出版日期:2025-09-25

发布日期:2025-10-23

通讯作者:

叶光华

作者简介:解勤勤(2001—),女,硕士研究生,y30230202@mail.ecust.edu.cn

基金资助:

Qinqin XIE( ), Junqi WENG, Zhenli LIN, Guanghua YE(

), Junqi WENG, Zhenli LIN, Guanghua YE( ), Xinggui ZHOU

), Xinggui ZHOU

Received:2025-04-11

Revised:2025-05-22

Online:2025-09-25

Published:2025-10-23

Contact:

Guanghua YE

摘要:

甲醇制芳烃是一种可行的替代石油路线的芳烃生产技术,其关键在于开发高性能甲醇制芳烃工业催化剂。考虑到反应器尺度传递过程会影响工业催化剂的整体性能,建立了从工业催化剂到固定床反应器的双尺度颗粒分辨计算流体力学模型,并借助该模型探究了工业催化剂结构对甲醇制芳烃性能的影响规律。结果显示,拉西环催化剂颗粒对应的床层空隙率大,催化剂内扩散限制小,相比于其他催化剂外形具有最低的床层压降和较高的反应器出口芳烃收率。减小催化剂颗粒粒径能有效提升反应器出口芳烃收率,但是也会显著增加反应器压降。催化剂孔径为200 nm以及空隙率为0.5时能有效平衡催化剂内扩散以及催化材料含量和分布,显示出最高的反应器出口芳烃收率。研究结果将为甲醇制芳烃工业催化剂设计优化提供一种强大的模型工具以及一些重要的理论依据。

中图分类号:

解勤勤, 翁俊旗, 林振利, 叶光华, 周兴贵. 固定床反应器中甲醇制芳烃工业催化剂结构影响的研究[J]. 化工学报, 2025, 76(9): 4487-4498.

Qinqin XIE, Junqi WENG, Zhenli LIN, Guanghua YE, Xinggui ZHOU. Effects of industrial catalyst structure on methanol to aromatics in a packed bed reactor[J]. CIESC Journal, 2025, 76(9): 4487-4498.

| 反应编号 i | 活化能 | 指前因子Ai /h-1 |

|---|---|---|

| 1 | 2.08×104 | 1.61×103 |

| 2 | 6.99×104 | 3.64×106 |

| 3 | 7.87×103 | 1.46×102 |

| 4 | 2.17×104 | 1.13×103 |

| 5 | 6.05×103 | 1.06×102 |

| 6 | 5.98×104 | 1.45×106 |

表1 集总动力学模型参数[25]

Table 1 Parameters for the lumped kinetics model[25]

| 反应编号 i | 活化能 | 指前因子Ai /h-1 |

|---|---|---|

| 1 | 2.08×104 | 1.61×103 |

| 2 | 6.99×104 | 3.64×106 |

| 3 | 7.87×103 | 1.46×102 |

| 4 | 2.17×104 | 1.13×103 |

| 5 | 6.05×103 | 1.06×102 |

| 6 | 5.98×104 | 1.45×106 |

| 参数 | 数值 |

|---|---|

| 入口速度uin/(m/s) | 0.2 |

| 压力Pin/MPa | 0.1 |

| 入口温度Tin/K | 630 |

| 壁温Twall/K | 630 |

| 催化剂孔隙率εcat | 0.5 |

| 催化剂孔径dp/nm | 20 |

| 催化剂直径ds/mm | 8 |

| 催化剂密度ρs/(kg/m3) | 2230 |

| 反应管直径dt/mm | 40 |

| 床层高度L/mm | 110 |

表2 本文模拟所用参数

Table 2 Simulation parameters in this work

| 参数 | 数值 |

|---|---|

| 入口速度uin/(m/s) | 0.2 |

| 压力Pin/MPa | 0.1 |

| 入口温度Tin/K | 630 |

| 壁温Twall/K | 630 |

| 催化剂孔隙率εcat | 0.5 |

| 催化剂孔径dp/nm | 20 |

| 催化剂直径ds/mm | 8 |

| 催化剂密度ρs/(kg/m3) | 2230 |

| 反应管直径dt/mm | 40 |

| 床层高度L/mm | 110 |

图3 催化剂床层压降模拟值与实验值对比[39]

Fig.3 Comparison of the pressure drops in a catalyst bed calculated by the model in this work and obtained from experiments[39]

图4 不同反应管直径下的床层空隙率和压降(a),反应器出口甲醇和二甲醚(集总a)转化率和芳烃收率(b),轴向(c)和径向床层空隙率(d)

Fig.4 Bed voidages and pressure drops (a), conversions of methanol and dimethyl ether (lumped component a) and yields of aromatics at reactor outlet (b), axial (c) and radial bed voidages under different tube diameters (d)

图5 不同反应管直径下的床层流速(a)、温度(b)和芳烃浓度分布(c)

Fig.5 Distributions of fluid velocity magnitude(a), temperature (b) and concentration of aromatics (c) under different tube diameters

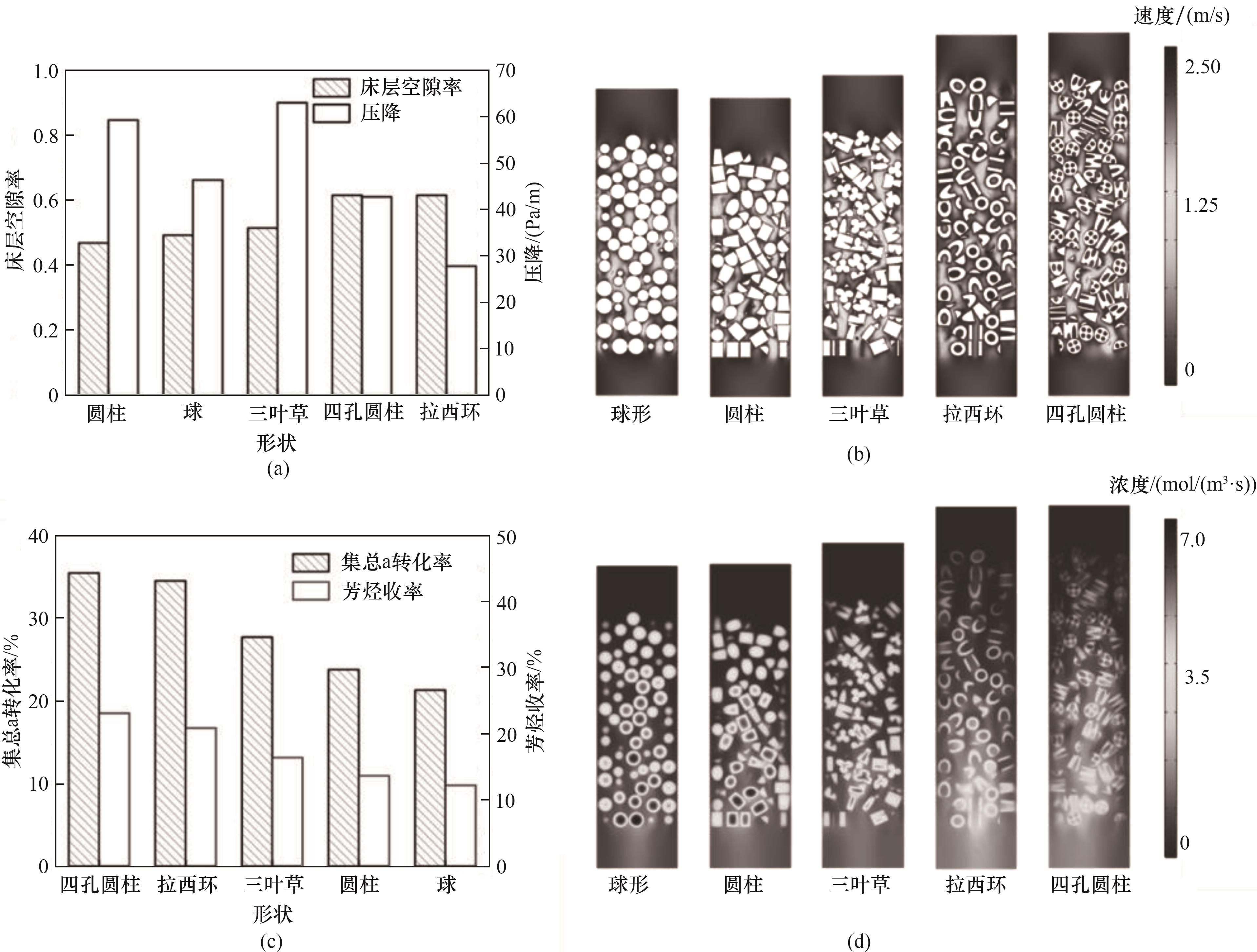

图6 不同形状催化剂颗粒床层的空隙率和压降(a)、速度分布(b)、集总a的转化率和芳烃的收率(c)以及芳烃浓度分布(d)

Fig.6 Voidages and pressure drops (a), velocity magnitude distributions (b), conversions of lumped component a and yields of aromatics (c), and concentration distribution of aromatics (d) for the beds packed with catalyst particles of different shapes

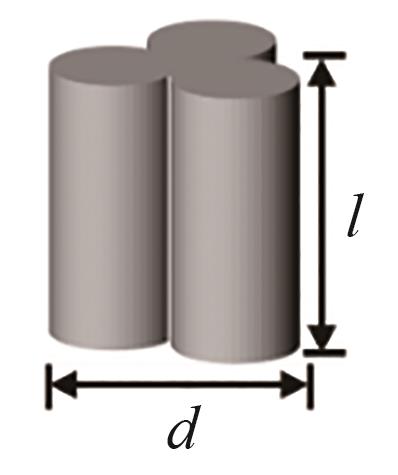

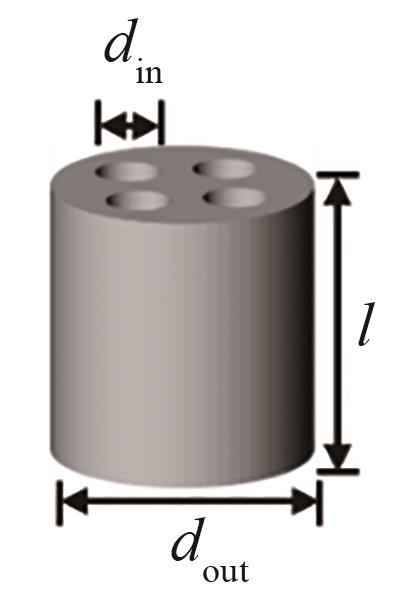

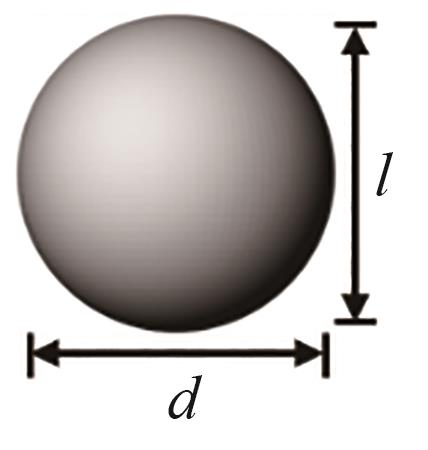

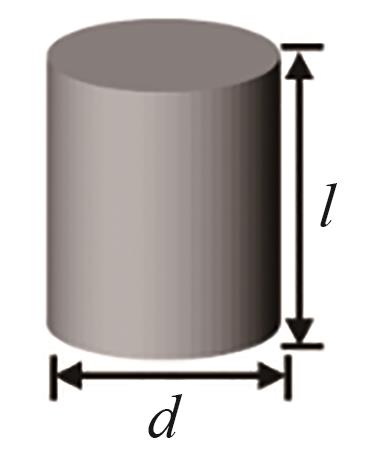

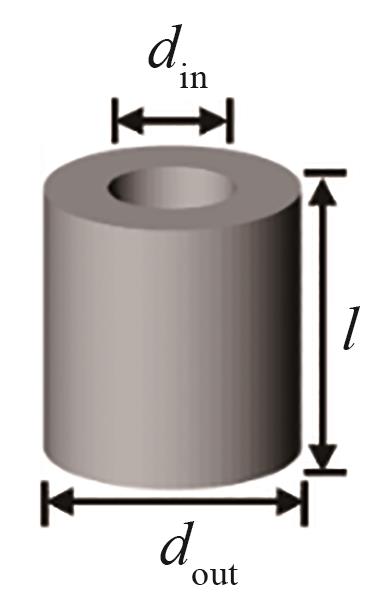

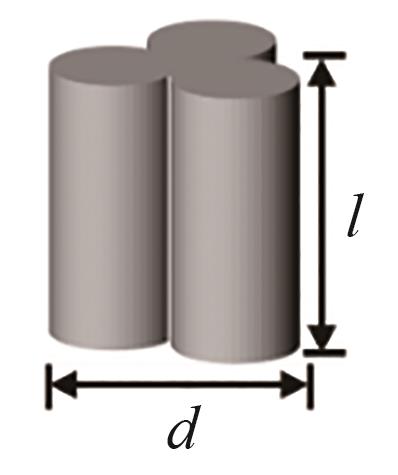

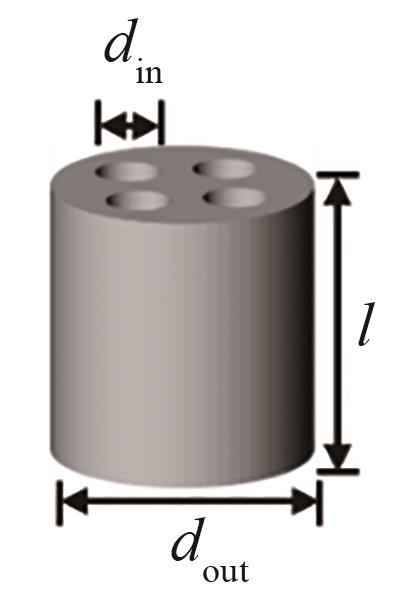

| 项目 | 球形 | 圆柱 | 拉西环 | 三叶草 | 四孔圆柱 |

|---|---|---|---|---|---|

| 示意图 |  |  |  |  |  |

| 尺寸 | d = 8.00 mm | d = 6.53 mm, l = 8.00 mm | dout = 7.54 mm, din = 3.77 mm, l = 8.00 mm | d = 6.98 mm, l = 8.00 mm | dout = 7.54 mm, din = 1.89 mm, l = 8.00 mm |

| 特征长度(Lp=6Vp/Sp) | 8.00 mm | 6.96 mm | 5.33 mm | 4.58 mm | 3.61 mm |

表3 不同形状催化剂颗粒的结构参数

Table 3 Structural parameters of catalyst particles of different shapes

| 项目 | 球形 | 圆柱 | 拉西环 | 三叶草 | 四孔圆柱 |

|---|---|---|---|---|---|

| 示意图 |  |  |  |  |  |

| 尺寸 | d = 8.00 mm | d = 6.53 mm, l = 8.00 mm | dout = 7.54 mm, din = 3.77 mm, l = 8.00 mm | d = 6.98 mm, l = 8.00 mm | dout = 7.54 mm, din = 1.89 mm, l = 8.00 mm |

| 特征长度(Lp=6Vp/Sp) | 8.00 mm | 6.96 mm | 5.33 mm | 4.58 mm | 3.61 mm |

图7 不同尺寸催化剂颗粒床层的空隙率和压降(a)、集总a的转化率和芳烃的收率(b)、轴向(c)和径向床层空隙率(d)、速度分布(e),以及芳烃浓度分布(f)

Fig.7 Voidages and pressure drops (a), conversions of lumped component a and yields of aromatics (b), axial (c) and radial bed voidages (d), velocity magnitude distributions (e), and concentration distribution of aromatics (f) for the beds packed with catalyst particles of different sizes

图8 不同催化剂孔径下反应器出口的集总a转化率和芳烃收率(a)以及芳烃浓度分布(b)

Fig.8 Conversions of lumped component a and yields of aromatics at reactor outlet (a), and concentration distributions of aromatics (b) for the beds packed with catalyst particles of different pore diameters

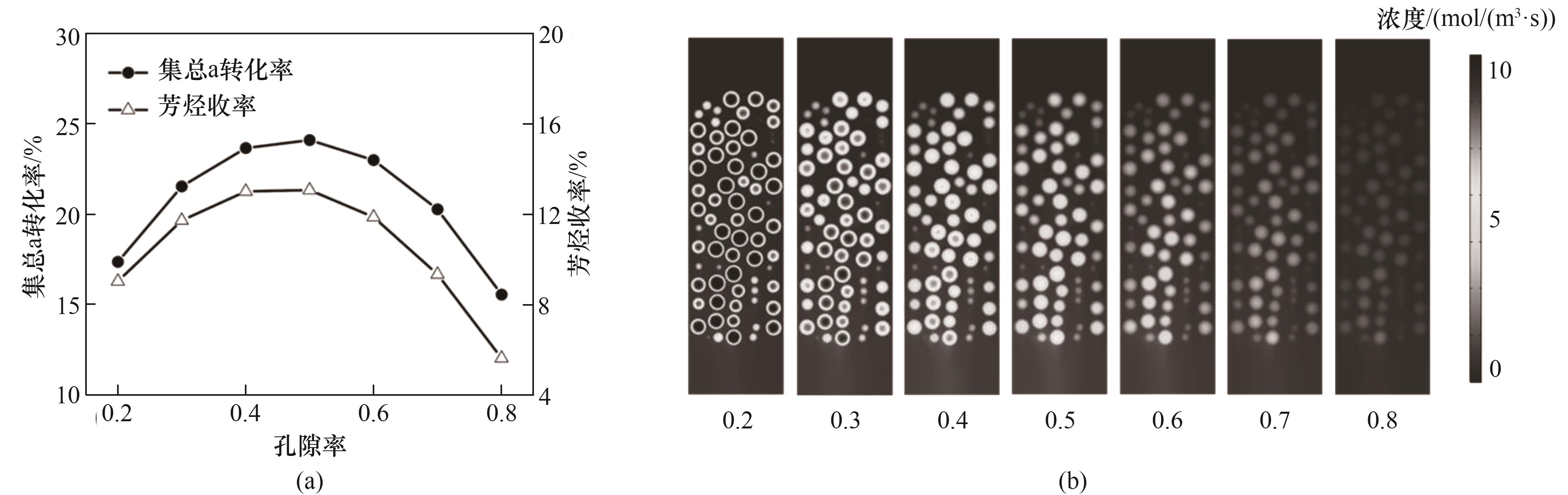

图9 不同催化剂孔隙率下反应器出口的集总a转化率和芳烃收率(a)以及芳烃浓度分布(b)

Fig.9 Conversions of lumped component a and yields of aromatics at reactor outlet (a), and concentration distributions of aromatics (b) for the beds packed with catalyst particles of different porosities

| [1] | 杜浩帆. 改性ZSM-5分子筛上甲醇芳构化动力学研究[D]. 北京: 北京化工大学, 2023. |

| Du H F. Kinetics of methanol aromatization on modified ZSM-5 molecular sieve[D]. Beijing: Beijing University of Chemical Technology, 2023. | |

| [2] | Ali S S, Zaidi H A. Experimental and kinetic modeling studies of methanol transformation to hydrocarbons using zeolite-based catalysts: a review[J]. Energy & Fuels, 2020, 34(11): 13225-13246. |

| [3] | Olsbye U, Svelle S, Lillerud K P, et al. The formation and degradation of active species during methanol conversion over protonated zeotype catalysts[J]. Chemical Society Reviews, 2015, 44(20): 7155-7176. |

| [4] | 张宝珠. 甲醇转化制芳烃(MTA)反应的研究[D]. 大连: 大连理工大学, 2013. |

| Zhang B Z. Study on the reaction of methanol conversion to aromatic hydrocarbons (MTA)[D]. Dalian: Dalian University of Technology, 2013. | |

| [5] | Janssens T V W. A new approach to the modeling of deactivation in the conversion of methanol on zeolite catalysts[J]. Journal of Catalysis, 2009, 264(2): 130-137. |

| [6] | 陈诗瑶, 申峻, 王玉高, 等. 甲醇制芳烃反应及生产工艺研究进展[J]. 现代化工, 2022, 42(2): 57-60, 67. |

| Chen S Y, Shen J, Wang Y G, et al. Progress in reaction and production process for methanol to aromatics[J]. Modern Chemical Industry, 2022, 42(2): 57-60, 67. | |

| [7] | Bi Y, Wang Y L, Chen X, et al. Methanol aromatization over HZSM-5 catalysts modified with different zinc salts[J]. Chinese Journal of Catalysis, 2014, 35(10): 1740-1751. |

| [8] | Zhang J G, Qian W Z, Kong C Y, et al. Increasing para-xylene selectivity in making aromatics from methanol with a surface-modified Zn/P/ZSM-5 catalyst[J]. ACS Catalysis, 2015, 5(5): 2982-2988. |

| [9] | Vicente H, Aguayo A T, Castaño P, et al. Dual-cycle-based lumped kinetic model for methanol-to-aromatics (MTA) reaction over H-ZSM-5 zeolites of different Si/Al ratio[J]. Fuel, 2024, 361: 130704. |

| [10] | 代成义, 陈中顺, 杜康, 等. 甲醇制芳烃催化剂及相关工艺研究进展[J]. 化工进展, 2020, 39(12): 5029-5041. |

| Dai C Y, Chen Z S, Du K, et al. Research progress of catalysts and related technologies for methanol to aromatics[J]. Chemical Industry and Engineering Progress, 2020, 39(12): 5029-5041. | |

| [11] | 许雄飞, 刘鹏龙, 张玮, 等. 两段法固定床甲醇制芳烃产物预测多元非线性回归模型[J]. 化工学报, 2022, 73(2): 838-846. |

| Xu X F, Liu P L, Zhang W, et al. Multivariate nonlinear regression model of methanol to aromatics by two-state fixed bed for product prediction[J]. CIESC Journal, 2022, 73(2): 838-846. | |

| [12] | Partopour B, Dixon A G. 110th anniversary: commentary: CFD as a modeling tool for fixed bed reactors[J]. Industrial & Engineering Chemistry Research, 2019, 58(14): 5733-5736. |

| [13] | Weng J Q, Akbar A, Deng Q H, et al. Enhanced performance of packed bed methane dry reformers using metal foam catalyst pellets: a particle resolved CFD study[J]. Chemical Engineering Science, 2024, 290: 119897. |

| [14] | 翁俊旗, 刘鑫磊, 余佳豪, 等. 蜂窝状催化剂中空结构对固定床反应器压降的影响[J]. 化工学报, 2022, 73(1): 266-274. |

| Weng J Q, Liu X L, Yu J H, et al. The impact of the hollow structure of honeycomb catalysts on pressure drop in fixed-bed reactors[J]. CIESC Journal, 2022, 73(1): 266-274. | |

| [15] | Sadeghi M A, Aghighi M, Barralet J, et al. Pore network modeling of reaction-diffusion in hierarchical porous particles: the effects of microstructure[J]. Chemical Engineering Journal, 2017, 330: 1002-1011. |

| [16] | Zhang Q F, Weng J Q, Yu Q H, et al. Computational design of pore structure in heavy paraffin dehydrogenation catalyst pellets[J]. Industrial & Engineering Chemistry Research, 2022, 61(32): 11666-11677. |

| [17] | Dixon A G. Heat transfer in fixed beds at very low (<4) tube-to particle diameter ratio[J]. Industrial & Engineering Chemistry Research, 1997, 36: 3053-3064. |

| [18] | Wehinger G D, Kraume M, Berg V, et al. Investigating dry reforming of methane with spatial reactor profiles and particle-resolved CFD simulations[J]. AIChE Journal, 2016, 62(12): 4436-4452. |

| [19] | Schulze S, Nikrityuk P, Compart F, et al. Particle-resolved numerical study of char conversion processes in packed beds[J]. Fuel, 2017, 207: 655-662. |

| [20] | Dong Y, Geske M, Korup O, et al. What happens in a catalytic fixed-bed reactor for n-butane oxidation to maleic anhydride? Insights from spatial profile measurements and particle resolved CFD simulations[J]. Chemical Engineering Journal, 2018, 350: 799-811. |

| [21] | Pashchenko D, Karpilov I, Mustafin R. Numerical calculation with experimental validation of pressure drop in a fixed-bed reactor filled with the porous elements[J]. AIChE Journal, 2020, 66(5): e16937. |

| [22] | Wehinger G D, Kolaczkowski S T, Schmalhorst L, et al. Modeling fixed-bed reactors from metal-foam pellets with detailed CFD[J]. Chemical Engineering Journal, 2019, 373: 709-719. |

| [23] | Jurtz N, Kraume M, Wehinger G D. Advances in fixed-bed reactor modeling using particle-resolved computational fluid dynamics (CFD)[J]. Reviews in Chemical Engineering, 2019, 35(2): 139-190. |

| [24] | Bai H, Theuerkauf J, Gillis P A, et al. A coupled DEM and CFD simulation of flow field and pressure drop in fixed bed reactor with randomly packed catalyst particles[J]. Industrial & Engineering Chemistry Research, 2009, 48(8): 4060-4074. |

| [25] | Yang F, Jia X Z, Xu R, et al. Kinetic modelling of methanol transformation into p-xylene on a 3Zn-3Si/ZSM-5 catalyst[J]. New Journal of Chemistry, 2023, 47(4): 1973-1978. |

| [26] | Bender J, Erleben K, Trinkle J. Interactive simulation of rigid body dynamics in computer graphics[J]. Computer Graphics Forum, 2014, 33(1): 246-270. |

| [27] | Moghaddam E M, Foumeny E A, Stankiewicz A I, et al. Rigid body dynamics algorithm for modeling random packing structures of nonspherical and nonconvex pellets[J]. Industrial & Engineering Chemistry Research, 2018, 57(44): 14988-15007. |

| [28] | Kehoe J P G, Aris R. Communications on the theory of diffusion and reaction: (Ⅸ): Internal pressure and forced flow for reactions with volume change[J]. Chemical Engineering Science, 1973, 28(11): 2094-2098. |

| [29] | Wakao N, Smith J M. Diffusion and reaction in porous catalysts[J]. Industrial & Engineering Chemistry Fundamentals, 1964, 3(2): 123-127. |

| [30] | Pollard W G, Present R D. On gaseous self-diffusion in long capillary tubes[J]. Physical Review, 1948, 73(7): 762-774. |

| [31] | Wilke C R. Diffusional properties of multicomponent gases[J]. Chemical Engineering Progress, 1950, 46: 95-104. |

| [32] | Fuller E N, Schettler P, Giddings J. New method for prediction of binary gas-phase diffusion coefficients[J]. Industrial & Engineering Chemistry Research, 1967, 58(5): 18-27. |

| [33] | Poling B E, Prausnitz J M, O'Commell J P. The Properties of Gases and Liquids[M]. 5th ed. New York: McGraw-Hill, 2001. |

| [34] | Yeh T S, Sacks M D. Effect of particle size distribution on the sintering of alumina[J]. Journal of the American Ceramic Society, 1988, 71(12): C-484-C-487. |

| [35] | Eppinger T, Wehinger G D, Jurtz N, et al. A numerical optimization study on the catalytic dry reforming of methane in a spatially resolved fixed-bed reactor[J]. Chemical Engineering Research and Design, 2016, 115: 374-381. |

| [36] | Markatos N C. The mathematical modelling of turbulent flows[J]. Applied Mathematical Modelling, 1986, 10(3): 190-220. |

| [37] | Dixon A G, Taskin M E, Nijemeisland M, et al. CFD method to couple three-dimensional transport and reaction inside catalyst particles to the fixed bed flow field[J]. Industrial & Engineering Chemistry Research, 2010, 49(19): 9012-9025. |

| [38] | Boccardo G, Augier F, Haroun Y, et al. Validation of a novel open-source work-flow for the simulation of packed-bed reactors[J]. Chemical Engineering Journal, 2015, 279: 809-820. |

| [39] | Pashchenko D. Flow dynamic in a packed bed filled with Ni-Al2O3 porous catalyst: experimental and numerical approach[J]. AIChE Journal, 2019, 65(5): e16558. |

| [40] | Liu X L, Qin B, Zhang Q F, et al. Optimizing catalyst supports at single catalyst pellet and packed bed reactor levels: a comparison study[J]. AIChE Journal, 2021, 67(8): e17163. |

| [41] | Zhokh A, Strizhak P. Thiele modulus having regard to the anomalous diffusion in a catalyst pellet[J]. Chaos, Solitons & Fractals, 2018, 109: 58-63. |

| [42] | Wang G, Johannessen E, Kleijn C R, et al. Optimizing transport in nanostructured catalysts: a computational study[J]. Chemical Engineering Science, 2007, 62(18/19/20): 5110-5116. |

| [43] | Johannessen E, Wang G, Coppens M O. Optimal distributor networks in porous catalyst pellets(I): Molecular diffusion[J]. Industrial & Engineering Chemistry Research, 2007, 46(12): 4245-4256. |

| [1] | 郭松源, 周晓庆, 缪五兵, 汪彬, 耑锐, 曹庆泰, 陈成成, 杨光, 吴静怡. 火箭上升段含多孔板液氧贮箱增压输运数值研究[J]. 化工学报, 2025, 76(S1): 62-74. |

| [2] | 郭纪超, 徐肖肖, 孙云龙. 基于植物工厂中的CO2浓度气流模拟及优化研究[J]. 化工学报, 2025, 76(S1): 237-245. |

| [3] | 孙九春, 桑运龙, 王海涛, 贾浩, 朱艳. 泥水盾构仓体内射流对泥浆输送特性影响研究[J]. 化工学报, 2025, 76(S1): 246-257. |

| [4] | 吴梓航, 徐震原, 游锦方, 潘权稳, 王如竹. 基于吸附式储冷技术的深井钻探设备冷却系统[J]. 化工学报, 2025, 76(S1): 309-317. |

| [5] | 贾志勇, 沈宪琨, 蓝晓程, 王铁峰. 气体密度对高压流态化影响的CFD-DEM模拟[J]. 化工学报, 2025, 76(9): 4383-4397. |

| [6] | 曹潇风, 张华海, 王江云, 王利民. 锥形气体层流元件结构设计及流动特性研究[J]. 化工学报, 2025, 76(9): 4440-4448. |

| [7] | 陈昇, 李子争, 苗超, 白学刚, 李飞, 刘家璇, 李天天, 杨爽, 吕蓉蓉, 王江云. 大尺度密集场景高危氯气非均匀湍流扩散特性三维CFD模拟[J]. 化工学报, 2025, 76(9): 4630-4643. |

| [8] | 张帅, 徐嘉宇, 华蕾娜, 葛蔚. 气固系统的CG-DPM与MP-PIC耦合模拟方法[J]. 化工学报, 2025, 76(9): 4412-4424. |

| [9] | 苏国庆, 田学梅, 李彦, 张建文, 张志军. 气力输送系统弯管三通的冲蚀分析及改进[J]. 化工学报, 2025, 76(8): 3894-3904. |

| [10] | 马永丽, 安澍, 杨捷, 刘明言. 气液固流化床直接数值模拟研究进展[J]. 化工学报, 2025, 76(8): 3772-3788. |

| [11] | 梁晓江, 陈薇薇, 罗佳南, 费浩天, 叶雪蕾, 李文豪, 聂勇. 电分散管式填充床中荷电气泡的分散特性研究[J]. 化工学报, 2025, 76(8): 3915-3931. |

| [12] | 王泽, 胡琼, 陈雅静, 王衍, 耿佳旭, 沈斐然. 液体自冲击密封泄漏特性、密封机理与优化设计[J]. 化工学报, 2025, 76(8): 4194-4204. |

| [13] | 唐羽丰, 陶春珲, 王永正, 李印辉, 段然, 赵泽一, 马和平. 超高比表面积碳基多孔吸附剂制备及其Kr气存储性能研究[J]. 化工学报, 2025, 76(7): 3339-3349. |

| [14] | 陈曦, 王淑彦, 邵宝力, 丁诺, 谢磊. 基于颗粒动态恢复系数二阶矩模型的液固流化床数值模拟研究[J]. 化工学报, 2025, 76(7): 3246-3258. |

| [15] | 王孝宇, 戴贵龙, 邓树坤, 龚凌诸. Laguerre-Voronoi开孔泡沫流动-传热综合性能孔隙尺度模拟[J]. 化工学报, 2025, 76(7): 3259-3273. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号